What’s new in Simcenter Testlab 2406

Accelerating the journey to zero prototypes

Manufacturers today are driven by the goal of creating products with minimal reliance on prototypes. However, while simulation and virtual modeling are becoming more advanced, physical testing remains essential to ensure safety and performance. Simcenter Testlab 2406, the latest software release, supports manufacturers in creating a full-scale prototype as late in the development cycle as possible while ensuring that the first physical version meets all performance requirements.

Simcenter Testlab 2406 empowers test engineers to integrate physical testing with simulation, allowing for the early evaluation of virtual prototypes, ultimately minimizing the need for multiple physical prototypes. This update brings enhancements in efficiency, testing capabilities, and data management—helping you transition toward a prototype-free future, whether you are a beginner or an experienced user.

Watch the video below to learn about the highlights of this year’s release:

With Simcenter Testlab 2406, you can test earlier, smarter, and faster—helping you bring better products to market with greater confidence and fewer prototypes.

Jump to the highlights:

Enhancing Testing Efficiency

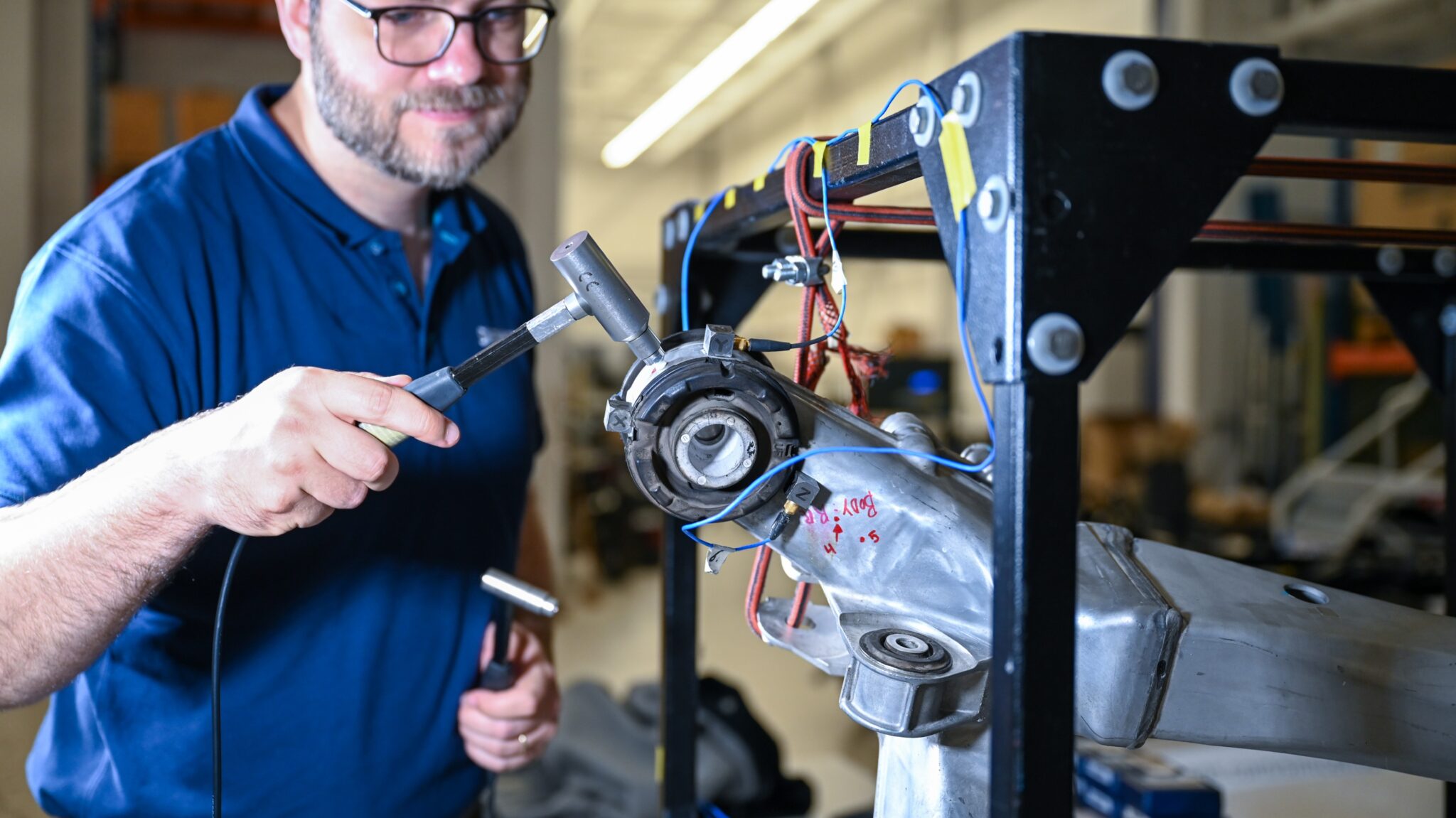

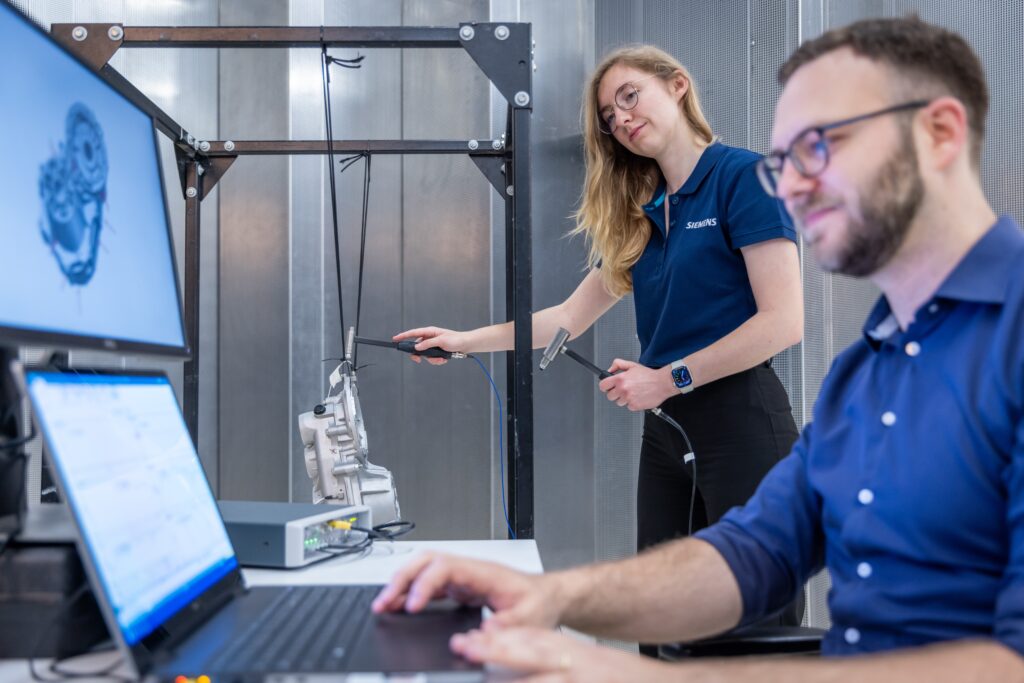

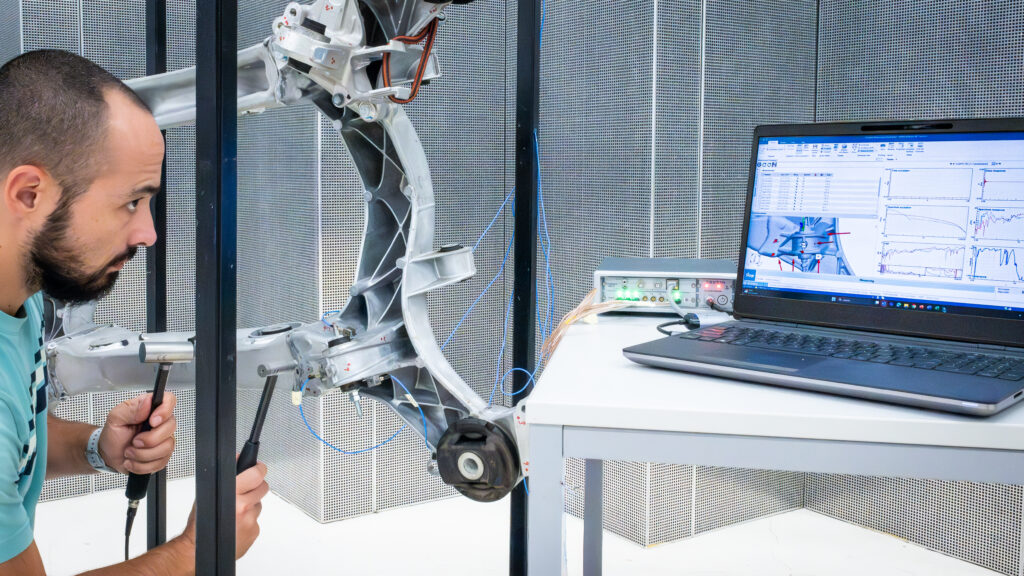

Multi-hammer impact testing

Traditional impact modal testing is often a time-consuming and inefficient process. First you need to determine how to best instrument the test subject, and then you need to perform the tedious process of hitting the specimen with a single hammer at hundreds of locations. At the final step, you then need to analyze and characterize the data you collected.

