Maximizing efficiency: Integrating layout planning into battery production

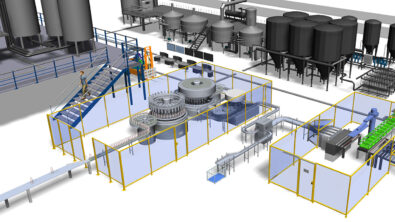

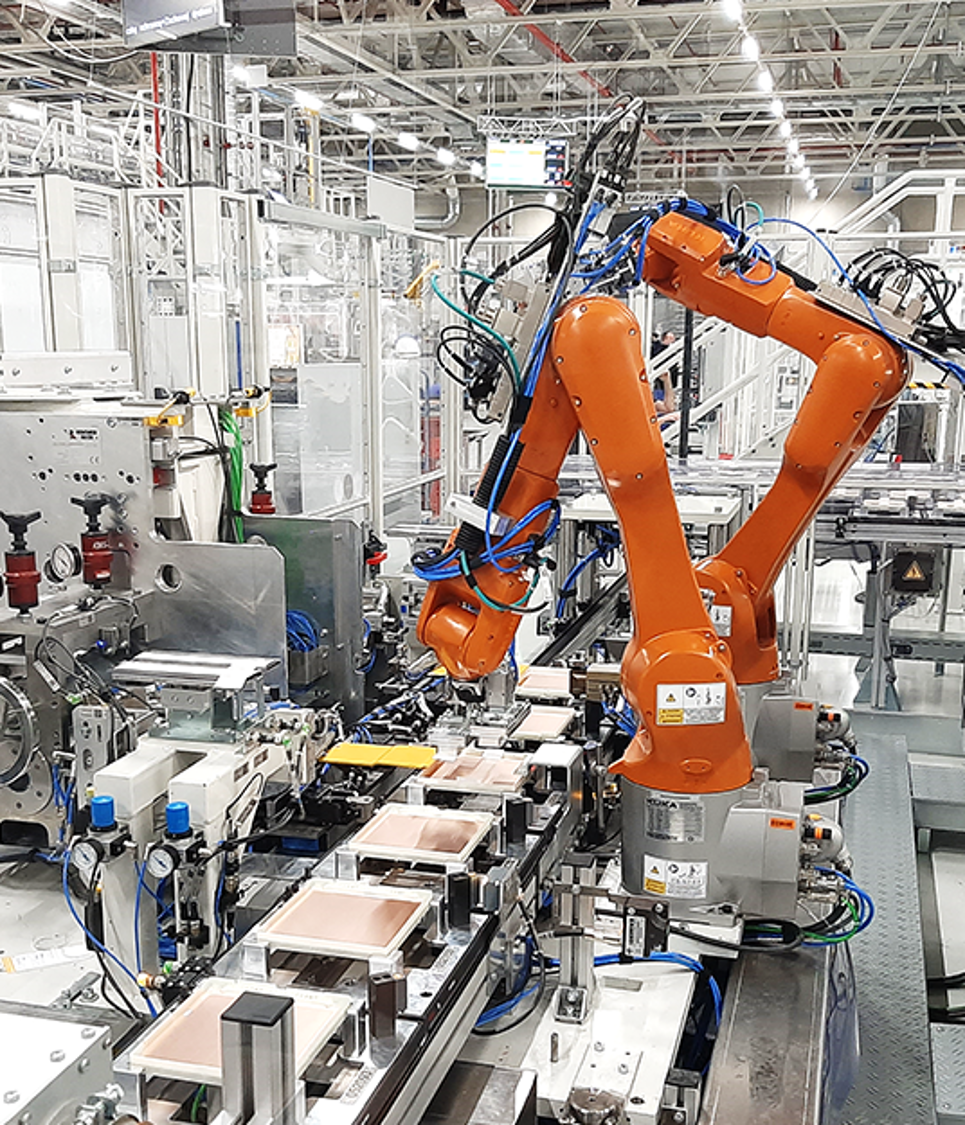

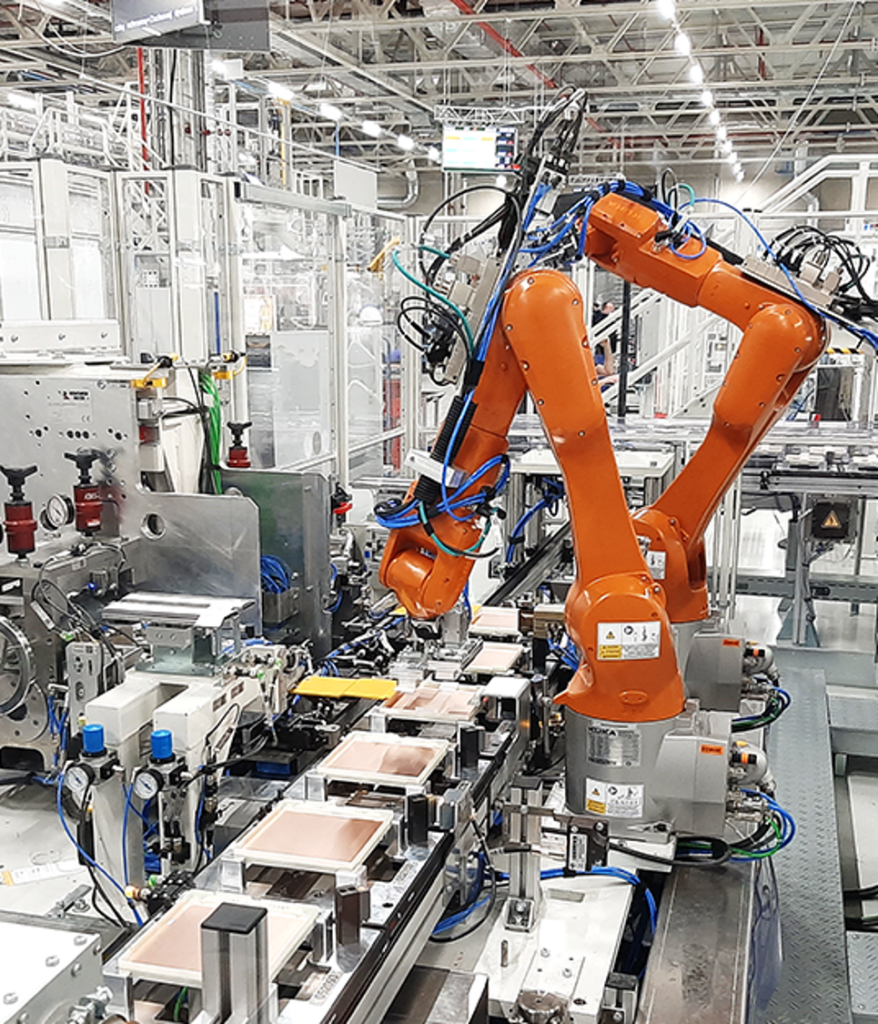

Battery production takes place in a dynamic landscape of manufacturing. Efficiency is the cornerstone of success. Nowhere is this more evident than in the realm of automotive battery production, where precision and optimization are paramount. At EBZ Group, a beacon of innovation in the transportation industry, Louisa Christin, a senior project manager in production planning, is leading the charge towards enhancing battery production through the integration of layout planning into material flow simulation.

