How electrified trailers are changing truck stability: a system simulation study

Introduction

Electrification is rapidly reshaping the commercial trucking industry, promising cleaner and more efficient transport solutions. Driven by new regulations [1], the electrification of heavy-duty vehicles (HDVs) and their trailers represents is essential to decarbonize freight logistics [2].

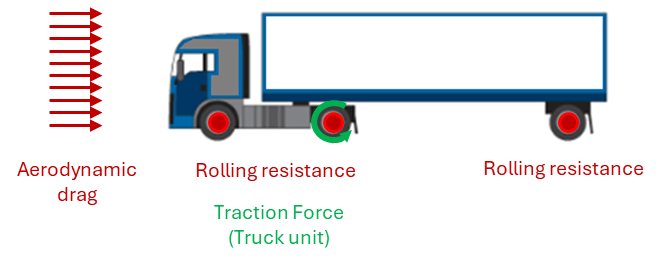

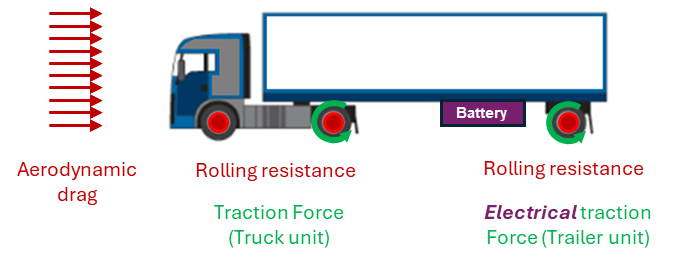

One emerging innovation is the electrified drive axle, or e-axle, integrated into heavy-duty vehicles (HDVs) and their trailers to provide regenerative braking and additional traction. But introducing this technology fundamentally alters the dynamic characteristics of the entire vehicle, bringing new challenges in vehicle stability, a critical safety aspect for heavy-duty trucks.

Our recent simulation-based study dives deep into these challenges, analyzing how electrified trailers interact with existing vehicle control systems like ABS and ESP. The goal: to identify potential stability risks including jackknifing, shaking, and roll-over [3], and uncover how a smart supervisory control system could help ensure safe operation across all driving conditions.

Methodology

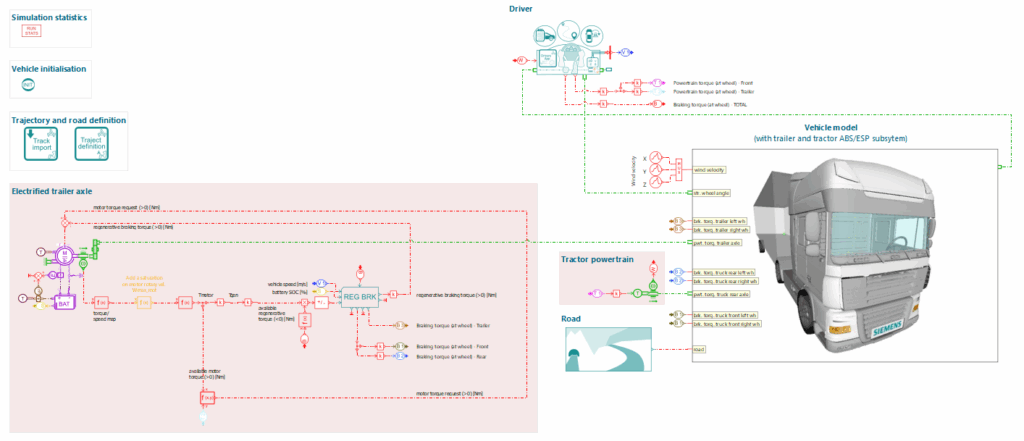

To investigate the complex dynamics of an e-trailer system, a detailed multi-body simulation model was developed using Simcenter Amesim [4]. Simcenter Amesim is a powerful platform for multi-domain system simulation, enabling the modeling of mechanical, hydraulic, pneumatic, thermal, and electrical components within a single environment.

