What’s new in Simcenter Flotherm 2310 and Simcenter Flotherm XT 2310

I am pleased to introduce you to a unique market leading new technology for reduced order thermal models that can be used in 3D CFD thermal analysis and allow easy trusted data exchange in the electronics supply chain. Please read on for details of Embeddable BCI-ROM technology in Simcenter Flotherm electronics cooling software and also for information on the latest features in Simcenter Flotherm XT 2310 release.

Simcenter Flotherm 2310

Embeddable BCI-ROM technology – accurate reduced order thermal models for 3D CFD simulation that protect IP

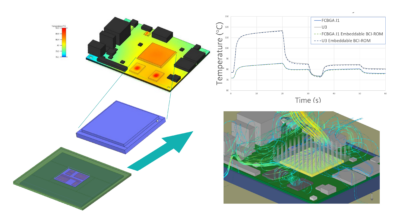

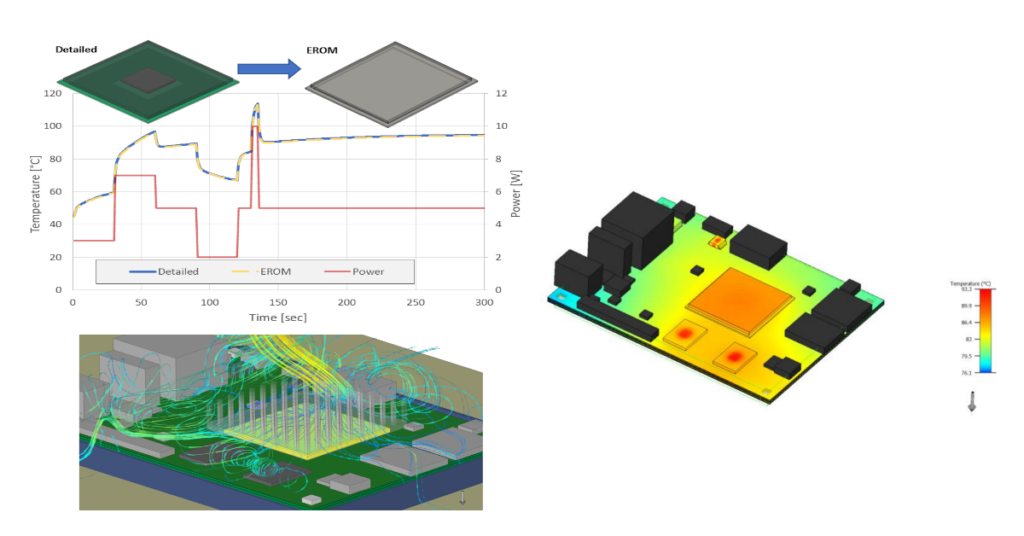

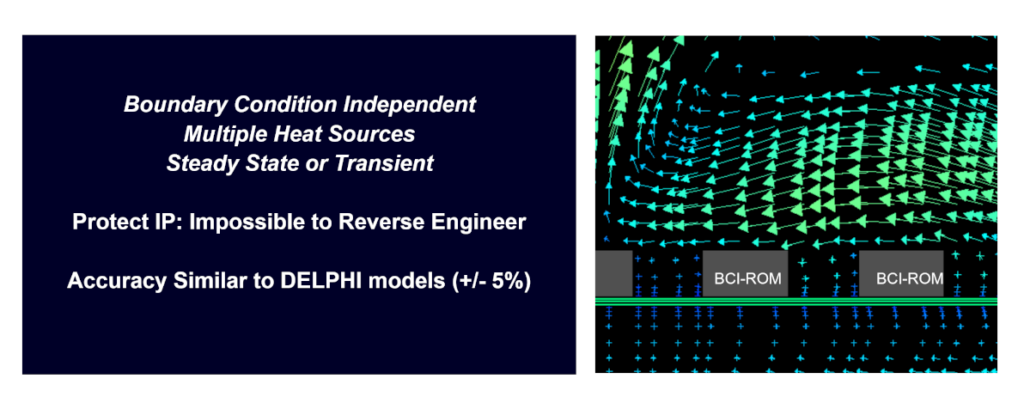

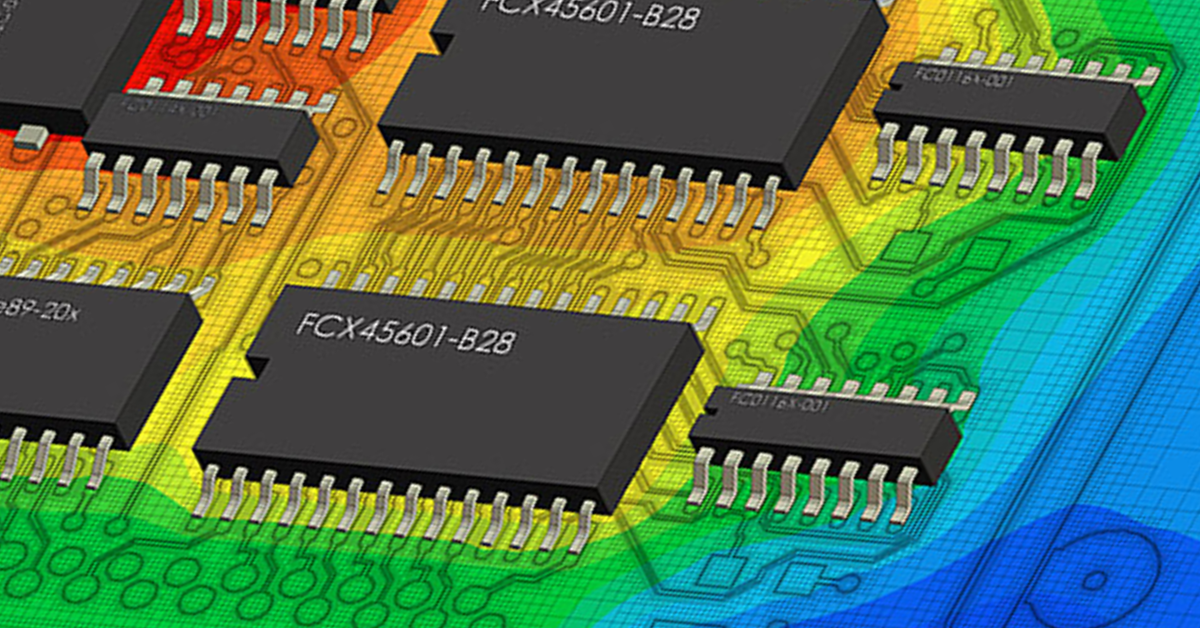

Embeddable BCI-ROMs are reduced order thermal models that are able to be imported and used in a 3D CFD system level thermal analysis preserving accuracy of a fully detailed thermal model while protecting IP sensitive internal physical details of an IC package. An Embeddable BCI-ROM is generated from a detailed model conduction only analysis.

Please read the focused blog on this new technology for technical insights, an introduction to generating and using Embeddable BCI-ROMs in 3D CFD, plus insights from comparing them to 2R, DELPHI and detailed thermal models.

Embeddable Boundary-Condition-Independent-Reduced-Order-Model (Embeddable BCI-ROM) technology in Simcenter Flotherm solves challenges for accurate thermal model exchange throughout the supply chain from semiconductor OEMS to electronics companies while protecting IP. As these models support transient analysis and also are able to include multiple heat sources – they offer accuracy and the ability to model complex modern package architectures like 2.5D, 3DIC, chiplet based designs, as well as traditional simpler packages.