Unlocking potential

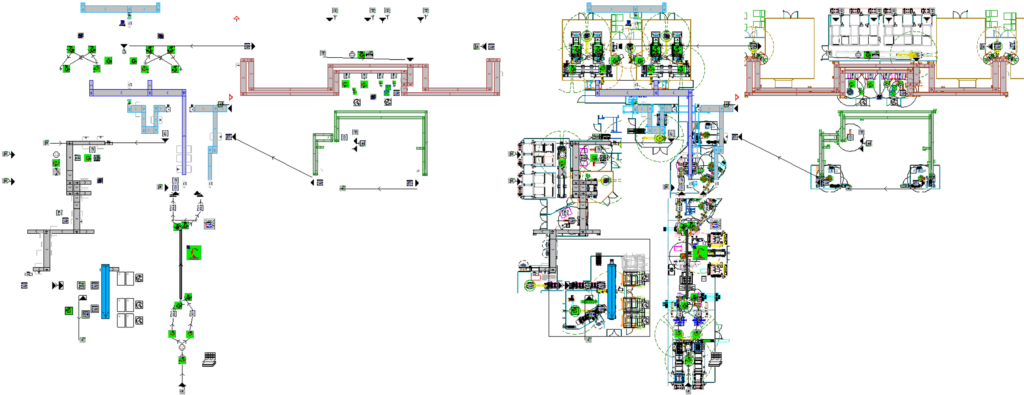

Louisa Christin’s journey into the world of mechanical engineering at the University of Applied Science Ravensburg-Weingarten laid the foundation for her pioneering work at EBZ. Since joining the company in 2018, she is responsible for projects in production planning, focusing particularly on body-in-white and battery production facilities. Her expertise extends to material flow simulation, where she has been instrumental in implementing static and dynamic simulations using Siemens Tecnomatix Plant Simulation software.

