Ultimate guide to IC package types: choose the right package technology

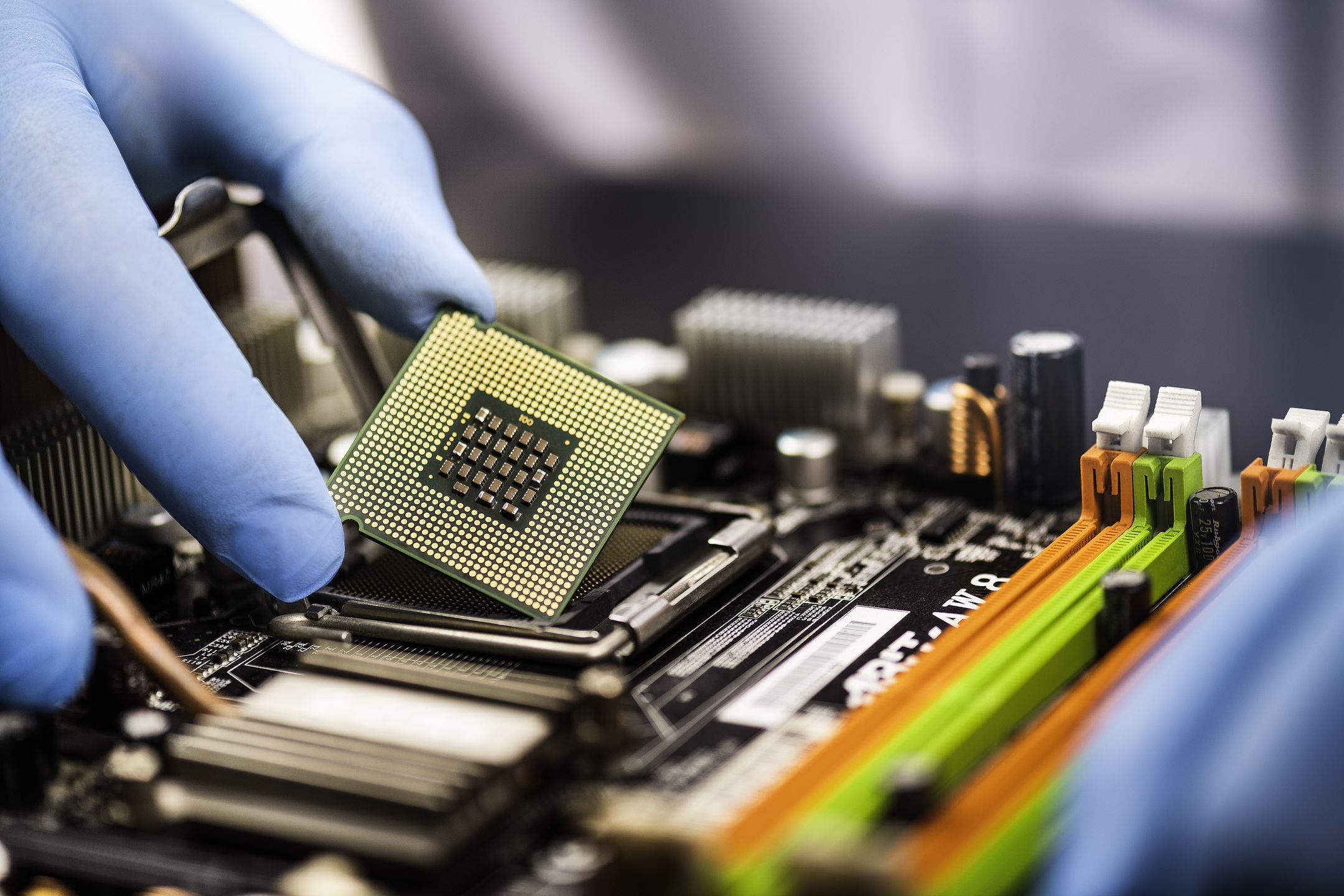

Integrated circuits (ICs) are the foundation of modern electronics, powering everything from smartphones and medical devices to servers and automotive systems. However, it’s not just the silicon component itself that determines real-world performance—it’s the IC package that plays a critical role. The IC package protects the silicon die, provides electrical connections to the circuit board, and helps manage heat dissipation. In this guide, we explore the major IC package types—also referred to as chip package types—and how they influence system design, thermal performance, and manufacturability.