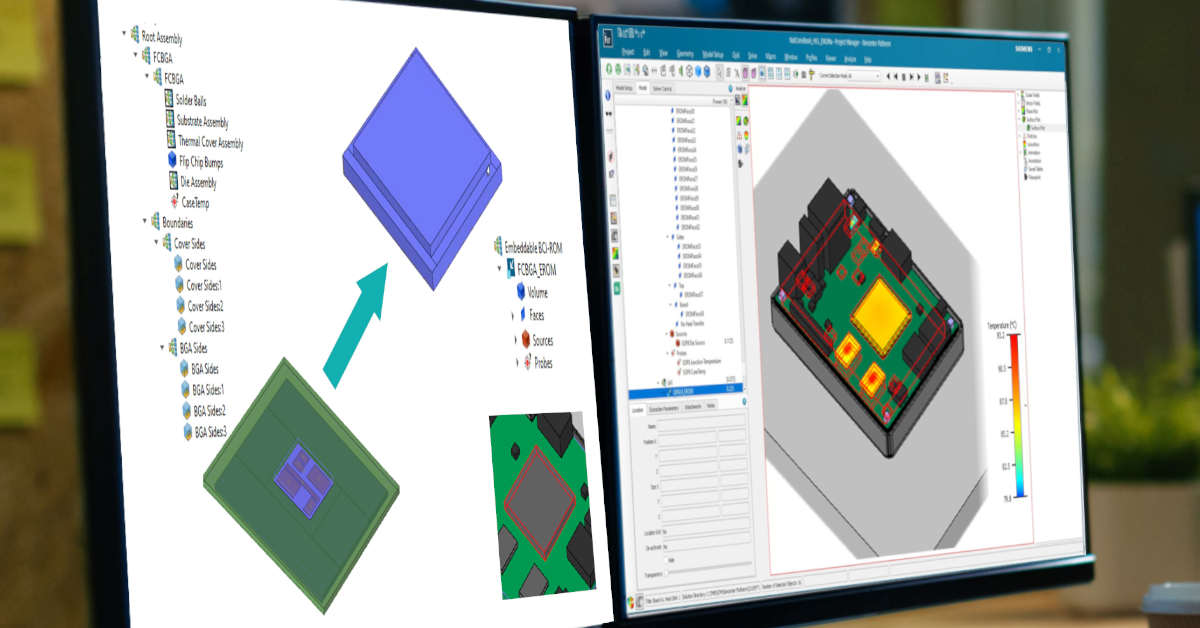

You can watch this short video for the steps involved in creating an Embeddable BCI-ROM of a Flip Chip BGA and then using it in a system level 3D CFD study in Simcenter Flotherm. You will observe the results for surface temperatures and temperatures from probe locations set during generation of the Embeddable BCI-ROM. It will also be clear that the internal structure of the detailed model is impossible to reverse engineer from the Embeddable BCI-ROM. Sensitive IP is completely protected.

Note: To create an Embeddable BCI-ROM it is necessary to have a license of the BCI-ROM module however to use an Embeddable BCI-ROM model only requires a Simcenter Flotherm license.

Curious to learn more or how the detailed 3D geometry of the FlipChip BGA was created to then generate the Embeddable BCI-ROM from for export? – see more details in the Embeddable BCI-ROM blog.

If you are interested in the historical development of component thermal modeling types over decades, and the contributions from academia and industry that helped activity resulting in Embeddable BCI-ROM technology, please see this blog with a personal perspective from my colleague Robin Bornoff.

Simcenter Flotherm XT 2310 – What’s new

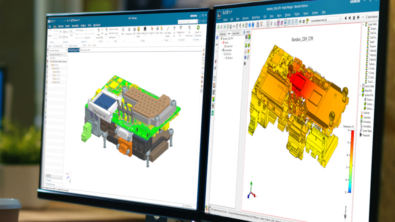

Below is a summary of the new features in Simcenter Flotherm XT, CAD centric electronics cooling software, that is part of the Simcenter Flotherm Flexx tool product family.

