Frontload Noise and Vibration challenges with System NVH Prediction in Simcenter Testlab 2306

Welcome to our latest blog post, where we embark on a journey into the realm of System NVH Prediction – an indispensable process that is transforming the way industries approach noise and vibration issues in their designs.

As technology advances with complex systems, electrification, increase of vehicle variants, short time to market, and cost considerations, so does the demand for quieter, smoother, and more refined products that enhance comfort and inspire trust in consumers. An answer to these challenges faced by the NVH engineering teams in the development of new products is the System NVH Prediction.

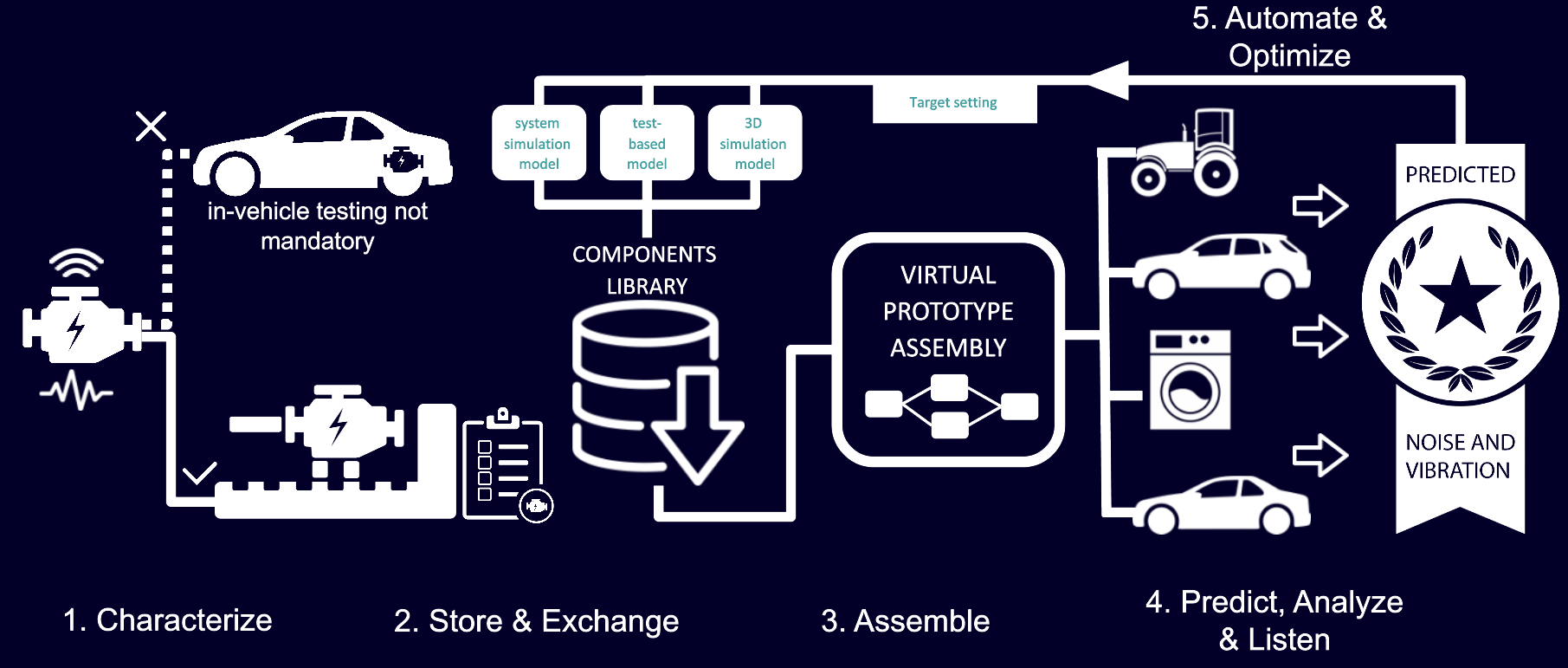

Based on the Component-based TPA, this methodology is composed of five steps:

- Component characterization

- Storage and exchange

- Assembly of components

- Prediction, Analysis and Listen

- Automate and Optimize

On this context, the new release of Simcenter Testlab 2306 brings updates on Virtual Prototype Assembly (VPA), the Testlab tool for System NVH Prediction, to improve all these steps enhancing the modeling of virtual prototypes.

