Simcenter STAR-CCM+ 2410 released! What’s new?

Solve toughest aerospace problems. Leverage integrated simulation data management. Run simulations with GPUs on Windows or Linux. Plus many more.

The Simcenter STAR-CCM+ 2410 release brings major enhancements to accelerate and improve your simulation workflows. It introduces powerful tools for modeling complex physics, such as the new Sub-grid Particle Aging model for accurate battery degradation prediction and advanced SPH surface tension modeling for rapid, accurate lubrication simulations. The release boosts productivity with multi-body instancing, providing faster geometry setup, and speeds up Volume of Fluid (VOF) simulations with a new Dynamic Implicit Multi-Step feature. For automotive aerodynamics and fluid further applications, GPU-accelerated sliding mesh and SPH solvers deliver significant performance gains, now with Windows support for GPUs, making high-speed simulations accessible across platforms. Integration enhancements like Teamcenter Active Workspace support and automatic material assignment streamline workflows, ensuring consistency across simulation projects. With these updates, Simcenter STAR-CCM+ 2410 empowers you to model complexity, explore engineering possibilities, and innovate faster than ever before.

Learn how to use Support Center

New enhancements in Simcenter STAR-CCM+ are aimed at helping you:

Model the complexity

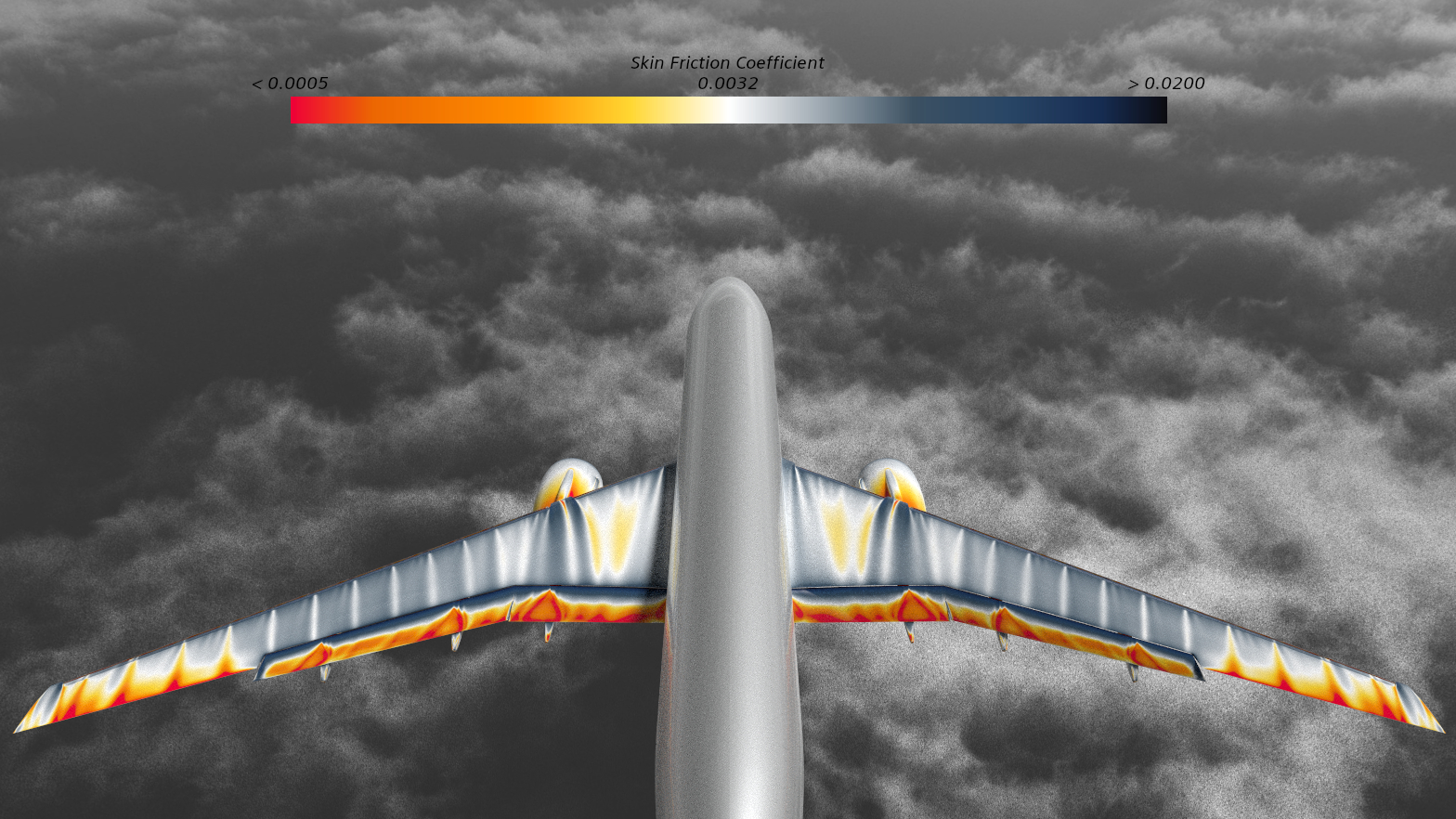

Improved fidelity for Battery Cell Degradation Prediction

Battery degradation due to mechanical stresses is a significant challenge, as it can lead to reduced capacity and increased internal resistance over time. In Simcenter STAR-CCM+ 2410, the introduction of two Sub-grid Particle Aging models addresses this issue by simulating local degradation effects, including cracking during lithium cycling. You can now use the “Loss of Active Material” and “Surface Crack Growth” options to understand the specific impacts of mechanical stress on cell performance. This enables you to identify the regions most affected by aging, improving predictions of battery life and reliability. Ultimately, this allows for a more accurate prediction of cell capacity and impedance evolution.

