What’s New: Simcenter 3D Motion Gear Design Optimization tool

Not only for Gear Design Optimization specialists

For the literal among you, gear grinding is the process of abrading a gear surface to give it its final shape and polish. However, it is also a common expansion to express annoyance at something, i.e., Do you know what grinds my gears? X, Y, and Z but not necessarily in that order.

Gggrrrrr!!!

Extremely repetitive processes that are easy to make mistakes during, grind my gears. This is especially true when I know a computer could do it in a flash if only I had the code to do it. As a very infrequent coder there is always the urge to code something, but cleaning up my buggy code will likely take longer to fix than it would have taken to do the original task. So, it is only worthwhile if the code is likely to get used somewhat regularly.

Consider macro and micro geometries

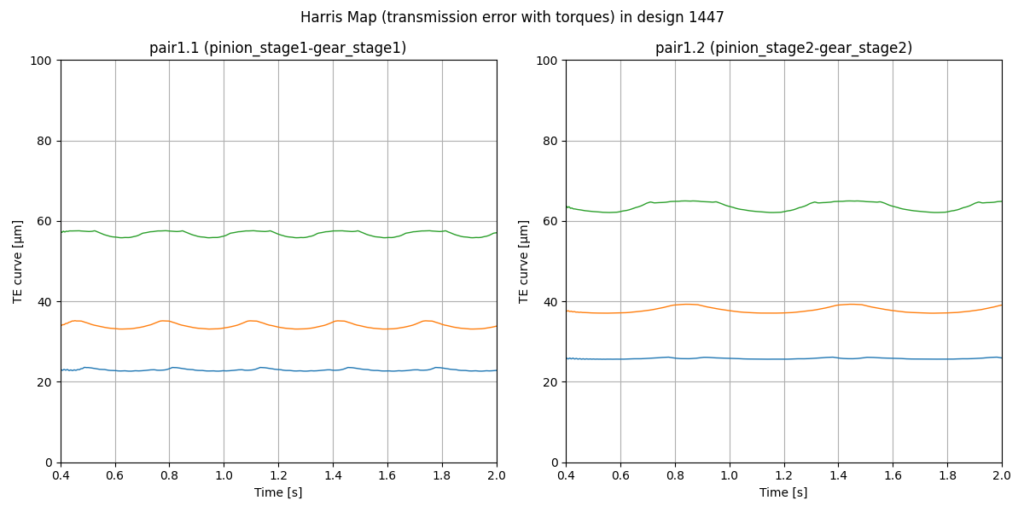

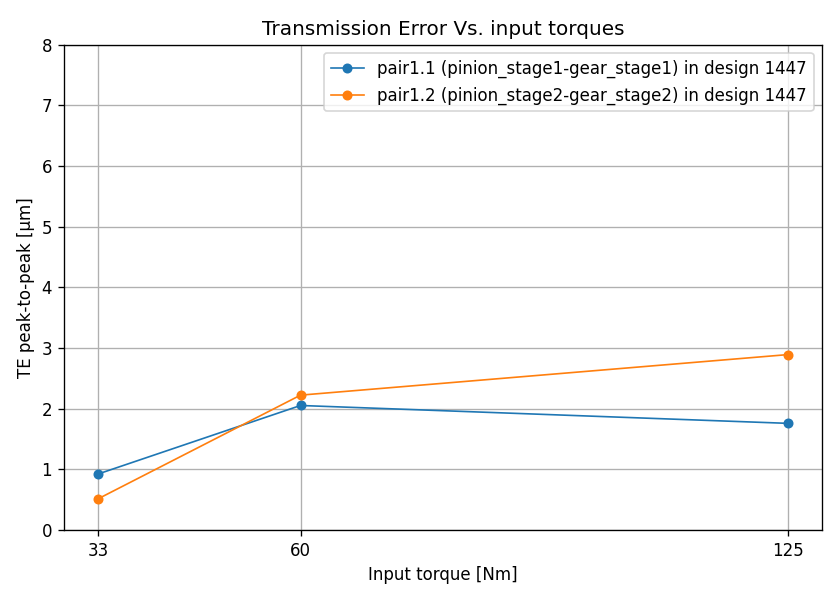

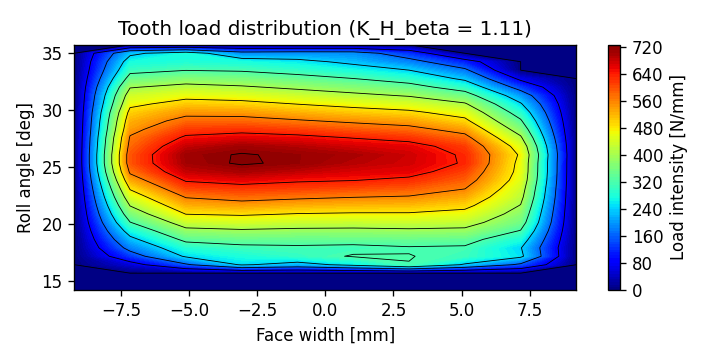

Therefore, I sympathize with gear specialists who may face both the literal and metaphorical incarnation of this expression. When developing a transmission, you may need to optimize it for NVH, durability, efficiency, or a combination. To do this, you need to consider both the macro and micro geometry