Simcenter STAR-CCM+ 2310 Released! What’s new?

Get 3D insights into Li-Ion battery cell performance. Export CFD study results for ROM creation. Automate sophisticated simulation workflows. Assess passenger thermal cabin comfort. Plus, many more features.

With the release of Simcenter STAR-CCM+ 2310, we provide engineers across industries with computational fluid dynamics (CFD) capabilities to go faster while modeling the complexity. Leverage exciting new features to explore engineering possibilities and turn complexity into a competitive advantage.

Learn how to use Support Center

New enhancements in Simcenter STAR-CCM+ are aimed at helping you:

Model the complexity

Get detailed 3D insights into battery cell performance quickly

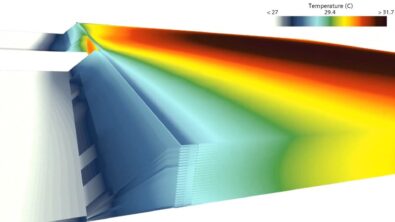

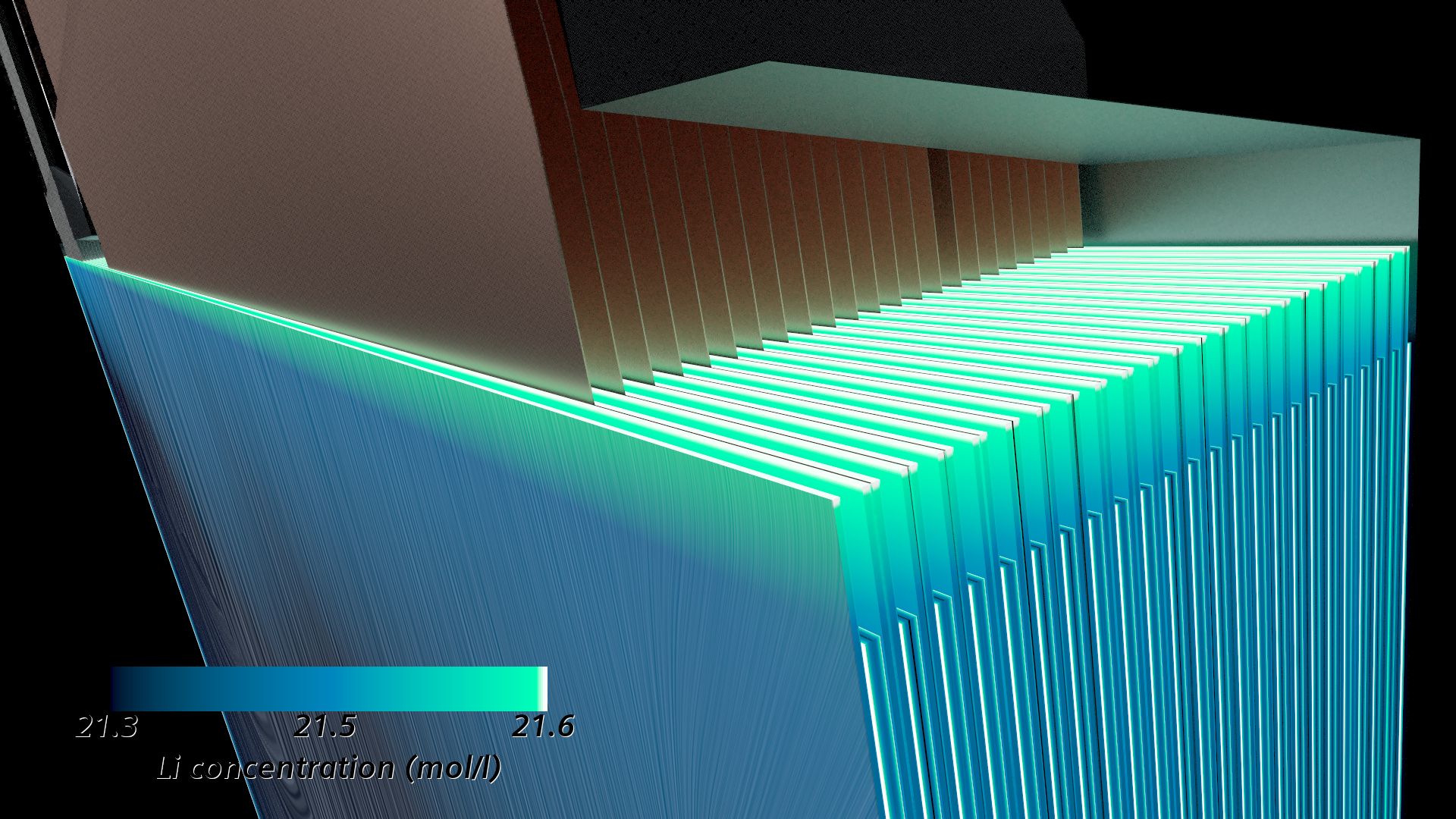

To virtually design reliable high-performance Lithium-ion cells, you need to consider three-dimensional anisotropic effects across battery cell layers. Currently available simulation approaches neglect such effects or make crucial compromising simplifications by reducing the problem to representative 2-dimensional battery layer descriptions.

