3 essential questions answered: How to combine NVH, power or even high voltage zone data

🚀 Introduction

As the electric vehicle (EV) revolution gains momentum, testing engineers face a dual challenge: ensuring mechanical integrity while maximizing energy efficiency, extending driving range, and controlling electrical losses. Traditional NVH (Noise, Vibration, Harshness) analysis alone no longer suffices. Today, integrated testing workflows spanning mechanical, thermal, and electrical domains are crucial. Modern test benches now deliver real-time, synchronized measurements across these domains, providing the insights needed to develop quieter, more efficient, and more reliable EVs.

At the heart of this integrated approach is the Simcenter SCADAS hardware platform, a high-performance, multi-physics data acquisition tailored for e-mobility applications. Complementing it, Simcenter Testlab software offers advanced postprocessing and analysis tools to interpret complex, synchronized data streams. Together, these solutions empower EV testing teams to tackle critical challenges with confidence.

⚡️ 1. How can electrical and NVH measurements be combined seamlessly using a single data acquisition system?

Electric powertrains bring entirely new sources of noise and vibration into play [1], from inverter switching and electromagnetic harmonics to current ripple-induced resonances or vibrations. To truly understand these phenomena, engineers must correlate mechanical behavior with electrical inputs. That’s exactly what modern testing setups enable: balancing NVH, electrical, and mechanical harmonics, even in the audible range as already discussed in the following scientific or blogpost articles [2][3][4][5].