Whether you’re an engineer evaluating package options or a packaging specialist managing complex integrations, this article offers in-depth insights into the types of packages that power today’s—and tomorrow’s—electronics.

Why IC packaging matters in modern electronics

IC packaging performs critical functions beyond simply housing the silicon:

- Mechanical protection from moisture, dust, and physical stress

- Electrical connection to printed circuit boards (PCBs)

- Thermal management to dissipate heat

- Support for multi-die systems, including SoCs and SiPs

- Enabling form factor optimization for mobile, industrial, and embedded applications

As semiconductor designs evolve, choosing the right IC package type can make or break the performance of a system. For a deeper dive into packaging’s foundational role, check out this

Siemens blog:👉 Chip packaging: basics to advanced 3D IC

Classification of IC package types

1.) Leaded packages

These are among the earliest IC package types. Metal leads physically connect the package to the PCB, either through-hole or surface-mounted.

Common leaded package types:

- DIP (Dual Inline Package): Through-hole format with two parallel rows of pins

- SOIC (Small Outline IC): Gull-wing leads and a smaller profile than DIP

- QFP (Quad Flat Package): Leads on all four sides for higher pin counts

- TQFP (Thin QFP): Slimmer version for height-sensitive applications

| Pros | Cons |

| Simple and low-cost | Limited pin count |

| Suitable for prototyping and hand-soldering | Larger board footprint |

| Easy to inspect and assemble | Lower electrical and thermal performance compared to newer packages |

2.) Grid array packages

Grid array IC package types increase pin density and improve electrical performance by placing the interconnects underneath the chip.

Key types include:

- BGA (Ball Grid Array): Uses solder balls for connectivity

- LGA (Land Grid Array): Flat contact pads; often used in socketed applications

- CSP (Chip-Scale Package): A package nearly the same size as the die itself

| Pros | Cons |

| High I/O density in compact formats | More difficult to inspect and rework |

| Good electrical and thermal performance | Requires precise manufacturing and assembly |

| Widely used in high-performance applications | Can be costlier for low-volume production |

To manage routing and design challenges for BGA and CSP, Siemens provides powerful IC packaging solutions.

3.) Wafer-level and fan-out packaging

These advanced IC package types shrink the packaging process down to the wafer itself.

Types:

- WLCSP (Wafer-Level Chip Scale Package): Directly connects die to PCB using solder bumps

- Fan-In WLP: A type of chip-scale packaging where input/output (I/O) connections are routed within the boundaries of the die, keeping the package size nearly identical to the die itself

- FOWLP (Fan-Out Wafer-Level Packaging): Uses redistribution layer (RDL) routing to expand I/O connections beyond the die footprint, enabling higher density and improved thermal performance without the need for a substrate

| Pros | Cons |

| Extremely small footprint | Complex thermal management |

| Excellent signal integrity and electrical performance | Higher initial cost for small production volumes |

| Ideal for RF, mobile, and consumer devices | Challenging yield control at very small geometries |

4.) 2.5D and 3D ICs

Modern systems demand unprecedented bandwidth and performance. Enter advanced IC package types like 2.5D and 3D ICs.

2.5D packaging

2.5D ICs place multiple dies side-by-side on an interposer, enabling high-speed communication between them. This structure supports integration of different chip types without the thermal complexity of vertical stacking. It’s widely used in high-performance applications like AI and networking.

