Beyond engine noise reduction – the future of powertrain NVH

Over the years, NVH engineers have become experts in engine noise reduction and cancellation techniques. Generations of young NVH engineers have started their careers in the powertrain department of automotive manufacturing companies. For many years, they have focused on solely one objective: hushing the engine noise down. And they have achieved excellence in engine noise reduction. So, what comes next? How would you define the role of the powertrain NVH engineer in this era? What is the next challenge that he will face?

This article resumes my discussion with automotive NVH expert Steven Dom. In the first article “Adopt a people-centric approach to electric vehicle sound engineering”, we entertained a conversation around the challenges faced by NVH engineers when it comes to developing electric vehicles. In this discussion, we go back to the basics and talk powertrain NVH engineering.

Engine noise reduction is a well-mastered technique

The old-style, regular internal combustion engine (ICE) holds no secrets anymore for the NVH engineer. Over decades, engineering teams have explored and refined the techniques to silence what used to be the single major noise source in a vehicle: the engine.

Consider transfer path analysis (TPA): the method lets engineers precisely map the various paths through which noise and vibrations travel from the source (the engine) to the receiver (the driver). It helps them find out which paths contribute the most to the driver’s discomfort, which ones are minor contributors, and which ones cancel themselves out. It allows for applying extremely effective countermeasures. An engine TPA is a relatively straightforward technique when compared to a road noise TPA.

Does this mean that powertrain NVH engineers perform an easy job in a relaxed atmosphere? Maybe they’re even bored, aren’t they?

Not quite so.

Gears are still whining

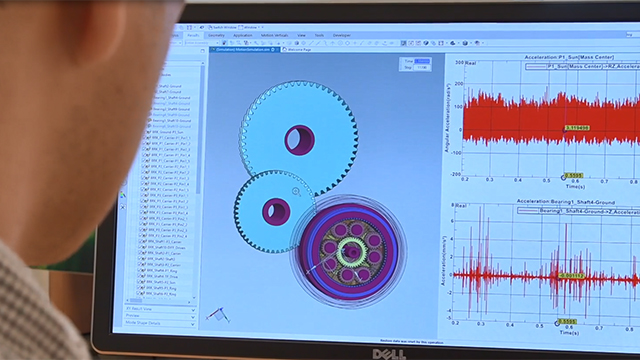

The more you silence the engine, the more audible the noise of other powertrain parts becomes. Gear whine is a typical example. And if you replace the combustion engine with an electrical one, you will hear the gears whine in the transmission even more clearly. Some simulation techniques prove very effective to help reduce the gear whine effect. Hyundai Motor Company, for example, selected simulation solutions from the Simcenter portfolio to minimize transmission gear noise. The method they applied as well as other methods are also described in the white paper Boosting productivity in gearbox engineering using a revolutionary approach to multibody simulation.

Fuel economy counters NVH refinement

Above all, modern engines must spare fuel. There’s hardly any recent engine that hasn’t been conceived in view of this objective. To meet their fuel economy objectives, car manufacturers applied mainly three techniques:

- Downsizing – which reduces the number of engine cylinders

- Turbocharging – which adds a component that injects more compressed air into the combustion chamber

- Downspeeding – which reduces the rotational speed of the engine components

All three techniques, whether considered individually or combined, negatively impact the powertrain NVH performance. Turbocharging, for example, often generates unpleasant engine booming noises. Downspeeding usually increases torsional vibrations along the transmission shaft. And downsizing is one of the causes of disturbing clutch judder.

Over the past decades, manufacturers have engineered their engines to meet the New European Driving Cycle (NEDC), which turned out to represent an unrealistic view of the actual average driving conditions in Europe. As they now must follow the Worldwide Harmonized Light Vehicle Test Procedure (WLTP), they are still challenged to meet stringent fuel economy requirements but often adopt a different strategy to reach their objective.

Manufacturers have stopped the further downsizing of engines. Rather, they opt for other tactics to meet their goals: partially electrify the combustion engines and/or make more efficient use of the electronic controls.

Next stop: Resolve the hybridization challenge

Manufacturers gradually invest less in the development of new, regular, internal combustion engines. Volvo, for example, only markets a single 2-liter, 4-cylinder internal combustion engine across all its passenger vehicle platforms. Other engine variants have disappeared, owing to the trend towards vehicle electrification.