Higher fidelity for Powertrain Lubrication simulations

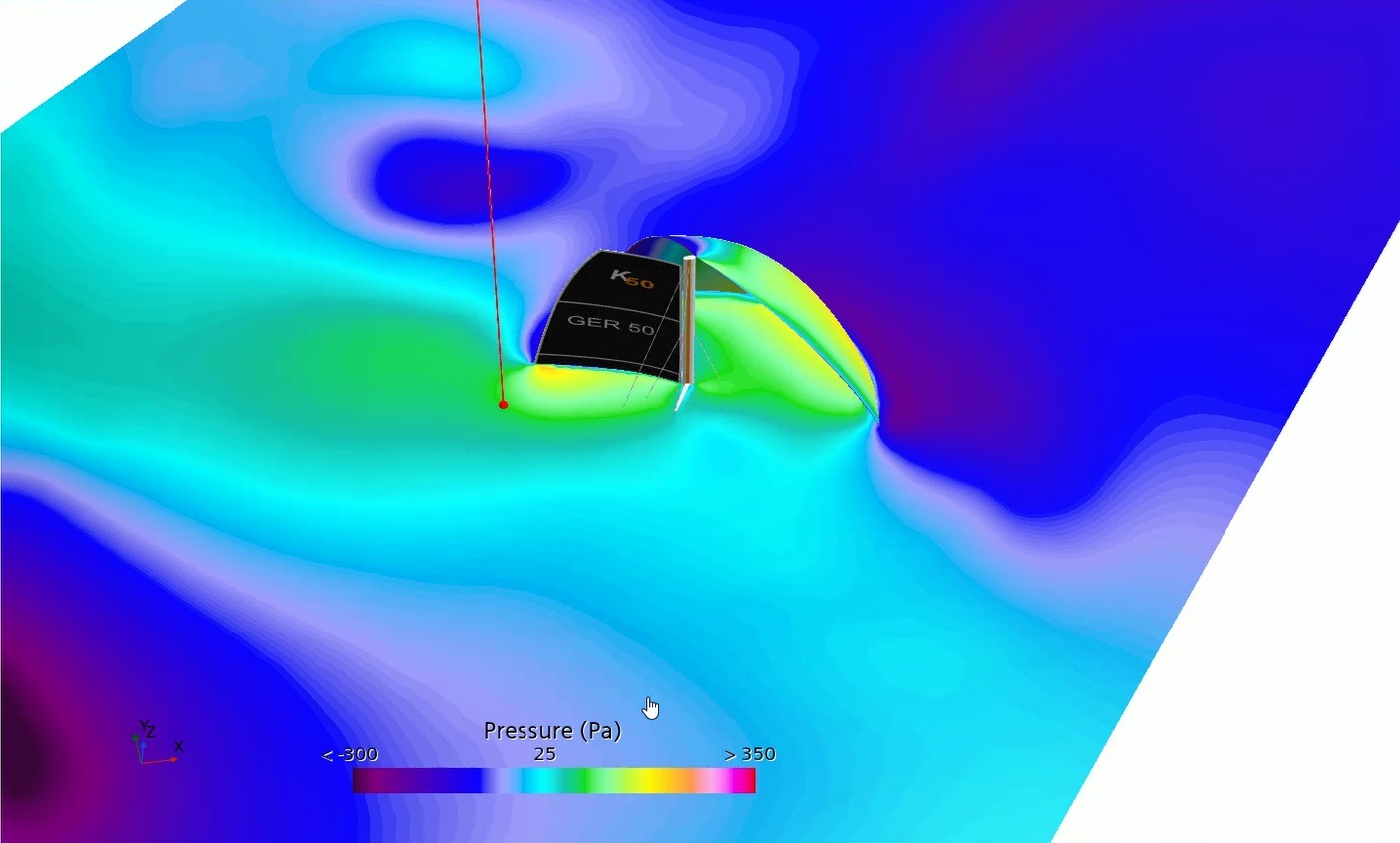

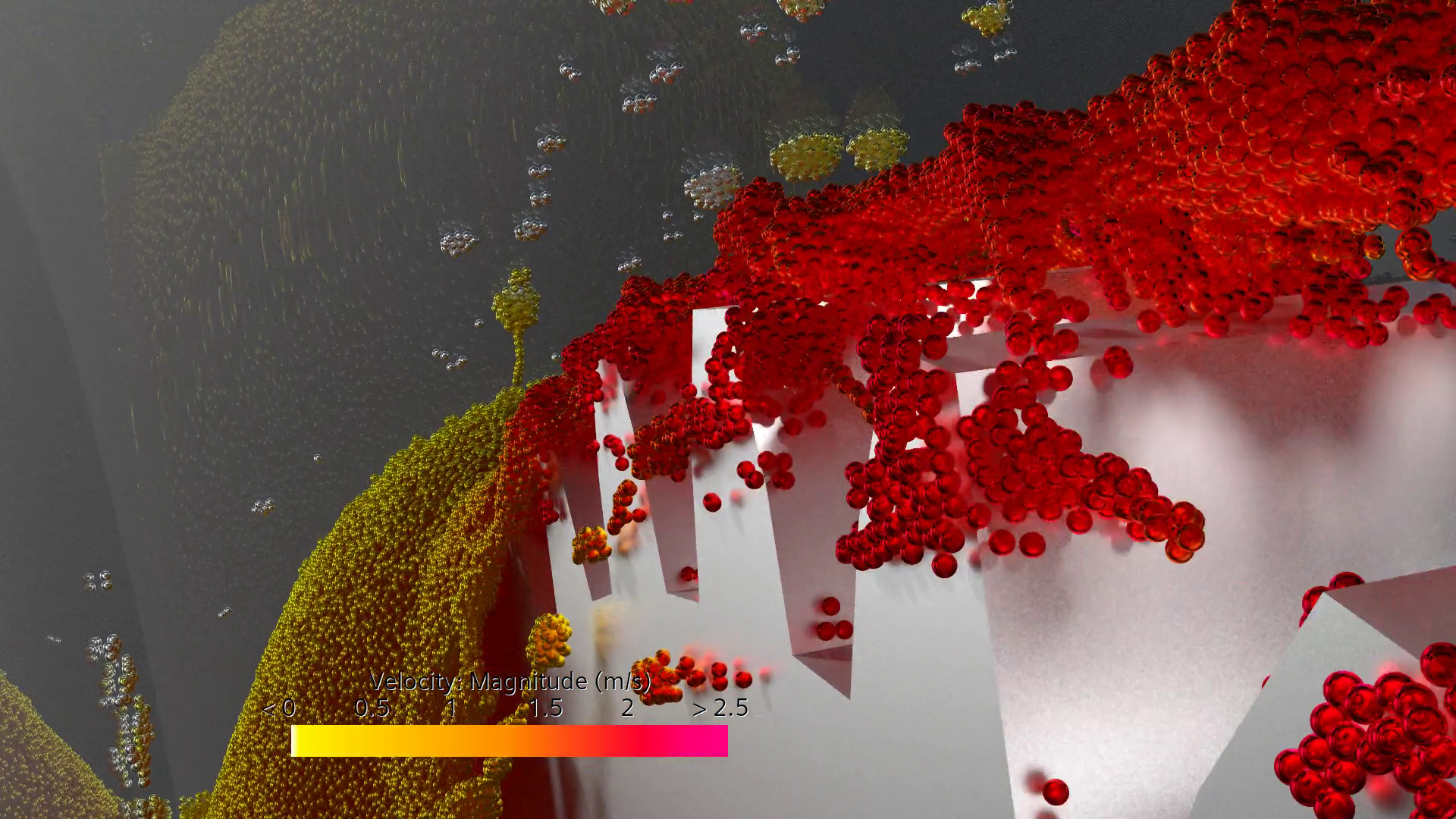

Modeling the interaction of liquids with solids presents a key challenge in powertrain lubrication applications. The latest release of Simcenter STAR-CCM+ 2410 addresses this by introducing a surface tension model for Smoothed-Particle Hydrodynamics (SPH), allowing for accurate yet rapid simulation of hydrophilic and hydrophobic fluid-solid interactions. You can now apply the same surface tension workflows used in finite volume methods, enhancing the accuracy of simulations in lubrication scenarios and other applications. This upgrade ensures more precise modeling of liquid-wall interactions, leading to better product performance prediction through higher fidelity in powertrain lubrication simulations with SPH.

Leaner modeling of complex CHT problems with Motion

Setting up complex Conjugate Heat Transfer (CHT) problems with moving meshes often requires manual mapping of data, which can be time-consuming and error-prone. With Simcenter STAR-CCM+ 2410, explicit mapped contact interfaces are now compatible with motion, eliminating the need for manual data mappers and Java macros. You can set up advanced CHT simulations, such as turbine blade cooling or E-Machine thermal management, more efficiently with automatic mapping of heat transfer coefficients and reference temperatures. This enhancement allows for leaner and more straightforward modeling of complex CHT problems with motion, saving time and reducing setup complexity.

