Logistics optimization enhancing plant efficiency: Analyzing logistic routes with heat maps for optimal efficiency and strategic improvements

Navigating efficiency: Unveiling logistics optimization through heat maps

Jéssica Cette Gomes

Analista de Logística Pleno

E&BM Logistics Engineering

Volvo Group

Volvo do Brasil

www.volvogroup.com

The visionary analyst: Introducing Jéssica Cette Gomes

Logistics optimization: In the intricate dance of manufacturing, logistics is the unsung hero that orchestrates the seamless flow of materials, ensuring that every component arrives at its designated place at the right time. Behind this seemingly effortless operation lies a complex web of routes, vehicles, and schedules, all of which must be meticulously analyzed and optimized to maximize efficiency and minimize costs. Jéssica Cette Gomes, an Analyst at Volvo Group, unveils a groundbreaking approach to this challenge: analyzing logistic routes with heat maps for optimal efficiency and strategic improvements. This innovative method not only enhances logistics optimization by streamlining routes but also provides valuable insights for future strategic enhancements in the logistics process.

The presenter, Mrs. Jéssica Cette Gomes, brings a wealth of expertise and experience to the forefront of logistics optimization. With a Bachelor’s degree in Product Design and a Postgraduate specialization in Engineering and Management of Innovation, her 23-year professional career spans across the manufacturing landscapes of the automotive and aeronautical industries.

Mrs. Gomes has honed her skills during her 4-year tenure at Volvo Group, where she has been instrumental in driving innovation and simulation initiatives. Her extensive background includes over 7 years of hands-on experience with Tecnomatix Plant Simulation, positioning her as a trusted authority in the field. As an Analyst at E&BM Logistics Engineering within Volvo Group in Brazil, Mrs. Gomes leverages her multifaceted skill set to navigate the complexities of logistics with precision and foresight, making invaluable contributions to the optimization of logistical processes.

By implementing this solution, we’ve not only ensured a safer process but also saved a remarkable 600 engineering hours and reduced data analysis time by 40 hours. Through comprehensive flow simulation training, our team has undergone significant development, contributing to an enhanced safety process. Moreover, these efforts have resulted in an impressive €65K in savings. It’s clear: investing in safety and efficiency pays dividends.”

Jéssica Cette Gomes, Analista de Logística Pleno, E&BM Logistics Engineering, Volvo Group

Identifying challenges: The genesis of logistics optimization

The journey embarked upon by Jéssica Cette and her team is not merely a tale of innovation, but a testament to the power of methodical problem-solving and data-driven decision-making. With over two decades of experience in manufacturing, particularly in the automotive and aeronautical industries, and armed with a bachelor’s degree in Product Design and a postgraduate specialization in Engineering and Management of Innovation, Jéssica is well-equipped to navigate the complexities of logistics optimization.

Charting the course: A methodical approach

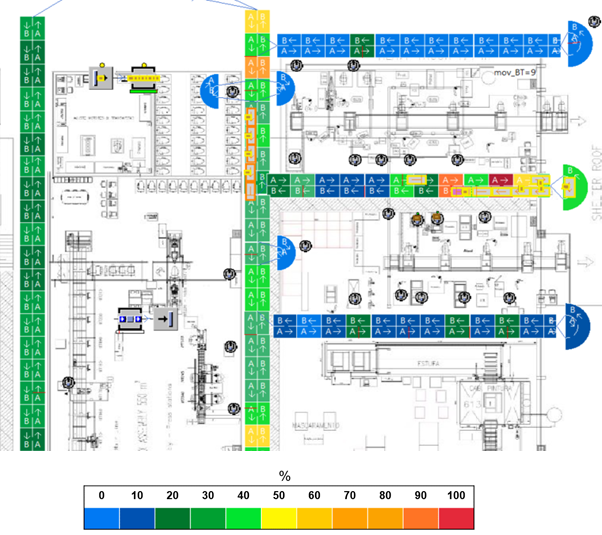

The genesis of this endeavor was the realization during the development activities of new engine projects in 2021 that analyzing the routes of material transporters was imperative. Facing challenges such as the allocation of engineering hours, safety risks associated with new routes, and the complexity of interpreting collected data, Jéssica and her team set out to devise a method capable of measuring and graphically demonstrating the intensity of routes.

Gathering insights: The power of data analysis

The process unfolded in a systematic manner, following a structured path:

- Study Selection: Identifying the problem areas and setting targets and premises.

- Data Collection: Gathering information on vehicles, routes, delivery points, and delivery times.

- Modeling and simulation: Utilizing advanced tools like Tecnomatix Plant Simulation to calculate routes, measure vehicle movements, and predict route utilization.

- Simulation Validation: Conducting before-and-after analyses to validate the efficacy of the developed solutions.

Modeling tomorrow: Simulation and strategy in action

At the heart of this approach lies the utilization of heat maps, which provide a visual representation of route intensity over time. By overlaying data on vehicle movements onto these heat maps, Jéssica and her team gained valuable insights into the flow of materials within the manufacturing ecosystem.

Validating success: Before-and-after analyses

The impact of this endeavor extends far beyond mere efficiency gains. Not only did the implementation of this method result in tangible benefits such as safety improvements, reduction in engineering hours, and cost savings, but it also fostered a culture of continuous improvement and development within the organization. Furthermore, it exemplifies the symbiotic relationship between innovation and pragmatism, demonstrating that transformative solutions can emerge from the intersection of theory and practice.

Visualizing intensity: The role of heat maps

In conclusion, Jéssica Cette Gomes’s journey serves as a beacon of inspiration for those navigating the intricate landscape of logistics optimization. By leveraging cutting-edge technology, harnessing the power of data, and adhering to a relentless pursuit of excellence, she and her team have unlocked new frontiers in efficiency and effectiveness. As manufacturing continues to evolve, it is innovators like Jéssica who will shape the future of logistics, steering us towards a world of unparalleled precision and performance.

Beyond efficiency: Impact and innovation

2024 Plant Simulation User Conference

On June 6th 2024 at the 2024 Plant Simulation User Conference, taking place at the Infinity hotel in Munich, Germany, we will delve deeper into this topic. This event, taking place right after Realize LIVE Europe, is an ideal opportunity for attendees to learn from industry experts, network with peers and explore the latest advancements in Plant Simulation software. They will experience presentations like what’s new in Plant Simulation 2404 and engaging discussions that might transform their approach to material flow simulation. Other lectures at the 2024 Plant Simulation User Conference are for example:

•https://blogs.sw.siemens.com/tecnomatix/bosch-user-friendly-modeling-plant/•https://blogs.sw.siemens.com/tecnomatix/decarbonization-strategies-plant/•https://blogs.sw.siemens.com/tecnomatix/wp-admin/post.php?post=9770&action=edit

•https://blogs.sw.siemens.com/tecnomatix/sustainability-bsh-co2-reduction/•https://blogs.sw.siemens.com/tecnomatix/layout-planning-battery-production/•https://blogs.sw.siemens.com/tecnomatix/8-axis-log-handler-simulation/•https://blogs.sw.siemens.com/tecnomatix/ai-and-digital-twin-real-time-guid/•https://blogs.sw.siemens.com/tecnomatix/electrolux-driving-efficiency/