AVAS: electric vehicle warning sounds

In part 1 of this blog post series we saw that in 2019, Pass-by Noise (PBN) is about preparing for lower noise limits that are coming up. These require more engineering. Another big trend in PBN is about dealing with electrification and minimum noise limits, certifying AVAS systems for electric vehicle warning sounds, where this part 2 will focus on.

Hybrid and Electrical vehicles require Acoustic Vehicle Alerting Systems (AVAS)

The absence of exterior sound in hybrid and electrical vehicles, especially at low speeds, has a negative impact on pedestrian safety. Think for a moment, how you cross the street yourself: you probably listen first if there is any vehicle passing by to make sure you won’t get run over, then put one foot on the street, and only then you start looking to scan traffic a bit further away. That’s exactly the problem with electric vehicles. You don’t hear them as they make very little sound at low speeds. It’s potentially a fatal habit to first listen and only then look. It’s not enough to work on those habits… Electric vehicles need some kind of warning sounds.

Therefore, regulators have worked on defining mandatory Acoustic Vehicle Alert Systems (AVAS) that add exterior noise to quiet vehicles. These systems induce additional noise while driving at low speeds (up to 20-30 km/h), where the tire noise contribution is very low. In terms of pedestrian safety, this is particularly important for those with visual impairments, but also for other so-called vulnerable road users such as bikers or children.

Designing branded acoustic signature

AVAS is a major opportunity for vehicle makers to redesign the brand sound of their fleet. Sound design has several goals. First, it needs to comply to legislation and serve its purpose of warning pedestrians. Next, the electrics vehicle warning sounds needs to sound pleasant for both the outside world, as well as for the passengers inside the vehicle. And finally, the designed sound signature has a unique potential to identify both the brand and particular vehicle model for years to come.

Legislation makes AVAS mandatory

Currently, legislation all over the world is moving towards making AVAS mandatory for vehicles with an electric mode of operation, imposing a minimum noise level. Several standards and regulations have been formulated over the past years, e.g. with ISO 16254, to define electric vehicle warning sounds. Two major regulations exist, United Nations Economic Commission for Europe (UN ECE) Regulation 138, and the Federal Motor Vehicle Safety Standards (FMVSS) 141 applicable in the United States (US) only. In Europe, hybrid and electric vehicles need to be equipped with an AVAS from July 2019 onward, with the new testing method defined in the UN ECE Regulation 138. In the US, by September 2020, 100% of newly produced hybrid and electrical vehicles must comply to FMVSS 141. Apart from the detectability of the presence, direction and location of quiet vehicles, AVAS sound must allow pedestrians to identify critical operating scenarios such as constant driving speed, acceleration, or deceleration.

What about other regions in the world? Although a member of UN ECE, the US has defined their own testing standard in FMVSS 141. But most countries adopt the UN ECE Regulation 138 in their local legislation. For example, in China, GB/T 37153 will become mandatory. It’s fully aligned with UN ECE Regulation 138, except that all minimum noise levels are 2dB higher.

UN ECE Regulation 138 Minimum noise test

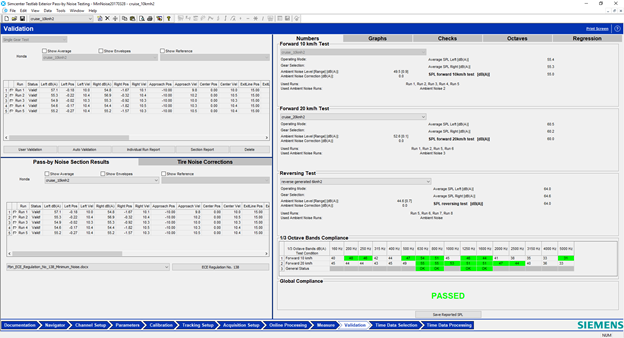

UN ECE Regulation 138 requires testing with microphones positioned at only 2 m from the center of the vehicle and requires cruising tests at low speeds in forward and reverse. Besides, it also requires frequency shift tests to ensure that acceleration or deceleration of a vehicle can be detected.

