Why Simcenter SCADAS RS could be the best measurement system in the world for multi-physics testing

In every blog of these series, I am going to highlight one of the specific features of our Simcenter SCADAS RS measurement system most appreciated by our customers and explain why this feature could be the feature that you are missing in your current test setup.

Simcenter SCADAS who, you say? Well, the Simcenter SCADAS RS is the latest addition to our Simcenter SCADAS hardware product family, enabling our customers to acquire & synchronize a wide variety of different types of sensors for different types of applications, such as durability or NVH testing.

Universal signal conditioning

In this blog post, I will elaborate on the universal signal conditioning supported by the Simcenter SCADAS RS.

Do you also (need to) buy several types of measurement devices to test your vehicle for its durability and NVH performance? Do you also find it annoying that you need to switch to another measurement system every time you want to measure some other attributes of your vehicle? Do you also always need to figure out to which signal conditioning module or unit you need to connect your strain gauges or accelerometers? And what about non-analog or digital sensors you would like to measure? You also need to add some extra boxes in order to measure the vehicle CAN buses or GPS position? Not easy to connect (and accurately synchronize !) these to the rest of your analog channels, right?

Well, good news: Simcenter SCADAS RS comes to the rescue!

Testing for durability, NVH, …

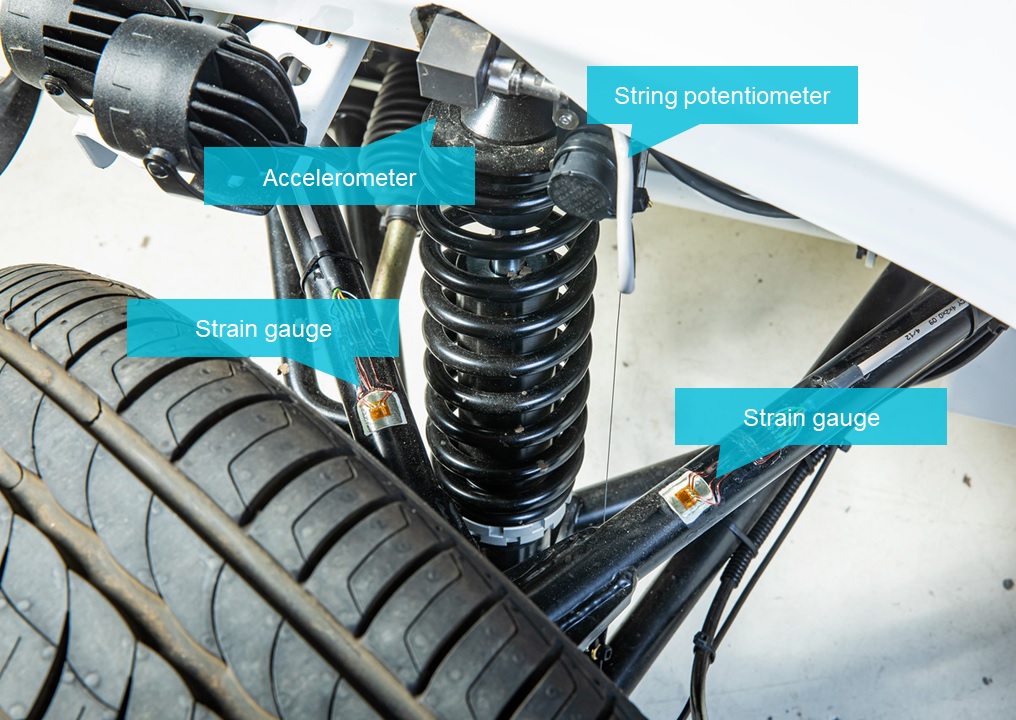

One specific application that is a good example of where you need to measure a wide of different types of sensors, is durability testing. To get an idea about the durability performance of your vehicle, you typically need to measure strain gauges, accelerometers, displacement sensors, force cells, vehicle CAN bus data, thermocouples, wheel force transducers, GPS location, and in some cases even video images.

When performing NVH tests on your vehicle or component, you also need to measure some ICP accelerometers and microphones.

