Ensure power domain compatibility by finding missing level shifters with Insight Analyzer

By Bhanu Pandey

Level shifters are essential for safe, reliable mixed-signal IC design—especially as designers deploy more power domains than ever before. Still, even experienced teams can overlook one, leading to costly silicon failures. Below, we explore why missing level shifters are so easy to miss, the impact they can have, and how tools like Siemens’ Insight Analyzer automate their detection and enable shift-left verification for robust circuit integration.

The role of level shifters in modern IC design

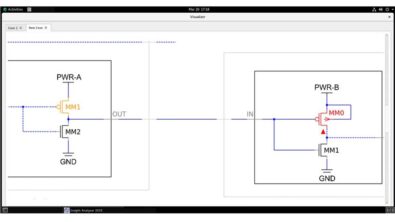

In the realm of mixed-signal design for integrated circuits, level shifters play a critical role in interfacing circuits that operate at different voltage levels. A level shifter converts signals from one voltage level to another, ensuring compatibility between components. Figure 1 illustrates a missing level shifter between power domains.

It’s not uncommon for a member of the design team to miss a level shifter while designing a large IC. Although it is a seemingly obvious mistake, there are many practical factors that can contribute to such an oversight: assumptions about voltage levels, incomplete documentation, time constraints, design complexity, inexperienced team members, insufficient simulation/testing, or relying on a previous design as reference.

Depending on the company’s resources or project timeline, formal verification checkpoints may not occur as often as needed. If absent, opportunities for mistakes to slip through rise dramatically.

It’s not uncommon for a member of the design team to miss a level shifter while designing a large IC. Although it is a seemingly obvious mistake, there are a plethora of pragmatic factors that can contribute to such an oversight in a large complex design. Some of these include assumptions about voltage levels, lack of documentation of specifications, time constraints, design complexity, inexperienced designers, inadequate simulation and testing and using a previous design as reference.

Depending on the design team and company size, and the time constraints and resources available for a particular project, checkpoints may or may not be available. If absent, the likelihood of design mistakes to inadvertently slip through before fabrication significantly increases.

The difficulty of accurately identifying the need for a missing level shifter, despite all kinds of checkpoints, presents an opportunity for the electronic design automation (EDA) industry to provide a more robust solution that can avoid these all too common human mistakes.

Consequences of a missing level shifter

A missing level shifter in an IC design can have profound consequences that may completely compromise the integrity, performance and even power consumption of the design. Some examples of the consequences that may occur due to missing level shifter somewhere in the design are:

- Signal integrity problems

- Device damage or failure

- Increased power consumption/leakage

- Reduce system performance

- Interoperability bugs between blocks

- Heightened noise sensitivity

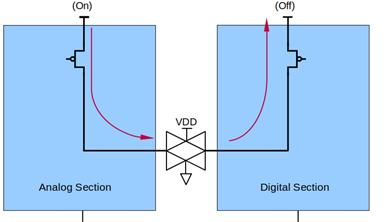

Figure 2 shows a diagram of an IP with two power domains. When both power domains are powered up and the voltage difference between the power domains is less than a threshold value (which you can set in the simulator), there are no issues in the design. However, if the voltage difference is greater than the threshold value, let us say Power domain 2 is operating at a higher-voltage level than Power domain 1, then a logic ‘1’ at Power domain 1 can be assumed a logic ‘0’ at Power domain 2. This leads to incorrect data transmission.

Why simulation sophisticated simulation tools and checklists aren’t always enough

Even with sophisticated simulation tools, manual review and checklists, design teams struggle to identify all risky inter-domain crossings. When design complexity grows, and power architectures become more granular, the chance of oversight increases. These traditional approaches often miss subtle voltage mismatches that only manifest under specific operating conditions, as well as paths not covered by test vectors.

Find inter-domain power leakage Insight Analyzer

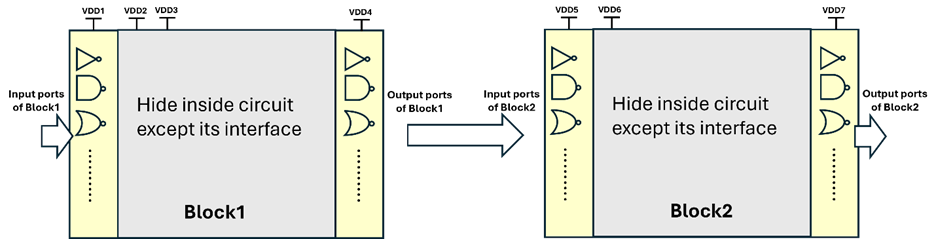

The first step towards finding an inter-domain power leakage is finding all DC paths between all power domains. This step is immensely helpful and will list all possible combinations of DC paths possible between two or more power domains. The Insight Analyzer tool finds every single combination of paths that may exist between two or more power domains. Fortunately, this first step of finding all DC paths is relatively easy.

Once paths and crossings are identified, Insight Analyzer performs a sophisticated evaluation to determine whether these crossings actually require level shifters. It analyzes the circuit’s architecture in detail, examining critical voltages (such as gate-to-source in PMOS devices and gate-to-drain in NMOS devices) and compares measured to expected values based on each power and ground rail. Deviations signal a requirement for a level shifter.

Insight Analyzer can quickly and accurately identify missing level shifters, as well as other circuit reliability issues that are hard to find with simulation or ERC (electrical rule checking). By using pre-layout, state-based analysis without the need for vector simulation, Insight Analyzer lets designers perform early “shift-left” checks—making the process more efficient and helping teams catch issues before they become costly.

Shift-left verification—why early checks matter

Modern shift-left methodology means moving critical verification earlier in the design flow, where mistakes are faster and cheaper to fix. Automated analysis with Insight Analyzer exemplifies shift-left in practice: designers can scan for missing level shifters and voltage crossing issues from the earliest schematic iterations, not just before tapeout. This leads to higher design confidence, fewer last-minute surprises, and smoother project schedules—especially as ICs grow in size and voltage domain count.

Improving reliability for next-generation ICs

As semiconductor technology advances and chip designs grow more complex, the risk of missing a level shifter increases. Relying only on simulation, checklists, or late-phase verification is no longer enough. Insight Analyzer supports a designer-driven reliability verification flow, enabling rapid, full-chip analysis—even at the transistor level. With Insight Analyzer, circuit designers can efficiently flag and resolve missing level shifters and improve overall design reliability from the earliest development stages.

Bonus content!

Technical paper now available: Finding missing level shifters between power domains with Insight Analyzer

Our library of resources for Calibre Reliability Verification: Calibre suite for reliability and multi-domain verification