of the gear pairs. In a case with just two gear pairs, there will be approximately 40 design variables, and several objective functions for the microgeometry, plus several more objectives with multiple constraints for the macrogeometry.

Code that works

As I just described, setting up a test that looked at two gear sets in mesh could take an experienced engineer weeks. However, you could reduce this to days if you were fortunate enough to be in a company that already has and does a good job of maintaining a script that evaluates gear key performance indicators. Much time is spent by gear specialists on repetitive workflows or maintaining code at much expense to their companies. This is why Simcenter 3D Motion has developed the Simcenter 3D Motion Gear Design Optimization Software, released as part of the Simcenter Mechanical Solution 2412 release.

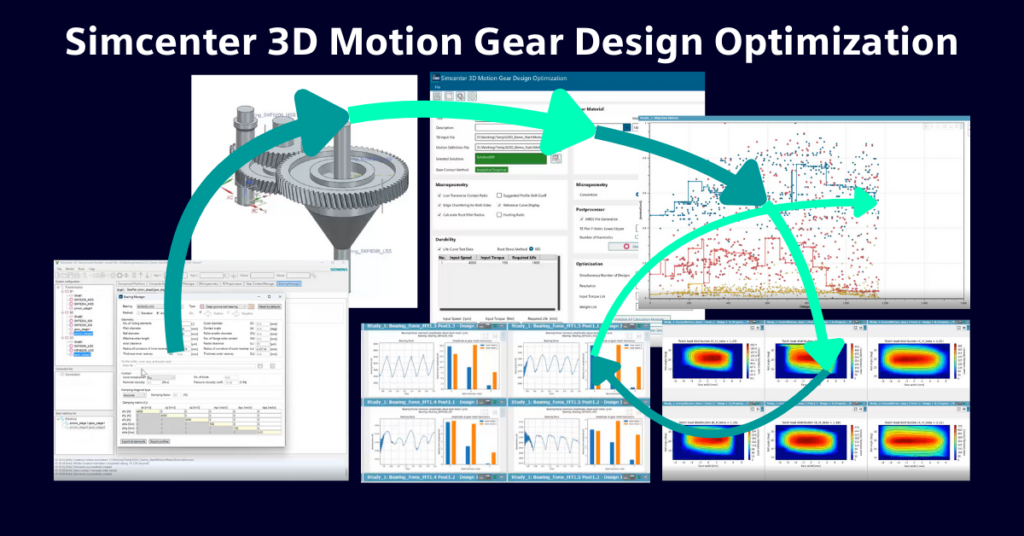

Simcenter 3D Motion Gear Design Optimization

This new tool removes the need for coding and maintaining internal scripts. Simcenter 3D Motion Gear Design Optimization enables you to fine-tune the micro geometry of gear faces. Furthermore, it works with Simcenter 3D Motion Transmission Builder and Simcenter HEEDS in an intuitive workflow to optimize your macro and micro gear geometries to ensure a fully optimized design.