2.1 Vehicle Model Description

The simulated vehicle configuration consists of a 3-axle articulated vehicle: a 2-axle tractor unit coupled with a 1-axle semi-trailer featuring an electrified drive axle. The multi-body template model VDCAR22DOF01 was employed, which is specifically designed to account for critical stability issues in articulated vehicles, including:

- Jackknife: The acute angle formed between the tractor and trailer.

- Shaking: High-frequency oscillations of the vehicle body. (Trailer swing)

- Roll-over: Lateral instability leading to vehicle overturning.

2.2 Control Systems

The model incorporates realistic chassis stability controllers for both the tractor and the trailer:

- Tractor Unit: Equipped with ABS (Anti-lock Braking System) and ESP (Electronic Stability Program) [5].

- Trailer Unit: Equipped with ABS and TCU (Traction Control Unit).

The e-axle’s regenerative braking and electrical traction capabilities are integrated with specific blending strategies. The interactions between these e-axle controls and the conventional chassis stability controllers are a central focus of the analysis.

2.3 Driver Model

An advanced driver model, utilizing Model Predictive Control (MPC) techniques, was implemented. This robust control strategy ensures accurate path following and effective sway control of the trailer, providing a realistic representation of driver inputs during various maneuvers.

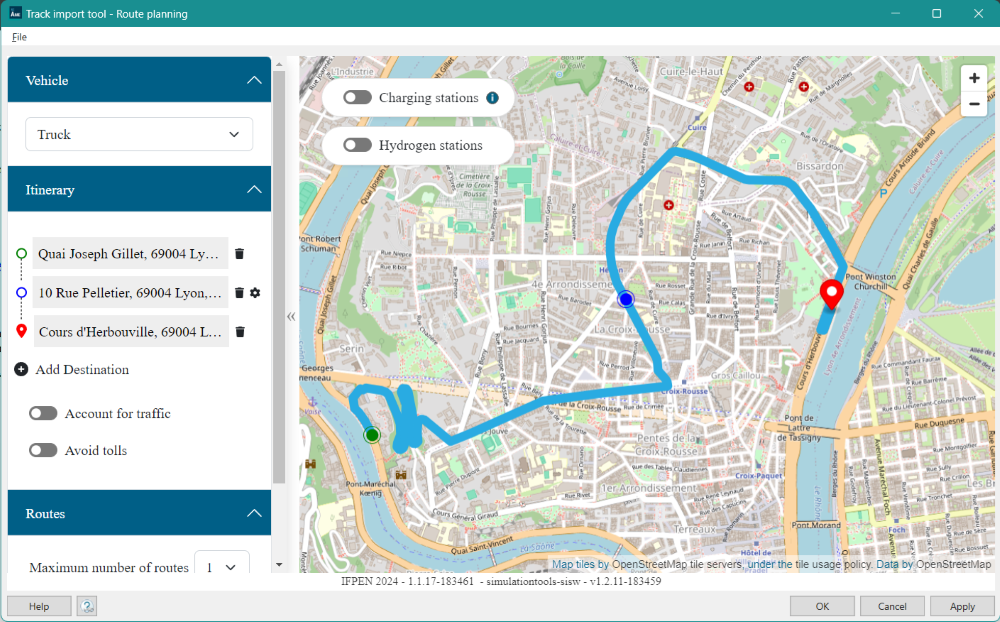

2.4 Test Track Definition

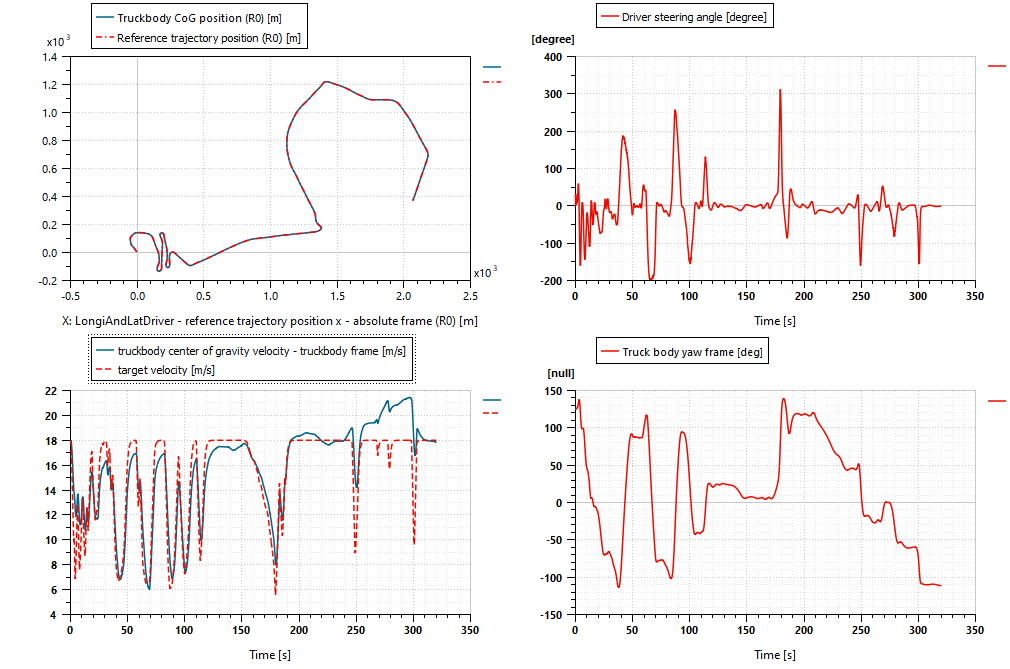

The simulations were conducted on a virtual test track based on a real-world road section in Croix-Rousse, Lyon, France. This challenging route includes significant ascending and descending slopes, which are crucial for evaluating the e-axle’s performance during regenerative braking and traction phases. The varying gradients and curves allow for the assessment of vehicle stability under diverse load conditions and driving scenarios.

Results and Discussion

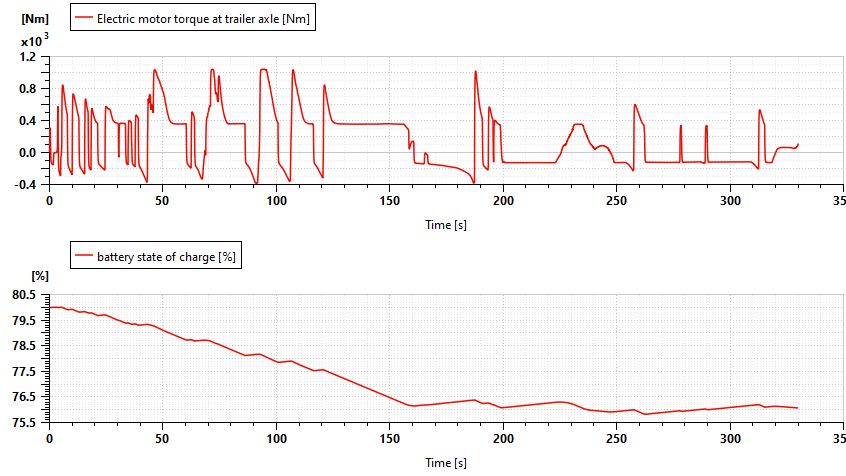

The Simcenter Amesim simulations provided comprehensive data on electric machine performance, battery state of charge (SOC), and overall vehicle dynamics.