Model the complexity and stay integrated

Export Package Creator thermal models straight to Simcenter Flotherm

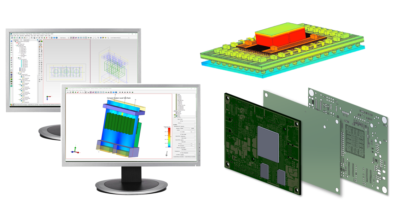

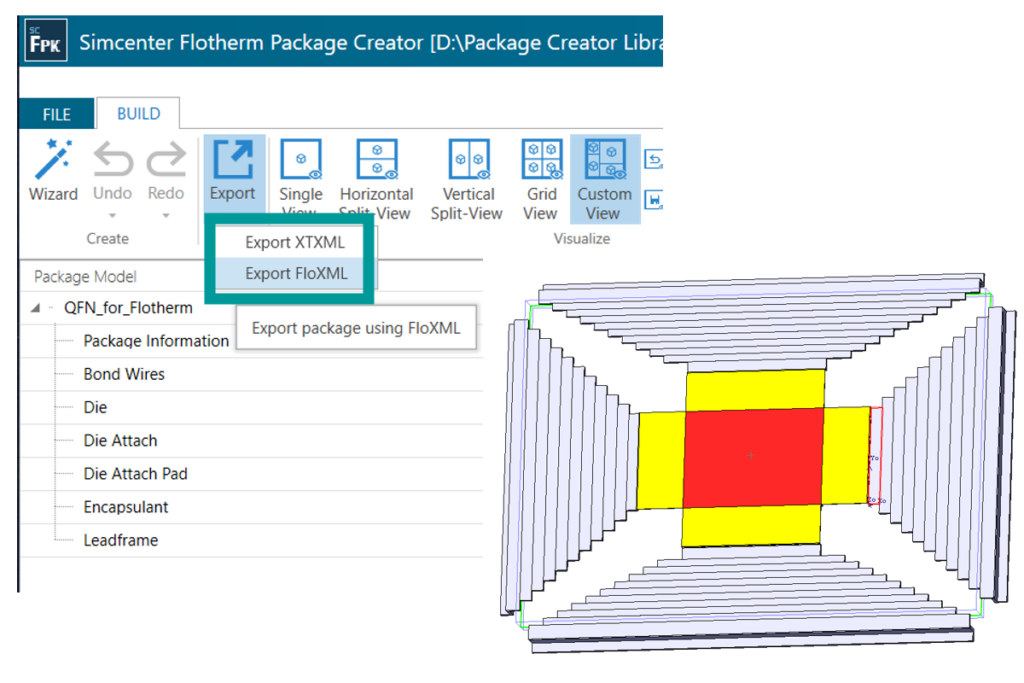

What is Simcenter Flotherm Package Creator? If you are not already using it – Simcenter Flotherm Package Creator helps engineers easily create accurate detailed, 3D CAD based, electronics chip package thermal models in minutes for direct use in PCB & system level electronics cooling simulation.

Previously, users were able to export from Package Creator in XTXML format to Simcenter Flotherm MCAD bridge. You can now export 3D geometry based detailed thermal model information from Package Creator to Simcenter Flotherm using the FLOXML export type.