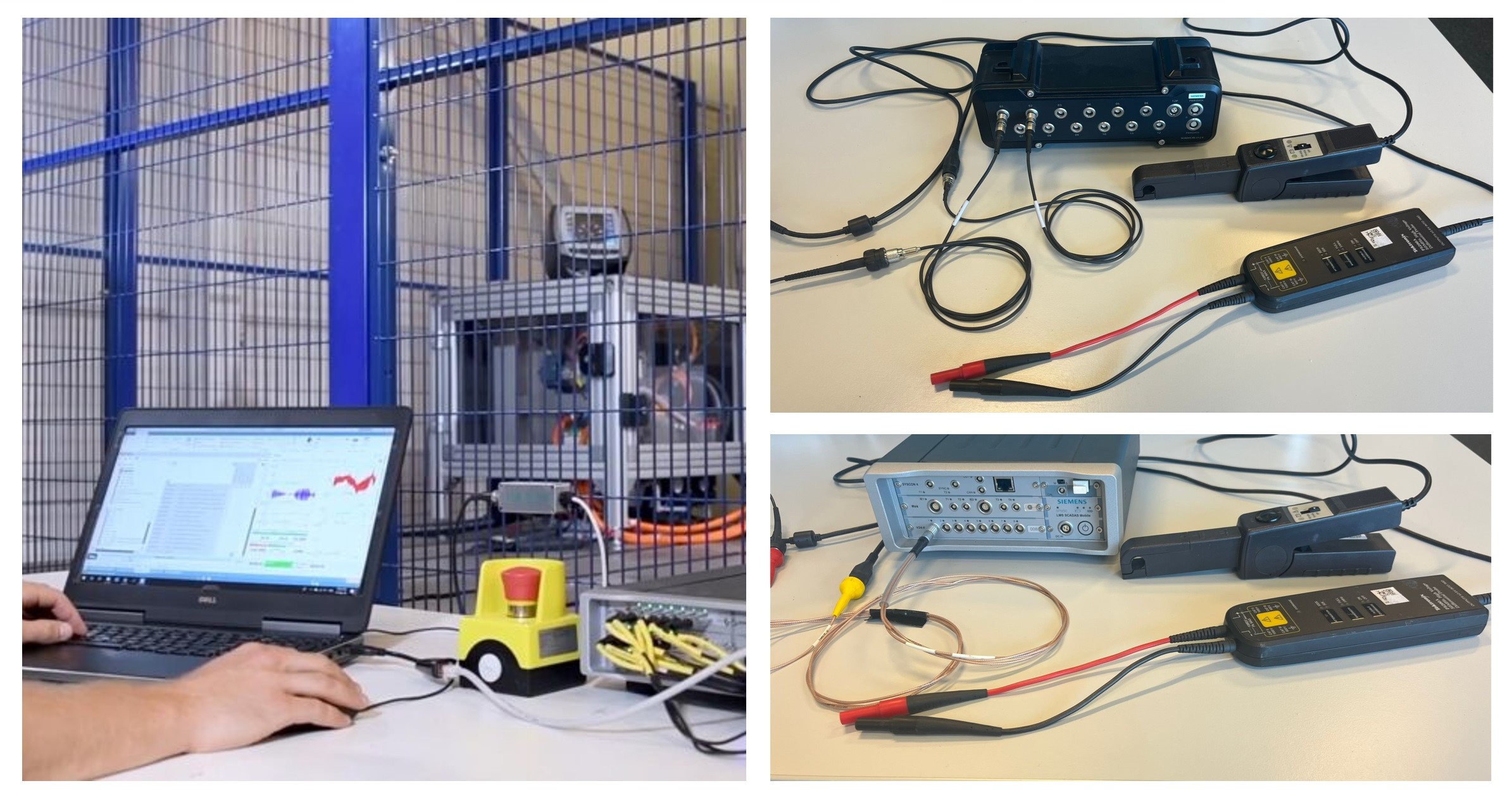

This example highlights how Simcenter SCADAS makes this integration possible in real e-mobility scenarios. You can directly measure currents up to 1000 A and voltages beyond 1000 V using compatible galvanic isolated high-voltage probes, all within the same system you use for microphones, accelerometers, and strain gauges. You don’t need to stitch together data from separate devices. Instead, everything like voltage, current, speed, sound, temperature, strain, and much more is time-aligned and ready for cross-domain analysis within Simcenter Testlab.

Safety is paramount. Unlike test setups that may compromise on isolation or calibration, Simcenter SCADAS is engineered for demanding environments, where strict compliance with high-voltage safety protocols and proper electrical safety training is essential. A clear understanding of the relationship between personnel safety, sensor placement (in low- or high-voltage zones), sensor type (including galvanic isolation), and the data acquisition system is critical to ensuring both accurate measurements and safe operation.

🔋 2. How do you safely access high-voltage zones without compromising data integrity or safety?

Modern EV validation isn’t done in lab benches alone. Whether it’s road testing, dyno simulations, or hardware-in-the-loop, you’re often required to measure (quasi-) static or dynamic signals inside High-Voltage (HV) areas such as:

- Battery cell and module housings

- Inverter enclosures

- E-motor and stator regions

That’s where Simcenter SCADAS excels in integration. Through a close partnership with CSM GmbH [6], the system supports HV-safe modules for measuring temperature, strain, acceleration, and voltage inside energized enclosures. These automotive-grade modules communicate via XCP-on-Ethernet or CAN to the data acquisition system to ensure online data transfer.

This methodology is already being used in the field. Engineers are capturing HV signals using these tools on public roads and in secure test environments. Combining real-world driving with controlled testbench campaigns helps define boundary conditions that are both realistic and directly relevant to system performance. Typical setups include:

- High-speed NVH measurements from e-machine shaft or housing, alongside precise shaft speed monitoring

- Temperature readings from embedded thermocouples in HV components such as the inverter or batteries

The HV zone data communicates seamlessly within the Simcenter data acquisistion platform, enabling time-aligned validation and visualization in Simcenter Testlab Neo.

🔍 3. How can power efficiency losses be revealed through integrated NVH and electrical testing?

Understanding vibration and heat generation is only the beginning. Power efficiency analysis requires moving beyond simple RMS voltage or current readings to a time-resolved examination of electrical behavior. Key analyses include:

- Harmonic decomposition

- Switching pattern analysis

- Power factor variation over time

- Correlation of energy losses correlated with temperature and acoustic signatures

Simcenter solutions support this by enabling synchronized acquisition of NVH, thermal, and electrical signals. Power analyzers like from ZES ZIMMER [7], connect via CAN, ensuring compatibility across the entire Simcenter SCADAS hardware lineup. These analyzers support MHz-range resolution and high-speed harmonic tracking, allowing engineers to investigate how high-frequency switching generates harmonic components or how current phase shifts induce motor vibration.

Typically, the power analyzer is located outside the climate chamber, while the Simcenter SCADAS units are installed close to the system under test. The synchronized, time-aligned data offers detailed insight into the cause-and-effect relationship between electrical events and NVH behavior.

Though this example uses the Simcenter SCADAS RS and its Simcenter SCADAS RS Recorder App for real-time, multi-device monitoring, the core integration is hardware-agnostic. The app simplifies live data visualization across multiple devices but isn’t mandatory. It streamlines access and improve your testing efficiency. Other Simcenter SCADAS systems can also connect with power analyzers via CAN.

