User-friendly modeling and simulation of manual production lines

Melanie Wolf and Tobias Lechler, of Robert Bosch GmbH, will deliver a presentation at the 2024 Plant Simulation User Conference.

At Robert Bosch GmbH’s Working Group Digital Production, Tobias Lechler, Melanie Wolf and their team are focusing on improving manual production line planning and execution. Through user-friendly modeling and simulation techniques, they’ve developed a standard library, called the Bosch Factory Simulation Library, that streamlines the modeling process, offering benefits such as reduced effort and automated model generation. Their approach holds promise for enhancing manufacturing efficiency and productivity.

Melanie Wolf After studying mechanical engineering at DHBW Friedrichshafen, Melanie worked as a system engineer in the military aircraft industry. In the first years after transition to the automotive industry, she took on responsibilities in technical management and quality assurance for international suppliers, followed by project coordination for ramping-up new productions lines within an international production network. In her current role as project engineer and Plant Simulation expert, her simulation tasks have a focus on new Bosch Products in the H2 business. |  Tobias Lechler Tobias studied mechanical engineering at DHBW Stuttgart and FAU Erlangen-Nuremberg. From 2018 to 2021, he conducted research at the Institute for Factory Automation and Production Systems (FAU) at Friedrich-Alexander-University Erlangen-Nuremberg in the field of production systems simulation. Since 2022, he has led the central Industry 4.0 working group ‘Digital Production’ at Robert Bosch GmbH in the Power Solutions division. This group focuses on the further development, standardization and roll-out of simulation solutions for production systems. |

In the realm of modern manufacturing, efficiency is paramount.

In an era where time is money and precision is king, the ability to simulate and optimize manual production lines is a game-changer.

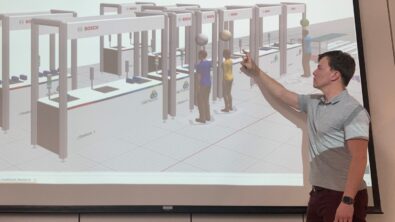

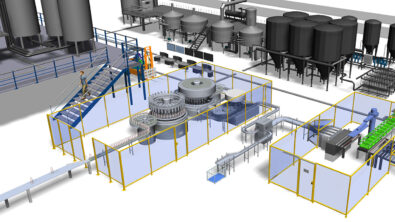

Tobias Lechler, Melanie Wolf, and the committed team at Robert Bosch GmbH’s Working Group Digital Production are on a mission to transform the planning and execution of manual production lines. Their strategy centers around the creation of a standard library that covers both automated and manual production lines. This library acts as the foundation for simplifying the modeling process, providing users with numerous advantages, including decreased effort, standardized data storage, and automated model generation.