Do not pass Meshing, Do not collect a designer, Go straight to gear design optimization.

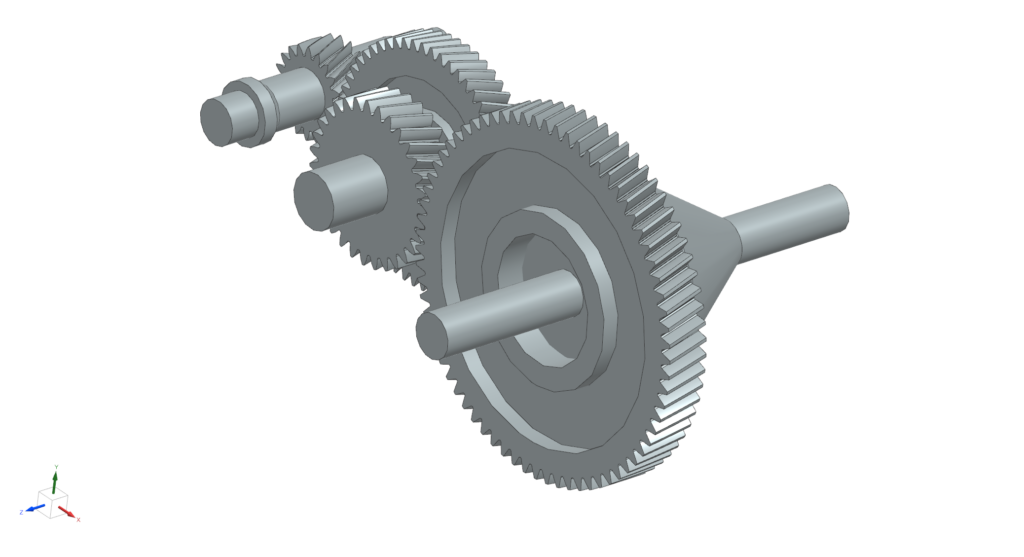

Those of you who have had the pleasure of rapidly developing gear systems using Simcenter 3D Motion Transmission builder will know that you can use its wizard to select your required gear parameters and generate a model without having to produce any CAD yourself. You will also see your model generated in Simcenter 3D, where you were able to conduct simulations and test your designs. You may even have included Simcenter HEEDS in your workflow to optimize your design.

With the New Simcenter 3D Motion Gear Design Optimization tool, you follow the same steps to produce your initial macro and micro geometry as Simcenter 3D Motion Transmission builder. But now, with the addition of the new tool, you can also optimize the design using Simcenter HEEDS and evaluate non-motion Key performance indicators such as efficiency and durability.

The new workflow

Start in Simcenter 3D Motion Transmission Builder.