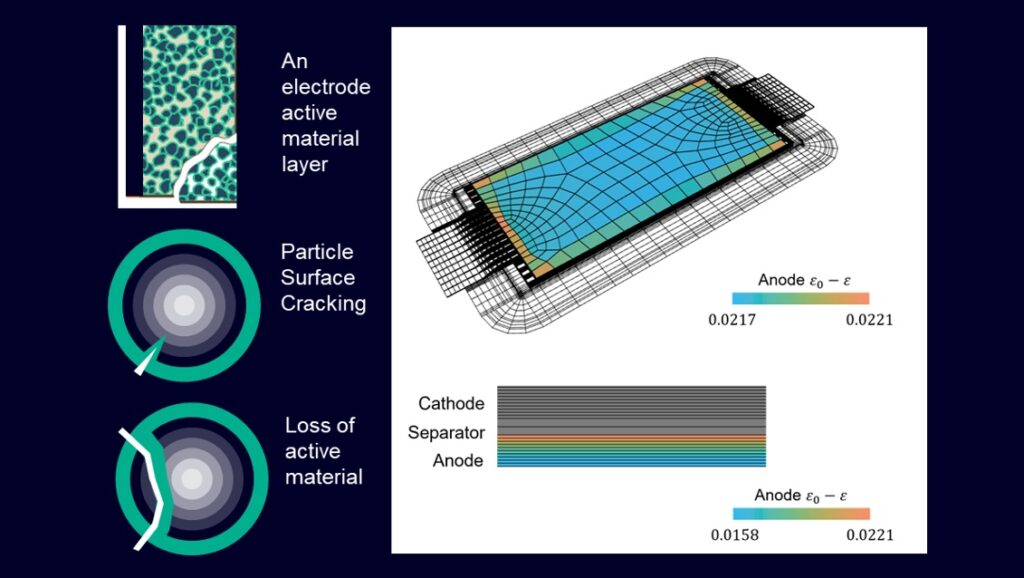

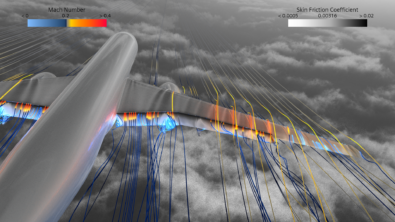

Maximum modeling flexibility for Turbulence Transition

Turbulence transition modeling is a research topic in continuous evolution, with numerous variations presented in the literature. Each model offers specific advantages for different industrial applications. Hence, to achieve optimal results for a given use case, customization is often required to enhance prediction accuracy. Simcenter STAR-CCM+ 2410 introduces user-defined source terms for Gamma and Gamma-ReTheta models, providing you with the flexibility to adjust transition behavior for specific industrial applications. This approach enables you to fine-tune simulations for scenarios like turbine blade flows, ensuring more accurate thermal and fluid dynamics predictions. The added flexibility allows you to achieve maximum modeling customization to match your specific needs.

Accurate and realistic Colliding Spray shapes for any mesh

Accurate spray modeling can be limited by the influence of mesh size and grid topology on collision outcomes, sometimes leading to unrealistic spray shapes. Simcenter STAR-CCM+ 2410 addresses this with a new superior collision detection method that uses cell clusters to identify collision pairs and eliminate mesh-related artifacts. By dynamically re-clustering cells, this solution reduces unrealistic spray patterns caused by mesh dependencies, such as “clover-leaf” artifacts. As a result, you can achieve more reliable predictions of droplet sizes and spray shapes, ensuring accurate and realistic spray shapes even for trimmed meshes.

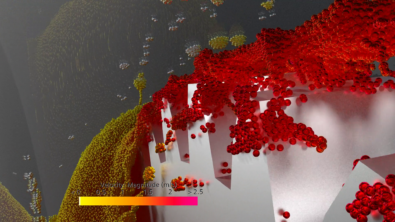

Increased realism for Pharmaceutical and Chemical processing applications

Simulating wetting phenomena in pharmaceutical and chemical applications can be challenging due to the need for an accurate representation of liquid-solid interactions. In Simcenter STAR-CCM+ 2410, a new absorption model for Lagrangian-DEM interactions enables you to model mass transfer from liquid droplets to solid particles. This feature allows for the realistic simulation of processes like tablet coating, where droplet deposition on the surface of solid particles must be resolved. By modeling wetting behavior accurately, you can achieve increased realism in simulations related to pharmaceutical and chemical processing.

Quickly and easily model multi-stage solid stress and fluid-structure interaction

In complex solid mechanics simulations, dealing with multiple stages of stress and deformation can be challenging, especially when different load conditions and boundary parameters need to be considered. In the latest release of Simcenter STAR-CCM+ 2410, you can now utilize staged physics and simulation operations to automate multi-stage solid stress and fluid-structure interaction (FSI) cases. This allows you to bundle specific sets of loads and boundary conditions into distinct stages, streamlining the setup process. As a result, you can efficiently model sequential applications such as the deformation of an O-Ring under various conditions, from being stretched onto a piston to achieving full sealing capacity when squeezed between components. By automating these simulation sequences, you save significant time and effort while maintaining the accuracy of complex physical behaviors.

