Smart Factory: Unlocking operational excellence: Integrating Plant Simulation in the era of smart factories

Alhona; Adrián García

Unveiling the potential of smart factories

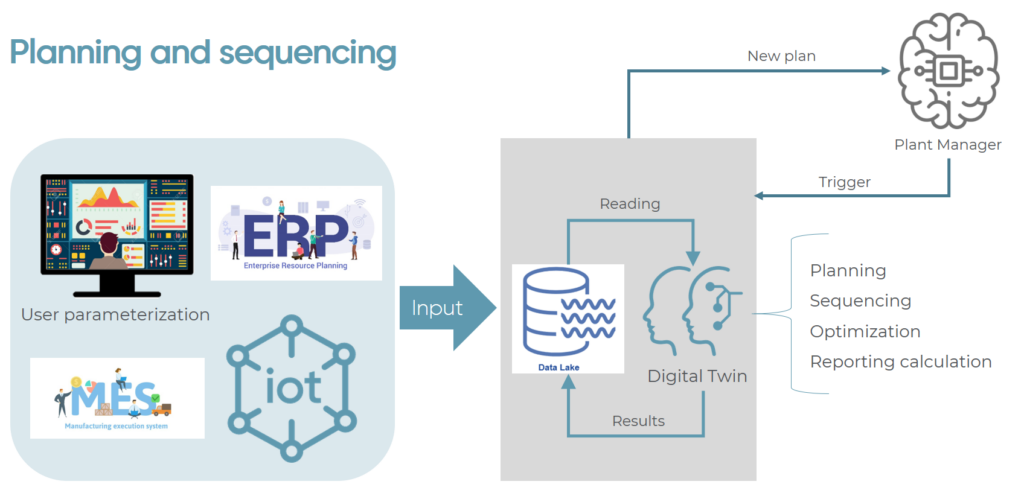

Smart Factory: In the grand scheme of industrial evolution, the advent of the fourth industrial revolution marks a significant milestone. However, as we find ourselves on the cusp of the fifth industrial revolution, it’s evident that many businesses have yet to fully unlock the potential inherent in this transformative era. One area where this potential is particularly pronounced is in the realm of smart factories.

Deciphering the essence of smart factories

So, what exactly constitutes a smart factory? At its core, a smart factory leverages cutting-edge technologies such as artificial intelligence, Internet of Things (IoT), and advanced robotics to create a highly connected and automated manufacturing environment. This interconnectedness allows for real-time data exchange and analysis, facilitating smarter decision-making and enhancing overall operational efficiency.

Enhancing productivity through connectivity

One of the primary benefits of adopting a smart factory approach is the tangible improvements it brings to productivity. By streamlining processes, minimizing downtime, and optimizing resource allocation, smart factories can significantly boost output without compromising quality. This newfound efficiency not only translates to cost savings but also enables businesses to respond more effectively to dynamic market demands.

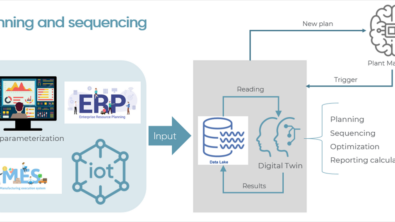

The crucial role of Plant Simulation

However, achieving the full potential of a smart factory requires more than just implementing state-of-the-art technology. It also necessitates careful planning and strategic utilization of tools like Plant Simulation. Plant Simulation software enables businesses to create the digital twin of production for their manufacturing processes, allowing for comprehensive modeling, analysis, visualization and optimization. By simulating various scenarios and identifying potential bottlenecks or inefficiencies, Plant Simulation empowers businesses to optimize their operations and maximize output.

Smart Factory: Driving operational excellence

In essence, Plant Simulation serves as a vital cog in the machinery of a smart factory, enabling companies to fine-tune their processes and adapt to ever-changing market conditions. Its role in driving operational excellence cannot be overstated, as it provides the analytical backbone necessary for informed decision-making and continuous improvement.

Adrián García, a senior virtual factory consultant born in Barcelona, brings a wealth of experience to the table, with 10 years dedicated to discrete event simulation, predominantly using Plant Simulation in the automotive sector. Leading the virtual factory department at Alhona, he orchestrates simulation projects across diverse industries, applying his expertise to optimize processes and drive operational excellence.

Smart factories are undoubtedly the future of the industry. The integration of Digital Twins stands as a cornerstone in maximizing their potential, elevating operational capacities to unprecedented heights. Through the strategic fusion of Digital Twins and Genetic Algorithms, we unlock the pathway to operational excellence, paving the way for transformative advancements in manufacturing.”

Adrián García, Senior Virtual Factory Consultant at Alhona

Embracing the future

As we stand on the precipice of the fifth industrial revolution, the importance of embracing technologies like Plant Simulation becomes increasingly apparent. By harnessing the full potential of smart factories, businesses can not only thrive in today’s competitive landscape but also lay the foundation for a more resilient and agile future. It’s a journey that requires vision, innovation, and a willingness to embrace change, but the rewards are well worth the investment.

Unlocking operational excellence: Exploring Plant Simulation integration at the 2024 user conference in Munich

On June 6th 2024 at the 2024

Plant Simulation User Conference, taking place at the Infinity

hotel in Munich, Germany, we will delve deeper into this topic. This event,

taking place right after Realize LIVE

Europe, is an ideal opportunity for attendees to learn from industry

experts, network with peers and explore the latest advancements in Plant

Simulation software. They will experience presentations like what’s new in

Plant Simulation 2404 and engaging discussions that might transform their

approach to material flow simulation. Other lectures at the 2024

Plant Simulation User Conference are for example:

•https://blogs.sw.siemens.com/tecnomatix/bosch-user-friendly-modeling-plant/•https://blogs.sw.siemens.com/tecnomatix/decarbonization-strategies-plant/•https://blogs.sw.siemens.com/tecnomatix/wp-admin/post.php?post=9770&action=edit

•https://blogs.sw.siemens.com/tecnomatix/sustainability-bsh-co2-reduction/•https://blogs.sw.siemens.com/tecnomatix/layout-planning-battery-production/•https://blogs.sw.siemens.com/tecnomatix/8-axis-log-handler-simulation/•https://blogs.sw.siemens.com/tecnomatix/ai-and-digital-twin-real-time-guid/•https://blogs.sw.siemens.com/tecnomatix/electrolux-driving-efficiency/

•https://blogs.sw.siemens.com/tecnomatix/logistics-optimization-heat-maps/