Simcenter Flotherm XT 2020.1: What’s new

The latest release of Simcenter Flotherm XT 2020.1 – CAD Centric electronics cooling software and sister product to Simcenter Flotherm, has just been announced. Let’s take a look at new functionalities that continue to support the creation of a thermal digital twin of an electronics product during development and also enhance productivity and workflow.

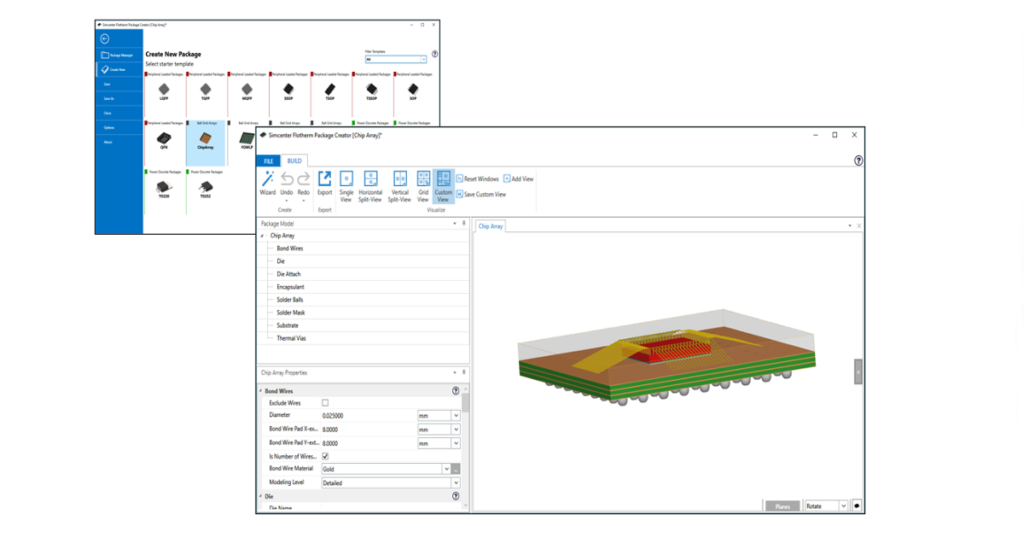

Accelerating package thermal modeling – chip array added to Simcenter Flotherm Package Creator

The prior release, Simcenter Flotherm XT 2019.3, featured the launch of Simcenter Flotherm Package Creator to accelerate thermal modeling through fast and guided generation of clean CAD geometry based, detailed chip package models. Newly added to Simcenter Flotherm Package Creator is the Chip Array style (CABGA) package type under Ball Grid Array Package families. This enables engineers to quickly create Chip Array type detailed package models to integrate into 3D electronics cooling models.

For more information on Simcenter Flotherm Package Creator, please view the fact sheet or watch the recent recorded chip package modeling on-demand webinar that reviews appropriate package modeling vs the design stage and includes a demonstrated workflow.