Explore the possibilities

Gain deeper insights into your study results

Design exploration often generates large datasets that can be difficult to analyze effectively. With Simcenter STAR-CCM+ 2410, you can perform operations on columns within the Output Table, using expressions to calculate metrics such as averages, sums, or standard deviations. This spreadsheet-like functionality lets you derive reports from any combination of study metrics, giving you a deeper understanding of your results. By enabling the creation of user-defined reports, you can gain insights more quickly and make informed decisions on design optimizations, allowing you to gain deeper insights into study results.

Quick and dynamic Qualitative Field Analysis

Volumetric CFD data analysis can be complicated by obscuring surfaces that hide important result details. Simcenter STAR-CCM+ 2410 introduces dynamic slicing and clipping for resampled volumes, allowing you to visualize the complete dataset while hiding unnecessary elements. This feature makes it easier to identify areas of interest and understand flow behavior. The ability to slice through the data dynamically enhances your exploration capabilities and supports a deeper understanding of complex phenomena, facilitating quick and dynamic qualitative field analysis.

Go faster

Faster interactive CAD handling with user-defined hotkeys

Navigating through the 3D-CAD interface for geometry preprocessing tasks can be time-consuming, impacting productivity. With the new release of Simcenter STAR-CCM+ 2410, you now have the ability to define custom hotkeys for any 3D-CAD action, providing faster access to frequently used operations. This update not only enhances your workflow but also supports collaboration by allowing the export and import of defined hotkey sets among users. The hotkey table also includes filtering and clash detection features, ensuring seamless navigation and optimal use of your shortcuts. This improved usability in 3D-CAD translates to faster simulation setup, enabling you to explore more design iterations in less time.

