How to create and optimize the design of your external gear pump

Dive into the pump modeling world and find out how the Simcenter Amesim helps you create and optimize the design of your external gear pump.

A large number of industries widely use external gear pumps. Thanks to their low maintenance, and high reliability they became over the years the favorite choice for generating flow in fuel systems. The small number of parts associated with the design makes it an easy pump to build.

The simplicity of a mechanical assembly does not necessarily mean the simplicity of the design.

Easily and quickly create a pump model

Simcenter Amesim provides a simple and efficient way to build a detailed model of an external gear pump. The CAD Import tool helps in creating a pump 1D model easily and quickly starting from a CAD file.

Check out the video below to get to know more about this pump model generation workflow:

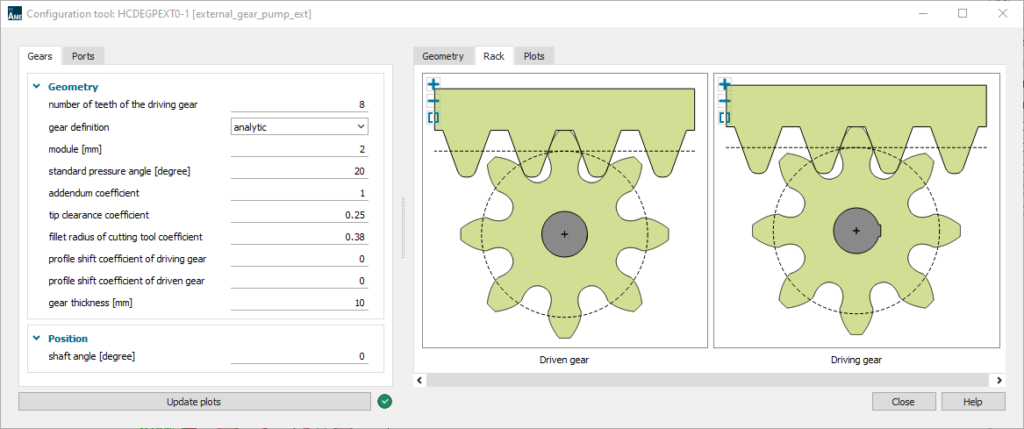

Building a pump from CAD is not the only way. Simcenter Amesim also provides a solution for those who need to start from nothing and build their own design.

Involute spurs gears design are generated using geometric parameters in order to get a customized gear set up.

What actually makes a good design for an external gear pump?

We can think of the number and the shape of the gear teeth as well as the shape of the inlet and outlet ports for instance as they are clearly visible characteristics.

