Hyundai Motor Group uses AI to reduce the parameter optimization process from 1 week to 15 minutes

AI-powered shift left

In the vehicle development process, it is advantageous for companies to shift left in the V-cycle as much as possible. By avoiding late-stage design changes, engineering teams can achieve significant time and cost savings and help drive products to market faster.

Artificial intelligence (AI) is an increasingly popular tool to enable engineering teams to shift left. For example, engineers can train neural networks to search through enormous amounts of simulation models and data and help identify the ideal vehicle or component configuration.

Powered by AI, the effort to shift left is more urgent than ever as the world transitions to a more sustainable future with electrification. Many original equipment manufacturers (OEMs) are in the process of transitioning from producing internal combustion engines (ICEs) to battery-powered vehicles. Each of these vehicles has years of development data and simulation models that now need to be adapted for electrification.

Neural networks for vehicle target setting

At the start of their electrification journey, Hyundai Motor Group (HMG) recognized the need to implement AI to enable a seamless shift left in the electric vehicle development process. In 2023, they partnered with Simcenter Engineering and Consulting services to build the neural networks that will enable them to define architecture-driven requirements at the concept stage of vehicle development.

Early in the design process (at the left of the V-cycle), engineering teams typically have an estimate of what they would like to see from their next generation of vehicle, including mass, size, suspension technology, etc. These early ideas need to be explored and analyzed in the most efficient way possible to define the ideal design and configuration. Target setting for attributes such as optimal mass, kinematics, drivability, ride and handling gives engineering teams subjective key performance indicators (KPIs) to meet. The earlier these targets can be met, the more time and cost savings a company can reap.

Ilsoo Jeong, comfort engineer, is part of the driving comfort virtual development team at Hyundai Motor Group. His team was tasked with target setting for chassis development of the Genesis GV 80, which will be released in a future generation as an electric vehicle (EV).

“Our goal was to achieve the best possible comfort and handling performance, so we had to consider hundreds of chassis parameters, such as mass distribution, suspension kinematics, the mounting system,” says Jeong. “We also needed to consider how these designs and configurations would need to be changed considering the ICE will be replaced with a battery.

“Additionally, we wanted the ability to perform sensitivity analyses to quickly understand how changes to the design of one component may impact the performance of others. We realized that taking advantage of AI could help us accomplish this quickly and efficiently. We partnered with Simcenter Engineering and Consulting Services to build these neural networks because they had the most expertise in Simcenter Amesim, our preferred tool, and because of their vast expertise in the vehicle development process.”

EV architecture optimization

In a separate project, the Simcenter Engineering Services team had collaborated with HMG engineers to develop an architecture in Simcenter Amesim software that could be used to evaluate a variety of vehicle maneuvers and provide automatic postprocessing.

This architecture allowed criteria to be weighed separately – including 52 individual KPIs for each requirement – to achieve an overall score, and it could handle over 350 parameters as input.

In this project, Simcenter Engineering Services expanded on this work to apply it to the chassis. Using the targets provided by HMG, Simcenter engineers generated over 200,000 simulation models in Simcenter Amesim and validated them against real vehicles. They saved the simulation results in a high-performance computing (HPC) to make them run faster in the future.

“Simcenter Amesim was the driving force behind our decision to select Siemens for this project,” explains Jeong. “Only Simcenter Amesim had the capabilities to perform the number of simulations we needed, as well as the flexibility for attributes such as NVH frequency. Simcenter Amesim was also advantageous because it enabled us to work with our own templates rather than a prepackaged one. When it came to flexibility and simulation time, Simcenter Amesim was the best choice.”

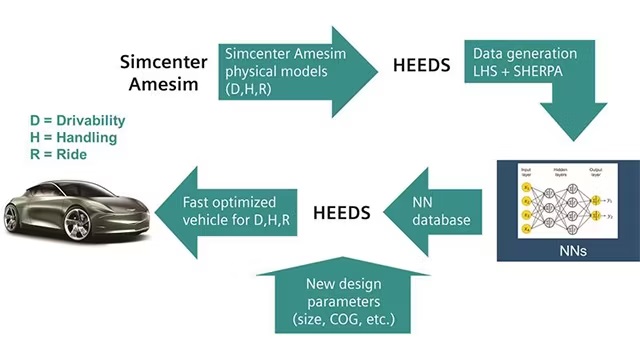

Using Simcenter Reduced Order Modeling software, Simcenter Engineering Services created and trained a neural network to deliver simulation results that enables direct optimization of models later in the process. This neural network integrates with HEEDS software to assist HMG engineers in identifying the ideal vehicle configuration.

“If our targets or parameters change, we will no longer need to start the entire process from scratch,” says Jeong. “We can now find the optimal parameter set very quickly by searching through the neural network built by Simcenter Engineering Services. The ability to easily retrieve these simulation results means we can give very quick feedback to each subsystem team on the ideal configuration. Later in development, we will also be able to efficiently compare the vehicle’s driving performance to our targets by using the benchmarking data retrieved by the neural network.”

AI-enabled time savings

The collaboration with Simcenter Engineering Services and use of Simcenter software has led to significant engineering process benefits for Jeong’s team.

“Before this project, one requirement evaluation took two minutes to run in simulation,” says Jeong. “Using the neural network developed by Simcenter Engineering Services, this was reduced to one-tenth of a second. Similarly, our subsystem parameter optimization process used to take a week. With the help of Simcenter Engineering Services, this has been reduced to 15 minutes.”

Together, Jeong and the Simcenter Engineering Services team are working to reap even more efficiency benefits from this neural network. They will soon integrate with Teamcenter software to fully link to and provide traceability for parameters and requirements. This will enable a program manager with no knowledge of simulation to directly input their requirements and use parameters from a previous project to run simulations directly on the web. They can then predict system performance or optimize parameter sets for subsystems, bringing the power of system simulation to nonexperts.

“Siemens’ Simcenter portfolio and Simcenter Engineering Services will continue to be a special development partner for HMG,” says Jeong. “Our companies have a strong relationship and I look forward to collaborating on future projects.”

Learn more about AI-based parameter ID

You may also enjoy:

- Blog: How to use AI to reduce the Parameter ID process from weeks to minutes

- Blog: Making your historical NVH data work for you

- Blog: 4 Myths about AI in CFD