With Simcenter STAR-CCM+ 2310, we are releasing a new unique 3D cell design capability to design lithium-ion battery cells with high geometric and physical fidelity. This new high-fidelity cell design template allows for the design of Lithium-ion cells in full 3D, with geometrically resolved electrode layers, separators, and tabs.

The templated simulation leverages easy-to-use dedicated custom trees and the new Stages feature for a customized and tailored workflow for cell designers, with industry-standard terminology and units. It provides you with a simplified mesh setup with a few inputs and clicks and supports dedicated industry-standard post-processing to facilitate the analysis from the simulation results. The capability is driven by simulation templates for industry standard cell shapes. With Simcenter STAR-CCM+ 2310 we release the stack cell template; cylindrical, and prismatic wound cell templates will be available soon. Along with this automated workflow, the 3D cell design capability provides highly accurate electrochemical models via an enhanced physics-based model of the initial Newman-Doyle-Fuller formulation.

The 3D cell design capability gives you detailed insights into cell performance quickly. Investigate in-plane and through-thickness ion concentration to understand local and edge effects, or predict the effect of tabs and surface cooling to design better battery cells faster.

The full capability requires the Batteries add-on license.

Set up thermal runaway gas venting simulations in minutes

Setting up thermal runaway simulation with gas venting for a battery pack with hundreds of cells is a time-consuming and error-prone process.

Therefore, in Simcenter STAR-CCM+ 2302, we started with consecutive releases of a dedicated workflow to accelerate the setup time of thermal runaway propagation simulation. With the release of version 2310, we are continuing this effort with integration of gas venting setup. With respect to pre-processing, the new capability allows for a very rapid setup with an easy selection of the cell’s venting surfaces. In addition, a dedicated field function manages the energy balance between the energy released from the venting and the one generated by the cell’s internal parts, removing the need for complex field functions and monitors. Trigger and gas release conditions are now also simplified to a few inputs. Ultimately, the workflow only requires one set of input parameters to deploy it on all cells of the battery pack. Integrated automation handles the gas venting actuation upon reaching the trigger condition and post-processing is managed automatically with dedicated gas venting quantities in the “Battery Module Reports” tool.

Overall, with Simcenter STAR-CCM+ 2310, you will continue to benefit from fast setup and analysis of thermal runaway simulations, now even including gas venting with minimum effort. The workflow can only be accessed from within the Simcenter STAR-CCM+ Batteries add-on and therefore requires the associated add-on license.

Improve accuracy and speed of water management simulations

Many multiphase applications require accurate, yet efficient treatment of droplets sliding across surfaces. Typical use cases include tracing rain droplets sliding on the surfaces of moving vehicles, including windshields, mirrors, and car sensor surfaces. While it is in principle possible to use the high-fidelity Volume of Fluid (VOF) method, it is very expensive, and for a large number of sliding droplets, the VOF simulation is computationally prohibitive. To predict the dynamics of these droplets on surfaces, a Lagrangian approach is very efficient, but it is of fundamental importance to take surface tension effects into account with high accuracy.

With Simcenter STAR-CCM+ 2310 we therefore introduce a new type of Lagrangian phase, so-called wall-bound droplets, and a new particle shape model called Spherical Cap Particles. The latter provides a more accurate prediction of particle drag and heat transfer. Wall-bound droplets can also be absorbed into fluid film to precisely model the formation of filaments. A new Adhesion Force model allows for capturing the typical stick and slip motion for wall-bound droplets by using the Contact Angle Hysteresis concept. This is of particular importance in applications like wipers.

The whole new modeling framework, with its first sub-models, enables you to run simulations with accurate and fast tracking of sliding droplets and rivulets. This results in improved accuracy and speed of water management simulations.

Explore the possibilities

Create Reduced Order Models from CFD design exploration studies in a few clicks

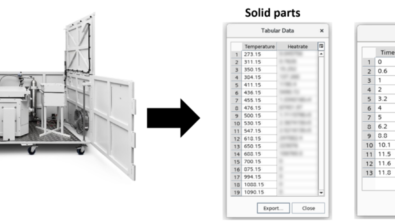

Reduced Order Models pose huge opportunities to rapidly explore design space and create fast-running models for real-time feedback. However, for valid conclusions such models need to be provided with sufficient, validated, and – not to be underestimated – well-organized data. Compiling such training and validation data sets from CFD results for Reduced Order Model (ROM) creation can be a tedious and error-prone process if the interface for data transfer is not handled appropriately.