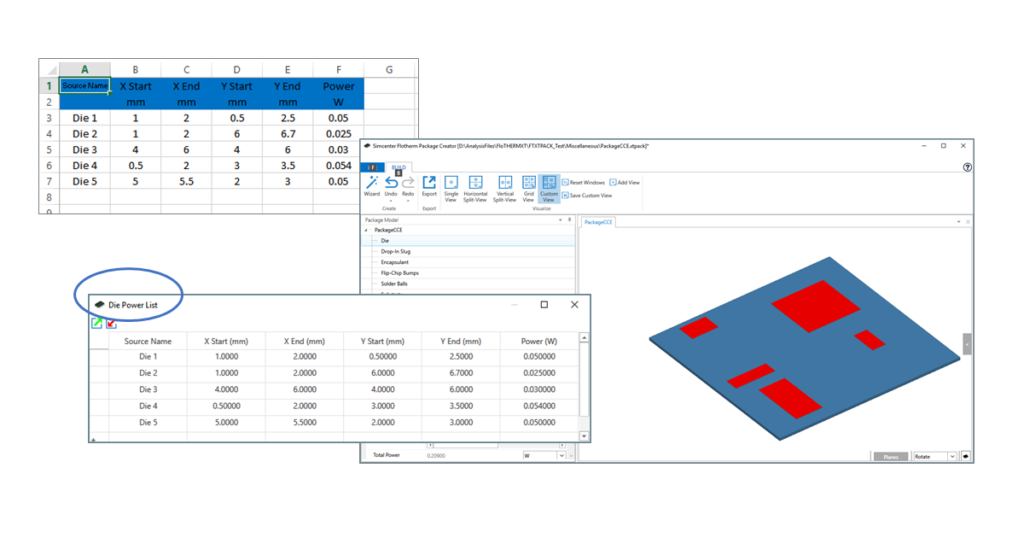

Multiple heat sources on a die – Excel import ease of use

In response to user feedback, a faster way to build and specify power to multiple heat sources on a single die in an electronics package model has been created in Simcenter Flotherm Package Creator. Users can now directly import from Microsoft Excel, the data to specify position, size and power applied when creating a package.

Transient electronics cooling simulation – Simplified thermostatic control

From modern electronics, e.g smartphones and tablets, to power electronics in electric vehicles – transient thermal modeling has increasingly been adopted to better model in-use scenarios and evaluate power control strategies to go beyond the prediction of critical component temperatures for reliability purposes.

Performing full 3D transient thermal CFD analysis is computationally intensive and simulation time for long studies is often limited during competitive electronics development timescales so providing options to simplify and speed the set up, run, stop and restart of multiple transient analysis cases is very advantageous.

Transient modeling with simple thermostatic control in Simcenter Flotherm XT 2020.1 helps this in 2 related ways:

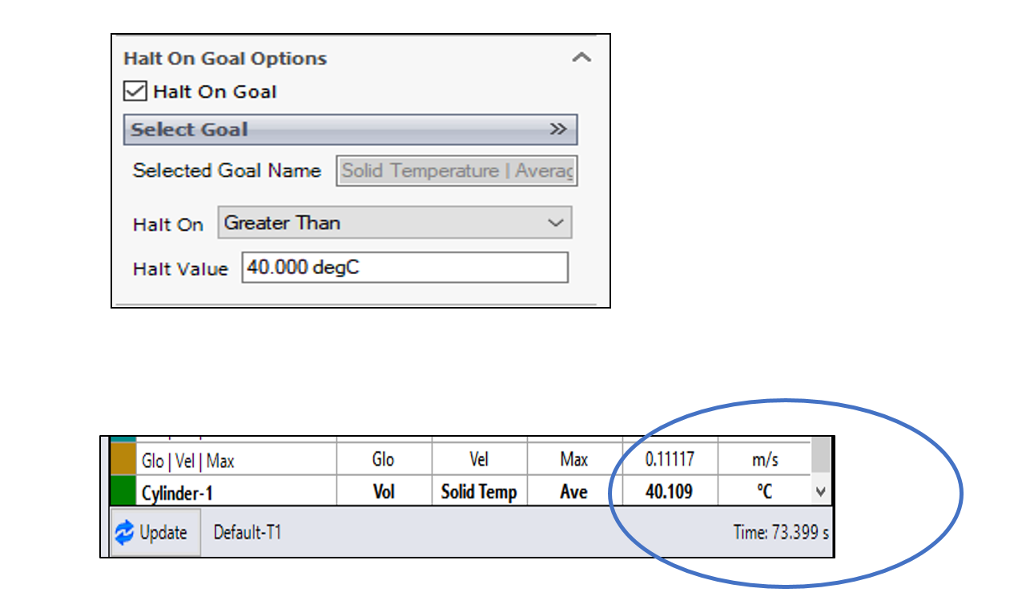

1. Using goals to stop a transient thermal analysis – Halt on Goal

Goals are possible to set as a temperature of a component, a surface, junction temperature or otherwise. To halt a simulation based on reaching, exceeding a temperature, it is as simple as setting this criteria in the “Solution Control” sheet now

The time the simulation reaches this goal during a simulation run and halted is then reported.

