Gil Morris: How crucial is the education of future engineers for the industry?

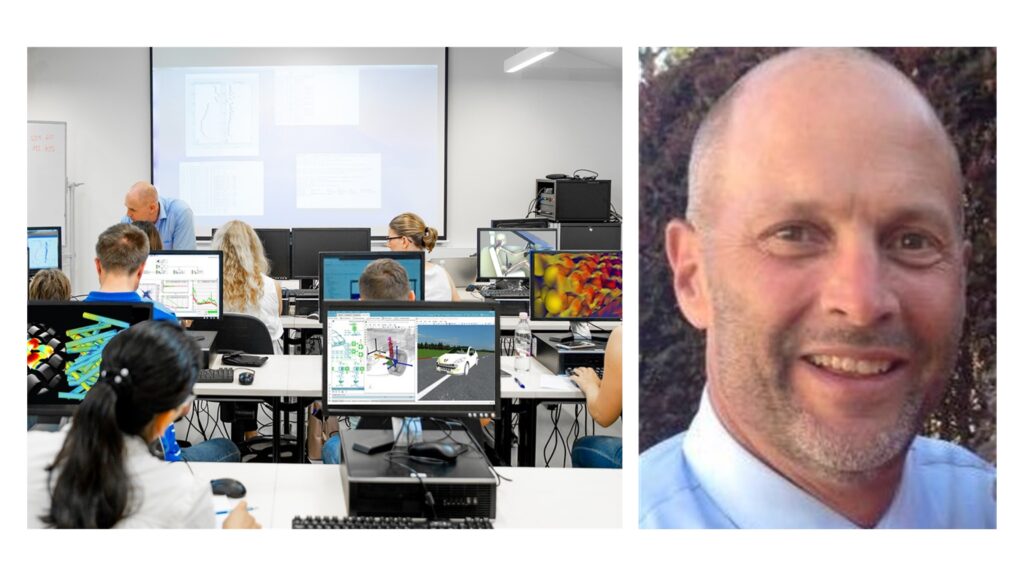

Why testing and simulation should be part of universities’ programs for future engineers education? In part two of the Simcenter for Academia series, we’ll be talking to some of our leading experts — engineers with years of experience — to hear their opinion of today’s market challenges and how Simcenter is supporting the academic community. Today, we’ll look back at an exciting engineering career with Gil Morris, Project Manager for the Siemens Academic Partnership Program.

You have had a really diverse career as an engineer. Can you give us a few highlights?

Gil Morris: After receiving my mechanical engineering degree from Purdue University, I started at General Motors in an engine manufacturing plant. My first job involved designing a test for gear noise, which I knew nothing about. So I took the initiative and taught myself and worked with my colleagues to learn the technology. While working at GM, I completed my masters in engineering from Purdue via a distance-learning program. After that, I transferred from manufacturing into product engineering, where I developed engine accessory noise requirements. These were the early days of the ‘V-cycle’.

After more than 12 years at GM, I left and joined what was then LMS International* as a sales engineer. There, I was the major account manager for the Asian automotive OEMs in the US, including Honda, Toyota, Nissan, and Hyundai. (*LMS International was acquired by Siemens in 2013.)

What is your role today?

G.M. : For several more weeks, I’ll be the program manager of the Siemens Digital Industries Software Global Academic team. Over the past years, we have developed an engagement model for strategic universities. Our main goal is to use our hands-on experience with a few select universities to develop and communicate best practices and lessons learned.

Our engagement model is both a top-down and bottom-up approach. We connect university executives with industry leaders while simultaneously working with faculty and students to evolve engineering education curriculums. The end goal is to address the skills gap we are seeing emerge in the world of engineering.

What are currently the main challenges you see in the industry?

G.M.: This skills gap is definitely one of the main challenges. There’s an aging workforce of engineers retiring (and I count myself amongst them shortly.) Unfortunately, many of us are taking our years of hands-on, self-taught experience with us. And we are seeing a tremendous boom in digitalization. I might add this is even more relevant with the pandemic.

Digitalization and the new speed of innovation are creating more complex engineering challenges that require out-of-the-box thinking. We have to make sure the future engineers are getting the right type of educations to meet these challenges.

In your opinion, what type of skills will tomorrow’s engineer need?

G.M.: Companies expect new employees to hit the floor running. They need to be productive the moment they start. This not only includes understanding multiple engineering disciplines and mathematics and physics theory, but being able to communicate effectively, integrate into a team successfully, and use a variety of tools efficiently.

How crucial is the education of the future engineers for various industries?

G.M.: Educating the next generation of engineers is crucial to success on so many levels. The next generation will need to understand multiple disciplines, not just mechanical engineering, electrical engineering, computer science, computer fluid dynamics or mechatronics as separate fields. They will have a strong base in various areas to understand how everything interacts and works together.