With the release of Simcenter STAR-CCM+ 2310 and the just-released Simcenter Reduced Order Modeling software, we enable the most seamless approach to go from scalar field screenshots of your steady-state CFD results straight to a static ROM. You can now export data from Designer Manager studies in one click, ready to be used as a training and validation dataset in Simcenter Reduced Order Modeling. The current capability supports snapshots from scalar scenes with a fixed color scale from any design study type. Upon export, Simcenter STAR-CCM+ creates a comprehensive package including all pictures from your snapshots. Simcenter Reduced Order Modeling will then generate the ROM prediction using Proper Orthogonal Decomposition (POD) and report a ROM fidelity index. While the data export feature can generally be used for any type of parameter, the POD method works best for moderate parameter variance, when rotation effects are negligible and geometry movement is sufficiently small.

Overall, the new ROM data export allows for rapid ROM building from CFD simulation studies. You can now create fast-running models from CFD simulations with confidence and benefit from improved collaboration between CFD analysts and system designers thanks to immediate scenario variant views through ROMs. Included in Design Manager, the CFD data export does not require a license. For subsequent ROM generation, a Simcenter Reduced Order Modeling license is required.

Explore and share engineering results from your browser

Introduced in early 2022, the Simcenter STAR-CCM+ Web Viewer allows you to easily explore and share your engineering results directly from your browser. This powerful tool offers quick and interactive data analysis capabilities, free of charge, and from almost any device, with no installation effort, ultimately enhancing your CFD results communication. However, when working with a Scene file in the Simcenter STAR-CCM+ Web Viewer, you need to be able to work as autonomously as possible, without the necessity to go back to Simcenter STAR-CCM+.

Therefore, in the 2310 release, we are taking a great leap in this direction with the Simulation Structure feature. By providing the ability to freely hide and show objects on multiple visualization layers, it is easy to understand how a Scene is set up and understand the setup of the originating simulation better.

Frequent users of Simcenter STAR-CCM+ will immediately identify the similarities to displayers and their hide-and-show concepts of the desktop client. Users who are foreign to Simcenter STAR-CCM+, on the other hand, get acquainted with the different visualization layers by easy-to-understand naming.

The degree of control over the visibility is very granular since it goes from high-level displayer control all the way down to individual part surfaces. This gives you unrestrained control over what should be shown and what should be hidden.

