Advanced virtual reality with Plant Simulation software

Lecture and LIVE demonstration by Eduard Kinas, Stefan J. Koch and Gottfried Roosen of more3D at the 2023 Plant Simulation User Conference July 13th, 2023, Infinity hotel, Munich, Germany.

About more3D

Eduard Kinas has more than 15 years of experience in concept and creation of stereoscopic

and virtual reality turnkey solutions. He pioneered virtual reality (VR) solutions with more3D as early as 2005 and influenced the evolution of VR hardware and software.

Having the strong belief in 3D and VR, Eduard acquired the company, more3D, in 2011.

Following that, more3D was set to develop a new VR software: moreViz, the universal VR

bridge for professional applications. Today, moreViz enables direct virtual reality access for

over 35 applications. In 2015, Siemens discovered the huge potential of more3D and ever since they have been a Siemens Solution partner for VR solutions and stereoscopic display systems.

As of 2022, the collaborative development between Siemens and more3D yielded the first

results – a two way information interface between Siemens Tecnomatix Plant Simulation software and more3D moreViz software. Eduard and his colleagues, Stefan Koch and Gottfried Roosen will present their VR solution for Plant Simulation software to the 2023 Plant Simulation User Conference participants.

Presentation

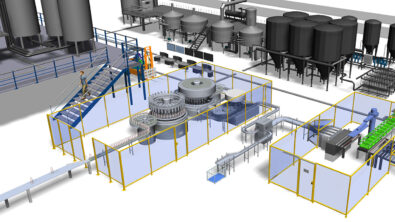

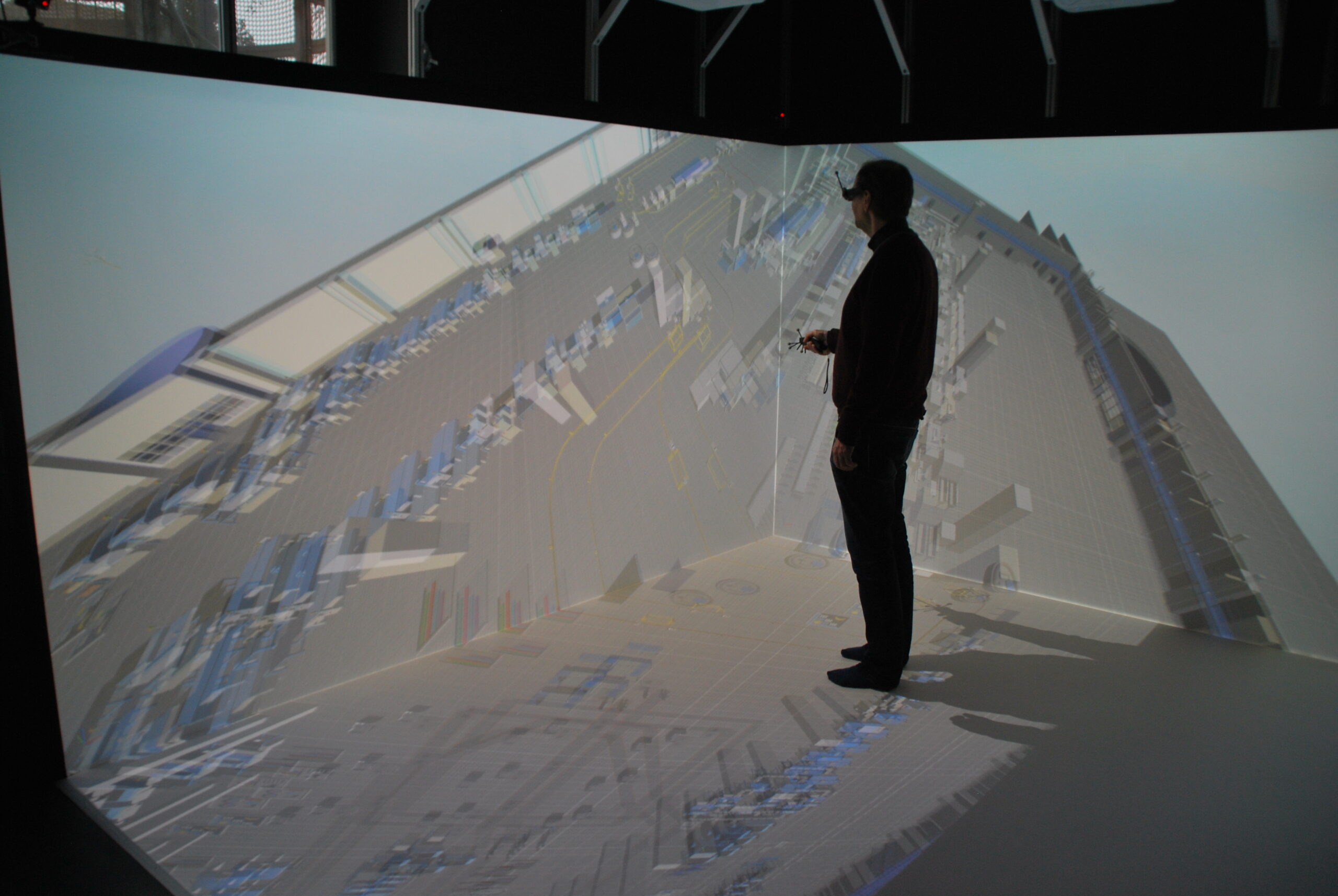

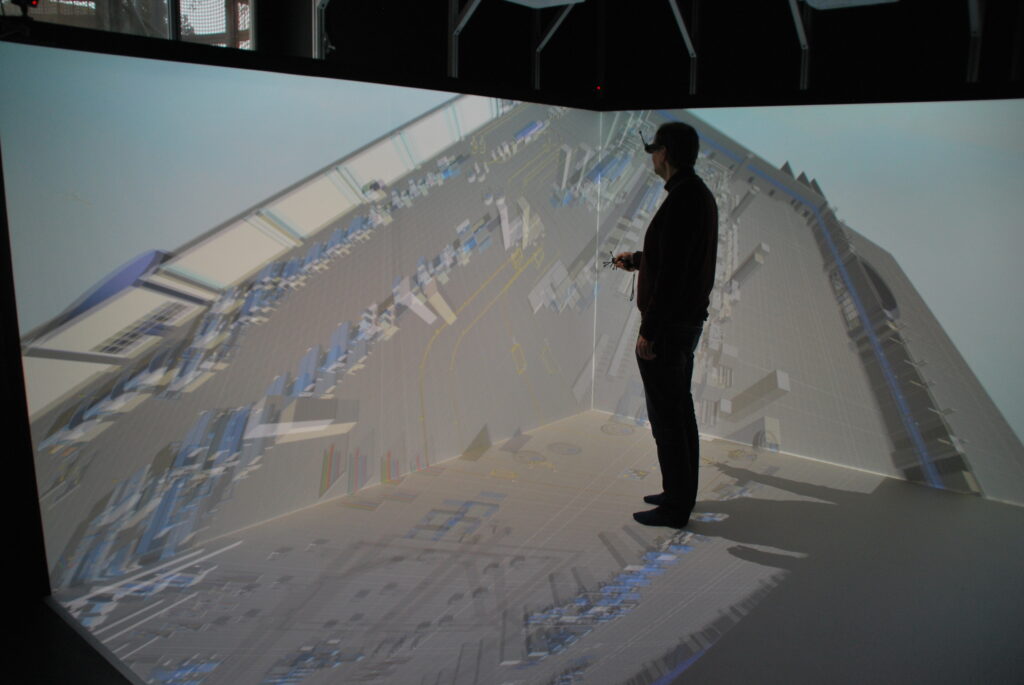

Virtual reality (VR) technology has revolutionized numerous industries and its application in manufacturing and factory simulation is no exception. When combined with visualization devices such as head-mounted displays (HMDs) or classic 3D VR projections (Powerwall, CAVE), VR opens up a whole new dimension of possibilities for enhancing the efficiency and effectiveness of factory simulation processes. Explore the benefits of using VR in conjunction with Siemens Digital Industries Software Tecnomatix Plant Simulation software and how the HMDs and classic VR devices can take these benefits to the next level.

1. Immersive visualization

One of the primary advantages of utilizing VR in Plant Simulation software with the moreViz VR bridge is the ability to create immersive visualizations. With head-mounted display (HMD) VR technology and the moreViz HMD software users can step into a virtual environment, right at the users work desk, to replicate the actual factory layout and equipment. User groups and teams benefit from the new moreViz 3D Stereo projection functionality. Creating life-like 3D visualization directly from within the factory simulation allows you to experience the VR insights directly, shared with colleagues.

2. Realistic interactions

VR, when coupled with HMDs, Powerwalls or CAVE (Cave Automatic Virtual Environment), enables realistic interactions within the virtual environment. Users can interact with virtual objects, machinery and controls just as they would in a real factory. This hands-on experience enhances training, as employees can practice operating equipment and troubleshoot potential issues in a safe, virtual setting. It also enables engineers to experiment with different layouts and configurations, test assembly line optimizations and evaluate ergonomic factors before implementing changes in the physical factory.

