The future of in-system testing for automotive safety

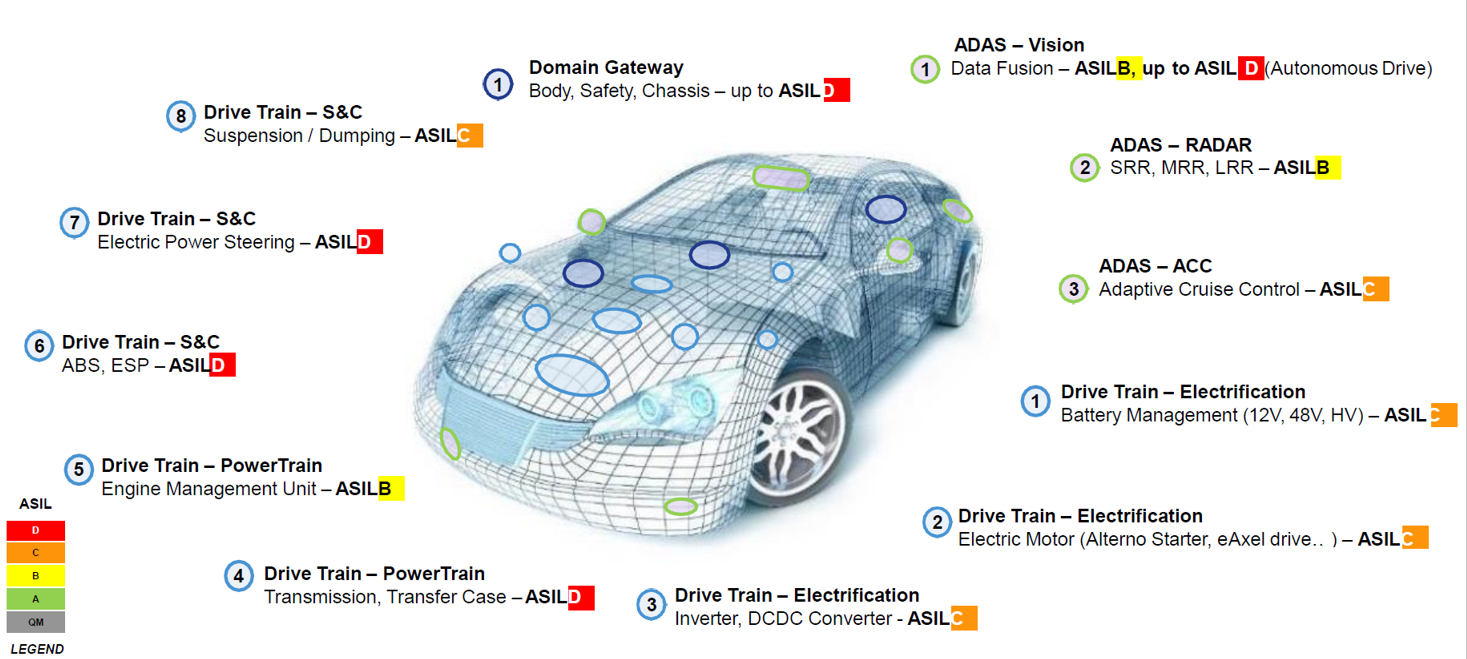

As cars become increasingly computerized, the chips that power them use lots of complex commercial IP. Much of the electronics are used for safety-critical components, and it’s up to the IP provider to ensure that the device can achieve ISO 26262 certification and ASIL levels to meet automotive safety requirements. We worked with leading IP supplier, arm, to create a reference flow to demonstrate how to do this using available tools and methods.

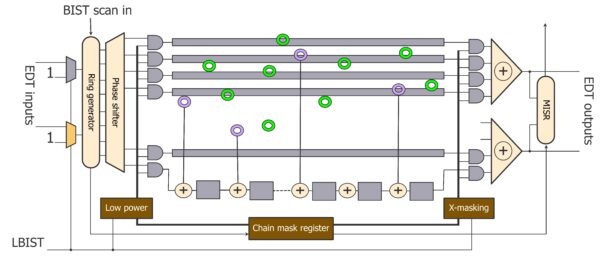

The key to the solution is the use of logic built-in-self-test (LBIST) that is monitored and managed by an on-chip safety manager. The reference flow can be enhanced to use a newer BIST called LogicBIST with observation scan technology to significantly simplify the overall implementation at the same time as dramatically reducing the overall diagnostic test time interval (DTTI). This ensures highly reliable operations of automotive chips for the duration of their lifespan.