Now all these sensors have their own specific signal conditioning, and – in most cases – you need a different, dedicated acquisition device or unit to measure each of these sensors. So what is the problem, I hear you think? Well, all these different devices take up space in the vehicle, space which is not always available. All these devices need to be powered, but you do not want to hook up all these devices to your vehicle battery because they will drain down very quickly, …

So the challenge is that you want (or even need ?) to limit the number of different acquisition devices that you put inside the vehicle.

Simcenter SCADAS RS U12 unit

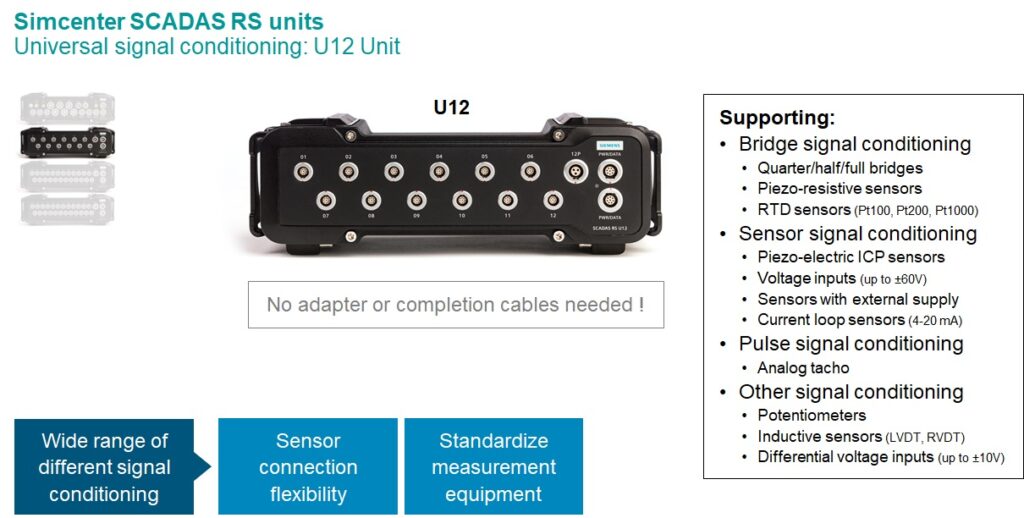

Enter the Simcenter SCADAS RS U12 unit! This unit embeds a complete range of different signal conditioning in one single, compact unit, enabling total channel flexibility with a limited hardware footprint.

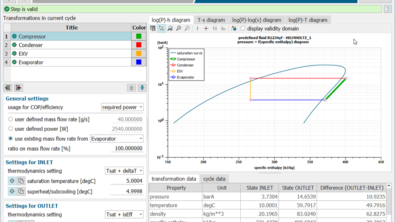

As you can see in the picture below, this unit does not only cover bridge signal conditioning (like strain gauges, DC accelerometers, and RTD sensors), but also sensor signal conditioning (like piezo-electric ICP sensors, voltage inputs, …), pulse conditioning (analog tacho) and a couple of other frequent signal conditioning (potentiometers, like string displacement sensors, inductive sensors and sensors with a differential voltage input). Please check the product information sheet of this unit for more details.

So thanks to this wide range of different signal conditioning, the U12 unit offers you total sensor connection flexibility – you do not need to think where to plug which cable in which unit, you can really put them all in the same unit – and with the U12 unit you can also standardize your measurement equipment: if you only have U12 units, then you can measure all types of sensors.

Of course, this universal signal conditioning is not something unique on the market, but what is unique is the fact that with the Simcenter SCADAS RS you do not need to use adapter or completion cables! There are several other so-called universal signal conditioning systems on the market, but when you take a closer look at them, you realize you need to add an extra cable between your sensor and measurement system in order to be able to measure for example a quarter bridge 350 Ohm, or an ICP sensor. More cables to buy, more time to fix, also more items that can break, … Not really an ideal solution, right?