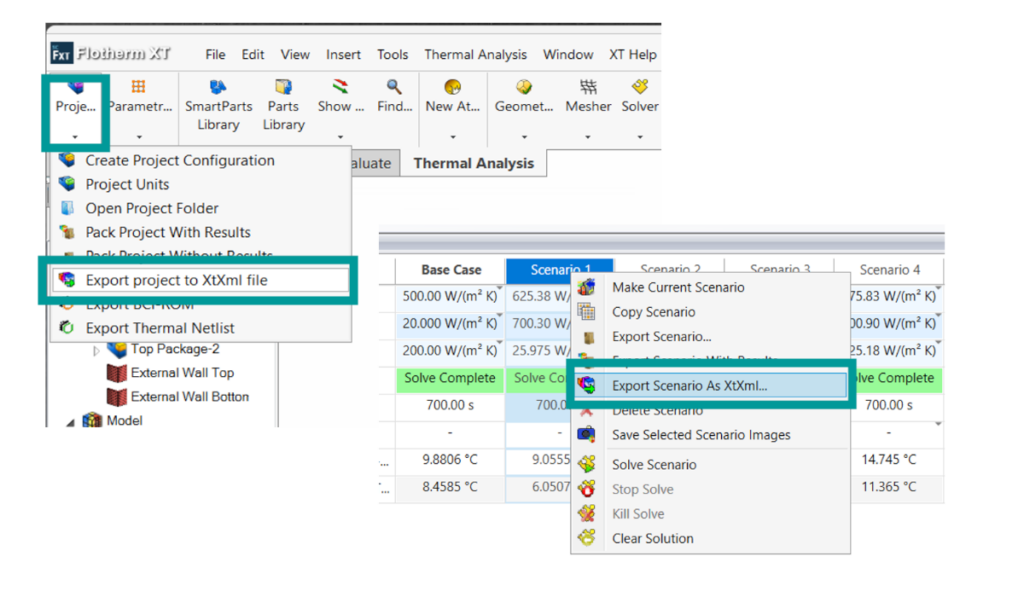

Export your entire project in the XTXML format

To aid inter-tool transport within Siemens Simcenter tools you can now export your project in XTXML format. You can export :

• an entire project with geometry and model setup data

• a project from a parametric study for a single or all scenarios

Go faster and stay integrated

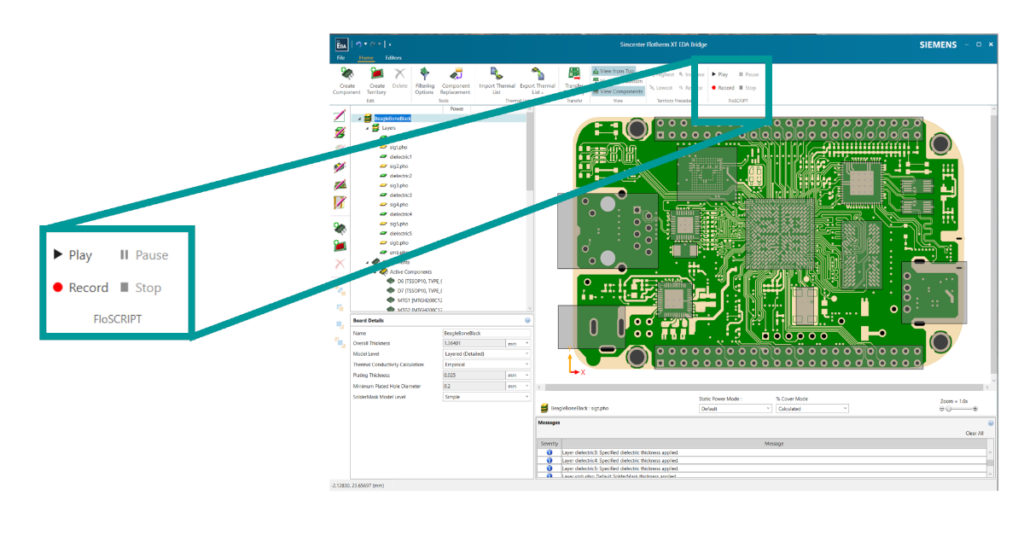

Use scripting for efficient, consistent workflows

There is now functionality to automate certain workflows that you would perform in the main window of Simcenter Flotherm XT. You can record a workflow and then playback with alternative designs using controls added to record and playback scripts. Scripts can be edited to create custom workflow alterations.