3.1 Electric Machine Performance and Battery SOC

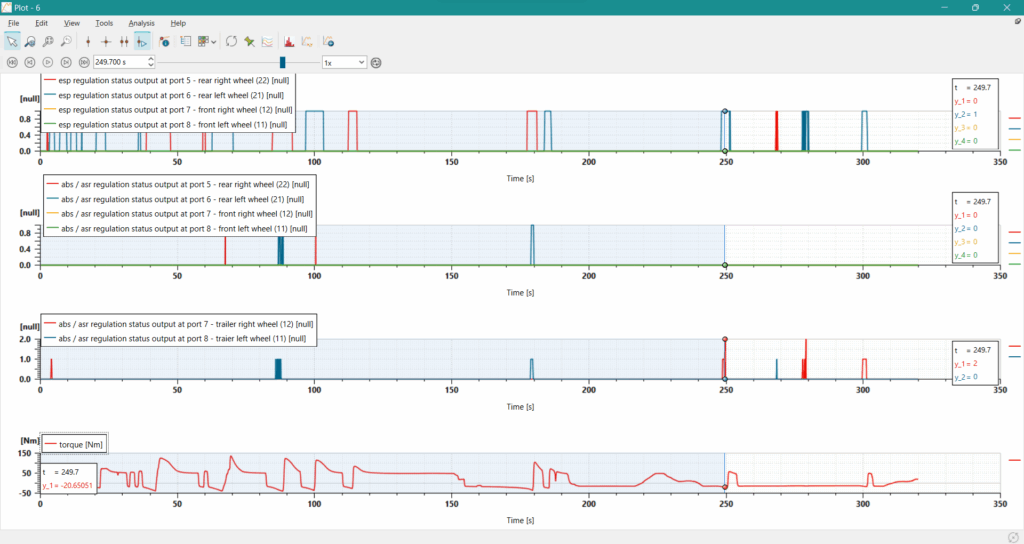

During the ascending sections of the test track (e.g., 0-150 seconds), the e-axle required significant traction torque to assist the tractor. Conversely, during important descending sections (e.g., 250-300 seconds), the e-axle effectively engaged in regenerative braking, leading to a notable increase in the battery’s SOC. This demonstrates the e-trailer’s potential for energy efficiency and reduced reliance on friction brakes. Rapid torque sign switches (from traction to regeneration) were observed before and after overcoming road cornering, indicating dynamic operation of the e-axle.

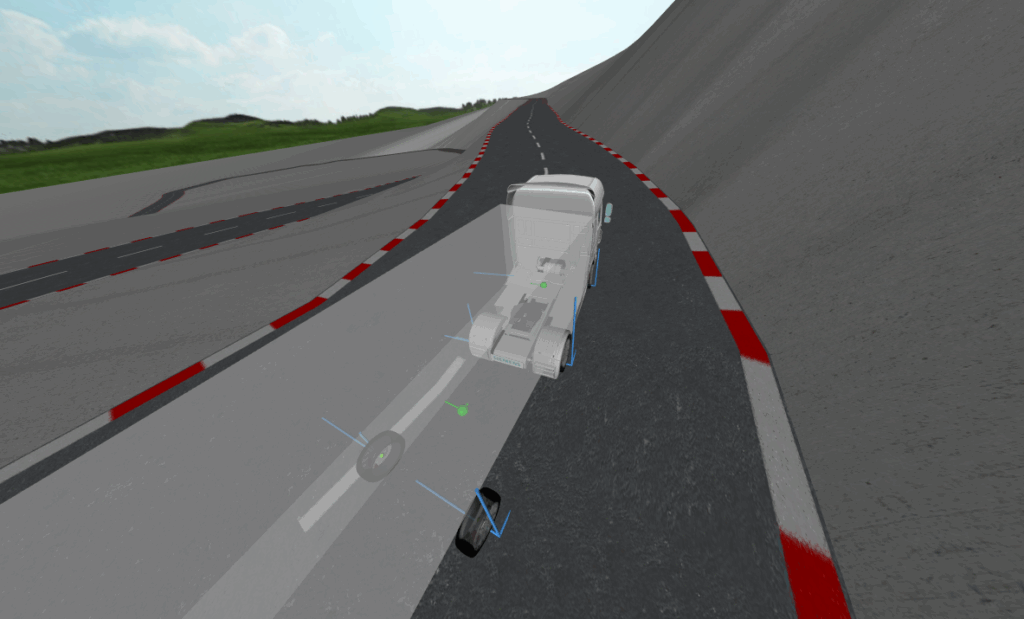

3.2 Vehicle Dynamics and Pathological Situations

The simulations revealed several critical “pathological” situations that underscore the stability challenges introduced by e-axles. One such instance occurred during a combination of significant driver steering input and braking action, where a trailer wheel was observed to be on the verge of losing contact with the road. This scenario, if unmanaged, could lead to a roll-over event.

