Ice protection: is your aircraft ready for the winter season?

“You better watch out

You better not cry

You better de-ice

I’m telling you why

Winter season is coming to town”

We all know it, the winter season is coming, and we have to change our summer car tires to winter tires for a better grip during the cold season… Well, at least some of us do it. In the aerospace industry, specialized tires are irrelevant for wintertime. The focus is on de-icing and ice protection systems. While de-icing is done at the airport before a flight, ice protection systems are built into the airplane and are required by certification regulations for various critical components.

Have you ever flown during winter and had to wait on the plane in line to be de-iced at the airport before take-off? Well, you’ve experienced only a tiny portion of what is required to fly under these conditions. There are four types of de-icing fluids the aircraft is sprayed with, depending on the type of aircraft and conditions. They usually have different colors for aiding in the identification of the fluid and the application of the surface with the fluid. The fluids are based on some propylene or ethylene glycol.

Depending on how harsh the season is and how many flights take off (considering Covid conditions, for example), there are over 95 million liters -or 25 million US gallons- of liquid being used for de-icing of aircraft during the year in the US only.

By the way, did you know that if the plane cannot take off within a limited time after being sprayed with the de-icing liquid, it has to be de-iced again?

This is called the “Holdover Time” and can range from a few minutes to almost 3 hours. To name a few factors, it can depend on the wind, aircraft skin temperature, ambient temperature, fluid concentration and the fluid type that is used. Type I fluid is used in most cases and has a Holdover Time of 2 to 22 minutes, Type IV fluid Holdover Time can range from 0 to 4 hours and depends strongly on the product chosen.

The FAA releases the Holdover Time1 every year as products might improve or new products are released to the market.

But all of that is only useful as long as the airplane is on the ground and during take-off, when the fluid gets sheered off by the wind and the aircraft is free of it again. But what happens then?

What happens when rain, snow or ice hits the plane and freezes while climbing and passing through the clouds and into colder altitudes?

This is where ice protection devices come in and keep the airplane’s critical components free of ice.

Aircraft ice protection: where, when and how?

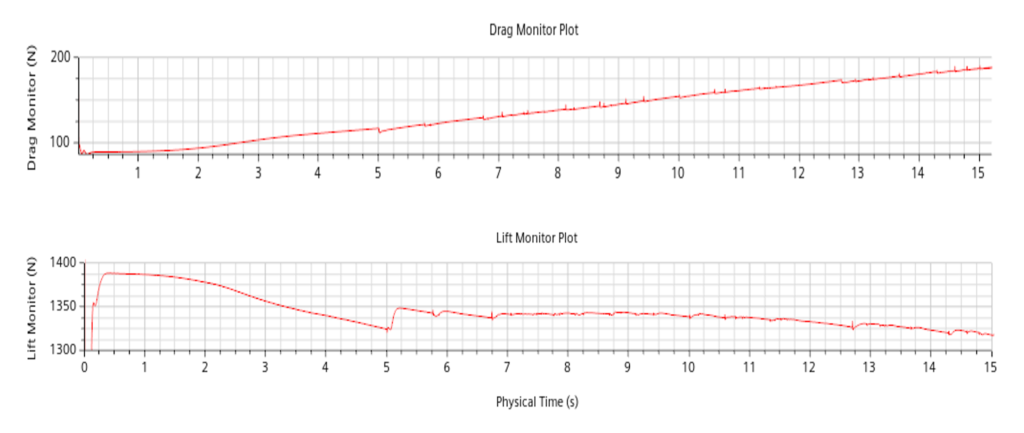

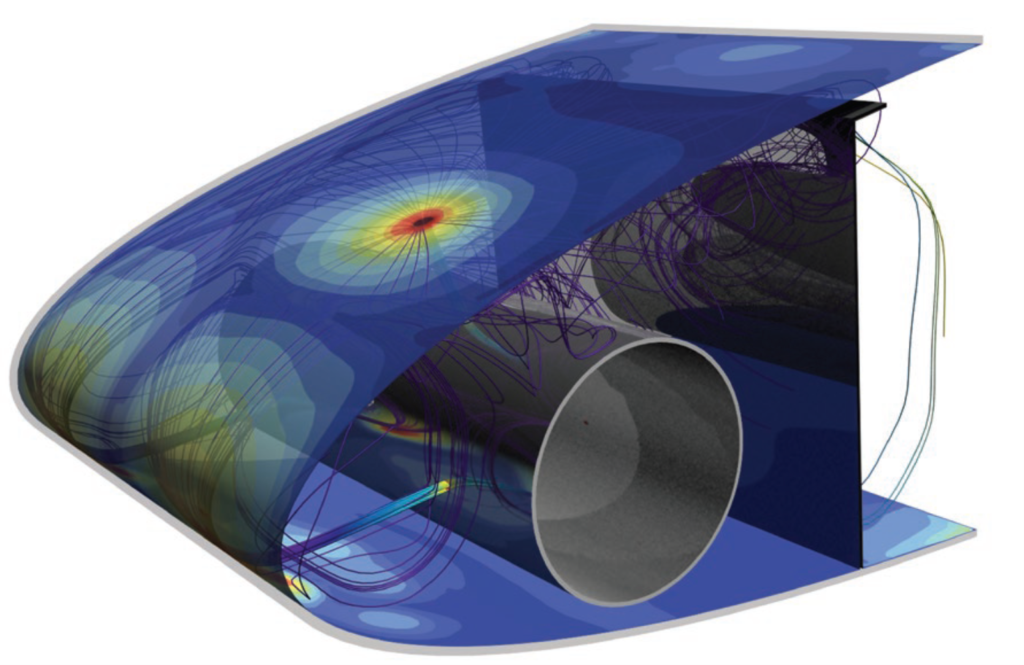

There are various types of systems located at multiple components which need ice protection. Some of these critical systems are engine nacelle intakes, spinners, and wings. The reason is that ice on the wings can drastically reduce the aerodynamic performance and cause flow separation and lift reduction where it is unwanted. The engine nacelles intakes are usually heated at the leading edge or lip of the nacelle. Any ice that would form and shed can damage the fan blade or any of the following components, such as compressor blades and can cause a surge or flame out and more significant damage.

Other components are probes that indicate the airspeed and other important flight conditions such as the Pitot and Static pressure tubes. But even ice ridges in front of those probes can disturb the flow and deliver wrong readings.

If you are wondering how to know when such an icing condition exists, then I have bad news. Not only does it appear in winter, but the condition for icing can also exist all year-around, even at the equator and at any altitude (forget about the rule of thumb you have for car tires: from October till April). But aircraft have ice detection sensors that can work at a specific ultrasonic frequency driven by an electric current. Any change in that frequency due to ice accumulation would be sensed and a warning signal for the pilots would be activated to engage the ice protection systems.

Depending on the budget, the plane type or size and the location of the ice protection system, it might be a heating method based on bleed air from the jet engine that is used to heat the leading edge of the wing or nacelle through a piccolo tube or an electrically heated surface with some heating foil or mat. Some older types are boots driven pneumatically by inflating a rubbery section on the leading edge, which cracks the ice and blows it away into the airstream.

Even propellers and helicopters have icing issues and typically use electrically heated solutions on the rotor blades.

If you want to know more about how they work and how the overall ice protection system is designed and certified, look at this white paper:

And with that, I will try not to tell you to stay frosty, but stay warm and ice-free! 😉

You might also be interested in:

- Webinar | Don’t let thermal management issues limit aircraft systems performance and safety

- Case Study | Airbus Helicopters

- Ice Scalloping Simulation in Simcenter STAR-CCM+