- Applications: HBM integration, AI accelerators, networking

- Benefits: Shorter interconnect paths and modular architecture

| Pros | Cons |

| Short, high-bandwidth interconnects via silicon interposer | Requires additional component (interposer), increasing cost |

| Easier thermal management compared to 3D IC | Larger footprint than 3D IC |

| Facilitates integration of heterogeneous dies | Interposer design and routing can be complex |

| Mature ecosystem and design tools available | Still more expensive than traditional 2D packaging |

| Ideal for memory integration (e.g., HBM) | Requires high-precision alignment in assembly |

3D IC packaging

3D ICs stack active dies vertically to reduce footprint and improve performance. While TSVs are common, newer methods like hybrid bonding enable even tighter integration. This approach is ideal for advanced applications needing high bandwidth in compact spaces.

- Applications: Mobile SoCs, high-performance computing (HPC)

- Benefits: Superior space efficiency, energy performance

| Pros | Cons |

| Extremely high integration density | Thermal management is more challenging due to heat stacking |

| Minimizes interconnect length for better performance and lower latency | More complex design, simulation, and manufacturing processes |

| Reduces board area—ideal for compact, high-performance applications | TSV (through-silicon via) design introduces electrical/structural risk |

| Supports advanced computing use cases like AI, HPC, mobile SoCs | Known-good-die (KGD) handling adds to cost and complexity |

| Potential for significant power savings via shorter interconnect paths | Difficult to test individual dies once stacked |

👉 For a detailed explanation, check out Siemens’ blog: Beginner’s guide to 3D IC

And explore Siemens’ 3D IC design solutions to accelerate your packaging innovation.

IC package type comparison table

| Package Type | Form Factor | I/O Density | Thermal Performance | Ideal Applications |

| DIP/SOIC/QFP | Large | Low | Low to Medium | Legacy boards, education kits |

| BGA/LGA | Medium | High | High | CPUs, GPUs, FPGAs |

| CSP | Very Small | Medium | Medium | Mobile, portable electronics |

| WLCSP/FOWLP | Ultra Small | High | Medium to High | RF chips, smartphones |

| 2.5D | Medium to Large | Very High | High | Networking, AI/ML, HBM |

| 3D IC | Compact | Ultra High | Very High (design-dependent) | High-performance computing |

Emerging trends and technologies in IC packaging

Heterogeneous integration

Heterogeneous integration is transforming the way complex systems are designed. By combining multiple dies—each optimized for a specific function like logic, memory, RF, or analog—heterogeneous integration allows engineers to create highly customized, high-performance system-in-package (SiP) architectures.

Unlike monolithic SoCs that require all components to be fabricated on a single die, heterogeneous integration enables different process nodes and technologies to coexist in a single package. For example, a 5nm logic die can be paired with a 28nm analog die, reducing cost and improving yield.

Key enablers of heterogeneous integration include:

- Silicon interposers with fine-pitch redistribution

- Embedded bridge technologies for localized die-die connections

- Die partitioning and reuse to support modular platforms

- Testability and yield management across multi-die assemblies

Siemens offers a full suite of IC packaging solutions to support heterogeneous integration workflows, including Tessent Multi-Die for hierarchical testing and Calibre 3D IC for multi-die verification.

👉 Read more: 3D IC & heterogeneous integration guide

Advanced 3D IC design

Advanced 3D IC packaging is rapidly becoming the standard for pushing performance boundaries in high-density computing applications like AI, ML, and edge computing. However, stacking multiple dies in a vertical configuration introduces new complexities not found in traditional 2D or even 2.5D designs.

