Accelerate EV Geartrain NVH Simulation: 5x Faster with Simcenter 3D Motion

Why NVH performance matters

The electric vehicle (EV) revolution is here, promising a cleaner, more efficient future for transportation. But as the roar of internal combustion engines fades, a new challenge emerges: the intrinsic quietness of Electric Drive Units (EDUs) brings the subtle sounds and vibrations of other components, especially the geartrain, into sharp focus. For automotive engineers, this means NVH (Noise, Vibration, and Harshness) performance is more critical than ever.

In the fiercely competitive EV market, OEMs and TIER1 suppliers are under immense pressure to innovate rapidly. This intense competition demands:

- Faster Time-to-Market: Consumers expect cutting-edge features in new models, quickly.

- Cost Efficiency: Maximizing efficiency to reduce product development costs and protect shrinking margins.

- Digital Transformation: A strong drive towards increased digitalization and reduced reliance on costly physical prototypes.

These factors collectively force companies to significantly accelerate their product development cycles.

The NVH bottleneck

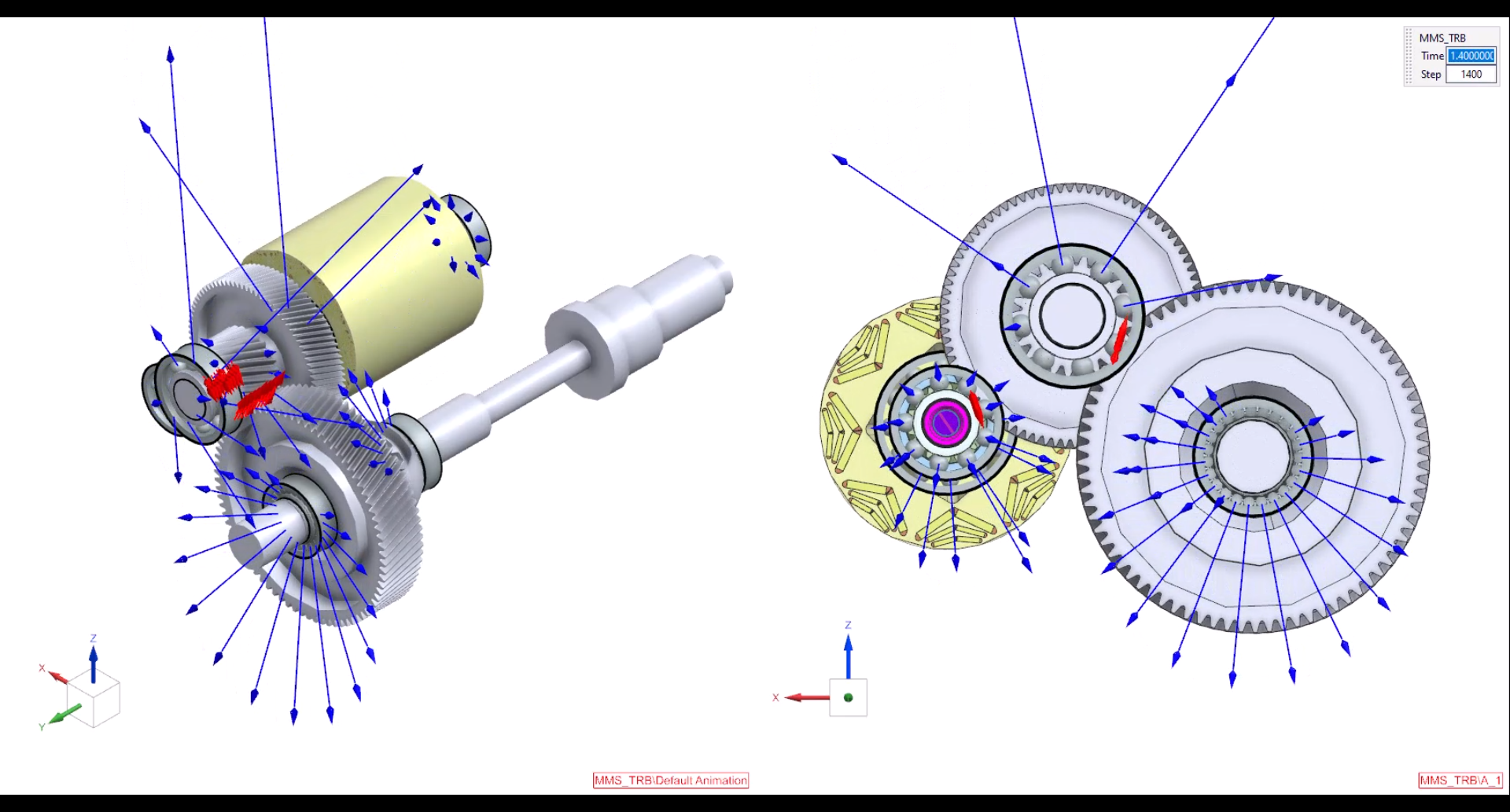

Accurately predicting geartrain NVH performance – and ultimately replacing expensive physical prototype testing – demands high-fidelity time domain simulation. However, this type of simulation has traditionally been incredibly computationally-intensive, leading to:

- Long Turnaround Times: Design studies can take days or even weeks.