Characterize

Principal Component Loads

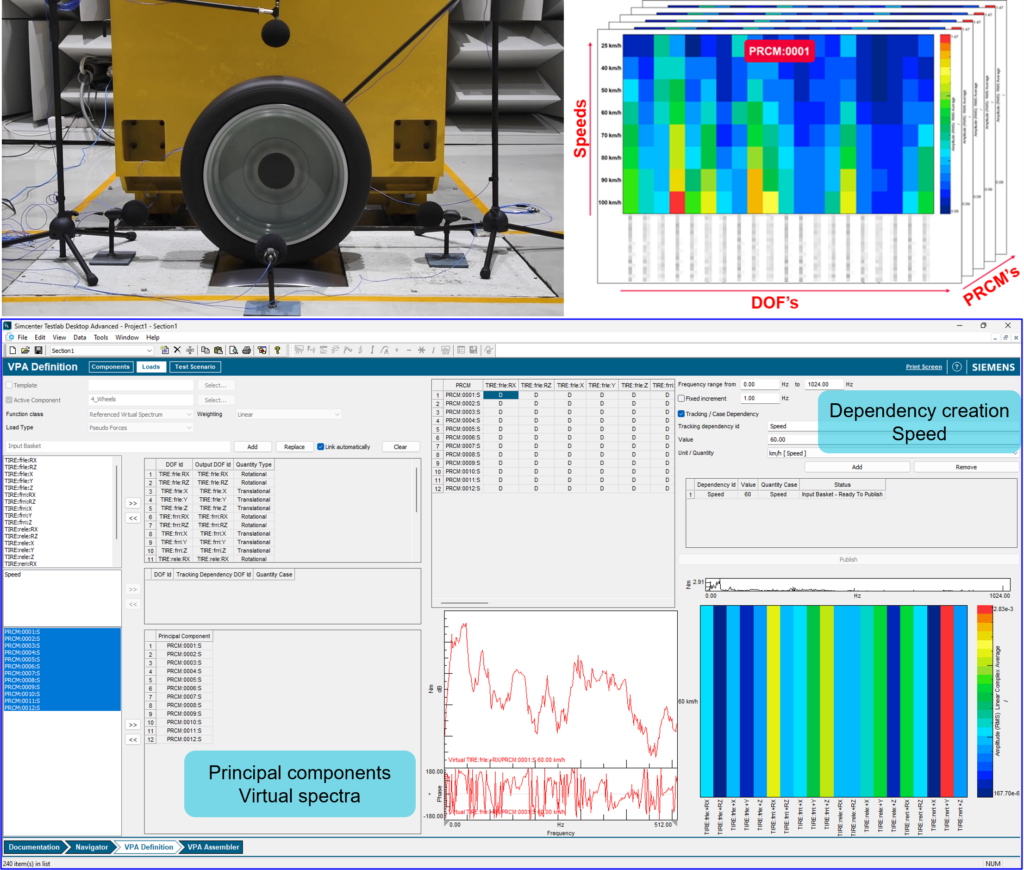

In the automotive context, the significance of Road Noise in a vehicle’s overall noise has grown substantially, particularly due to the rise of electrification. The Road Noise phenomenon involves each wheel acting as an independent source, contributing semi-coherently to the total cabin noise. To address this, engineers commonly employ the Principal Component method to derive orthogonal virtual references for analyzing this phenomenon accurately.