How automotive chips test themselves

Chips used for safety-critical applications need in-system test to detect faults and monitor circuit aging. Adding scan-based LBIST circuitry to the chip is the technique used for in-system test.

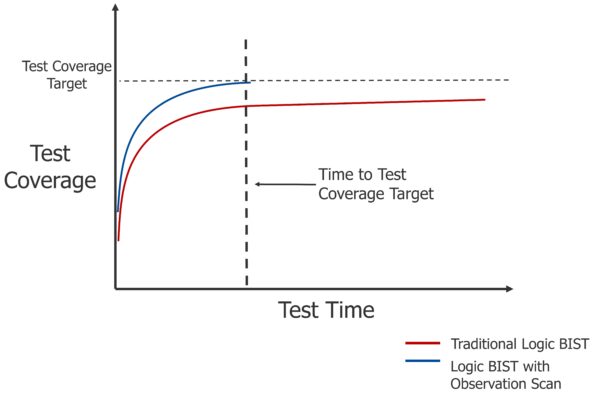

Traditional LBIST poses two challenges: it often cannot meet the 90% coverage goal required for Automotive Safety Integrity Level (ASIL) D certification and fault detection happens only during the capture phase of the LBIST cycle. Each LBIST cycle has two phases—shift and capture. There are as many shift cycles as the length of the longest scan chain and all scan chains are filled with a test pattern before it is applied. The capture phase uses the values written into the scan chain to drive the combinational logic and capture potential faults. As a result, most test time is spent on just shifting test data, not detecting faults.

Consider a design with 100-cell long scan chains. In logic BIST, applying 100,000 single-capture test patterns will require 10,000,000 cycles for scan shifting, while only 100,000 cycles are deployed to capture test responses. Hence, 99.99% of test time is spent on scan shifting.

Better LBIST test quality and faster test time

A newer method uses LBIST with Observation Scan Technology (LBIST-OST) to dramatically improve the efficiency of in-system test, making vehicles safer.

LBIST-OST works with observation test points that capture faulty effects every shift cycle (instead of only during capture cycles) into separate observation scan chains. Tessent LBIST-OST employs control and observe test points with a new scan cell functionality that essentially connects the observe points in separate chains. This is what allows them to capture circuit responses not just during a capture cycle, but also during the shift cycles. Empirical results demonstrate 90% test coverage with up to 10X fewer LBIST patterns when compared with previous industry-leading LBIST solutions.

By reducing on-chip test time, any defect that might occur during the operation of a vehicle will be detected more quickly and the vehicle can respond quicker, lowering the chance of a serious incident. For our customers, the faster test time they can achieve with LBIST-OST can make the difference between meeting ISO 26262 requirements or not, which affects their bottom line and competitiveness in the fast-growing automotive electronics market. For example, one of our customers was able to achieve a 6-millisecond test time with their incumbent LBIST solution, but they needed a 1 millisecond test time to reach ISO 26262 certification. With LBIST-OST, they reduced their test time to 0.5 milliseconds.

Tessent LBIST-OST from Siemens is the only technology on the market that can configure scan chains to capture test responses at observation sites during both scan shift and scan capture cycles, significantly reducing the test time interval. A faster test time interval means more tests can be run and any defects in the operation of the system will be detected quicker, enhancing the safety of the system.

Tessent LBIST-OST was developed by engineers from Siemens EDA in cooperation with engineers from Infineon Technologies and Poznan University of Technology. The work was first published at the 2019 International Test Conference (ITC). LBIST-OST has been adopted by many of the largest companies creating ICs for automotive and will become the new standard for improving the safety of automotive devices.

Click the button below to watch a video describing how Infineon used LBIST-OST to reduce test time for their automotive MCU.