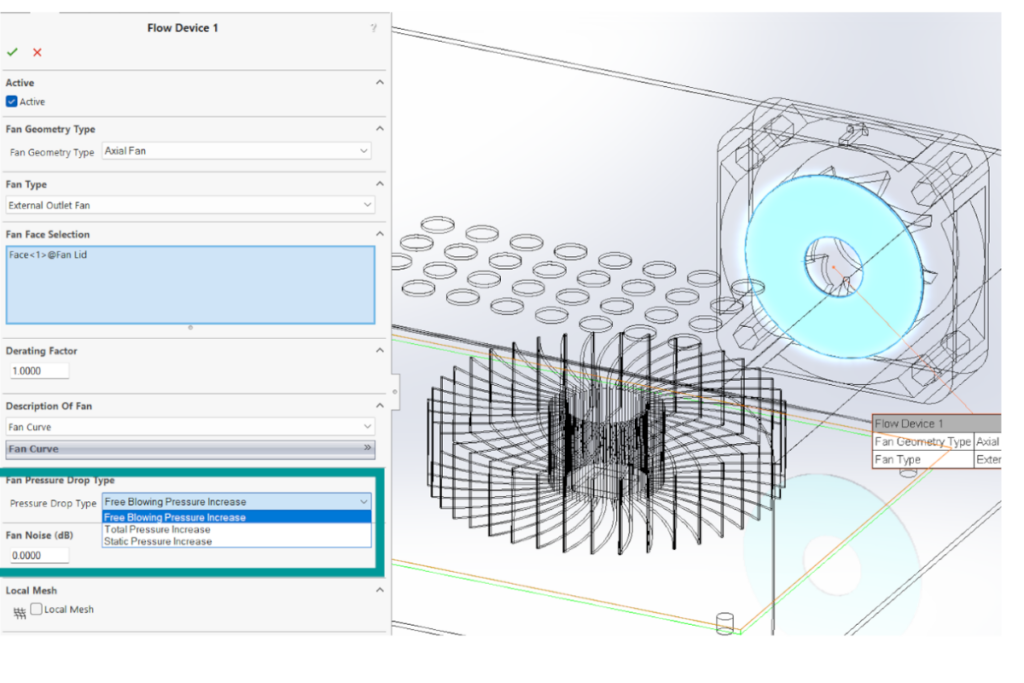

Enhanced Smart Part Fan Modeling calculation options

Fan and Flow Device using SmartParts is now more capable for free blowing pressure drop treatment for most situations. Options now include a Total Pressure based calculation and Static Pressure based calculation.

Smart Part Goal Setting

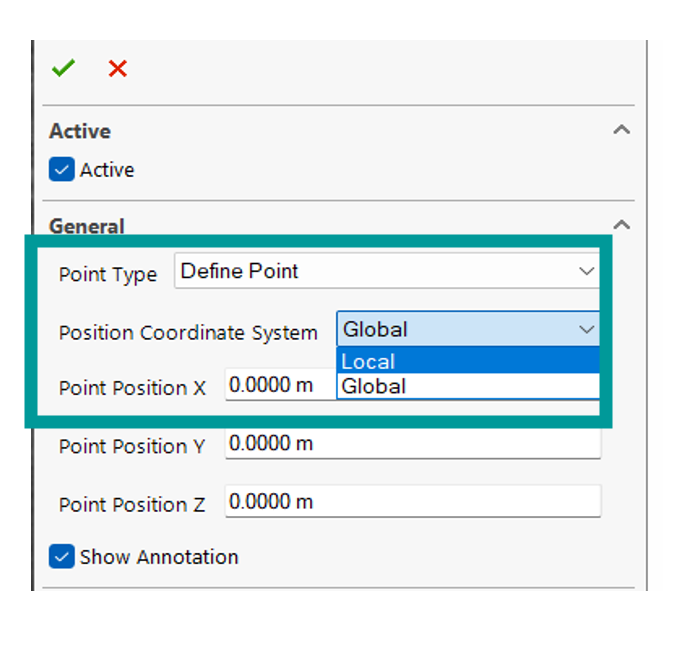

When assemblies with point goals based are saved in the library and reused in different projects, you can opt for global coordinates to be used or you can now set point goals based on the local coordinate system of the parent assembly. This means if you change the location of the assembly the point goal remains and also if you re-use it in a different project.

Download Simcenter Flotherm 2310 versions now

Users can download latest versions from Siemens Support Center