This integrated approach reduces testing effort and duration, while directly enabling the optimization of E-drive performance alongside NVH. It facilitates precise identification of how high-frequency switching contributes to tonal noise, how operational attributes affect acoustic behavior, and how current phase shifts induce motor vibrations, among other key insights. A particularly valuable application is the analysis of torque ripple-induced NVH directly correlated with PWM switching strategies.

By linking electrical power, NVH and thermal effects, this approach gives design engineers and NVH specialists a common language, helping them solve efficiency and comfort challenges faster together. Because each expert can continue using their preferred tools and workflows, they are able to conduct in-depth analysis while maintaining traceability, consistency, and confidence in the results.

💪 Future-proof your setup with the latest Simcenter Physical Testing tools

Handling such multi-domain data is possible thanks to Simcenter SCADAS RS, a high-performance data acquisition system featuring a scalable, user-friendly web interface. Combined with Simcenter Testlab Neo, it delivers powerful postprocessing and analysis across diverse applications. Benefits include:

- Scalable architecture with web-based interface

- Flexible, distributed integration options

- XCP digital input for openness to external data flow PTP synchronized

- A consistent data processing platform supporting tests from small components to large (sub)systems

- Advanced multi-domain data processing workflows through Simcenter Testlab Neo

✅ Conclusion

As electrification reshapes the automotive industry, testing complexity grows. Addressing this shift requires more than just isolated measurements, it demands a unified approach that seamlessly combines NVH, durability, and advanced power analysis. Simcenter SCADAS rises to meet this challenge by offering a scalable, multi physics data acquisition system that safely integrates high voltage measurements with detailed performance insights.

Whether you’re measuring current and voltage, monitoring vibration and temperature inside high voltage zones, or evaluating powertrain efficiency with harmonic analysis, Simcenter’s data acquisition systems provide with its companion devices the flexibility and precision needed for EV development. By future proofing your testing setup with Simcenter’s robust ecosystem, you’re not just solving today’s challenges, you’re equipping your team for the innovations of tomorrow.

📞 Contact us

Interested in learning more or have questions?

Our industry experts are here to help you navigate your Simcenter Physical Testing needs.

Feel free to connect directly with:

Tristan Enault — LinkedIn Profile

Mathieu Sarrazin — LinkedIn Profile

We look forward to assisting you!

📚 Related resources

Check out the following links for more information:

Stand-alone data acquisition system

Switching Frequencies and Pulse Width Modulation (PWM) Signals

Vehicle energy management facility

📖 Extra references

[1] H. Van der Auweraer, B. Meek, M. Sarrazin, K. Janssens, 2013. NVH challenges with Hybrid and Electric Vehicles. Symposium on International Automotive Technology (SIAT 2013), SAE International, Pune, India, Jan. 9-12, 2013.

[2] M. Sarrazin, J. Anthonis, H. Van der Auweraer, C. Martis, J. Gyselinck, 2014. Signature analysis of switched reluctance and permanent magnet electric vehicle drives. XXXIth International conference on Electrical Machines(ICEM), Berlin, Germany, Sept. 2-5, 2014.

[3] M. Sarrazin, K. Janssens, W. Claes, H. Van der Auweraer, 2014. Electro-vibro-acoustic analysis of electric powertrain systems. FISITA WORLD AUTOMOTIVE CONGRESS, Maastricht, The Netherlands, June 2-6, 2014.

[4] M. Sarrazin, K. Janssens, H. Van der Auweraer, 2013. Influence of inverter PWM control schemes on noise signature of electric powertrains. 20th International congress on sound and vibration (ICSV20), Bangkok, Thailand, July 7-11, 2013.

[5] Siemens Digital Industries Software, “Efficient e-powertrain measurement,” Simcenter Blog, Apr. 24, 2024. [Online]. Available: https://blogs.sw.siemens.com/simcenter/efficient-e-powertrain-measurement/

[6] CSM GmbH, “HV-safe modules,” CSM Solutions, 2024. [Online]. Available: https://www.csm.de/

[7] ZES ZIMMER Electronic Systems, “Precision power analyzers for electric drives,” ZES Official Site, 2024. [Online]. Available: https://www.zes.com/

⚠️ Safety advisory

Electrical and high-voltage testing must be performed exclusively by certified professionals. Siemens offers expert engineering services that deliver precise, reliable measurements and in-depth sensor analysis. If you don’t want to take risks, partner with us to test faster, smarter, and safer.