What’s New in Simcenter Mechanical 2306

Products across the Simcenter Mechanical range are growing, fast! The latest releases are no exception, with updates across all of the products enabling users to visualize their results more easily and more collaboratively than ever before. Enhancements in current releases help you drive engineering innovation while continuing to focus on our four key pillars:

Go Faster

With both internal and external demands always putting pressure on the delivery date and the total cost of a project, it is unsurprising that our customers demand rapid simulation times. The following enhancements are some of the highlights in this release that help you model and simulate faster:

Electromagnetics (low-frequency)

Reduce the workload by utilizing patterns

With the new patterning tool, you can eliminate the repetition of tasks when setting up coil and magnet designs. This saves significant time, especially when multiple coil definitions exist per slot, such as those in hairpins.

Structures

Flutter, static, or dynamic analysis in one modelling approach

Integrated parametric workflow for aerodynamic and structural models, and for the whole aeroelastic analysis set-up!

Start with embedded Simcenter 3D CAD to make your parametric geometry, create both structural and aerodynamic meshes that auto update with design changes. Then use the new selection recipe to select elements and define splines that bond both models, and finally set-up your analysis.

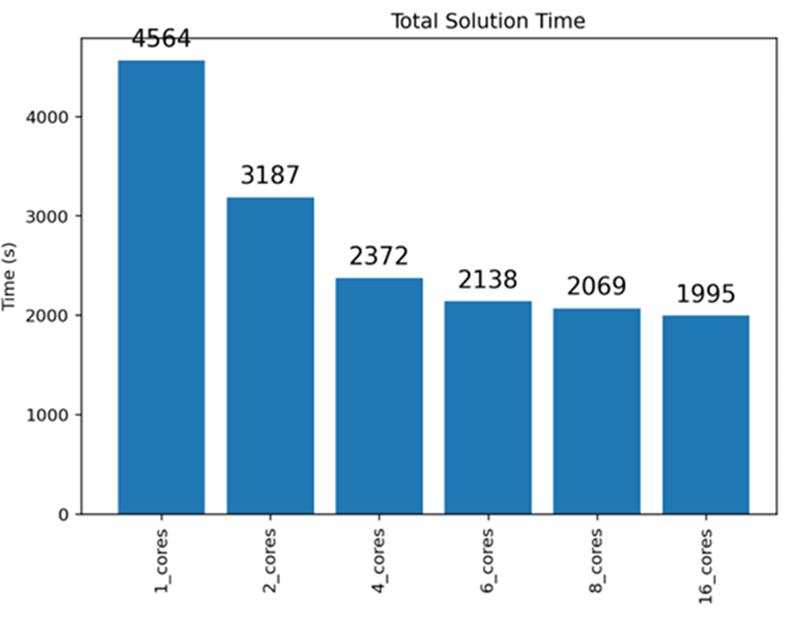

Thermal Multiphysics

Parallelization of the thermal finite element solver

Get results faster and solve higher fidelity models for better accuracy. When tested on a model with 3.2 million elements and 5.2 million nodes, our engineers found the solution to be up to 18.66% quicker in the new release compared to the previous release.

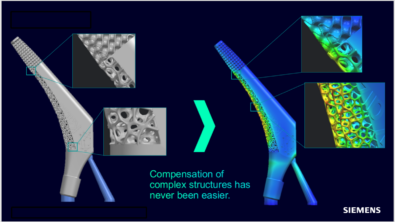

Additive Manufacturing

Export compensated geometry for the powder bed fusion solution

New robust and easy-to-use meshing and compensation workflow makes process simulation and compensation available to additive manufacturing engineers

Model the Complexity

Your products are complex, and you need to accurately simulate and predict performance by capturing the right physics, geometry and operating environment. Simcenter 3D’s multidiscipline integration helps you simulate real-world conditions more accurately, seamlessly transfer data and streamline multiphysics workflows. Here are some of the highlights from the 2306 release that help you model the complexity of your products better:

