Is Simcenter Motorsolve 2020.2 Update Install Pending?

If your answer is yes, that’s a mistake. This blog will hopefully convince you why Simcenter Motorsolve 2020.2 should be update complete.

Design motors based on realistic workloads

The typical design sequence of electric machines involve many iterations, especially during early stages of design. And identifying the most important load points for a given design problem is difficult.

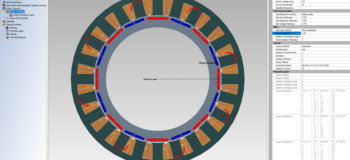

In Simcenter Motorsolve 2020.2, we’ve added a user defined duty cycle based performance analysis capability. Therefore, the new capability allows the designers to incorporate realistic vehicle behavior into the design process and calculate losses for an arbitrary load profile.

By importing the machine performance requirements from Simcenter Amesim, Simcenter Motorsolve can use this data to advance the design process. The losses and top five most important load points are calculated.

Included are a number of standard drive cycles for the automotive sector. The users will have to supply the vehicle torque and rotor speed information to use the new feature.

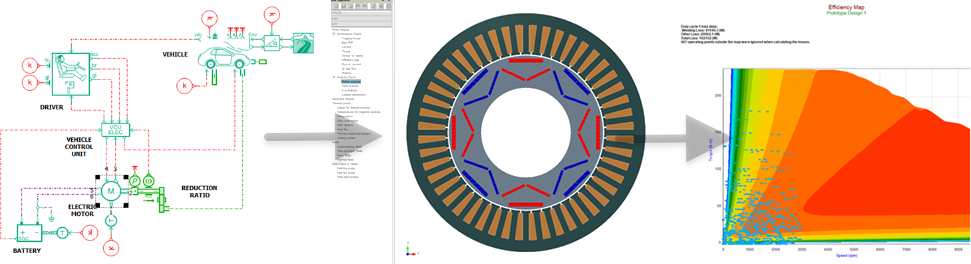

Pulse Width Modulation analysis with arbitrary voltages

Calculating machine performances based on measured or arbitrary voltages using low frequency electromagnetic finite element analysis based calculations is time consuming or impractical, often due to high signal frequencies.

In Simcenter Motorsolve 2020.2, the Pulse Width Modulation (PWM) analysis option can determine these results. An additional option of simulating arbitrary voltage profile based performance calculations is now part of the PWM analysis capability

Therefore, digital twins or model calibrations can be based off of measurements imported directly from dynamometers or other sources.

