E-powertrain packaging validation: Tackling the “dynamic clearance” challenge with Smart Virtual Sensing

Packaging for dynamic clearance

Validating the packaging of electric vehicle powertrains is essential for space optimization, safety, performance, squeak and rattle. Yet, measuring the relative e-powertrain movement during real-world driving maneuvers is a major challenge. Traditional tools—like optical cameras and string pots—often fall short due to limited access (especially underneath the vehicle chassis) and dynamic measurement gaps. This blog discovers a breakthrough method that makes Electric Vehicle (EV) powertrain packaging validation both efficient and reliable.

In the world of Electric Vehicle design, the phrase “tight packaging” is an understatement. As motors migrate beneath the chassis to maximize cabin space, engineers face a high-stakes puzzle, that they call ‘Packaging Validation’. This is the baseline where engineers ensure the e-powertrain assembly doesn’t interfere with other components.

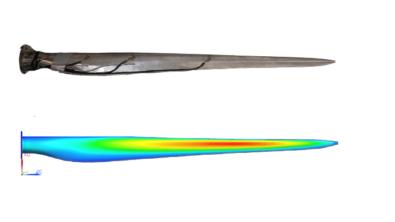

Verifying the fit of a powertrain in a static CAD model [static clearance] can be complex, but the complexity increases when you need to consider that the powertrain doesn’t sit still but moves and vibrates.

This dynamic behavior needs to be perfectly understood to ensure the correct fit with the required clearance. The complexity is raised to a much higher level when you need to consider what will be required of the vehicle, such as 0-60 mph sprints that induce massive torques in the powertrain, or rapid cornering maneuvers that make the powertrain move on its mounts. Ensuring the fit under these conditions is referred to as dynamic clearance. If the movement isn’t precisely validated, the motor could strike the chassis or worse, pinch high-voltage cables, leading to catastrophic failure.That’s why dynamic clearance analysis of e-powertrains is a critical step for all electric vehicles.

The challenge: When traditional methods can’t keep up

Validating these clearances during a physical road test has historically been a big challenge for test engineers. You need to install measurement hardware in the engine bay and subject the vehicle to a series of maneuvers, such as accelerating, braking, lane changes & steering variations, across a variety of different road surfaces (cobblestones, potholes, …). All the while ensuring that all dynamic powertrain movements are captured to precisely measure their relative movement with respect to the subframe and/or chassis.

For an Internal Combustion Engine (ICE) vehicle, optical cameras are state-of-the-art to validate engine-to-body design space clearance. The optical cameras are typically mounted on top of the engine bay. For an ICE vehicle, removing the hood allows to monitor the motor movement. This is not the case for EVs, as the motors are often mounted underneath the chassis, making it impossible to monitor powertrain movement using traditional optical cameras without significant vehicle modification. Typically, test engineers need to cut the vehicle’s body panels to install the camera, which, unfortunately, will irreversibly damage the vehicle – this is therefore not a great solution.

Alternatively, string pots can be used, as these sensors can be mounted underneath the vehicle chassis. However, string pots tend to struggle to capture the full spectrum of the highly dynamic powertrain movement, not allowing to fully validate the packaging design.

That’s why a breakthrough approach adapted to EV packaging validation is needed.