With the standard U12 unit, you can measure all your sensors at 48 kHz and with a bandwidth of 8 kHz, which is more than enough for doing typical durability tests (in most cases, 1 kHz is enough). Even for most NVH test campaigns, this sample rate and bandwidth are adequate. For those NVH (or other) tests for which you require higher bandwidth, we have developed the U12-E unit. This unit offers the same signal conditioning and sample rate as the U12 unit, but with a higher bandwidth of up to 20 kHz, broadening the range of NVH tests you can do with the Simcenter SCADAS RS system!

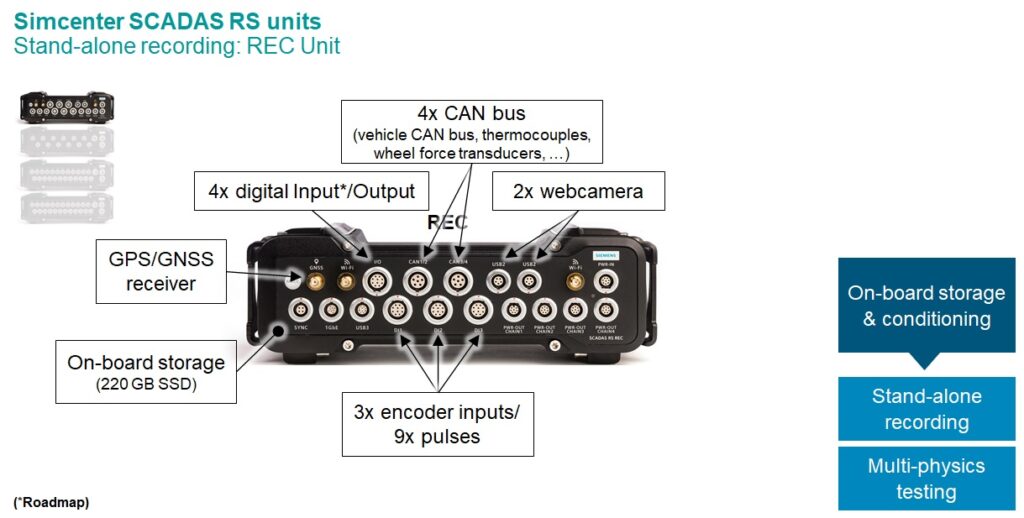

Simcenter SCADAS RS REC unit

Now, doing durability and NVH test measurements is not only about measuring analog sensors, like strain gauges, accelerometers, displacement sensors, … In many (or most?) cases, you also want to measure other characteristics of the vehicle that are offered to you in a digital form, like for example the vehicle CAN bus.

This is where the Simcenter SCADAS RS REC unit comes in!

This REC unit is the master of the system, the brain if you will. Besides an on-board storage of about 200 Gb – on which you can save your measurement templates and measured data – this unit also supports other signal conditioning:

- It has a GPS/GNSS receiver on board, to measure the location of your vehicle and link it to your other channels. Very helpful when measuring on public roads!

- You can measure 4 digital input (*roadmap) and output signals

- You can read out up to 4 CAN buses (coming from vehicle CAN bus, thermocouples, or wheel force transducers which stream their data via CAN)

- You can connect two USB cameras, allowing you to for example record the surroundings or the inside of the vehicle. In case of some strange peaks or phenomena in your measured data, you can look at the automatically synchronized video images to see if there was something wrong with the vehicle or the driver

- And this unit also has 3 connectors for 9x digital pulse signals (or 3x digital encoders), allowing you to measure TTL or HTL signals, but also to convert the pulse signals to frequency (RPM, speed, …) or counter values up/down (distance, angle, …)

Also, here, nothing that the competition does not have. But what the competition does not have, is the fact that all this “extra” signal conditioning comes standard (and for free !) with this REC unit. For most other competitive systems on the market, you need to buy this extra signal conditioning in the form of extra modules or boxes, which you need to connect, and need to be powered separately, … I think you are getting the picture here!

With the Simcenter SCADAS RS all this is embedded in one single & compact unit, saving a lot of money, time and effort!

So, if you are looking for a measurement system covering 80-90% of all your measurement tasks, with universal, compact measurement units, one answer: Simcenter SCADAS RS!

Do you want to discover more capabilities? Then please also read my next blog post, explaining how you can simplify your load data collection campaigns using the Simcenter SCADAS RS!