Superior shipbuilding modeling and simulation

Shipbuilding and more: The STS library for Plant Simulation

Lecture by Dirk Steinhauer at the 2023 Plant Simulation user conference, July 13th 2023, Infinity hotel Munich, Germany.

The Simulation Toolkit Shipbuilding (STS) library originated in an industrial company as a foundation for simulating intricate production and logistics processes. Through subsequent collaboration on an international scale, the STS library has undergone further enhancements, now offering diverse capabilities for constructing models, conducting analyses and managing data. It has application in a range of industries and contexts, like serving as the fundamental component of advanced planning and scheduling systems in unique production scenarios.

Having pursued a degree in mechanical engineering at the university of Hannover, Dirk Steinhauer embarked on his professional journey by joining Flensburger Shipyard in 1995. During his tenure, he played a pivotal role in setting up and overseeing the simulation team responsible for production and logistics. Since 2016, he has assumed the position of manager at SimPlan AG Hanau, specifically overseeing the north branch. In addition to his industry role, Dirk Steinhauer has been actively involved in academia, delivering lectures on ship production at the Technical University of Berlin since 2003.

Established in 1992, SimPlan AG emerged as a service provider specializing in the simulation of operational processes. Over the years, it has evolved into one of the prominent providers of simulation services in Germany, boasting a workforce of over 120 dedicated professionals. SimPlan AG offers a comprehensive range of services, encompassing simulation, virtual commissioning and the creation of digital twins for various processes. These versatile services cater to a broad spectrum of industries, making SimPlan AG’s offerings applicable to virtually any company, irrespective of its field of operation.

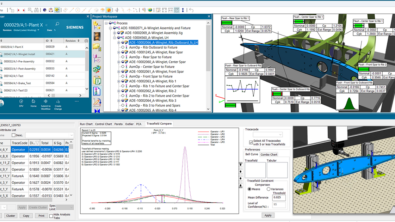

Enhancing shipbuilding efficiency with material flow simulation using Tecnomatix Plant Simulation

In the dynamic world of shipbuilding and shipyards, optimizing production processes and logistics is of paramount importance to ensure efficient operations. One technology that has revolutionized the industry is material flow simulation, with Tecnomatix Plant Simulation software and the STS library leading the way. This lecture explores the benefits of material flow simulation using Plant Simulation software in shipbuilding and shipyards, showcasing its potential to streamline operations and enhance productivity.

Streamlining production processes

Material flow simulation enables shipbuilding companies to simulate and visualize the entire production process, from the arrival of raw materials to the final delivery of finished ships. By creating digital replicas of the production environment, engineers and planners can identify potential bottlenecks, optimize resource allocation and implement efficient production layouts. With Plant Simulation software and the STS library, shipbuilders can simulate complex production scenarios and make data-driven decisions to streamline processes and reduce lead times.

Optimizing logistics and supply chain

Efficient logistics and supply chain management are critical factors in shipbuilding. Material flow simulation empowers shipyards to model and analyze the movement of materials, components and equipment throughout the facility. By considering various parameters such as transportation routes, storage locations and loading/unloading procedures, simulation helps identify opportunities for optimization. Plant Simulation software allows shipbuilders to analyze and improve logistics processes, ensuring seamless material flow, minimizing handling time and optimizing resource utilization.

Minimizing manufacturing costs

Cost control is a key concern for shipbuilding companies, especially in the context of one-off production. Material flow simulation plays a vital role in identifying cost-saving opportunities. By simulating production scenarios and analyzing resource utilization, shipyards can optimize production schedules, avoid overcapacity and reduce unnecessary material handling. Tecnomatix Plant Simulation software, coupled with the STS library, serves as the backbone for advanced planning and scheduling systems, enabling shipbuilders to make informed decisions, optimize workflows and minimize production costs.

Enhancing productivity and quality

Material flow simulation empowers shipyards to analyze and optimize their production processes for maximum productivity and quality. By modeling and simulating different production scenarios, shipbuilders can identify potential bottlenecks, implement efficient layouts and fine-tune production parameters. This iterative approach allows for continuous improvement, leading to enhanced productivity, reduced cycle times and improved product quality. Using Plant Simulation software, shipyards can virtually test and validate their production strategies, minimizing errors and maximizing efficiency.

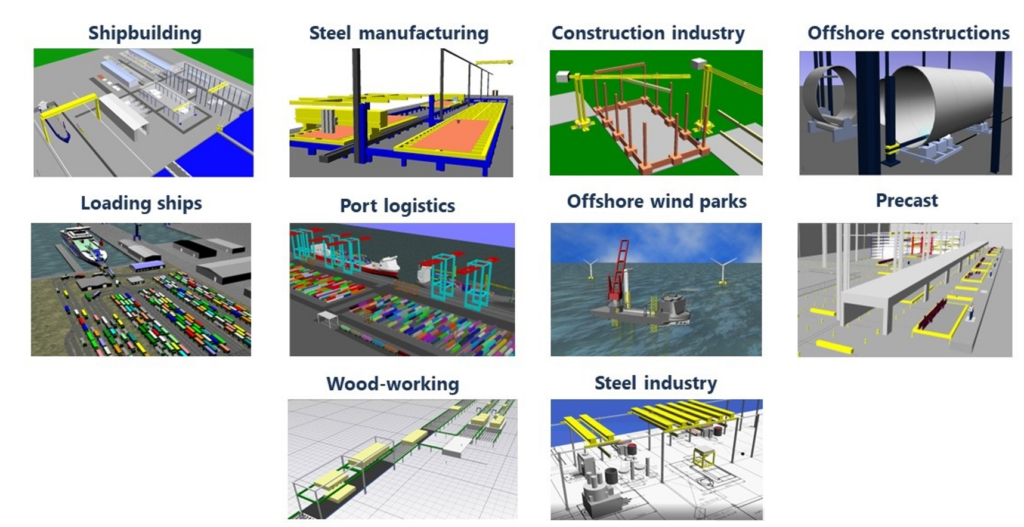

Cross-industry applicability

One of the remarkable advantages of material flow simulation using Plant Simulation software and the STS library is its versatility across industries. While its origins lie in shipbuilding, the simulation technology can be applied to various sectors, including automotive, aerospace, electronics and more. The STS library’s comprehensive functionality for model building, analysis and data management makes it a valuable asset in different industrial applications, enabling organizations to optimize their production and logistics processes regardless of their specific field.

Conclusion

Material flow simulation, facilitated by Tecnomatix Plant Simulation software and the STS library, offers immense benefits to shipbuilding and shipyards. From streamlining production processes and optimizing logistics to minimizing costs and enhancing productivity, the technology empowers shipbuilders to make data-driven decisions, improve operational efficiency and deliver higher-quality ships. With its cross-industry applicability, material flow simulation has become an indispensable tool for organizations seeking to optimize their production and logistics processes, ensuring competitiveness and success.