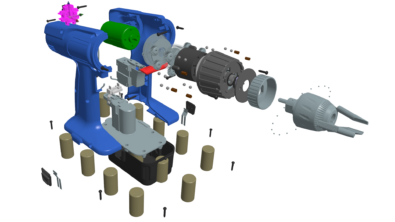

Increased productivity and reduced memory footprint

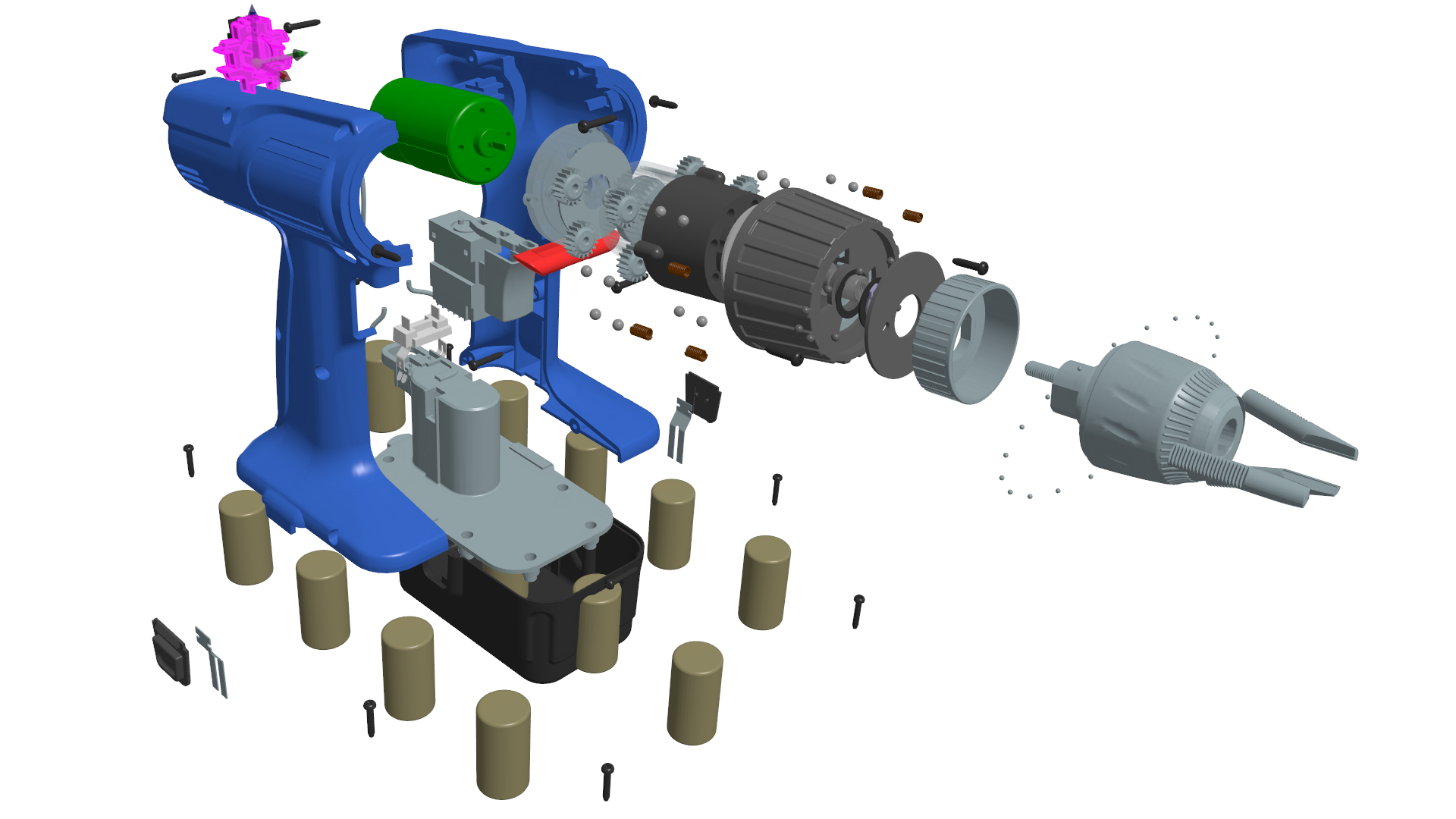

Managing complex CAD assemblies is time-consuming, particularly when explicitly dealing with multiple instances of the same part. Simcenter STAR-CCM+ 2410 addresses this by introducing multi-body instancing, enabling you to create instances of bodies using pattern or rotation features. Allowing modifications on one instance to be propagated across all instances with ease, this approach reduces geometry preparation time and memory usage. As a result, you can handle large assemblies more efficiently, increasing productivity and reducing memory footprint.

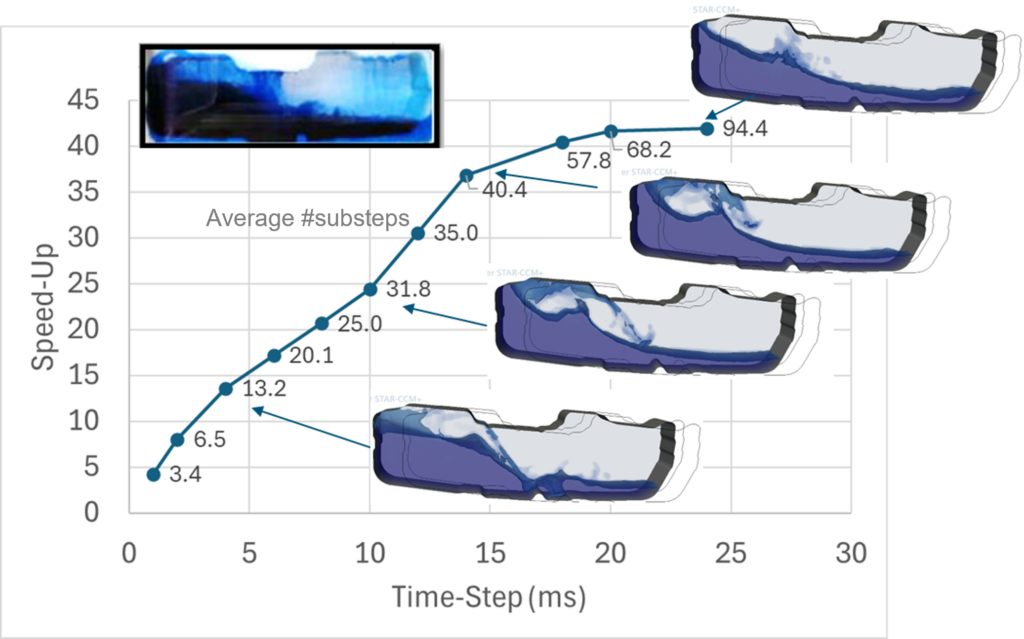

Accessible Order of Magnitude speed-up for VOF Simulations

Volume of Fluid (VOF) simulations often require long run times, limiting their usefulness for time-sensitive applications. The previously introduced Implicit Time Stepping approach, while offering speed-ups led to variable time steps, which many users try to avoid. With the new Dynamic Implicit Multi-Step feature in Simcenter STAR-CCM+ 2410, you can now achieve speed-ups of almost two orders of magnitude by using large and constant timesteps without sacrificing accuracy. This improvement is made possible by dynamic sub-stepping, which maintains stability during the simulation. The result is significantly faster simulations, allowing you to achieve accurate results more quickly and making accessible order of magnitude speed-up for VOF simulations.