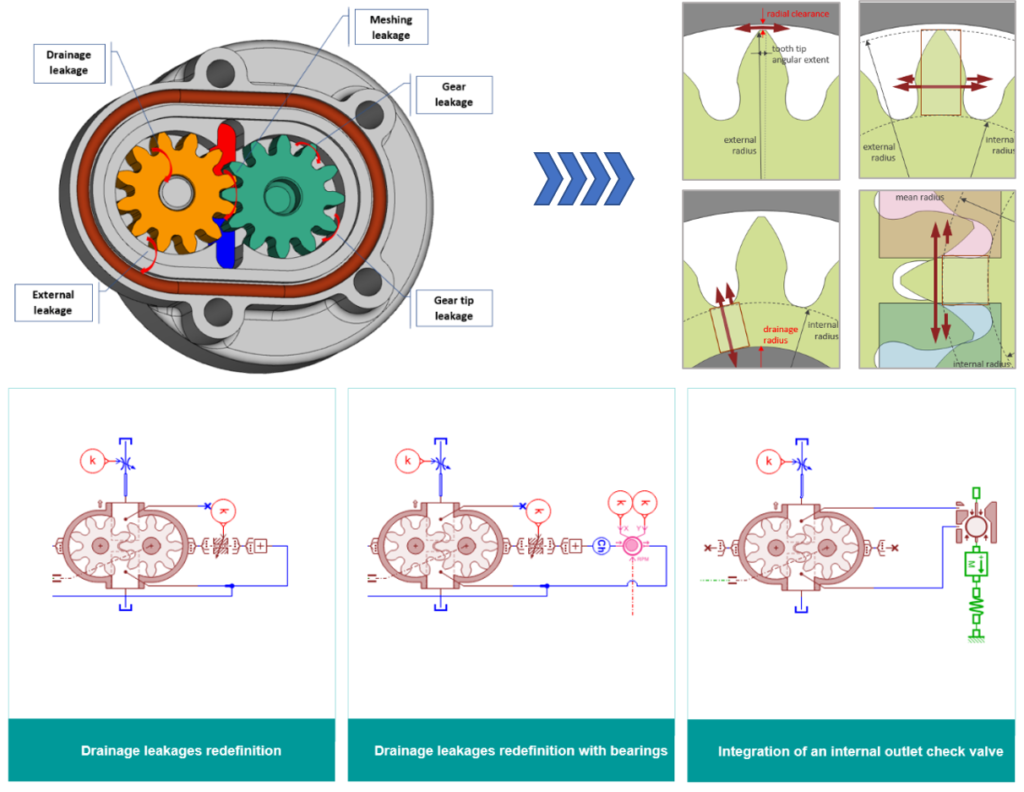

Many factors are often ignored when designing a pump as they seem secondary. The leakages are a typical example of the “small details”. But leakages have a non-negligible impact on both the volumetric efficiency and the pressure peaks. Thus, greatly influence the performance of the pump.

Hereafter you will find the accounted leakages and some examples of their usage.

The Simcenter Amesim external gear pump model integrates most of the leakages that occur within the pump case. As a result, the accuracy of the pump performance assessment increases.

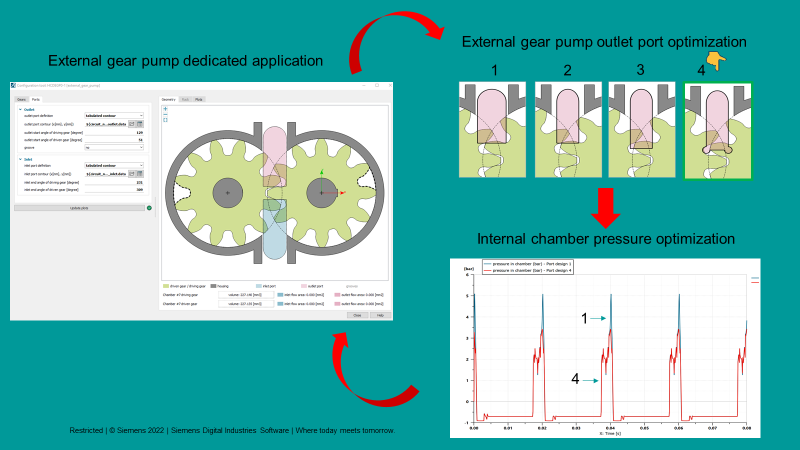

Optimization of the ports shape design

Now, let us focus on one of the biggest concerns while trying to optimize an external gear pump design: the outlet port shape. The shape and position of the outlet port have a great influence on several characteristics of the pump.

Here are the main:

- The amount of flowrate transferred at the pump outlet and thus the volumetric efficiency. (Hydraulic performance analysis)

- The pressure peaks at the meshing zone impact the mechanical efforts on the gear. (Torque analysis)

- The flow and pressure pulsations are the sources of the fluid-born noise created by the pump. (NVH analysis)

Conclusion

I hope you enjoyed this first look at the current capabilities that Simcenter Amesim offers for external gear pumps modeling. Keep in mind that external gear pumps are among a group of volumetric pumps such as Vane pumps or Gerotor pumps for which Simcenter Amesim provides a couple of tools and apps. The purpose is to make easier and more user-friendly the detailed modeling of pumps. Feel free to reach us for more information.

Learn more about Simcenter system simulation tools:

- Watch the video Simcenter System Simulation – Innovating the future

- Discover the latest new capabilities of our solutions