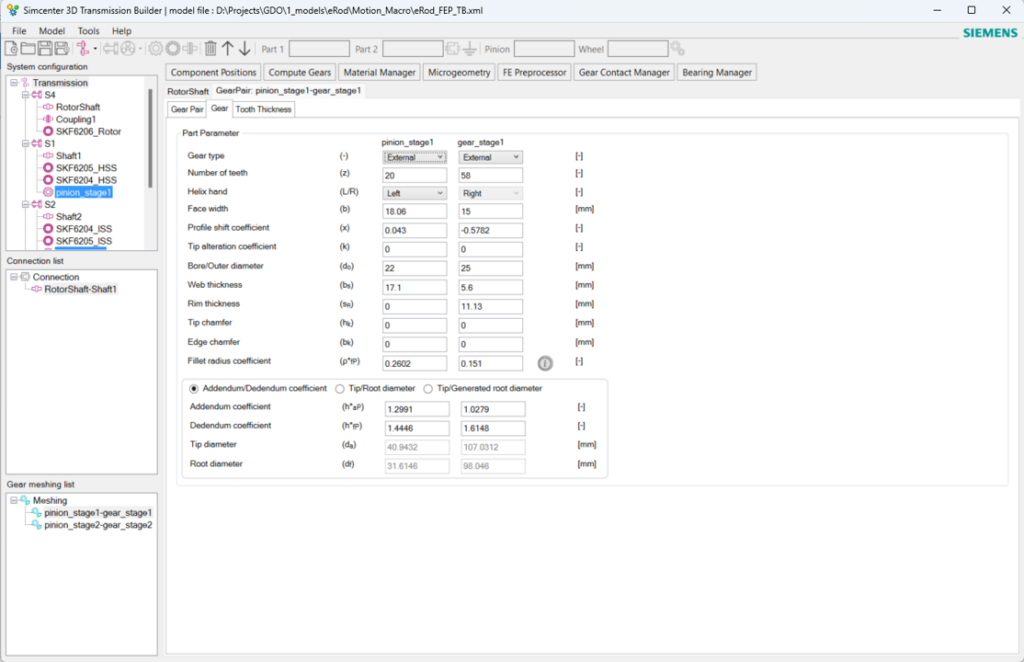

As you did previously, you start by defining your baseline layout using the Simcenter Motion Transmission builder wizard to parameterize the shaft, gears, and bearings from the selection menus. Once you have your gears defined, you can define/ choose your meshing pairs.

Flanks can be either predefined by common standards or loaded from a CSV file to provide your own initial design. Note that if you are planning to complete an optimization using Simcenter HEEDs, this initial input is only used for the baseline; Simcenter HEEDS will alter it.

To control the level of detail at the contact location, you define the number of gear slices. Where, the number of slices can be set to create imaginary gear layers in a sandwich-like fashion.

Once your initial parameters are set, you can generate a model for the entire gear set with just one button. You can watch the model materialize as you watch in Simcenter 3D.

The level of fidelity for Gear contact and bearing analysis can also be defined in the transmission builder tool and exported directly into your Simcenter 3D model by simply clicking ‘export all elements.’

Drivers and load cases can now be added, which is done in the Simcenter 3D Motion application. While the user does this, the total time to complete this task is measured in seconds.

Now is a good time to create a solution and run the solver to check your setup. Once complete, you should review the outputs and results. Finding any errors in your setup at this stage will prevent you from wasting a lot of time later.