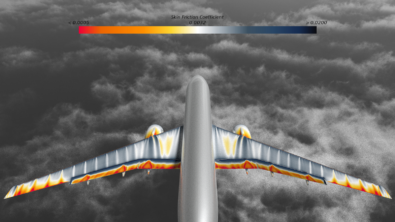

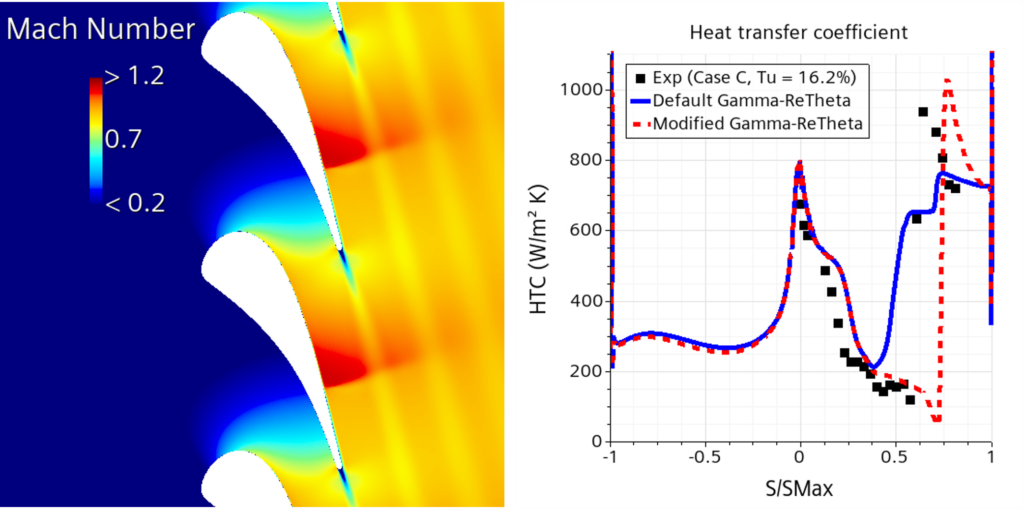

GPU-accelerated sliding mesh for automotive applications

To meet CO2 emissions standards while coping with a multitude of vehicle variants, faster simulation tools are needed for external vehicle aerodynamics. Simcenter STAR-CCM+ 2410 introduces GPU-accelerated sliding mesh simulations to cope with rotating wheels on GPUs, providing over 30% faster performance compared to CPU-based methods. This acceleration is crucial for validating CO2 emissions and aerodynamic performance in compliance testing. The improved speed enables you to complete more design iterations in less time.

Rapid SPH simulations on single GPUs

Smoothed-Particle Hydrodynamics (SPH) simulations in Simcenter STAR-CCM+ were limited to CPU-based calculations. In Simcenter STAR-CCM+ 2410, we introduce a GPU-native SPH solver which significantly reduces simulation compared to CPU solutions. This allows you to run complex SPH simulations, such as multiphase flow analysis, much faster while maintaining accuracy. The seamless transition and a shared code base between CPU and GPU ensure consistent results, enabling rapid SPH simulations on single GPUs and enhancing your productivity in fluid dynamics simulations.

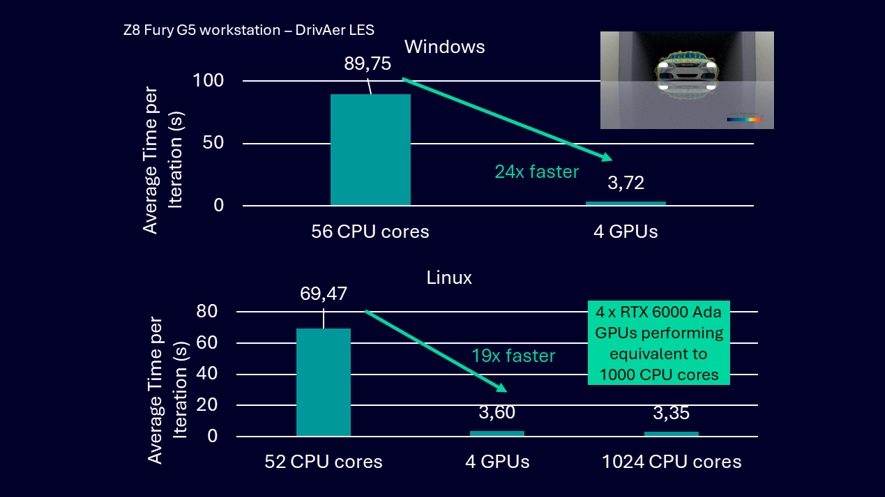

Achieve faster simulations with GPU acceleration on Windows

To date the use of GPUs for accelerated simulation runs with Simcenter STAR-CCM+ have been limited to Linux systems. With Simcenter STAR-CCM+ 2410, GPU-native physics solvers are now available on Windows, bringing significant performance improvements to your workflow. You can now leverage GPU acceleration on your Windows workstation, achieving reductions in simulation time by up to 24 times compared to CPU-only runs. This capability extends support to various physics scenarios while delivering consistent results across both Windows and Linux systems. The ability to unlock such speed enhancements on Windows greatly broadens accessibility, allowing you to solve large-scale problems on more commonly used platforms.