Simcenter Testlab 2406 changes this by enabling engineers to utilize existing CAD models to define instrumentation and virtual points, drastically reducing test planning time. Moreover, multiple hammers can now be used simultaneously, extending the frequency range and providing the critical data needed for electric vehicle evaluations. Real-time data merging during tests also ensures that you see accurate results immediately, leading to up to a 50% reduction in overall testing time!

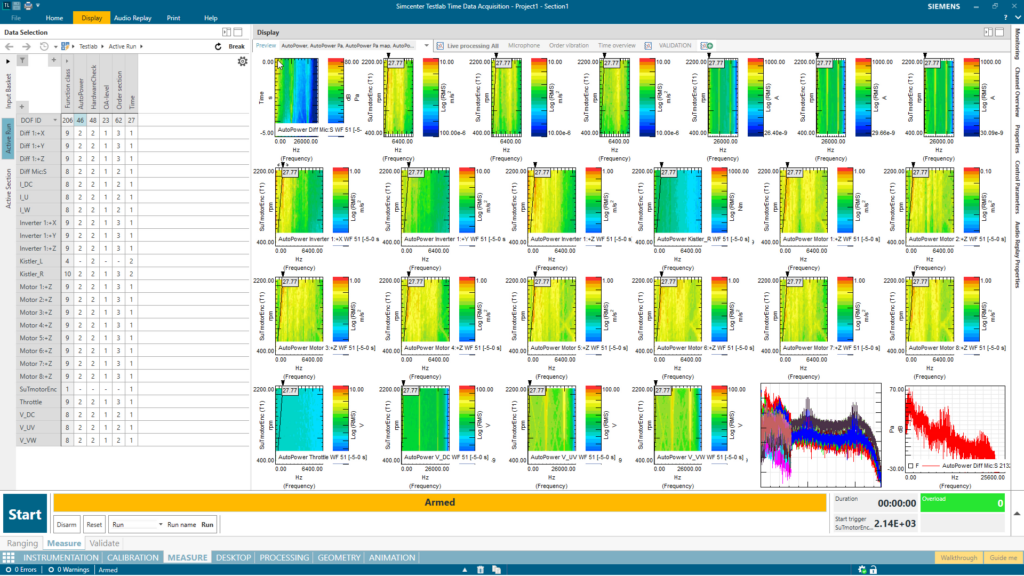

Easier signature testing workflow

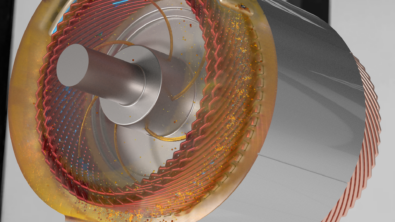

Rotating machinery—whether in electric powertrains or small motors—is a major contributor to noise and vibration. However, testing tools you need to analyze the NVH performance of your machines come with many options, settings, and sometimes hidden features that it’s easy to become overwhelmed, and getting efficient takes time.

Simcenter Testlab 2406 makes signature testing simple for engineers of all experience levels. Simcenter Testlab Neo now fully supports the signature testing process from instrumentation to reporting, offering intuitive tools to reduce the learning curve. Real-time monitoring and automatic report generation simplify the process, allowing for faster and more accurate data analysis.

Expanding Testing Capabilities

Time-domain loads and auralization for Virtual Prototype Assembly and NVH Simulator

How something sounds, and how loud it is are critical parts to your end-users’ experience. But on the journey to zero prototypes, how will you know how you product really sounds if the product doesn’t even exist yet?

The latest release supports time-domain loads, allowing engineers to evaluate system-level performance virtually. This, combined with the new Simcenter Testlab NVH Simulator, enables teams to aurally experience and analyze the sound of virtual prototypes. This capability helps ensure an optimal customer experience, even before a vehicle is physically built!