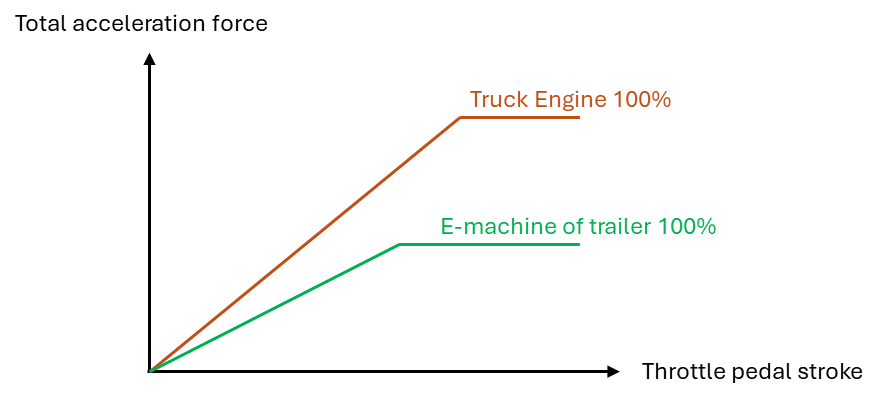

A crucial observation pertained to the interaction between the electric machine controls and the chassis stability controllers. In certain cases, particularly during rapid torque switches or intense braking/traction demands, the individual actions of the ESP on the tractor unit, ABS on the trailer, and the e-axle’s torque control were not harmonized. The absence of a high-level supervisory control system to coordinate these conjoint actions was identified as a significant risk factor. Without such a supervisor, the study indicated that a complete instability of the truck + trailer vehicle could foreseeably occur at higher velocities, highlighting a critical safety concern.

3.3 Implications for Control Strategy Development

The findings emphasize that simply integrating an e-axle with independent control strategies for regenerative braking and traction is insufficient. Effective integration requires a sophisticated, higher-level supervisor that can intelligently blend the e-axle’s operations with the conventional chassis stability controllers. This supervisor would need to dynamically adjust torque distribution, braking effort, and traction forces across all axles to maintain overall vehicle stability under varying road conditions, driver inputs, and e-axle operational modes.

Conclusion

The findings from this study highlight a key takeaway: electrified trailers hold great promise, but they require sophisticated coordination between new and legacy control systems to keep trucks stable and safe. A high-level supervisory control system is essential to avoid dangerous scenarios such as wheel lift and rollover, especially at highway speeds.

If you’re involved in vehicle design, control system development, or fleet safety management, this research offers valuable insights to guide your work. Staying ahead in the electrification journey means embracing integrated solutions that prioritize stability.

Want to learn more about how advanced control technologies are shaping the future of truck electrification? Follow our blog for the latest research updates, reach out to Siemens experts to explore solutions tailored to your needs or try out Simcenter Amesim yourself. Let’s drive safer, smarter, and greener together!

Want to try out Simcenter Amesim for yourself? Sign up for a free 30-day online trial!

References

[1] United Nations Economic Commission for Europe (UNECE). Global Forum for Road Traffic Safety (WP.1). Available at:https://unece.org/transport/publications/consolidated-resolution-road-traffic-re1

[2] European Automobile Manufacturers’ Association (ACEA). Commercial Vehicles: Decarbonisation. Available at: https://www.acea.auto/fact/commercial-vehicles-and-co2/

[3] G. G. P. Van Der Heijden, H. B. Pacejka, and J. M. J. Van Der Knaap, “Dynamic behaviour of articulated vehicles,” Vehicle System Dynamics, vol. 20, no. sup1, pp. 294-307, 1991. (General reference for articulated vehicle dynamics, not specific to e-trailers, but foundational).

[4] Siemens Digital Industries Software. Simcenter Amesim. Available at: https://plm.sw.siemens.com/en-US/simcenter/systems-simulation/

[5] Bosch Global. ABS and ESP: The history of vehicle safety. Available at: https://www.bosch-mobility.com/en/mobility-topics/safety-for-all-road-users/driver-assistance-systems-for-commercial-vehicle/

![[Hyster Yale] How to convert a conventional lift truck into an electric truck?](https://blogs.sw.siemens.com/wp-content/uploads/sites/6/2021/05/HY_Teaser-350x160.png)