Critical design considerations include:

- TSV placement and density: Optimizing vertical interconnects for minimal parasitic effects

- Power delivery and IR drop analysis: Ensuring uniform voltage across stacked dies

- Thermal modeling: Accurate prediction of hotspots due to heat stacking

- Cross-die signal integrity: Minimizing crosstalk and latency between tiers

- Yield and binning strategies: Managing known-good die (KGD) and cost implications

Siemens provides integrated 3D IC solutions to help packaging teams handle these challenges:

- Calibre 3D IC supports 3D-aware DRC/LVS and cross-die verification

- Innovator 3D IC offers co-design visualization and placement exploration

- Tessent Multi-Die enables die-to-die and die-to-system test planning

For engineers looking to implement advanced 3D ICs in production, these solutions provide a robust foundation for success.

How to choose the right IC package type

Choosing the best IC package type depends on your application requirements, performance expectations, and manufacturing constraints. Each package type has its own trade-offs in terms of size, cost, signal integrity, thermal management, and assembly complexity.

Start by considering:

- System-level thermal and power requirements

- Desired pin count and data bandwidth

- Physical size constraints of the end device

- Environmental reliability and lifecycle demands

- Cost targets for high-volume production

Here’s a general guide to choosing the right IC package type:

| Design Requirement | Recommended Package Type |

| Small form factor + low power | CSP, WLCSP |

| High data transfer or memory stacking | 2.5D, 3D IC |

| Simplified assembly, low complexity | QFP, SOIC |

| Rugged, low-cost prototyping | DIP, TQFP |

| Multi-function integration | FOWLP, Heterogeneous Integration |

Frequently asked questions (FAQ)

Q1: What is the most common IC package type?

A: The most common for high-performance ICs is the BGA (Ball Grid Array) due to its compact size and high I/O support. For mobile devices, WLCSP and CSP are also prevalent.

Q2: How are IC packages manufactured?

A: The process includes die attach, interconnect (wire bonding, flip-chip, TSV), molding, singulation, substrate attach, and test. Fan-out and 3D IC processes add complexity through redistribution layers and vertical stacking.

Explore Siemens IC packaging solutions that support this full lifecycle.

Q3: What’s the difference between 2.5D and 3D IC?

A: 2.5D ICs place multiple dies side by side on a shared interposer. 3D ICs vertically stack dies using TSVs for tighter integration and higher bandwidth. Read the beginner’s guide to 3D IC.

Q4: Are fan-out packages better than BGA?

A: Fan-out wafer-level packages (FOWLP) offer better electrical performance, thinner profiles, and more flexibility than traditional BGAs. However, BGAs are more cost-effective for high-volume applications. Explore FOWLP in this Siemens blog.

Q5: Which Siemens solutions support 3D IC and multi-die design?

A: Siemens supports 3D IC and heterogeneous integration workflows through:

Conclusion: Choosing the right IC package type for performance and scalability

The rapid evolution of semiconductor design has made IC packaging a cornerstone of electronic system performance. Whether you’re dealing with legacy systems, mobile devices, or cutting-edge AI processors, choosing the right IC package type is crucial.

From leaded DIP and QFPs to wafer-level fan-out and advanced 3D IC designs, each packaging style offers unique benefits and trade-offs. By understanding these chip package types—and by leveraging Siemens’ trusted, production-proven IC packaging solutions—you can ensure your systems are designed for success, from concept to high-volume manufacturing.

💡Explore more IC packaging and design resources

If you’re looking to dive deeper into advanced packaging, heterogeneous integration, or chiplet-based system design, check out these helpful resources from Siemens:

- Beginner’s Guide to 3D IC – Understand the fundamentals and benefits of 3D IC design.

- Ultimate Guide to Heterogeneous Integration – Learn how this design approach enables next-gen performance and functionality.

- IC Packaging Solutions – Explore Siemens’ full suite of design, analysis, and verification tools for packaging.

- Calibre 3D IC – Drive accurate 3D design rule checking, LVS, and parasitic extraction for multi-die systems.

- Innovator 3D IC – Achieve early planning and co-design for 2.5D/3D ICs and advanced packaging architectures.

- Tessent Multi-Die – Enable scalable test and yield analysis for complex multi-die systems.