Go faster

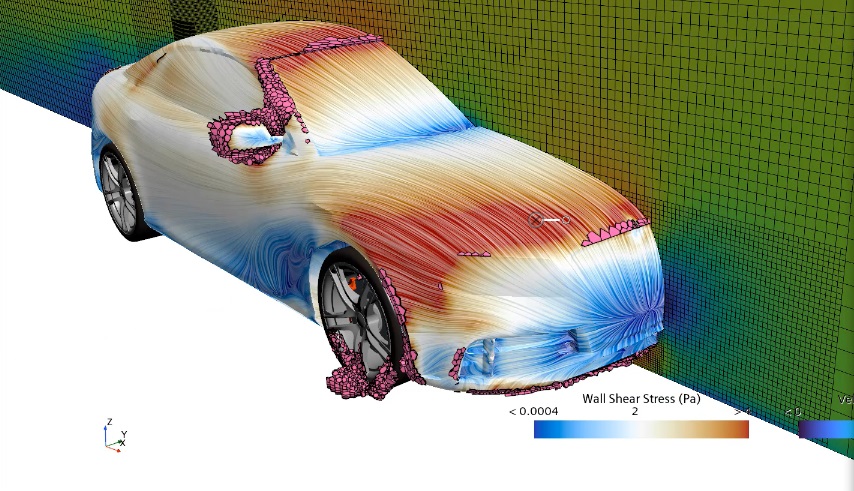

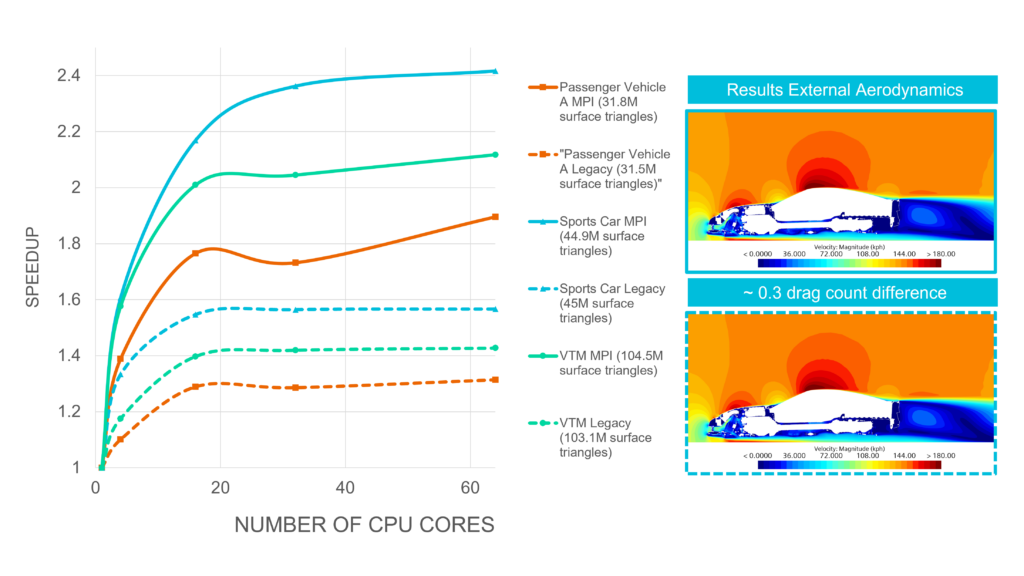

Prepare large complex geometries faster with the Parallel Surface Wrapper

Time to mesh is a critical factor for fast overall CFD simulation turnaround time, especially for complex assemblies. The surface wrapper has proven to be a very powerful tool to automatically prepare watertight surfaces for subsequent surface remeshing and volume meshing. To date, surface wrapper employed shared memory parallelism.

In Simcenter STAR-CCM+ 2310, we are introducing the first phase of distributed memory (MPI) parallelized surface wrapper. In this first version, the surface wrapper pipeline up to gap closure has been parallelized.

Overall, the speedup of the new algorithm is up to 2.4x (total wall clock time – for MPI wrapper vs serial 1 core). Compared to legacy surface wrapper, there is roughly up to 43% reduction in wrapping time for a number of industrial cases. While the new MPI surface wrapper produces consistent results across different core counts, it locally offers an improved placement of gap closure faces for better mesh quality and generally can adhere better to the user input e.g., gap closure size.

Quickly automate sophisticated simulation workflows with Stages and the Automation node

To model the complexity of today‘s products and simulate those under real-world conditions, you need to implement sophisticated multiphysics CFD simulation workflows. Traditionally this task requires the usage of scripts or the cumbersome and error-prone data transfer from one simulation model to the other.

Simcenter STAR-CCM+ has been designed around a streamlined CAD-to-results pipeline providing fully integrated native automation capabilities. Building on this foundation, Simcenter STAR-CCM+ 2310 further extends the simulation automation intelligence with Stages. Stages enable you to handle multiple physics configurations in a single simulation, reducing the need for scripts. With a single click, you can stage different physics models, conditions – like interface or boundary conditions, and other settings. A staged object can have different settings for each stage. Objects that are not staged will keep the same values in all stages.

Applications immediately benefiting from Stages are the vehicle thermal soak, the just-released battery cell design template, and many more. Combined with Simulation Operations, this opens the rapid, consistent management of complicated simulation sequences. You can now manage complete stages of simulation setups and orchestrate their execution without manual intervention or Java macros, and share these workflows with your colleagues within one single simulation file.

To further boost your productivity, we are introducing a new node in the simulation tree: the Automation node. You will now benefit from one place in the simulation tree containing all automation aspects of the simulation workflow. This enables you to generate automated workflows faster and increases the discoverability of already-defined simulation workflows with better node organization and less scrolling.

Together Stages and the automation node, take the concept of an intelligent simulation file enabling end-to-end automation from CAD to results to the next level. Enabling you to explore more designs and handle complex multi-physics problems faster.