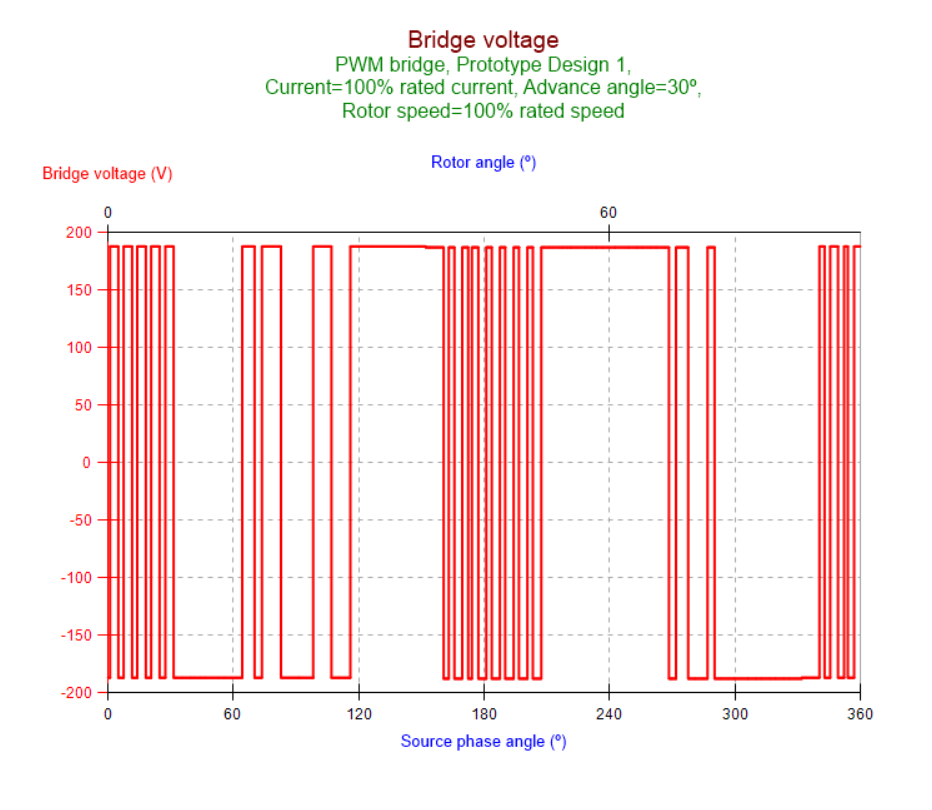

Design Halbach Array electric motors in Simcenter Motorsolve 2020.2

New templates support the creation of Halbach array patterns with even and odd numbered magnet segments per pole. It also includes the ability to apply unevenly distributed segments with user defined magnetization directions. Here’s an excerpt from “What is a Halbach array and how is it used in electric motors?” by Danielle Collins highlights their benefits:

“…electric motors based on the Halbach array offer measurable benefits over conventional designs, including high power density and high efficiency. One of the enablers of these benefits is that a Halbach array motor does not require laminations or back iron, so the motor is essentially ironless. This significantly reduces eddy current losses and hysteresis losses… “

Maximum torque and flux weakening control

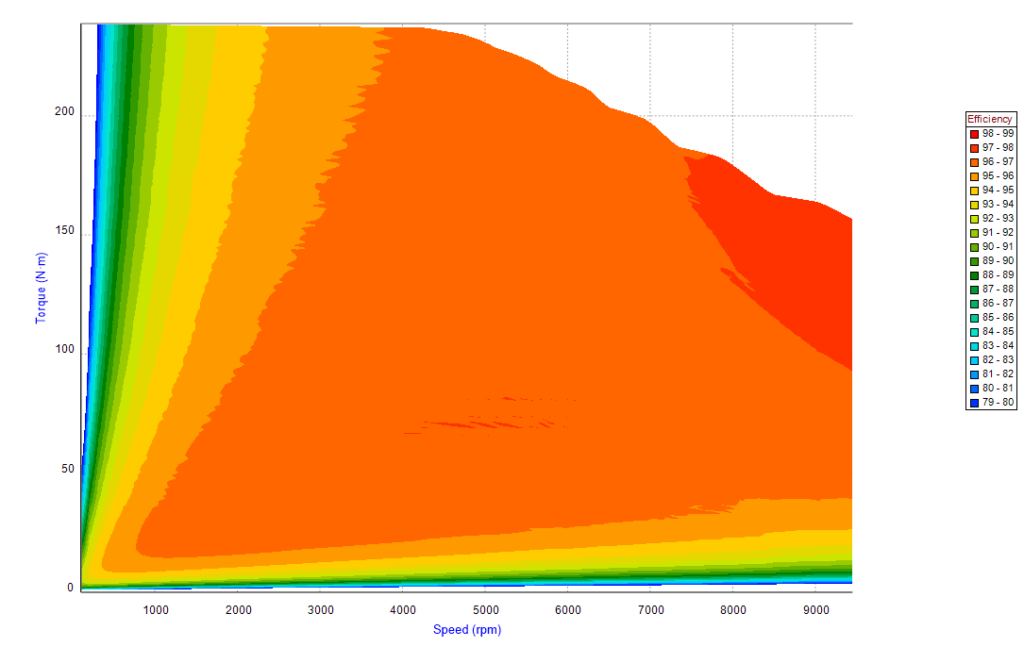

Motor performance is highly dependent on the control strategy. This link impacts performance parameters like efficiency, loss and power output. In Simcenter Motorsolve 2020.2, the maximum torque per amps and flux weakening control strategy based optimal load point calculations have been added. Consequently, you can plot efficiency maps, loss maps and several others using these new control strategies.

With the newly added duty cycle based analysis feature, the design process is significantly improved on account of being based on realistic vehicle behavior and control strategies.

Simcenter MAGNET 2020.2 is also available, and in this blog post we cover the new stuff. The enhancements made to the modeling capabilities of permanent magnets with regards to their irreversible demagnetization behaviour and defining permanent magnets as strong or weak in Simcenter MAGNET 2020.2 also apply to Simcenter Motorsolve.

In the upcoming webinar Drive cycle based design and optimization of electric machines, some of the new features in Simcenter MAGNET and Simcenter Motorsolve 2020.2 will be presented. Please register for this webinar today.