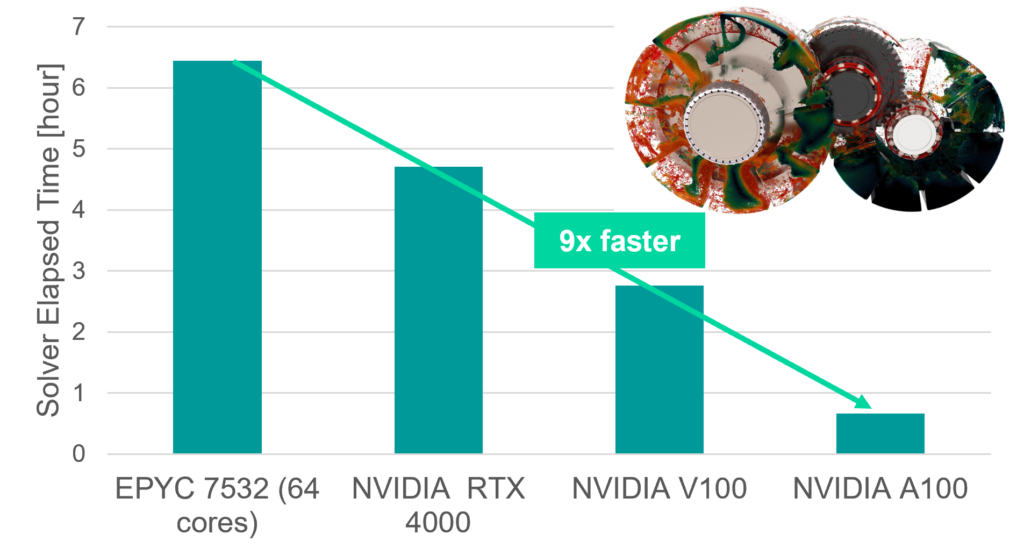

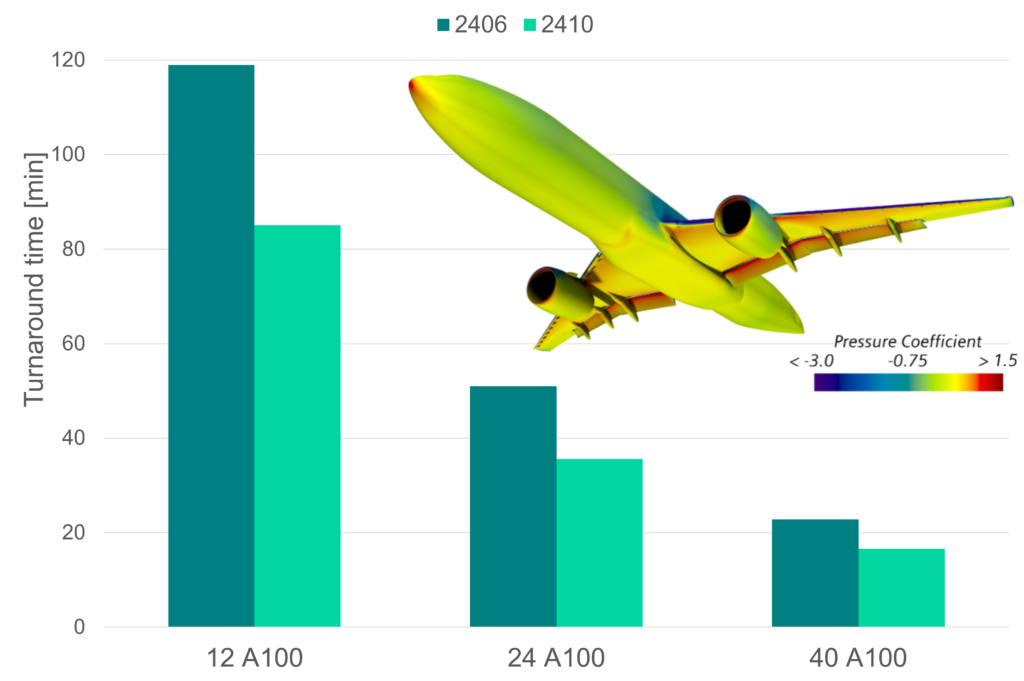

Benefit from faster-coupled flow and energy simulations with improved GPU linear solver

Even with the adoption of GPUs, the need for faster solver technologies remains critical for complex simulations. The new Simcenter STAR-CCM+ 2410 addresses this by incorporating algorithmic improvements in the GPU linear solver, significantly boosting the performance of coupled flow and energy simulations. You will experience the largest speedups in cases where most of the computational effort is focused on solving linear systems, such as turbomachinery aerodynamics and thermal management of automotive components. This update allows you to complete demanding simulations more efficiently, freeing up valuable resources for additional analyses or higher-fidelity studies.

Stay integrated

Increased confidence in simulations being Correct and Relevant

Adding new parts to complex simulations as a corrective retrofit can disrupt workflows if done in a non-orchestrated manual ad-hoc way. Simcenter STAR-CCM+ 2410 integrates Teamcenter Active Workspace directly, enabling you to add parts and automatically update traceability information within the simulation environment. This integration ensures that you are always using the correct data, fostering collaboration across teams and improving data accuracy in large assemblies. As a result, you can achieve increased confidence in simulations being correct and relevant.

Seamless Material Properties assignment from CAD to CFD

Manually assigning material properties in large-scale simulations of complex assemblies is tedious and error-prone. The automatic material assignment feature in Simcenter STAR-CCM+ 2410 reads metadata from CAD models, matches it to user-defined material databases, and propagates the material assignments to the physics regions and boundaries set up, streamlining the setup process. This automation reduces errors and ensures consistent material properties across all components, enhancing the reliability of your simulations by allowing seamless material properties assignment from CAD to CFD.

These are just a few highlights in Simcenter STAR-CCM+ 2410. These features will enable you to design better products faster than ever, turning today’s engineering complexity into a competitive advantage.

Comments

Comments are closed.

Any adjoint-related updates for 2410? Thank you.