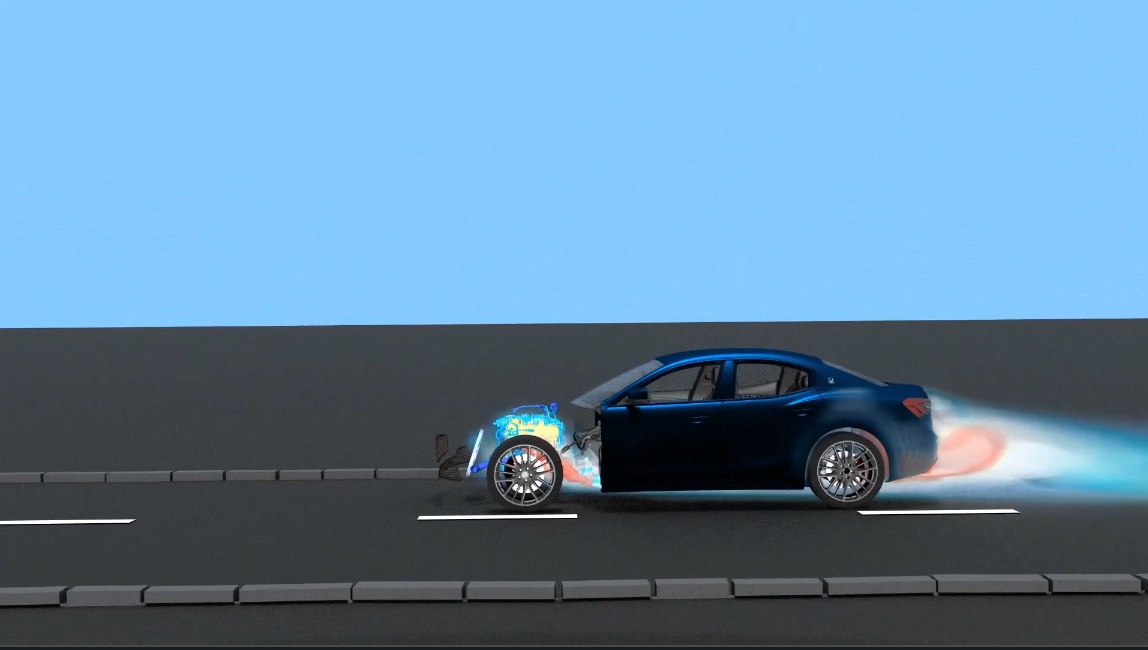

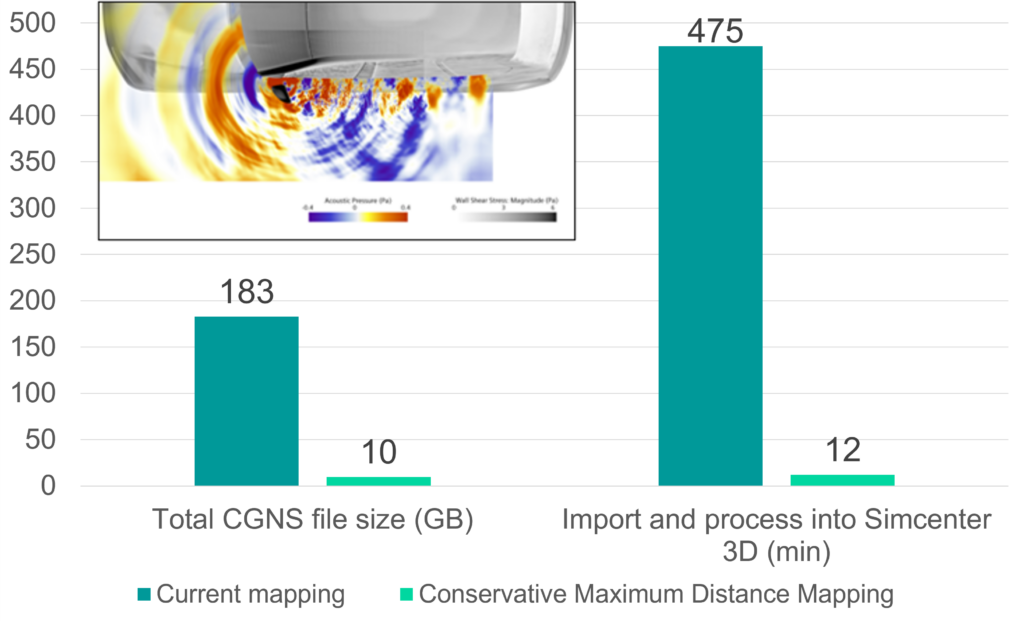

More efficient aero-vibroacoustic simulation workflow

Reduction of the CGNS file size and import time into Simcenter 3D through the new mapping method for the loosely coupled aero-vibroacoustics workflow. Example: Side-mirror induced noise assessment

Vibro-acoustic simulations are typically undertaken in two steps: Following a CFD simulation in Simcenter STAR-CCM+, Simcenter 3D is used for the vibration and acoustic field analysis. The legacy workflow consisted of exporting a very large CGNS file with the CFD mesh and force information, importing that file into Simcenter 3D and mapping the results onto a coarse acoustic mesh.

With Simcenter STAR-CCM+ 2310, we offer a new option to map a fine CFD mesh to a coarser acoustic mesh directly in Simcenter STAR-CCM+ prior to data export. This Conservative Maximum Distance Mapping ensures consistent results to the legacy process by using the same mapping algorithm as in Simcenter 3D but significantly reduces the size of the resulting CGNS file. Depending on the case, the new CGNS file can be between 35% and 90% smaller with this new method, and the added mapping step has virtually no impact on the overall Simcenter STAR-CCM+ simulation time.

Whenever you are looking to couple a fluid solution in Simcenter STAR-CCM+ to a structural analysis in Simcenter 3D, you will benefit from a significantly slicker process and data transfer.