To do this right now, students need hands-on, real-world experience. This is why industry interaction is so important. This could take a variety of forms: a real hands-on industry problem to solve as a class or hands-on hardware and laboratory experiments and projects. As a company, we support a variety of student teams involved in events like the World Solar championship Challenge. These types of academic team events give students excellent hands-on experience. Across our organization, we also offer a variety of internships from starter levels to masters and PhD exchanges that let students share experiences and branch into real industrial world issues.

Educators need to be more connected with companies and industry experts to truly understand the industry’s needs. This isn’t something you can just read in a book or on a blog. Also, I believe that academics and professors should all promote a multi-disciplinary approach and hands-on experiences as part of their programs. Examples could include a series of courses involving multiple engineering disciplines, a senior seminar or capstone course prior to graduation, mandatory internships or team project participation.

Many recent graduates do not meet the hiring expectations for starting engineering roles. As an industry leader, what can Siemens do to help?

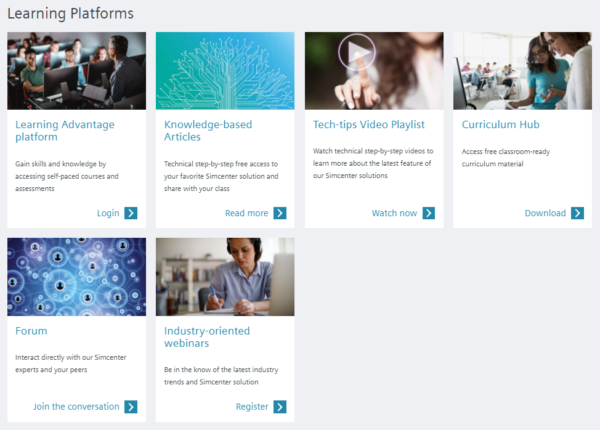

G.M.: Our role as Siemens is to help connect industry know-how to academia. This means sharing our own experience and our customers’ experience. Our role is also to provide digital tools and training material to facilitate the learning experience. We should be thought leaders for academia, sharing insight on challenges facing industries as a whole.

Can you give a concrete example of this skills gap?

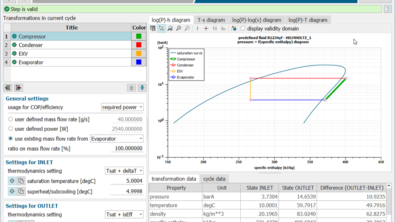

G.M.: One critical area where recent grads are lacking is their understanding of simulation and testing. And why it is important. From my point of view, simulation and digital twins are key tools to solve problems, but these simulations and digital twins are only as good as the data that goes in. Likewise, testing knowledge is equally important in knowing how to properly set-up a test and what to test — especially when validating a digital twin. Understanding both testing and simulation and how they work together is key.

Why should testing and simulation be part of every engineering curriculum?

G.M.: Labs, R&D departments, test benches, test tracks, workshops, warehouse hangers – where ever the hands-on part took place – have traditionally been the locations where the real engineering took place. With the paradigm shift to simulation and digitalization, the computer screen has taken over this role. But, we can’t let the next generation forget about the importance of testing and how it validates what you are seeing on that screen. Indeed, the days of prototype after prototype are long gone and lab time and testing know-how will become even more precious as the next generation deals with more advanced digital twins and even AI-driven applications.

Well, congratulations on your upcoming retirement. Any words of wisdom you would like to share?

G.M.: In my 35 years of industry experience, the most talented engineers I have met understand the importance of physical testing and advanced simulation techniques. Actually, they understand how best to use the tools at hand as well as the limitations. It takes the right balance of both simulation and testing to solve a problem. I think the Simcenter portfolio is perfectly positioned to be the tool to do just this. It facilitates a digital thread from start to finish and covers a broad spectrum of issues — mechanical design, fluid dynamics, and heat transfer can all be tackled using one common set of tools. Teaching Simcenter solutions at university will help fill the gap between education and industry.

But why stop there? Before I go, I would also like to point out that we are branching out to STEM students graduating from high schools as well. It is never too early to start encouraging engineering as an exciting career choice.

To conclude, on behalf of the Simcenter family, we would like to thank Gil Morris for his more than 20 years of dedicated service and wish him all the best with his future endeavors.

Previous article related to Simcenter for Academics blog post series

- The future for the next generation of engineers is…VUCA

- Future-ready: simulation and testing as part of a core engineering education

- Jan Leuridan’s vision about educating the next engineers’ generation with testing and simulation

Additional resources – success stories

- The ITA prepares new engineers

- UNIVERSITY OF CINCINNATI: Empowering the next generation of engineers with leading-edge technology

- Siemens solutions lead Agoria Solar Team to the win

- Connect Students with Real-Life Experience: The PurdueTracer

- Welcome to the next generation of Simcenter users

Visit our webpage