Undeniably, engine hybridization is a major trend. Nearly all recently-engineered powertrains feature some degree of hybridization. And the trend brings along a set of new challenges for the powertrain NVH engineers.

Indeed, hybridization means dealing with two, rather than one, potential noise and vibration sources in the car. And, foremost, ensuring a smooth transition from one to the other. Steven Dom remembers how the drivers of the first-generation Toyota Prius got confused about the unusual vehicle’s behavior. “And then, Dom adds, the Toyota engineers had the idea of inserting a large screen into the dashboard of the second-generation car. It showed the in-vehicle energy transfers. It was not only a cool gimmick but also a very clever way of giving the driver clear feedback about the vehicle’s behavior.”

The true challenge of hybrid vehicles NVH refinement is twofold. From a technical standpoint, it is to deal with integration issues and make sure that all the powertrain components perform as expected in the context of the full vehicle. From a human standpoint, it is to ensure that the driver always feels comfortable and is not startled, for example, by the sudden re-start of the combustion engine after a long, smooth, electric-only ride. “The driver, says Dom, shouldn’t even notice that he is driving a hybrid car. Perfect powertrain integration is key to refine the NVH performance of hybrid vehicles.” As an example, discover how Simcenter solutions helped Honda solve issues of hybrid engine restart vibrations.

Suppliers: learn more about vehicle system integration

If you want to understand better how suppliers can help solve the hybridization challenges by addressing integration issues at the component and subsystem level, watch the on-demand webinar Vehicle system integration guidelines for component suppliers.

Be in control of the NVH issues

Another trend highlighted by Steven Dom is how controls engineering helps circumvent noise and vibration issues: “Controls engineering gains importance in the industry. Not only for the motive of fuel economy but also for better NVH refinement.”

Dom quotes a technology such as dynamic skip fire, developed by Delphi. Confronted with the problem of a 4-cylinder engine that made a terrible booming noise at a certain frequency, the company modified the engine controls to simply shut down one cylinder at the given frequency, and thus skip the trouble-making engine order.

“Tuning the engine controls can help solve a wide range of NVH issues, says Steven Dom. The Simcenter engineering services explore these possibilities and can tackle certain NVH issues with adequate controls engineering.”

Tune it up: Active sound design in powertrain NVH

The last NVH trend that Steven Dom mentions might be a more surprising one. After years of focusing on silencing the engine, some acoustic engineers take over and… add sounds to the engine. More specifically, they design artificial sounds that, when replayed in or around the vehicle, shape the acoustic landscape and stimulate positive emotions with the driver.

“The numbers are astounding, says Dom. A vast majority of vehicles of the mid-to upper-segment features active sound design technology”.

Carmakers refrain from communicating around this trend. A 2018 article titled how car companies are getting sneakier about engine sound enhancement quoting a few examples of acoustically enhanced engines.

Active sound design is a technology by which engineers create and tune the desired sound effects in a car. Prior to active sound design, acoustic engineers had already been very committed to actively canceling unwanted sound waves. Automotive suppliers have been instrumental in advancing technologies for engine noise reduction. The supplier Eberspächer offers a full range of exhausts that incorporate active sound design. Mentor Graphics, a Siemens business, also proposes an active noise cancellation solution, as demonstrated in this short video.

Car manufacturers also make active noise cancellation and active sound design technologies their own. In 2015, Ford enthusiastically promoted the active noise control feature of its brand-new Ford Vignale.

Work hand-in-hand

Steven Dom concludes: “Today, we often witness situations where the powertrain NVH team successfully focuses on engine noise reduction, while the interior acoustic and multimedia team takes over with adding new sounds. A challenge for the future is to bring the two teams to work together, hand in hand, and create the perfect soundscape for a particular brand or car model.”

Learn more about Simcenter solutions by visiting the website NVH & Acoustics for Internal Combustion Engines, or alternatively check out the NVH Powertrain Engineering on-demand webinar series.

About Steven Dom

Steven Dom has been with Siemens Industry Software (and former LMS International) for over 20 years, working in various areas of engineering, engineering management, product management, and sales. He is currently Director Automotive Industry Solutions, responsible for developing Siemens Industry Software business in the automotive industry.

This article is the second one of a series on trends in automotive NVH engineering. Read the first article: Adopt a people-centric approach to electric vehicle sound engineering and share your thoughts in the comments below.