Accelerate EMP multiphase simulations with minimal loss of accuracy

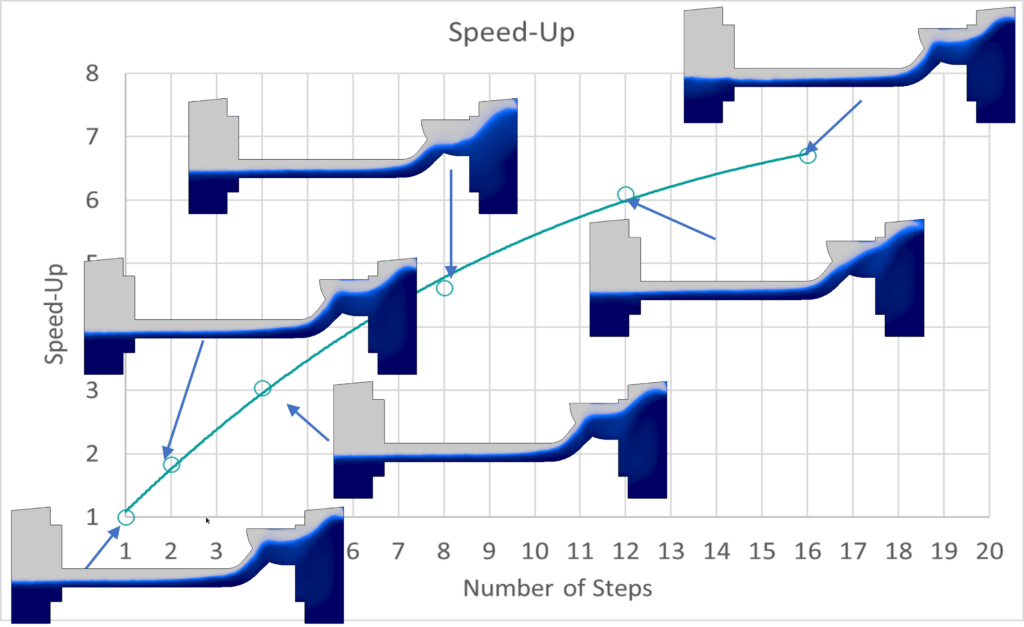

Speed-up of multiphase EMP-LSI simulations through implicit multi-step. Application from the nuclear industry where cooling water is introduced leading to a counter current of displaced gas. Speed-up is shown with an increasing number of sub-steps together with the flowfield at the end of the simulation. Source: Gas-Liquid Counter-Current flow in PWR [Deendarlianto et al., NED, 39 (2012)]

Multiphase simulations are often either computationally expensive or not sufficiently accurate. While smart hybrid multi-phase solutions offer the ability to apply the most effective approach in each state of the multiphase, the respective sub-models all need to be made as performant as possible for maximum throughput.

For this reason, in Simcenter STAR-CCM+ 2310, we have added implicit multi-step for Eulerian Multiphase (EMP) targeting Large Scale Interface (LSI) simulations mirroring equivalent capability previously added for VOF and MMP. This leads to more efficient EMP-LSI simulations by either reducing simulation time for a given level of accuracy; or increasing accuracy for a given runtime (budget).

Significant reductions in runtime can be achieved by carrying out N sub-steps within the flow timestep and then increasing the flow timestep by a factor N. This maintains the sub-step timescale associated with volume fraction transport at the same level (CFL number), but as the computational cost of a sub-step is a small fraction of the cost of a full flow timestep, there is a significant cost saving. Alternatively, this feature can be used to improve accuracy at little additional computational cost by adding sub-steps for a given flow timestep size.