2. Using halt on goal in a parametric study to run multiple transient simulation cases

The ability to halt simulations with a goal enables more efficient scheduling of multiple transient studies as part of a parametric study. More usefully, at Simcenter Flotherm XT 2020.1, this allows you to run cases consecutively using a previously halted simulation end point as the start point for the new simulation with different logic and new halt on goal criteria applied.

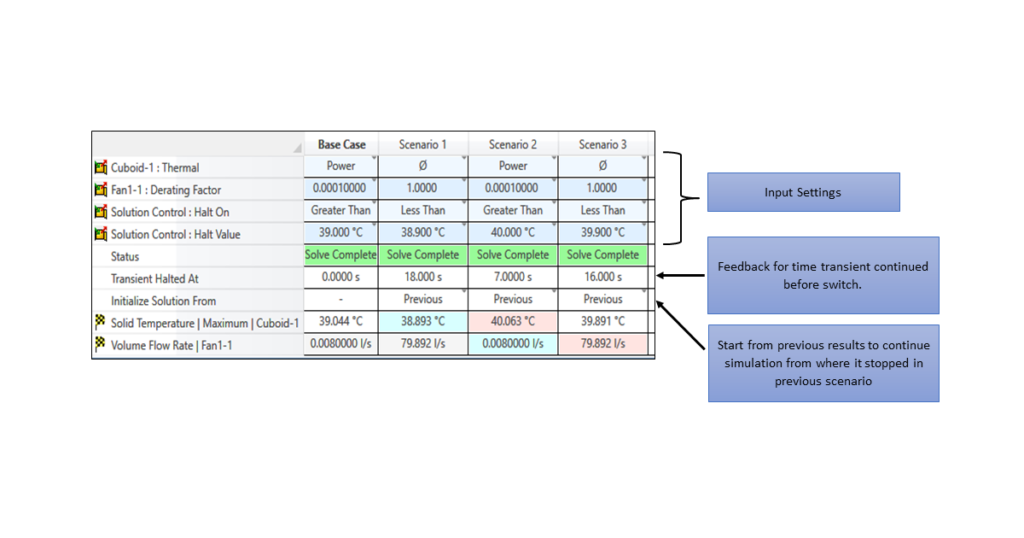

Consider a simple case: If you want to run a study with certain simulation control logic applied until a temperature is reached, stop the simulation, and then restart a simulation with different criteria, such as a component power setting or fan control logic option applied that would cool device until a lower temperature is reached, then you can do this easily. Below is an example parametric study tabular set up to illustrate:

The very simple parametric study above is broken down into a base initiation case and then 3 scenarios:

- Power switched off and a fan activated when temperature exceeded

- Power switched back on and fan deactivated when temperature reduced sufficiently

- Power switched off and fan activated

Please view a linked blog by Kelly Cordell-Morris – “Simple Thermostatic Control” for a more detailed look at transient modeling using the new halt on goal capabilities in Simcenter Flotherm XT.

EDA data integration – Simcenter Flotherm XT EDA bridge save/load and library enhancements

Simcenter Flotherm XT EDA bridge, for PCB model generation including component layout and trace, now includes the ability to save work during PCB ECAD data import process easily. This uses file extension *.edabridge. Now during a transfer or import the user is prompted if they want to save the current file or create a new file. Also, if a project includes a PCB transferred from EDA Bridge with components from a local library of one user and this is moved to a different user without the components in their library, then, the new user will be prompted to add the components to their own library.

Downloading Simcenter Flotherm XT 2020.1 and other resources

For clients – please go to Siemens Support Center to download the latest software release.

For an introduction to package thermal modeling from simple to detailed package thermal modeling, please view the on-demand webinar: Accelerate package thermal modeling in electronics cooling design

Download the factsheet on Simcenter Flotherm Package Creator

Related Blog: Simple Thermostatic Control in Simcenter Flotherm XT 2020.1