Accurate virtual sensing for complex aviation structures

1. The challenge of maintaining aircraft safety

Travelling by plane is nowadays very safe, thanks to frequent maintenance and inspections. The current level of reliability was reached after decades of analyzing past catastrophic events and responding with several aircraft improvements and with the introduction of stricter maintenance rules. Past failures have often been the result of a lack of knowledge on operational stresses and loads, and insufficient maintenance processes to detect complex failures and defects1. Overall, aircraft manufacturers face the challenge to design and operate the highly complex aircraft system/structure, comprising many parts and components, materials and connectors, flight systems, electronics and controls systems, etc. Aircrafts must last for decades and endure challenging and variable operational conditions. Moreover, a single local failure can have severe system-level consequences, up to an aircraft crash. Physical maintenance schemes are therefore scheduled, aiming at understanding the state or condition of the aircraft, its subsystems and components, and making all necessary repairs at the right time, but leading to significant aircraft downtime.

Wouldn’t it be great for aircraft operators to perform much more measurements on the aircraft, even in operational conditions? Such practice could yield real-time insight into the loads, the aircraft parameters … that can be analyzed to identify initiating failures early.

Unfortunately, this is not yet feasible today. One aspect is that each additional sensor will contribute to the overall cost as well as introduce additional weight. This also results in additional performance requirements, cost and weight of the system that processes these measurements. Moreover, some components and subsystems are not easily accessible for instrumentation. As a result of these challenges, the number of sensors that can be installed in an operational aircraft is limited. Today, it is therefore not yet possible to detect the initiation of failures, monitor degradation evolution, or directly measure the performance (e.g. static and dynamic response) at every possible location.

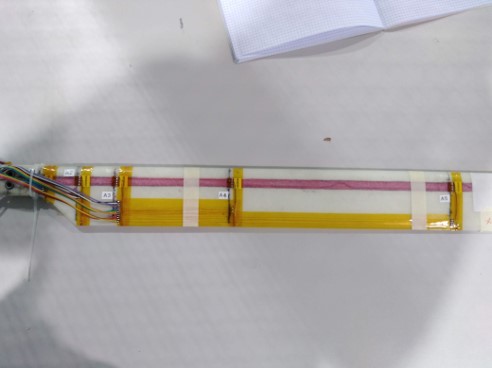

The materials used in modern aircraft add yet another challenge to its design and operation. For example, composite materials have the benefit of delivering the same level of strength as metals, while weighing significantly less, which contributes to the aircraft fuel efficiency and lowers the operational cost. Although composites require less maintenance than traditional materials, they are typically more expensive to fix when they do need a repair. Composite materials have complex failure modes, which makes it challenging to do the correct measurements over the full aircraft to monitor their condition. To address this challenge for composite laminates, Material Technologies Labs in Leonardo SpA supports scientific research into on-line monitoring of delamination growth in laminates. The strength and stiffness of composite structures reduce due to delamination, which can lead to loss of structural integrity and potentially failure of the structure. The ability to better estimate and monitor local structural and materials properties is therefore of great interest.

2. Ph.D. research results: Accurate parameter and load estimation for complex aerostructures

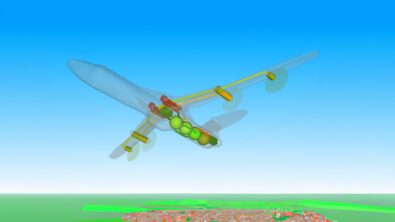

Considering the above, aircraft manufacturers are highly interested in capturing the aircraft state and condition more effectively, considering the benefits this can bring for aircraft operation and safety. This motivates new research for more accurate and robust estimation methods, as well as research for on-line monitoring of complex systems, including optimal sensor placement and Virtual Sensing (i.e. get more insights out of test data by leveraging accurate numerical models). Along these lines, Roberta Cumbo pursued her Ph. D. research project1, achieving multiple contributions to the field of accurate estimation of parameters and loads for complex aerostructures.

An important base technology for the research has been the Kalman filter, a widely established mathematical algorithm that combines noisy measurements series over time with a model of the system to estimate the state of a dynamic system. Roberta’s Ph. D. research adopted the Augmented Kalman Filter (AKF) formulation to solve joint input/parameter/state estimation1. A Virtual Sensing strategy was pursued to estimate unmeasured quantities by readily combining experimental and numerical data of the analyzed system.

The Ph. D. research led to new methodologies to achieve accurate and robust estimation techniques, and produced further industry-driven research outcome to ensure applicability in real-life aircraft structures:

- Increase the robustness of Kalman filtering methods. Research results reported include:

- Model calibration, reduction and virtual sensing, to allow using more accurate yet efficient models within the Kalman estimation workflow2

- Advanced Optimal Sensor Placement techniques for robust sensor selection to ensure system observability. This enables optimal sensor placement for Kalman-based input estimation3. This key contribution is further explained in Section 3.

- Extend and enable the usage of Kalman filtering for unexplored application domains: This research delivered further technology innovations to address the aircraft estimation challenge.