The power of integration

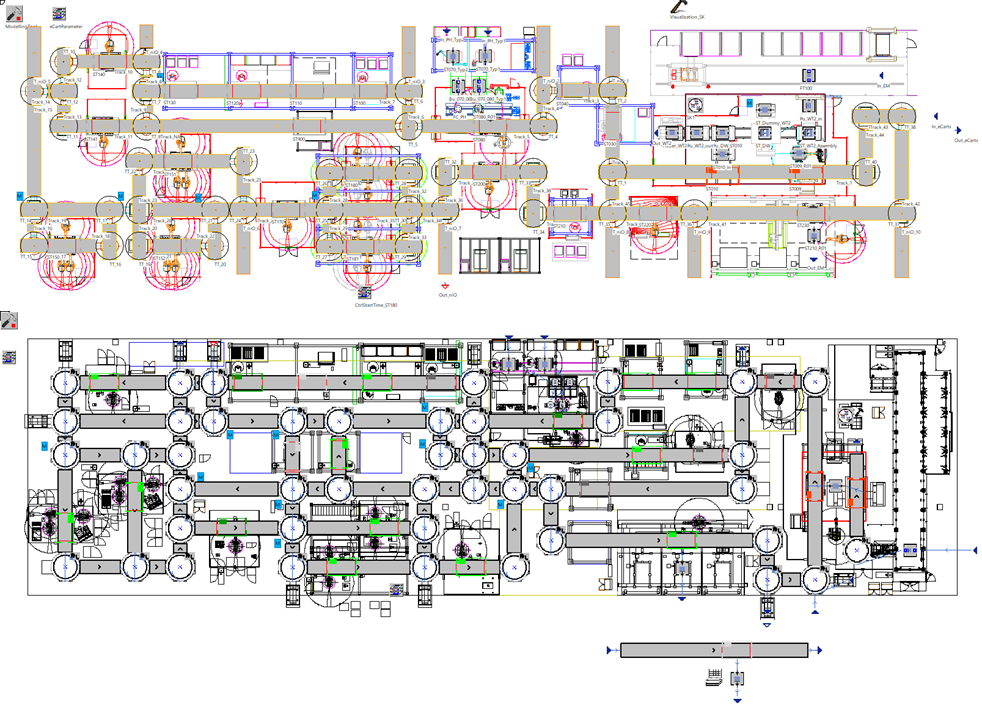

In her lecture, Louisa will shed light on the synergies between layout planning and material flow simulation, emphasizing the advantages of their integration in the context of battery production. By combining these methodologies, companies can gain invaluable insights into their production processes, leading to enhanced efficiency, reduced costs and improved quality.

Navigating challenges

Drawing from real-world experiences, Louisa will present three compelling use cases from EBZ’s project business. Each case will provide a comprehensive overview of the project, highlighting the differences between battery production in material flow simulation with and without layout implementation. Attendees will gain a deep understanding of the evolution of battery production in material flow simulation and the challenges encountered along the way.

Realizing benefits

Louisa will delve into the heart of each use case, discussing the biggest challenges faced and the strategies employed to overcome them. Attendees can expect to learn about the tangible benefits that have resulted from integrating layout planning into material flow simulation, including increased throughput, optimized resource utilization and streamlined processes.

By seamlessly integrating layout planning with material flow simulation, automated battery production lines engineered by EBZ not only optimize efficiency but also propel us into a future where precision and innovation converge to power the automotive industry forward.”

Louisa Christin, production planning, EBZ Group

Join the conversation

If you’re passionate about revolutionizing battery production in the automotive industry, don’t miss Louisa Christin’s lecture at the 2024 Plant Simulation User Conference. Gain valuable insights into the power of integration, glean practical strategies for navigating challenges and discover how you can unlock the full potential of your production processes.

Event details

- Title: Enhancing Battery Production: Integrating Layout Planning into Material Flow Simulation

- Presenter: Louisa Christin, Project Manager in Production Planning at EBZ Group

- Date: June 6, 2024

- Location: 2024 Plant Simulation User Conference

Contact information

For more information on how EBZ Group can help you to optimize automated battery production lines, please contact EBZ Group, Mrs. Maren Barreiro maren.barreiro@ebz-group.com. You can also visit EBZ Group’s website at www.ebz-group.com for additional details.

In conclusion, Louisa Christin’s lecture promises to be an exploration of how the integration of layout planning into material flow simulation can help battery production. Join the conversation and embark on a journey towards maximizing efficiency and unlocking the full potential of your production processes.

On June 6th 2024 at the 2024 Plant Simulation User Conference, taking place at the Infinity hotel in Munich, Germany, we will delve deeper into this topic. This event, taking place right after Realize LIVE Europe, is an ideal opportunity for attendees to learn from industry experts, network with peers and explore the latest advancements in Plant Simulation software. They will experience presentations like what’s new in Plant Simulation 2404 and engaging discussions that might transform their approach to material flow simulation. Other lectures at the 2024 Plant Simulation User Conference are for example:

User-friendly modeling and simulation of manual production lines, Empowering sustainability: Decarbonization strategies in construction process management with the integration and benefits of Plant Simulation and Driving Sustainable Transformation: BSH’s Journey Towards CO2 Reduction in Enameling.