Motion

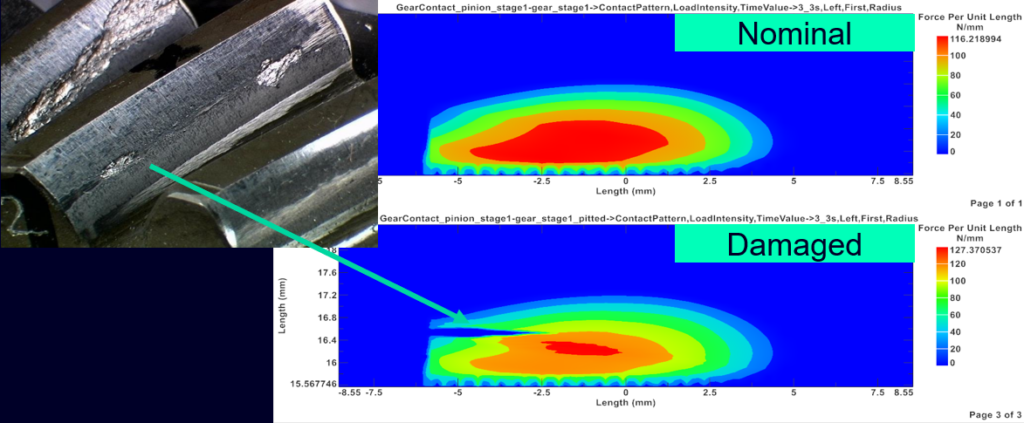

Model the effects of gear pitting

Discrepancies between meshing gear teeth creates vibrations that ultimately create noise and damage, that should be assessed in the NVH analysis. To model this behaviour you can now specify unique microgeometry for individual teeth to include features such as gear pitting and pitch errors.

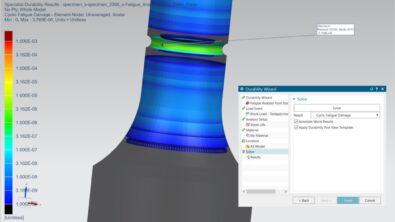

Durability

Discover when your part will fail via creep fatigue

Creep typically occurs in structures at higher temperatures, leading to damage beyond fatigue damage. With standard parameters, you can now calculate creep damage and analyze it individually or as a combined damage result.

Explore the Possibilities

Comparison of results and trialling ideas is an essential part of discovering new solutions and exploring possibilities. The ability to easily adjust parameters in a well developed workflow, run many simulations in a short time, and easily compare the results can all aid this process. It is precisely updates such as these that Simcenter aim to develop so you can find better solutions.

Tire

Test tire parameters in real-time

The prototype tire models can be updated in-line with professional driver feedback using a parameterized model. That, in turn, creates ‘updated’ prototype tire models, that can then be sent back to the tire supplier (or other internal end users at the AOEM) and used as a target or a benchmark for the next iteration of the prototype tire

Motion

Easily compare with multi-solution animations

Users can select up to 5 solutions and animate them in a single viewport. Animation also now supports drag and drop functionality, such as XY Graphs, thereby making plotting and animation behaviour consistent.

Motion

Change the modal frequency content of a flexible body

Reduce the time spent editing CAD and remeshing finite element models when changing the modal frequency content of a motion-flexible body. In this release, you can rapidly edit any selected modal frequency of ERFEM- based motion flexible bodies.

NX Performance predictor

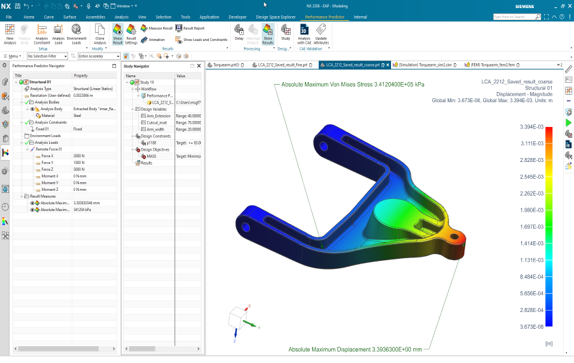

Shift design exploration to the left in the development cycle

NX Performance Predictor enables designers to perform fast simulation to review the design performance of their products with regard to structural stress and displacements. With Simcenter HEEDs enabled to help you find a solution faster

Stay Integrated

Simulation shouldn’t happen in a vacuum. Simulation is just part of the overall development process, and these enhancements in Simcenter 3D help you keep simulation integrated with that process:

Durability

A brand new Durability Wizard

Reduces the burden on strength and durability experts by enabling others to complete a broader range of tasks. The new tool finds existing FE solutions, helps define the loading, provides templates, estimates material properties, and simplifies postprocessing.

Teamcenter Integration

Simplify your workflow with Teamcenter: Simulation and test data in the same database

Teamcenter simulation makes life easier by letting you store simulation and test data in the same Teamcenter database ensuring you are always working from the correct data.

see how you can build the CAE BOM one single time, and Teamcenter Simulation can take care of keeping it up to date as components are updated, added or removed from the CAD BOM.

ASME NQA-1 Compliance

Compliance with nuclear Industry quality assurance policy ASME NQA-1

Safety is a major concern in the nuclear industry, and engineering companies operating in the nuclear space require the products they use to be compliant with ASME NQA-1 procedures. Simcenter 3D Engineering Desktop and Simcenter Nastran 2306 have been subjected to a number of extensive tests to validate compliance with NQA-1-2015 “Quality Assurance Requirements for Nuclear Facility Applications.”

Learn more..

We will continue to add blogs to our release series. keep checking the blogs site to stay up to date. Those already released can be seen on the cards below.