3. Enhanced collaboration

Another key advantage of combining the moreViz VR Bridge with Plant Simulation software is the ability to facilitate collaborative decision-making processes. Multiple users can connect in the virtual environment simultaneously, regardless of their physical locations and available VR hardware. Even participation with conventional 2D monitors is possible. This feature enables cross-functional teams to analyze, discuss and refine factory layouts, production strategies and resource allocation in real-time. The shared virtual space fosters effective communication and reduces the need for physical prototypes or time-consuming meetings, resulting in significant time and cost savings.

4. Risk mitigation and safety

By utilizing the moreViz VR bridge software with Plant Simulation software, engineers can contribute to risk mitigation and safety enhancement. Virtual simulations allow for testing and refining safety protocols and emergency procedures without putting employees in harm’s way. It becomes possible to identify potential hazards, assess ergonomic factors and optimize workstations for maximum safety and efficiency. VR training scenarios can also help employees prepare for high-risk situations, ensuring they are well-equipped to handle emergencies.

5. Cost and time savings

Virtual reality technology offers substantial cost and time savings in the field of factory simulation. Traditional methods often involve physical prototypes, trial-and-error iterations and time-consuming manual adjustments. By replacing these conventional approaches with virtual simulations, companies can streamline their product development cycles, reduce material waste and minimize the need for physical alterations. The result is shorter time-to-market, improved production efficiency and significant cost reductions.

6. Advanced feature set and cutting-edge technology

more3D has developed and delivered cutting edge 3D Stereo and VR technology since 2001. A notable function within moreViz is the composition feature. It enables the fusion of datasets from different host applications into a single virtual reality environment. This means that various datasets can be referenced and examined together, while still retaining the simulation and animation elements from the original host application. This capability empowers users to gain deeper insights by juxtaposing and analyzing different data sources within a unified VR environment.

Summary

The combination of moreViz VR bridge software with Plant Simulation software holds immense potential for revolutionizing the manufacturing industry. The benefits of immersive visualization, realistic interactions, enhanced collaboration, risk mitigation and cost savings make this integration a game-changer in optimizing factory operations and improving overall efficiency. As more businesses recognize the advantages and invest in these cutting-edge technologies, we can expect to witness a paradigm shift in how factory simulation is approached, leading to increased productivity, innovation and success in the manufacturing sector.