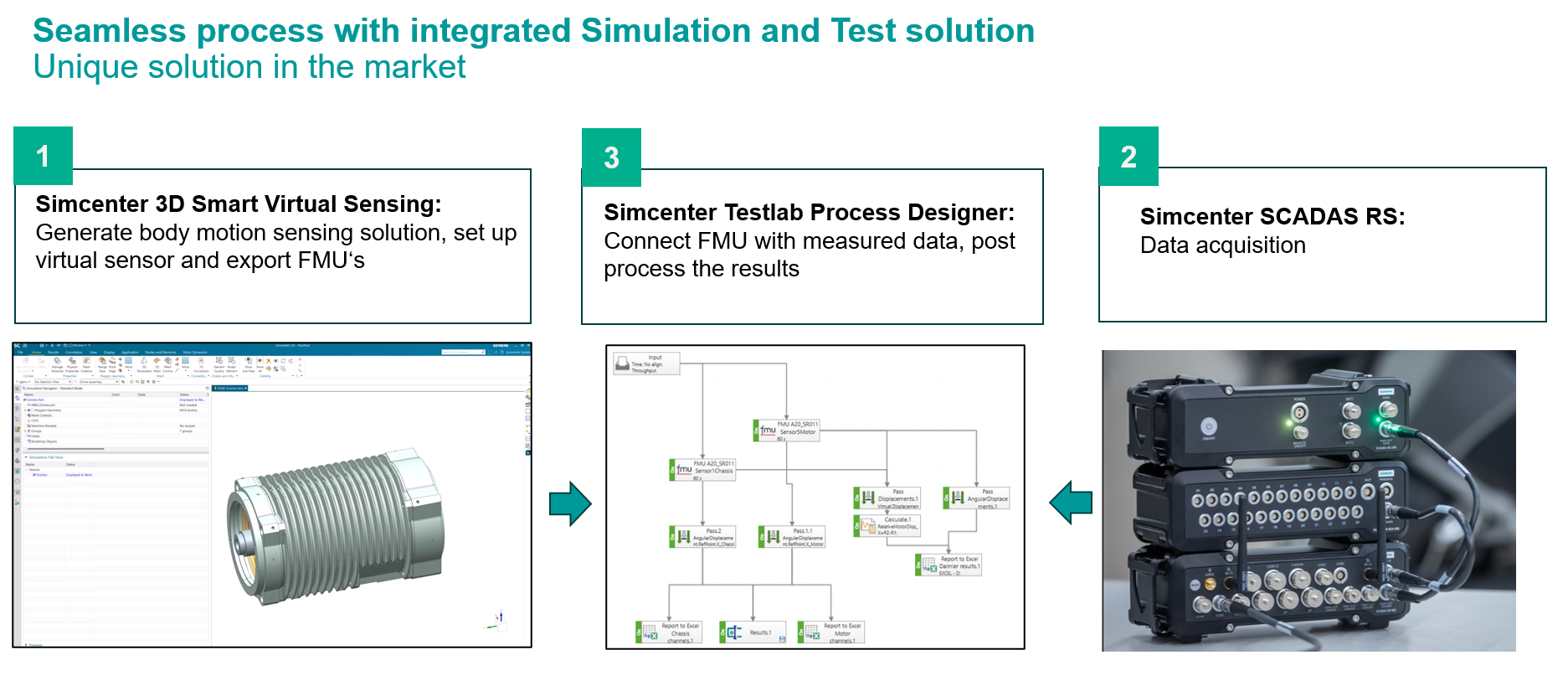

Siemens Simcenter 3D Smart Virtual Sensing combined with Simcenter Testlab Process Designer and Simcenter SCADAS: the integrated solution for High Precision

Siemens has developed a groundbreaking solution: Simcenter 3D Smart Virtual Sensing. This innovative technology offers a generic, robust, and non-intrusive method for precise engine/motor packaging validation. It’s designed to overcome the limitations of conventional approaches, providing highly accurate measurements (with an accuracy of 1mm) of relative body motion to enable robust movement envelope analysis for all possible driving maneuvers. Combined with high precision Simcenter SCADAS hardware and Simcenter Testlab Process Designer, it gears up to an unbeatable combination.