Consequently, blocked forces estimations, whether obtained in-vehicle or via test rigs, can also be broken down into multiple Principal Components to be effectively applied to the virtual assembly. With the latest version of Simcenter Testlab 2306, it is now possible to publish Load components using Principal Components datasets. Furthermore, a single Load component can contain information for multiple vehicle speeds, streamlining the analysis process.

Input Data Linearization

The success of a virtual assembly using the Frequency Based Substructuring (FBS) method heavily relies on high-quality input data. Inconsistent datasets can result in “Spurious Peaks” appearing on the Assembled Frequency Response Functions (FRFs). One of the causes of these issues is the presence of deviations in the resonances and anti-resonances of the uncoupled FRFs.

Therefore, it is crucial to ensure model reciprocity to prevent such deviations and eliminate non-linearities. To address this, Simcenter Testlab 2306 introduced a new feature where the user can enforce reciprocity during component publishing. [1]

Additionally, an advanced technique to avoid or overcome Spurious Peaks involves applying Modal Analysis and Maximum Likelihood estimation of a Modal Model (MLMM) to the measured FRFs (Link). This results in the synthesis of FRFs with common poles for the substructure, further enhancing the accuracy and reliability of the virtual assembly.

Store and Exchange

Tighter integration with TLDM

In a component-based approach of virtual prototypes, having lots of components and dealing with different data sources from both test and simulation can be a complex challenge. However, by adopting a single standard of data format, such as the ASAM ODS standard, organizations can establish a cohesive and consistent framework for data storage and exchange. This is the goal of the integration of the Simcenter Testlab Data Management and Virtual Prototype Assembly (VPA). It facilitates seamless integration and ensures that data from various sources can be easily accessed and interpreted. Moreover, the implementation of common and standardized data annotation further enhances data clarity and accessibility.

Within this release, users will have the possibility to directly annotate and publish the components in a common server following the ASAM-ODS standard. Plus, they can now efficiently query the database using annotated attributes to pinpoint specific components and retrieve relevant information, leading to more efficient and informed decision-making processes. This holistic approach to data management optimizes productivity, promotes collaboration, and empowers engineers to extract valuable insights from the wealth of data at their disposal.

Assemble

Multi-Level TPA

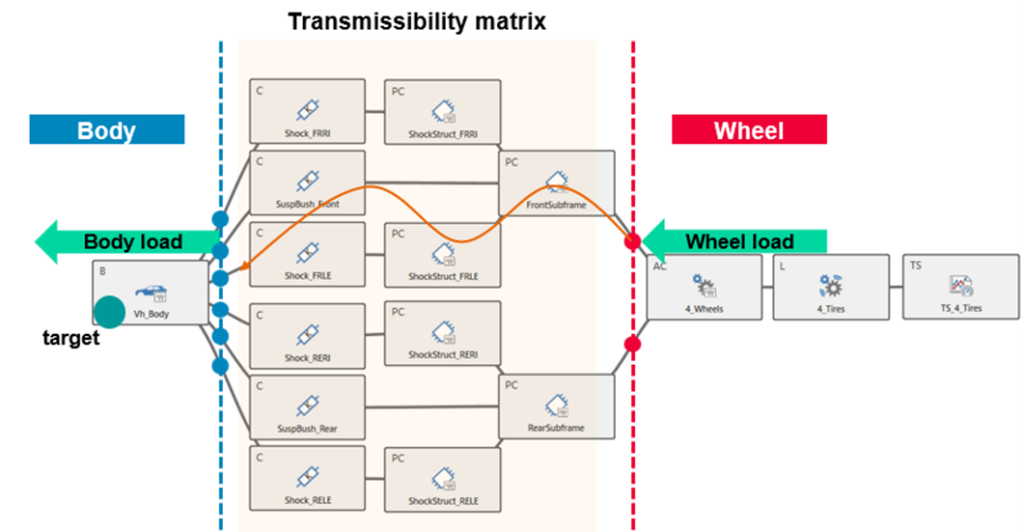

Last year’s release of the software introduced the incorporation of passive components, providing engineers with the capability to effectively model complex structures. This new feature enabled the implementation of Multi-Level Transfer Path Analysis, where loads can now be calculated in two critical interfaces, namely the body interface and the source interface. By accurately determining the loads in these interfaces, engineers can proceed to examine the Transmissibilities, which describe how forces and vibrations are transmitted between the interfaces.