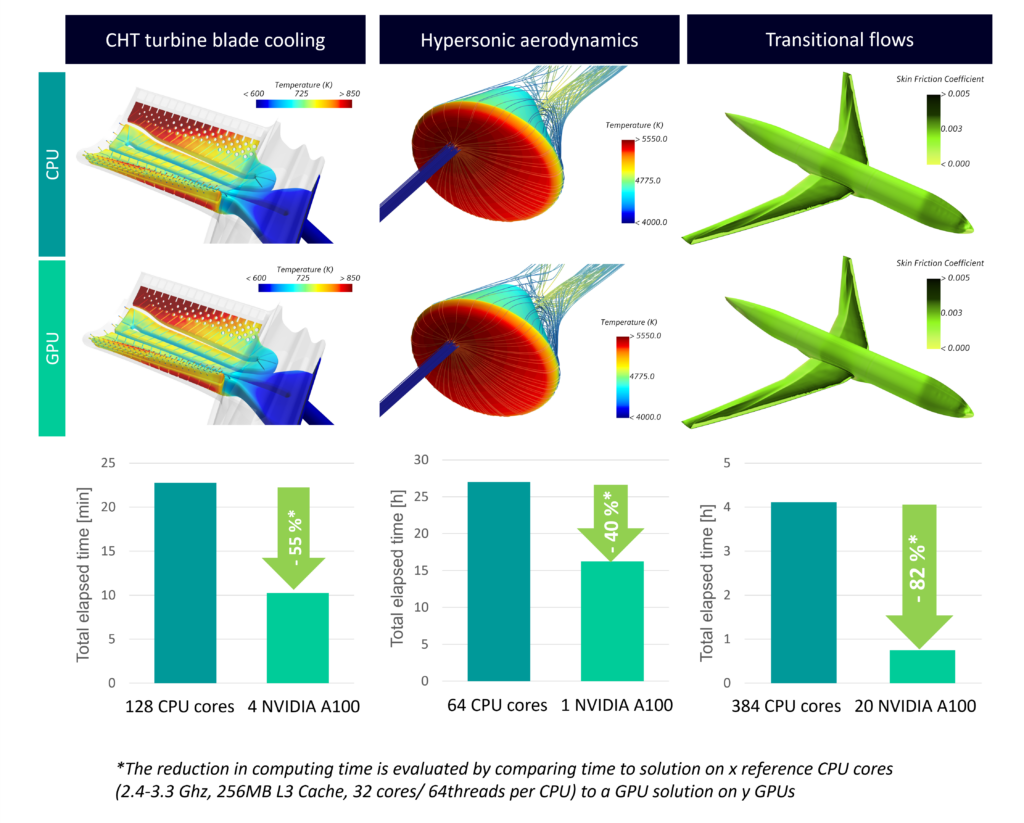

Simulate more applications on GPUs

The benefits of GPU-enabled acceleration of CFD simulations are without any doubt; significantly lower simulation cost on the cloud, massively reduced energy consumption, and the replacement of hundreds of CPU cores with a GPU node. Over several release cycles, the excellent performance of Simcenter STAR-CCM+ on GPUs has been shown. It is of fundamental importance to expand the ability to leverage GPUs to more models, and hence more applications.

With Simcenter STAR-CCM+ 2310, we therefore continue the porting of solvers and capabilities to become equally available for GPU- and CPU-native simulations. With this release, you are able to leverage a GPU native coupled solid energy solver, a GPU implementation of Equilibrium Air equation of state, and of the Gamma-ReTheta transition model.

This means for example more efficient conjugate heat transfer, e.g. turbine blade cooling simulations, faster supersonic and hypersonic aerospace aerodynamics, and laminar-turbulent transition flows. Continuing our philosophy of one unified code base for CPUs and GPUs you can rest assured that GPUs will deliver CPU-equivalent flow solutions.