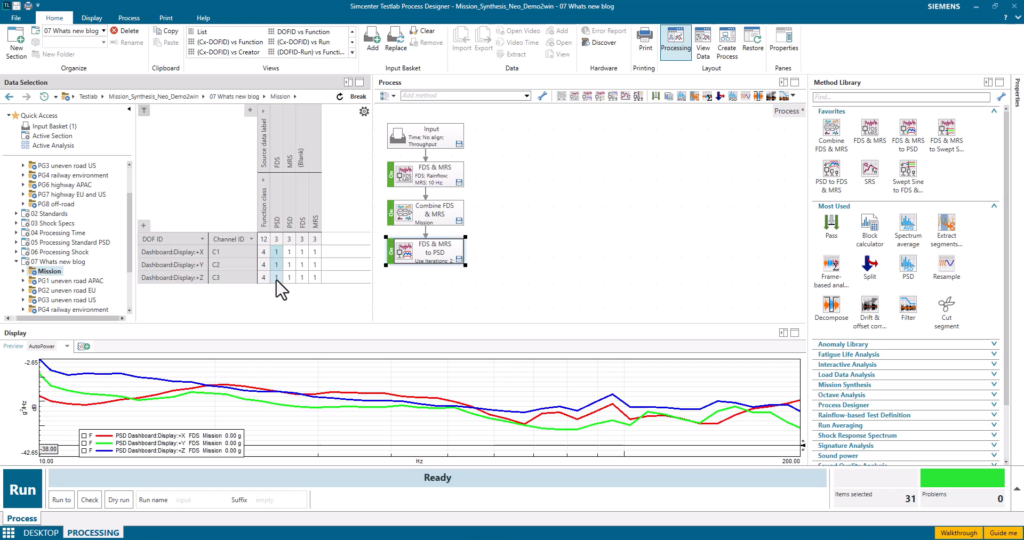

Streamline mission synthesis for durability testing

Predicting how long a vibrating component will last in the real world is always a challenge for engineers because there are many different variables to consider. Simply shaking something until it fails can take a really long time, which is something your development team doesn’t have. So, you need to find a way to accelerate your durability testing to be faster and use more accurate loading conditions.

Mission Synthesis in Simcenter Testlab Neo simplifies durability testing by creating realistic test profiles based on real-world data. Engineers can now accelerate their durability testing while ensuring accurate load conditions. This is ideal for test houses, automotive manufacturers, and labs seeking to predict failure points more efficiently.

Redefining Field Testing

Extended Simcenter SCADAS RS hardware and capabilities

A result of the journey to zero prototypes is that companies also want to spend less time on the physical testing that they still need to do. This means your testing processes need to be as efficient as possible, which can be complicated when having to perform field testing, like for road load data collection.

Simcenter SCADAS RS continues to redefine field-testing, making it easier for engineers to perform road load data acquisition without the usual hassles of weather, complex setup, or re-tests. Remote connectivity means that engineers can validate data during the test itself, ensuring accuracy and eliminating costly re-runs. Enhanced features like event marking and CAN decoding further streamline the process, making Simcenter SCADAS RS the go-to solution for field tests.

Enabling Collaboration

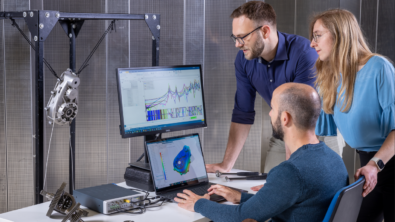

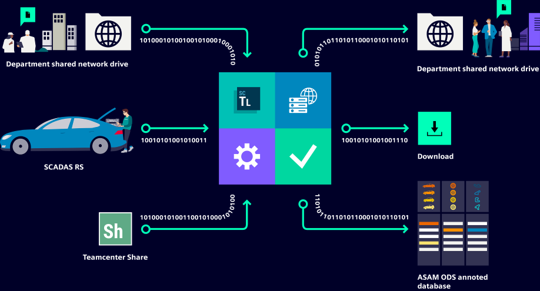

Centralized data management

There was a time when every subsystem R&D department was an island solving their own issues. Sharing data was often a chore since each team stored their data on different drives with different naming conventions.

Gone are the days of disparate data silos. Simcenter Testlab Data Management enables centralized storage and annotation of NVH data, ensuring that teams can quickly and easily access the information they need. Engineers no longer need to hunt for test data or question its validity—Simcenter Testlab provides seamless integration across your test environment, making collaboration and comparison of results easier than ever before.

Automatically retrieve, process and publish test data and reports

Many data analysis processes are repeatable processes that still perform manually after every test. This is a prime area where automated tools could help you be as efficient as possible and get to your results sooner.

Simcenter Testlab Workflow Automation offers a streamlined solution to process, validate, and store test data automatically. Whether you’re conducting a remote field test or working in a centralized processing hub, automation ensures that your data is processed consistently and made available for immediate analysis. With this feature, teams can remotely access data, reducing the need for costly re-tests and optimizing overall workflow efficiency.

Test Faster, Smarter, and Earlier

Simcenter Testlab 2406 is more than just an incremental update—it’s a transformative tool designed to accelerate your journey toward zero prototypes. With enhanced efficiency, expanded testing capabilities, robust data management, and seamless automation, this latest release empowers test engineers to meet the challenges of modern product development head-on.

To learn more about Simcenter Testlab 2406 and explore its full range of features, visit our Support Center or take advantage of our Xcelerator Academy’s online classes.

Try Simcenter Testlab Neo with a free 30-day trial and join the vibrant Simcenter community to stay connected with fellow users and share valuable insights.

Whether you’re a seasoned engineer or just getting started, these advancements open up exciting possibilities for the future of physical testing, helping you on your journey to zero prototypes!

Visit the website to learn more about our Physical Testing portfolio.