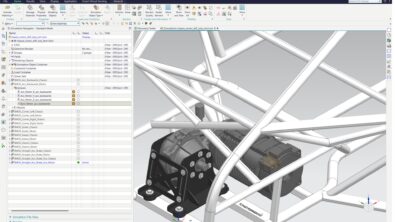

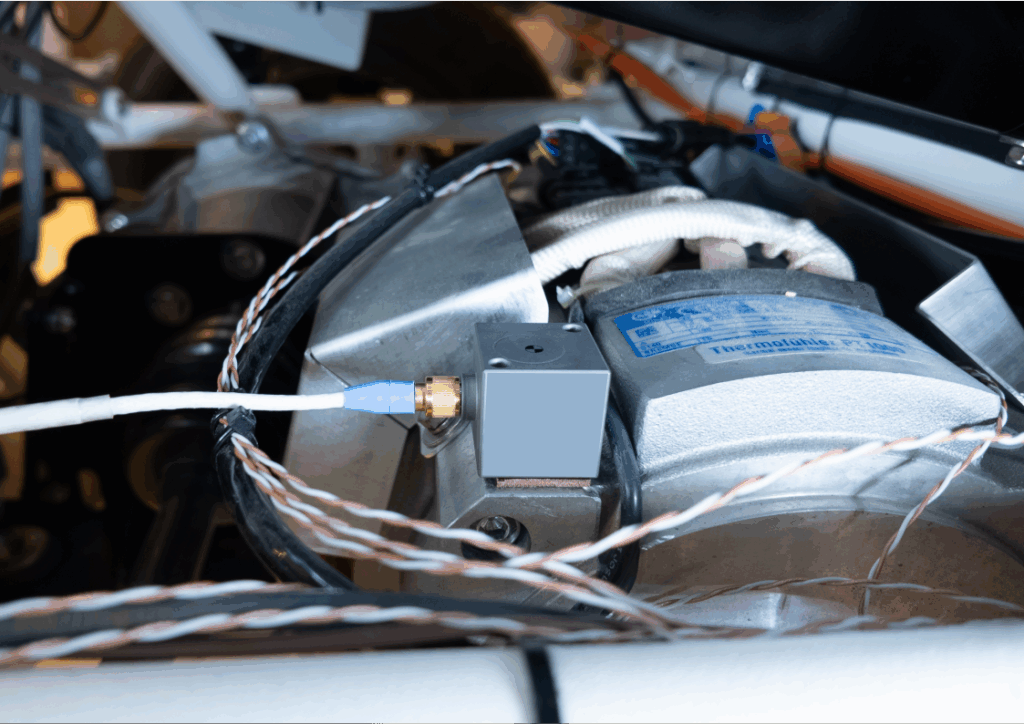

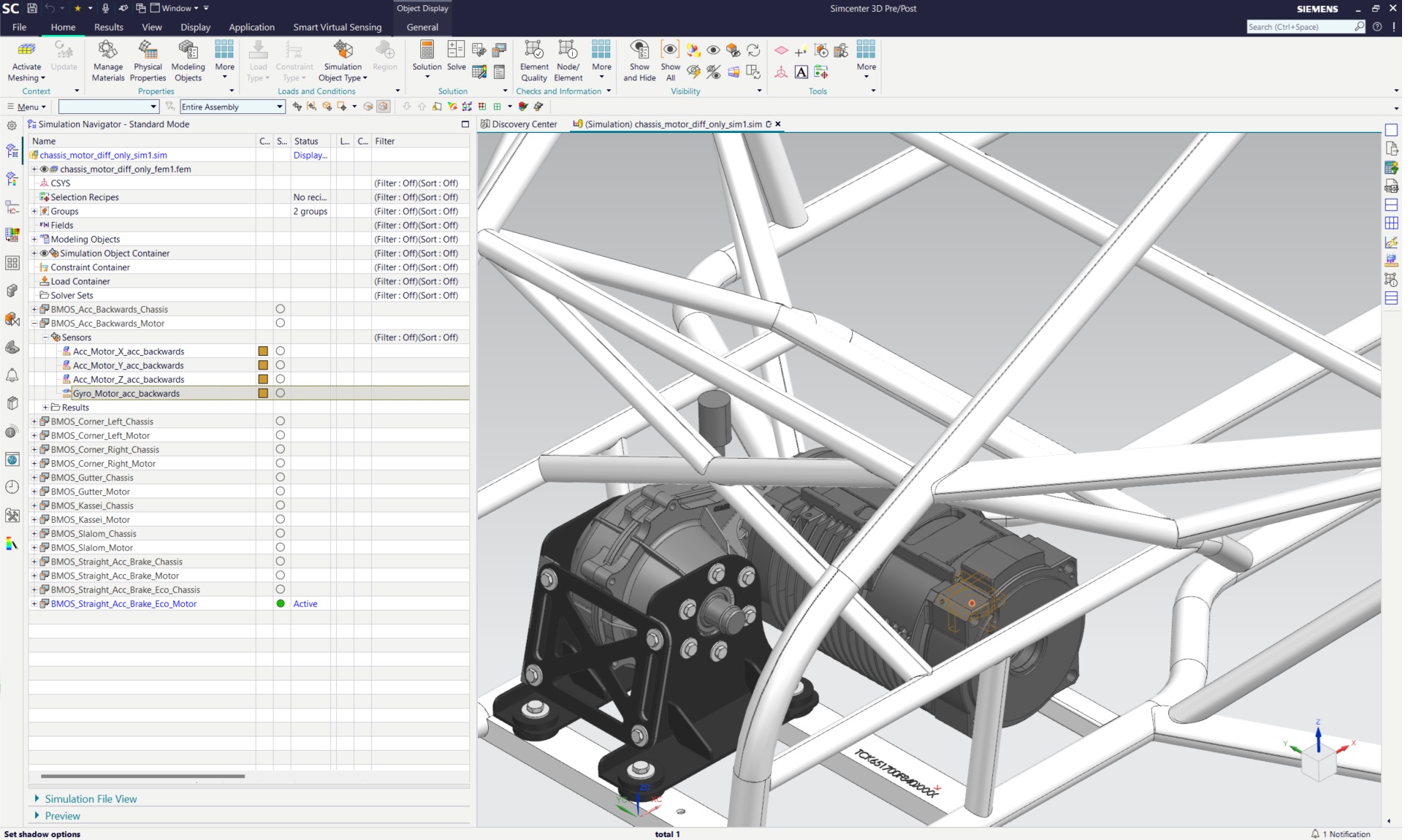

The core of this solution lies in its minimal and non-intrusive sensor instrumentation. Instead of an array of complex sensors or invasive setups, it utilizes just two 6-DOF (Degrees of Freedom) sensors – a combination of a tri-axial accelerometer and gyroscope – strategically mounted on the motor and chassis, respectively. Combined with Simcenter SCADAS RS, it directly captures all dynamic movements, giving you confidence in your validation results.

Simcenter portfolio enables an integrated end-to-end solution:

Firstly, you instrument the vehicle with a number of 6-DOF sensors equal to body movements to be captured. For the case of the relative movement of a powertrain with respect to the vehicle chassis, you would need two 6-DOF sensors to instrument both the powertrain and chassis with one 6-DOF sensor each. Connect the sensors to Simcenter SCADAS for accurate measurement and data acquisition. By collecting the 6-DOF sensors on both the motor and chassis, and storing data from all the different maneuvers, you can ensure precise evaluation.

Next, you can use Simcenter 3D Smart Virtual Sensing to generate the body motion sensing solution. Here, you configure virtual sensors based on your specific requirements and then export these as an xDT (executable Digital Twin) in FMU (Functional Mock-up Unit) format, which contains our unique data-fusion method.

Then you can connect the exported FMU/xDT with your measured data in Simcenter Testlab Process Designer . Here, you can post-process the results, retrieve the motor’s relative movement to the chassis, and verify that all relative movements stay within your designed limits.

This integrated test and simulation solution provides a unique and powerful capability in the market, ensuring that your e-powertrain packaging validation is both efficient and reliable.