Stay integrated

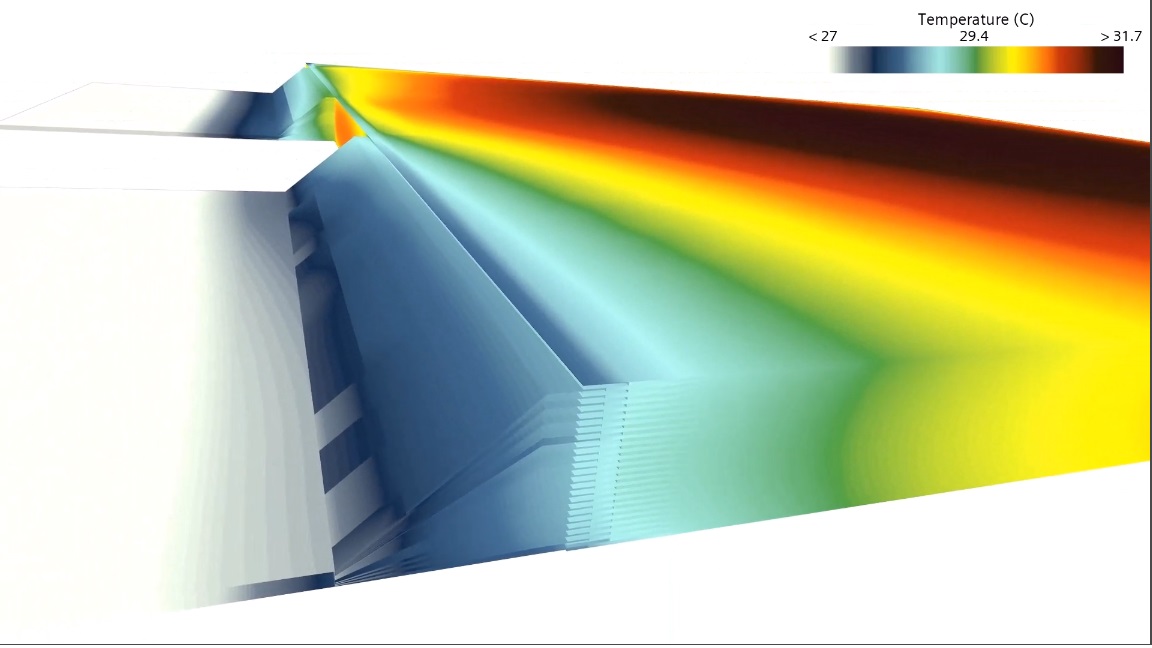

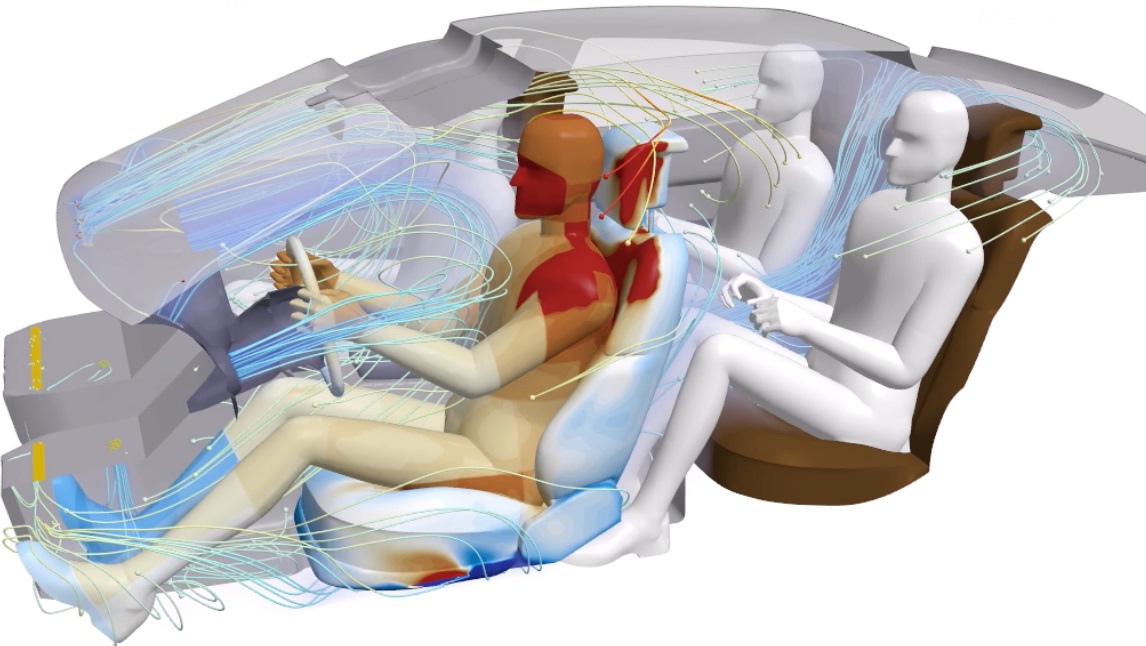

Optimize cabin design via fully integrated industry-standard passenger comfort assessment

Thermal comfort of passengers is a huge end customer satisfactory factor for any given vehicle. While internal combustion engine-powered vehicles made it comparably easy on HVAC and system energy management engineers thanks to the vast amount of excess heat, electric vehicles require a way more diligent treatment of energy and heat in the trade-off of comfort, safety, and range.

With Simcenter STAR-CCM+ 2310, you can now optimize vehicle cabin design and HVAC systems via a fully integrated set of industry-standard passenger thermal comfort assessment models. A new state-of-the-art thermoregulation model is now available to calculate the thermal response of the human body as a function of the conditions in the cabin (radiation, convection). The model also accounts for physiological factors, such as metabolism’s activity level, and use them to accurately compute the skin temperatures throughout the body. Said temperatures are then used to calculate the Dynamic Thermal Sensation (DTS) and the Predicted Percentage Dissatisfied (PPD) global comfort indexes as well as the Equivalent Homogeneous Temperature (EHT) local comfort indexes. These are widely recognized industry standard metrics that are crucial to assess passengers’ comfort perception overall via DTS and PPD as well as locally for each main body part via the EHT. All the mentioned new models are fully integrated with the latest automation capabilities of Simcenter STAR-CCM+.

This allows you to build leaner and more efficient end-to-end workflows for cabin design studies.

Access practically unlimited compute resources from within your simulation environment

Running CFD simulations on the cloud offers increased flexibility and scalability over on-premise hardware, with on-demand access and unlimited capacity. However, setting up and accessing the cloud using 3rd party providers often requires significant time and expertise in cloud and HPC technologies and interrupts existing workflows.

Directly from within Simcenter STAR-CCM+, Simcenter Cloud HPC gives you instant access to optimized Amazon Web Services (AWS) infrastructure, configured and managed by Siemens, with no additional setup needed.

With the Simcenter STAR-CCM+ 2310 release, we are expanding Simcenter Cloud HPC availability from the Americas to Asia-Pacific, with the service expected to launch in Europe, the Middle East, and Africa soon.

For more information on how to access and try Simcenter Cloud HPC for free, please contact your Siemens sales representative or authorized reseller.

These are just a few highlights in Simcenter STAR-CCM+ 2310. Those features will enable you to design better products faster than ever, turning today’s engineering complexity into a competitive advantage.

What do our users think about Simcenter STAR-CCM+?

Simcenter STAR-CCM+ customers explain how they solve some of the most difficult problems that industries have to offer, using multiphysics CFD.

Learn about Simcenter STAR-CCM+ strengths on G2.