- A rotating helicopter blade has been investigated and addressed with the Kalman-based state and input estimation framework4

- Research into on-line monitoring of composite delamination growth in the laminates has been worked out5 in close collaboration with Leonardo SpA. As mentioned above, the use of composites materials represents a key challenge – with interest to optimally design and define them in the aircraft that is built, and to be able to monitor the material characteristics over time, during operation, and learn early about possible failure initiation and degradation over time.

3. Optimal sensor placement: Motivation and achievements

Given a set of measurements, the system observability determines if joint input/parameter/state estimation can be performed. Therefore, being able to determine a-priori if, for a given sensor layout, input/parameter/state estimation can be carried out is key for its successful application to complex aerostructures and to ensure robustness of the overall methodology.

As part of the PhD research, two advanced optimal sensor placement strategies3 have been developed that not only provide sensor sets that guarantee system observability, but also yield a minimal sensor set, where each sensor is ranked based on its importance with respect to the system observability. Whilst guaranteeing observability, this feature also allows to assess the costs and benefits of removing sensors or expanding the overall sensor set. Furthermore, instrumentation constraints can be considered, such that only locations viable for instrumentation (e.g. enough clearance, not interfering with structural components) are selected.

Key insights regarding system observability, obtained during the development of these optimal sensor placement strategies, have been leveraged to develop a novel recursive parameter estimation approach to monitor composite delamination growth5. More specifically, every system input or parameter to be estimated requires one additional sensor to be added to the structure. In the case of composites delamination monitoring, this would lead to an intractable number of required sensors. Leveraging the inherently recursive nature of delamination (similar to crack propagation), a practical Virtual Sensing approach has been developed that still guarantees system observability, even for a reduced set of sensors.

These advanced optimal sensor placement strategies and their associated capabilities have been integrated into the Simcenter 3D Smart Virtual Sensing software [6, 7 & 8] as the Optimal Sensor Placement solution and is available to its users to leverage these capabilities and apply these to their structural load estimation applications.

4. Conclusion and outlook

By means of Roberta’s Ph. D. research, fundamental steps have been taken towards robust joint input/parameter/state estimation methodologies that have been demonstrated and validated [1-5] and enable accurate Virtual Sensing for Complex Aerostructures.

As next research steps and outlook, and leveraging the continuous and rapidly evolving data-driven fields of machine learning and data-based engineering, Roberta’s Ph. D. research methodology and application achievements will allow to even more adequately handle model uncertainties and its effect on optimal sensor placement, perform advanced Kalman filter tuning and move from specimen-level to medium and large-scale level damage detection and monitoring for composites materials – building towards the application of Virtual Sensing for Complex Aerostructures in operation and its use for aircraft operation and safety.

Key insights and methodologies from Roberta’s Ph. D. research have been integrated into the Simcenter 3D Smart Virtual Sensing software solutions and are available to its users to leverage and apply these to their structural load estimation applications.

Acknowledgements

The research work leading to this publication has been performed by Dr. Roberta Cumbo in the frame of the project “SINCRO – a general Strategy for load and parameter IdentificatioN for helicopter main Rotor systems”, which is a Baekeland mandate supported by VLAIO (Flemish government agency Flanders Innovation & Entrepreneurship). A Baekeland mandate provides individual researchers the opportunity to carry out a PhD in close cooperation with the business / industrial sector.

References

- Roberta Cumbo, Joint Kalman-based input/parameter/state estimation for structural applications, PhD dissertation, KU Leuven, Faculty of Engineering Science, June 2025. ↩︎

- Cumbo, R., Tamarozzi, T., Janssens, K., Desmet, W., Kalman- based load identification and full-field estimation analysis on industrial test case, MSSP 117, pp. 771-785, 2019. ↩︎

- Cumbo, R., Mazzanti, L., Tamarozzi, T., Jiranek, P., Desmet, W., Naets, F., Advanced optimal sensor placement for Kalman-based multiple-input estimation. MSSP 160, 107830, 2021. ↩︎

- Cumbo, R., Tamarozzi, T., Jiranek, P., Desmet, W., & Masarati, P., State and force estimation on a rotating helicopter blade through a Kalman-based approach. Sensors, 20 (15), 4196, 2020. ↩︎

- Cumbo, R., De Gregoriis, D., Danzi, F., Kumar, A., & Naets, F., Recursive parameter estimation for the on-line monitoring of delamination growth in composite structures, SHM 0(0), 1-20. ↩︎

- Xiaoting Kou, Jonathan Melvin, “Simcenter 3D Smart Virtual Sensing – Unveiling the Magic”, Simcenter Blog, January 15, 2024. ↩︎

- Xiaoting Kou, Jonathan Melvin, “The new revolution in testing: Simcenter 3D Smart Virtual Sensing and Model-based system testing”, Simcenter blog, May 31, 2024. ↩︎

- Siemens Digital Industries Software, Simcenter 3D, Retrieved 2025. ↩︎