The results speak for themselves. In recent validation campaigns, the Smart Virtual Sensing approach has been tested under various maneuvers, yielding robust results as follows. This includes maneuvers with high shocks, where camera systems can reach their limits, and might start to move slightly, additionally measurement on the rear underbody part is now feasible, without cutting the vehicle body panels.

Why it matters: Key benefits for automotive OEMs

For automotive OEMs, Simcenter 3D Smart Virtual Sensing with Simcenter Testlab Process Designer and Simcenter SCADAS, enables packaging tests:

- Accurate Clearance Verification: Precisely measure the gap between motor and chassis, even in hard-to-reach locations.

- Dynamic Movement Envelope: Accurately calculate the motor movement envelope for various maneuvers, ensuring tight packing and safety across all operating conditions.

- Robust & Non-Intrusive: Get reliable data without the need for intrusive setups or concerns.

- Time and Cost Savings: Streamline validation, reduce test cycles, and most importantly, accelerate time-to-market.

By embracing Simcenter 3D Smart Virtual Sensing, you can confidently ensure that your e-powertrain designs meet the rigorous demands of today’s and tomorrow’s electric vehicles, thereby eliminating collisions as a concern.

Conclusion: Future-proof your EV designs

Dynamic clearance validation is no longer a bottleneck. With Siemens Simcenter 3D Smart Virtual Sensing and Simcenter Testlab Process Designer, engineers can confidently deliver innovative EV designs that are safe, reliable, and ready for the road ahead. Furthermore, we’re performing research with the VLAIO-funded research project NexDT to prepare and advance these next-generation Smart Virtual Sensing technologies.

Ready to transform your EV packaging validation? Discover how Smart Virtual Sensing can future-proof your next project.

2512 release

To discover what else is new in the Simcenter 3D 2512 release see this release blog, or to always be up to date with the latest simcenter 3D news, check out Simcenter 3D:The Latest