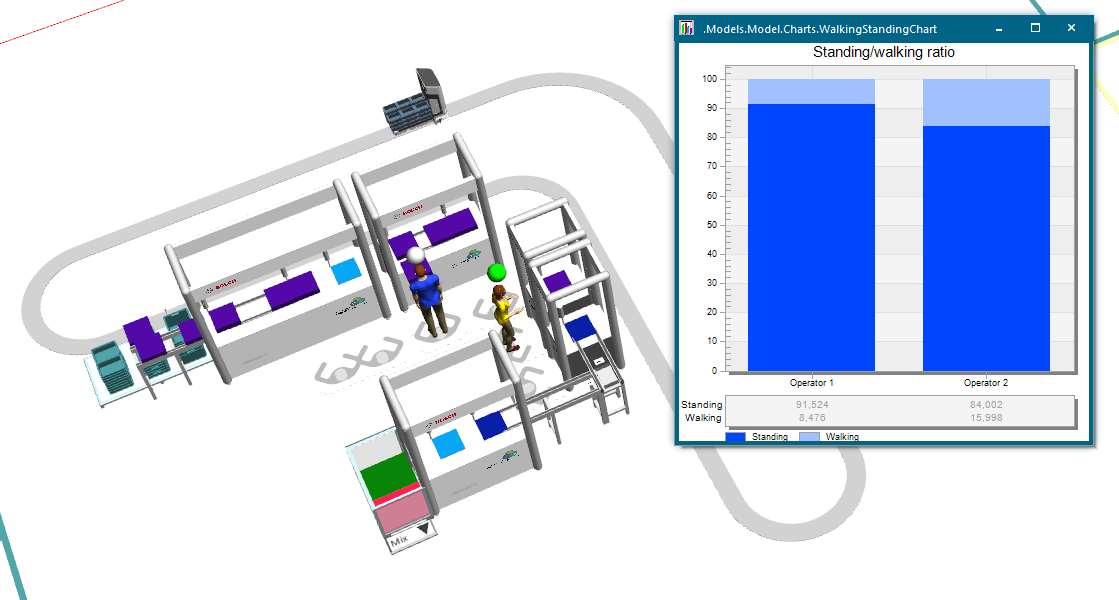

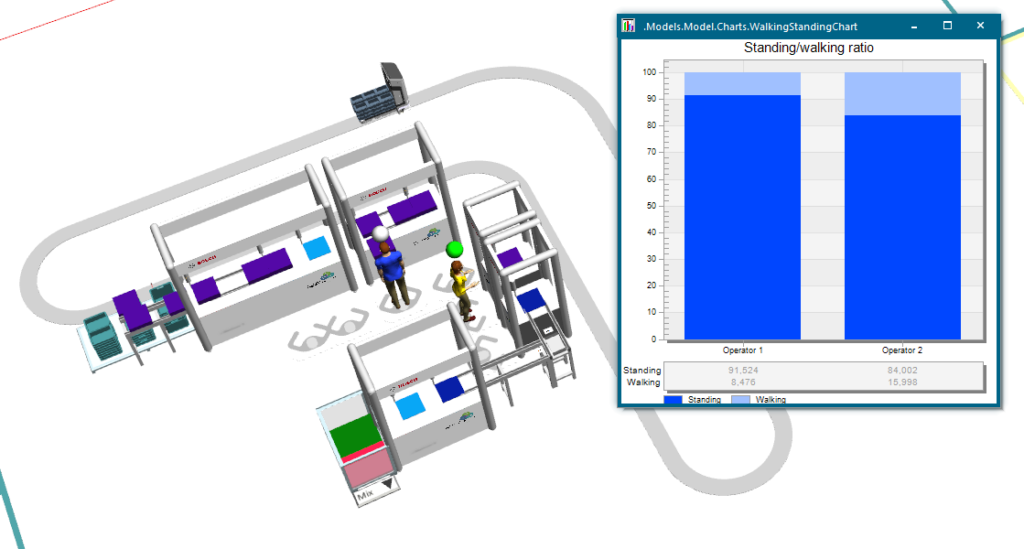

But what sets manual production lines apart in the realm of simulation? The challenge lies in accurately implementing human workers into the equation. Unlike their automated counterparts, manual lines require careful consideration of factors such as worker pools, station-based workplaces, and control mechanisms. Tobias Lechler, Melanie Wolf, and the team have tackled these challenges head-on, offering solutions that enable fast switching between controls, user-friendly adaptation without programming knowledge, and advanced analysis options for operators.

Read more at https://resources.sw.siemens.com/en-US/case-study-bosch-group

We establish key solutions for Power Solutions in digital planning and production – both for new (Greenfield) and running serial production (Brownfield), focusing simulation.

One of the key innovations introduced by the team is the concept of gameification of modeling. By incorporating elements of gamification into the simulation process, users are not only able to model production lines more efficiently but also enjoy a more engaging experience. This, coupled with the standardization of modeling through the library, has led to significant time reductions, lower error rates, and increased usage in a staggering 72% of projects.

Robert Bosch GmbH users provided invaluable feedback on the standard library, citing a 50% reduction in modeling time, improved functionality, and better transparency. The library’s user-friendly interface and customizable options garnered praise from users across various divisions.

Key facts speak volumes about the success of Lechler, Wolf, and the team’s endeavors. The user-friendly modeling and simulation using the Bosch Factory Simulation Library received a functionality scoring of an impressive 8.43 out of 10 and documentation & support not far behind at 8.40, it’s clear that their approach has struck a chord with users.

In conclusion, the journey towards user-friendly modeling and simulation of manual production lines is one marked by innovation, collaboration, and a relentless pursuit of efficiency. Thanks to the efforts of Tobias Lechler, Melanie Wolf, and the and the working Group “Digital Production” at Robert Bosch GmbH, the future of manufacturing is brighter than ever. As we look ahead, one thing is certain: the era of streamlined, user-friendly production line simulation is here to stay.