Setup Simcenter 3D Motion Gear Design Optimization

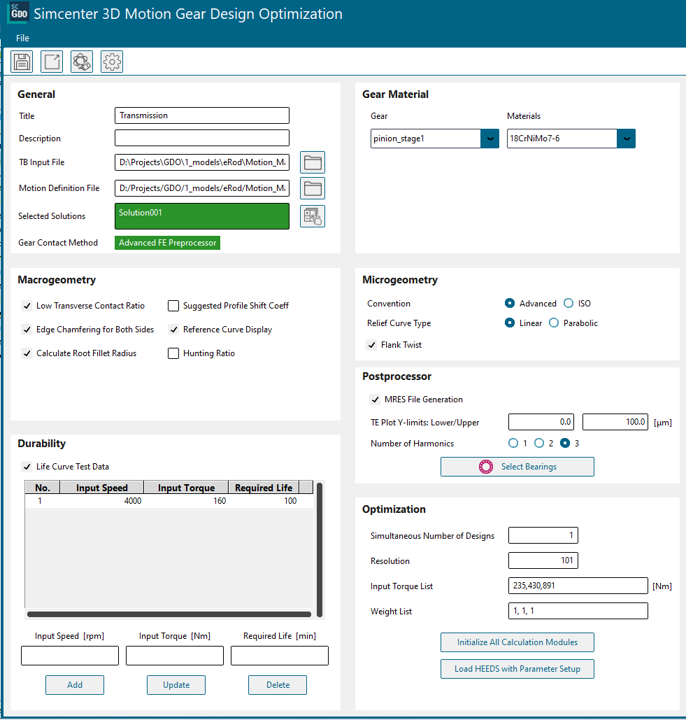

You can load the Simcenter 3D Motion Transmission Builder and Simcenter 3D Motion files in the new wizard menu screen. Suppose you wish to optimize the durability of your gear set. In that case, you start by choosing the macro geometry features you want to include and setting your durability test by defining the speed, torque, and required life. Further parameters for this test are also needed, such as the material that can be selected from a menu and the microgeometry convention you wish to follow. Finally, you choose your desired post-processing, select the bearings you want, and set the optimization parameters.

Start the design of experiments (DOE) study for your gear design optimization

While you are still in the Simcenter 3D Motion Gear Design Optimization tool, initialize the calculation modules to compute the baseline model. This confirms that the model will run in Simcenter HEEDS and provides Simcenter HEEDS with the baseline result from which it needs to start.

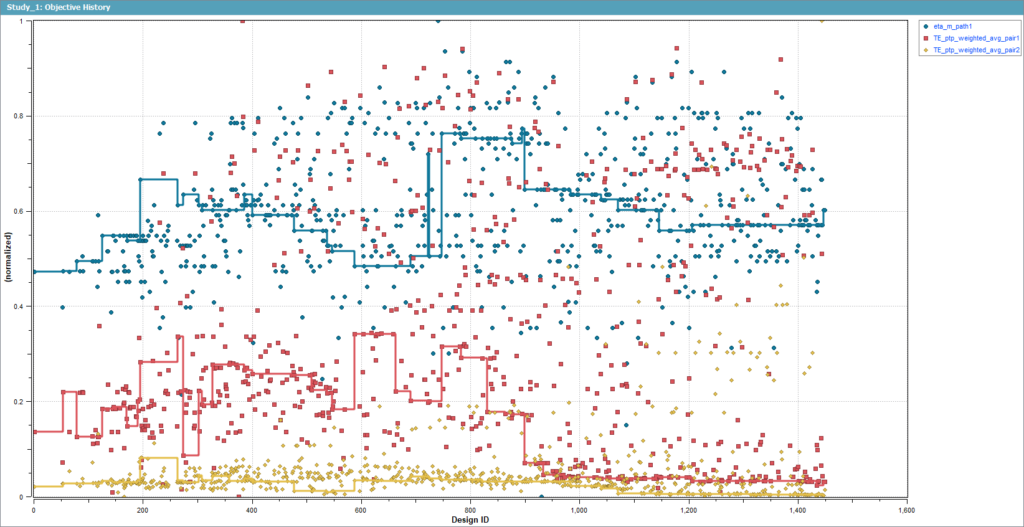

Now, when you open your project in Simcenter HEEDS, you will find that over 70 design variables for the macro and microgeometry have already been created for cases with just two gear pairs. You will also find that all your output responses have been made, saving you considerable time. All that is left is to set the output responses you want to consider for the objective function and the constraints. You can also set the range to the input parameters if you want to.

Getting a gear design optimization result

Now, you can run the full DOE in Simcenter HEEDS and, finally, post-process the results in Simcenter HEEDS.

Conclusion

The New Simcenter 3D Motion Gear Design Optimization tool builds on the existing capabilities of the Simcenter Motion 3D Transmission builder with new capabilities that allow you to optimize your design using the power of Simcenter HEEDS and evaluate non-multibody key performance indicators such as efficiency and durability. You can now develop designs you may never have conceived in a time frame you would have never thought possible in a general-purpose simulation tool.

White paper

Read our latest white paper to learn more about the capabilities Simcenter 3D has for the development of gears.

Simcenter 3D blogs

This new tool was released as part of the Simcenter Mechanical Simulation Solutions set of 2412 release. To find out more about the other updates in these releases see the Simcenter Mechanical 2412 release blog.

To ensure you are up-to-date on all things Simcenter 3D check out our news blog, Simcenter 3D: The latest, updated monthly so you never miss out of the latest news.