Simcenter E-Machine Design: Accelerate, innovate and optimize your electric machine design process

Meet Simcenter E-Machine Design software

Engineers and engineering managers often face a daunting challenge in the world of electric machine design. Product development can stretch on for a couple of years, prototypes are painstakingly built and tested, and costs often soar beyond budgets. Meanwhile, size, weight, and sustainability goals get tighter and tighter.

In 2023, we introduced you to our solution that transforms the design process and propels teams toward success, Simcenter E-Machine Design. Now, with almost two years since its first release, we take another look at what it can do for you and how it has developed over the last two years.

What is Simcenter E-Machine Design

Simcenter E-Machine Design is a simulation tool that accelerates electric machine development, validates designs early through multi-physics simulations, and strikes the perfect balance between performance and cost. It’s built on the legacy of Simcenter SPEED and Simcenter Motorsolve —bringing together the best of electric machine simulation into one unified platform.

You can’t use up creativity. The more you use, the more you have.

Maya Angelou, author and human rights activist.

What makes it extraordinary?

Template-based design

Engineers can leverage pre-defined templates tailored specifically for electric machines, enabling them to design hundreds of machines virtually—without needing to be FE experts.

• Slash design time

• Explore innovative topologies

• Automate geometry imports with DXF and scripting support, from your favorite CAD, such as Siemens DesignCenter NX

New with the updates added in 2406 and further improved in 2506: Scriptable geometry import, and enhanced Simcenter SPEED integration allows for seamless transfer of custom designs.

Temperature kills motors

Early Multi-Physics Validation

Thermal performance is critical—temperature can make or break motor reliability. A mere 10°C increase will halve a machine’s lifetime.

Simcenter E-Machine Design enables engineers to:

• Run quick electro-thermal simulations

• Predict and mitigate overheating issues

• Export thermal models as equivalent networks (LPTNs) to Simcenter AMESIM

New in 2412: LPTN export now supports interior permanent magnet and synchronous reluctance machines.

Axial flux machine module

Axial flux machines are gaining attention for their compact size and high torque density. Simcenter E-Machine Design now includes an axial flux module.

• Evaluate axial vs. radial flux alternatives

• Use analytical models to simulate performance in seconds

• Explore 500 configurations in 2 hours with Simcenter HEEDS

New in 2412: Air-core stator template for quieter, lighter machines with lower torque ripple—ideal for medical and precision applications.

Design is not just what it looks like and feels like. Design is how it works

Steve Jobs, co-founder of Apple, Inc.

Integration across the Simcenter Portfolio

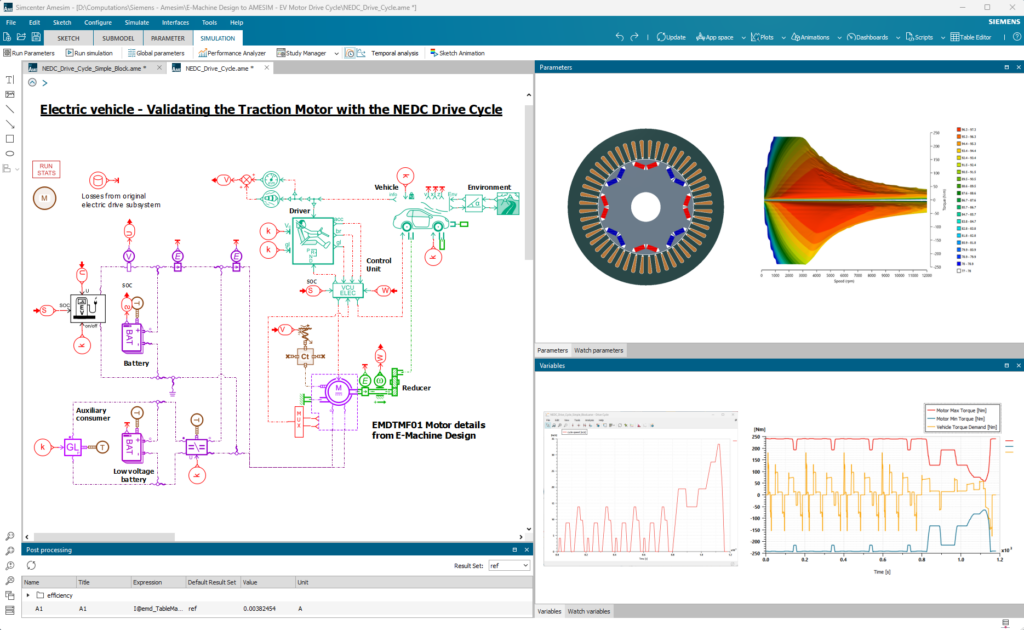

System integration

Simcenter E-Machine Design connects the dots across the V-cycle, enabling full-system validation.

• Create accurate Reduced Order Models (ROMs)

• Integrate with Simcenter AMESIM, Xpedition, and PartQuest Explore

Thermal integration

Build detailed multi-physics cooling models in Simcenter STAR-CCM+

Simcenter E-Machine Design helps you leverage your model and build detailed multi-physics cooling models in Simcenter STAR-CCM+, as our colleague Gaetan explained here.

want to know more? Deep dive into the topic with this on-demand webinar.

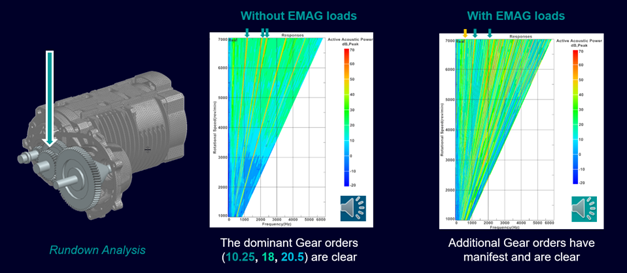

Mechanical integration

• Validate NVH performance of the machine, gearbox, and housing

• Export electromagnetic forces for vibro-acoustic analysis in Simcenter 3D

New in 2406: NVH force export now supports induction machines.

I feel the need – the need for speed!

Tom Cruise as Peter ‘Maverick’ Mitchell in Top Gun.

Ready to accelerate?

The story of electric machine design is changing fast. With Simcenter E-Machine Design, engineers can conquer challenges, accelerate time-to-market, and create products of unparalleled quality, efficiency, and performance.