The cruising speeds consist of 10 and 20 km/h forward constant speed driving, as well as reverse driving at 6 km/h. First, the measured overall levels of 10 and 20 km/h tests should not exceed 75 dB(A). Next, the 10, 20 and 6 km/h reverse overall levels need to be higher than 50, 56, and 47 dB(A). Finally, the 10 and 20 km/h conditions require additional minimum noise levels in at least two 3rd octave bands, of which one band shall be the 1600Hz 3rd octave band or lower.

Within those boundaries, AVAS sound designers have freedom to design their sound signatures. To give flexibility to vehicle manufacturers, legislators have given several options to choose the test site, and the operational conditions of the test. The test site can either be indoor or exterior, and the operating conditions of the vehicle can be in motion or standing still. When standing still, the required operational condition is directly applied to the AVAS system with an external system, usually with simulated CAN input. Generally, this simplifies the task, as AVAS systems are connected to the CAN bus already by design.

The frequency shift test for the UN ECE R138 regulation aims to determine the pitch increase of a tone at different speeds. This allows pedestrians to identify if a hybrid or electrical vehicle is accelerating, and if so, how fast. The increase of pitch is required to be more than 0.8% per 1 km/h speed increase. It is determined by following the frequency intended to shift in pitch at 5, 10, 15 and 20 km/h. Apart from the mentioned operational conditions of the constant speed tests, a fifth operational condition is allowed: without a vehicle, in an indoor facility, with simulation of the vehicle movement to the AVAS by an external signal generator.

Differences in the US AVAS regulation FMVSS141

The National Highway Traffic Safety Administration (NHTSA), the US legislator, choose a somewhat different approach in their FMVSS 141 standard, especially on the 3rd octave band analysis and the frequency shift. To list some of the differences:

- A stationary test, with a 3rd microphone added for a directivity test. It’s positioned at the front of the vehicle, on the CC’ line at 2m from PP’.

- A 3rd cruising speed is added at 31 km/h. The cruising speeds are set to be at minimum 10, 20, and 30 km/h. To make this practical, the standard chooses 11, 21, and 31 km/h with a +/- 1 km/h tolerance.

- 3rd octave bands are assessed differently and allow for two different compliance paths:

- 4 non-adjacent bands in a 9 bands span.

- 2 non-adjacent bands, one below 1000Hz and one above 800Hz, and a minimum overall level

- No frequency or pitch shift, but a relative volume change of 3dB for each cruising speed condition

The future is now: Active Sound Design for Automotive

But where does this AVAS sound come from? And how are these electric vehicle warning sounds generated?

Active Sound Design gives car makers the opportunity to add sound to the vehicle, both interior and exterior. Interior active sound systems add sounds dynamically based on the vehicle’s operational condition to amplify or attenuate wanted/unwanted sound. This could be to compensate for a cylinder deactivation or adding engine orders when only the electric motor is running. The exterior sound is embedded in the AVAS – typically a speaker installed in the front of the vehicle, synthesizing sound in function of the vehicle’s speed, load, and throttle. (Learn more about active sound design and attend this webinar)

In this AVAS white paper, we explain how Simcenter integrates simulation, testing and services, to design the right exterior sound for acoustic vehicle alerting systems. In addition, sounds, loudspeaker systems, their positions, and controls are evaluated. It offers the right answers on how to consolidate the AVAS for electric vehicles into the vehicle and properly evaluate alternatives. Download the white paper and discover how to:

- Design creative AVAS sounds and validate these against customer expectations

- Test and optimize AVAS sound models with real-time interaction to the vehicle can bus

- Optimize the location of the AVAS speaker systems and its geometrical, acoustical and control aspects

- Test and validate compliance to UNECE R138 and FMVSS 141 regulations

Simcenter Testlab 2019.1 includes a brand-new solution for Active Sound Design, with several sound design methods, and validation through real-time synthesis in the office, in-vehicle, or on a driving simulator. More on how to design these electric vehicle warning sounds in a next blog post.

Together with PBN engineering, AVAS and active sound design will define and shape the sound landscape of urban areas in the next decades, as electrification in vehicles continues.

Are you looking for more information to understand the latest PBN engineering methods? Register for this free PBN webinar compiling the latest updates in PBN engineering.

Comments

Comments are closed.