- Late-Stage Validation: Often relegated to the later stages of the development cycle, limiting its impact on initial design decisions.

This bottleneck significantly hinders the agility and effectiveness of the geartrain development process.

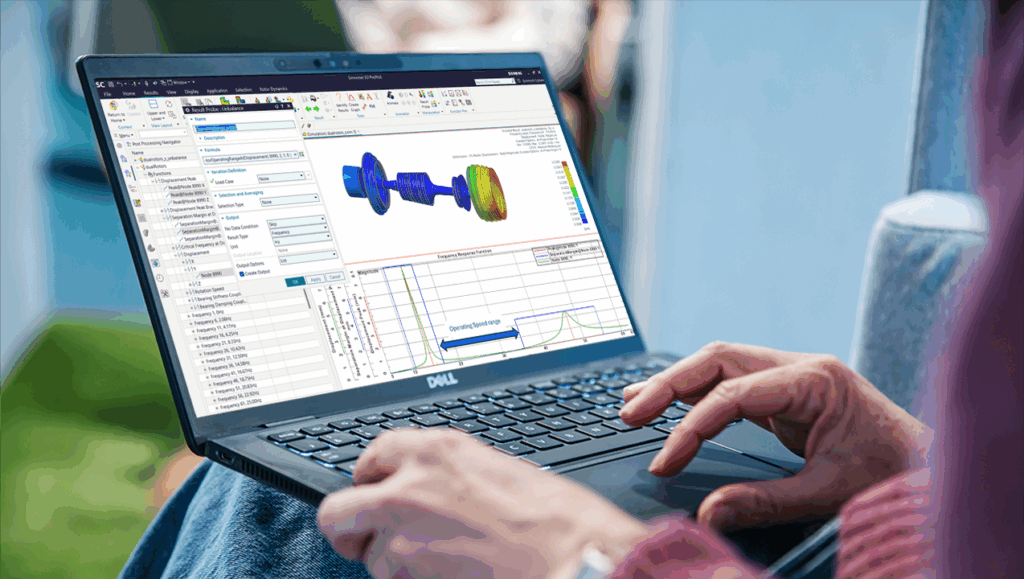

The new Motion solver

Enter the new 2512 release of Simcenter 3D Motion, featuring the groundbreaking Modern Motion Solver for geartrain time domain simulation. This isn’t just an update; it’s a leap forward. This is exactly the reason why we invite our customers to test this new capability, see the note below.

- Engineered for Speed: Built on a cutting-edge C++ code architecture, the Modern Motion Solver efficiently tackles even the largest and most complex models.

- Scalable Performance: It fully leverages parallel processing, allowing a single time domain simulation to be solved across multiple threads simultaneously.

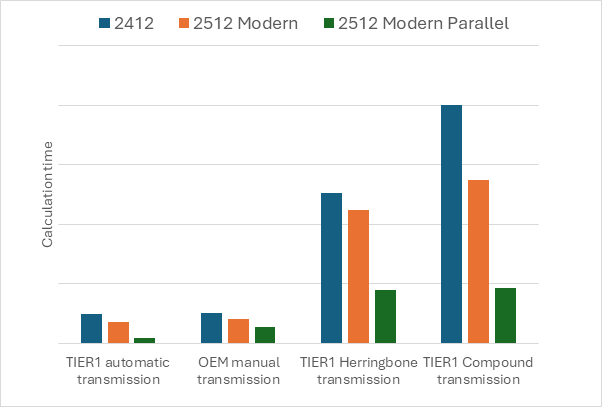

- Proven Results: Extensive tests on a suite of industrial geartrain models demonstrate performance improvements up to 5 times faster compared to the 2412 release – all while maintaining the same unparalleled accuracy.

Imagine the possibilities: evaluating significantly more designs, exploring a wider parameter space, and bringing innovative EV geartrains to market faster than ever before.

Please note: The Modern Motion Solver is currently still under a feature toggle. We warmly invite our customers to start testing their transmission models with the Modern Motion Solver and share their valuable experiences with us. Your feedback is crucial as we continue to refine and enhance this powerful tool!

What else was in 2512?

The 2512 release of Simcenter Mechanical products had a huge range of updates, to discover the highlights, check out our release blog.