This comprehensive analysis not only enhances the understanding of the structure’s dynamic behavior but also enriches the overall analysis capabilities by providing deeper insights into its response to external forces. Armed with this valuable information, engineers can make well-informed design decisions, optimize structural performance, and ensure the overall reliability of the complex system.

Calculation Options

The concept of Virtual Assembly using Frequency Based Substructuring offers immense benefits in structural analysis. With this approach, engineers can efficiently assemble and analyze complex systems by combining individual component models. Moreover, the software provides the flexibility to calculate the Assembled Frequency Response Functions (FRFs) in multiple interfaces, enabling a comprehensive understanding of the system’s dynamic behavior at different connection points.

Additionally, the tool allows the calculation of Assembled FRFs without the source components (active component and loads) and test scenarios, streamlining the analysis process when detailed source information is not required. This versatility empowers engineers to conduct focused investigations and efficiently assess the system’s response, making Virtual Assembly a powerful and efficient technique for tackling intricate engineering challenges.

Predict, Analyze & Listen

Integration with NVH Simulator

The development of virtual prototypes offers a multitude of benefits, including the exciting possibility of Auralization. With Auralization, engineers can not only visualize but also audibly experience the behavior of the virtual prototype, creating a more immersive and realistic simulation. Furthermore, there have been continuous efforts to enhance the integration between the Virtual Prototype Assembly (VPA) and the Simcenter Testlab NVH Simulator, leading to a more seamless and holistic approach to analyzing and optimizing the system’s performance.

The ongoing improvement in interoperability between VPA and the NVH Simulator has facilitated smooth data exchange and interaction, enabling engineers to gain deeper insights into the prototype’s acoustic and vibrational responses. This synergy between cutting-edge technologies holds tremendous potential for transforming the product development process and ensuring higher levels of accuracy and innovation in engineering endeavors.

Links for more information

Simcenter Testlab Virtual Prototype Assembly:

https://webinars.sw.siemens.com/en-US/predict-vehicle-nvh-performance

https://blogs.sw.siemens.com/simcenter/vpa-for-vehicle-nvh-prediction/

https://blogs.sw.siemens.com/simcenter/electrification-the-new-pressure-on-tire-manufacturers/

https://blogs.sw.siemens.com/simcenter/take-control-of-pass-by-noise-with-a-virtual-prototype/

https://blogs.sw.siemens.com/simcenter/vehicle-nvh-integration-how-to-combine-test-and-simulation/

https://blogs.sw.siemens.com/simcenter/4-steps-to-predict-road-noise-a-project-with-hyundai-motor-group/

https://blogs.sw.siemens.com/simcenter/simcenter-testlab-2206-scalable-data-management/

https://blogs.sw.siemens.com/simcenter/simcenter-testlab-2206-vpa/

https://webinars.sw.siemens.com/en-US/component-based-transfer-path-analysis/

https://mobex.io/webinars/road-noise-prediction-an-mbse-approach-to-virtual-nvh-development/

Simcenter Testlab NVH Simulator:

https://webinars.sw.siemens.com/en-US/master-sound-perception-using-vehicle-sound-simulator/

https://blogs.sw.siemens.com/simcenter/why-a-vehicle-sound-simulator-can-help-you-define-what-should-come-after-vroom/

Reference

[1] Rixen, DJ. (2008). How measurement inaccuracies induce spurious peaks in frequency based substructuring. In s.n. (Ed.), International modal analysis conference IMAC-XXVI (pp. 1-15). s.n..