Rimac Technology: Winning the ultimate car battery race?

Yes, yes…we will talk about that Bugatti car battery

But first…a short history lesson

Zagreb, Croatia isn’t really on the traditional automotive map. In the old days circa 1980 or so, there weren’t that many places-to-be when it came to car manufacturing: Detroit, Munich, Torino, Toyota, Wolfsburg…But Zagreb? Not top of mind.

Zagreb, for those of you who remember, wasn’t ‘behind the Iron Curtain’ but it was part of Yugoslavia, a communist but non-Soviet-Union-aligned country. This meant that things like cars were slightly easier to get your hands on in Zagreb than for example East Berlin or Prague.

But it was still the time of the Cold War and Western cars (amongst many other items) were for the privileged few. Normal folks in Zagreb lucky enough to get their hands on some wheels either drove relicensed, locally manufactured versions of popular Western cars, like the enviable VW Golf 1 or the more common Zastava Skala. But maybe there always was a car culture in Zagreb and we just didn’t know it in the West?

Yugoslavia produced a version of the Golf 1 under license from VW. The Zastava, based on the Fiat 128, was also exported to the West, redubbed the “Yugo”. It was famous for its 3990 USD price tag. Some of the other cars you might see would be imports from Eastern Bloc countries, like an East German Trabant…

The new-world EV map with Rimac Technology

Fast forward 45 years or so and we will need to redraw that automotive map – especially if you are talking EVs and the car battery. Looking at e-motor cities today, your list probably reads more like Shenzhen, Austin, Xi’an and…Zagreb.

Putting the Chinese powerhouses and Tesla aside, Zagreb (actually Sveta Nedelja, a small town on the outskirts of Zagreb – but why split hairs?) is home to the Rimac Group, which owns Rimac Technology as well as 55% of Bugatti Rimac.

Rimac might not be a name on everyone’s list, but it will soon be …at least amongst the nouvelle petrolhead crowd thanks to the group’s joint venture. Known as Bugatti Rimac and with global headquarters (also) in Sveta Nedelja, this iconic hyper-car brand is 45% in the hands of Porsche (and therefore the VW Group) and 55% in the hands of the Rimac Group. Bugatti Rimac employs 435 people — 300 in Sveta Nedelja and 135 at its bespoke assembly atelier in Molsheim, France.

Automotive excellence runs in the blood

With solid connections to automotive legends, one can safely surmise that Rimac Technology is a serious place for serious engineers and serious engineering. And the proof is in the pudding: Rimac Technology is a market-leading Tier-One supplier in automotive electrification. Known for its advanced car battery and e-powertrain technology, Rimac Technology employs around 1,000 people who innovate, engineer and manufacture batteries, powertrains and electric vehicle components for major OEMs like Bugatti, Porsche, BMW, Hyundai and CEER.

Presenting the Bugatti car battery

Take the Bugatti Tourbillon as an example of the team’s engineering excellence. Working from its car battery and e-powertrain know-how, the Rimac Technology team closely collaborated with Bugatti Rimac’s engineering teams to design a power-packed 800V hybrid system that seamlessly integrated with the Tourbillon’s whopping 8.3-litre V16 engine.

But how does one go about innovating when it comes to something like a Bugatti 800V battery pack which leans more towards the luxury power market when it comes to its car battery than the industry standard 400V systems. Where are the pitfalls in the 800V world and how do you go about solving them?

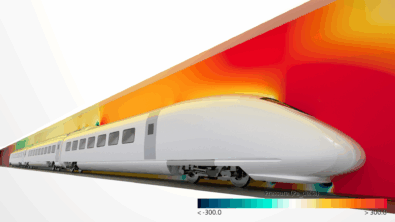

The obvious challenges are known issues. EV batteries age and lose their performance levels; charging times can be problematic and then there is safety – especially with a bespoke car like the Tourbillon. EV batteries require extensive testing to assess safety risks like fire, explosion and toxic gas release. These tests, which may include exposing the battery to extreme heat, mechanical impact, or short circuits, are performed in controlled laboratory environments to identify failure modes and improve overall battery design and safety. Taking a page out of top-end motorsports like F1 and Extreme H, the EV industry is seeing a shift towards advanced simulation as a solid source for testing processes and test data as well.

Enter CFD simulation

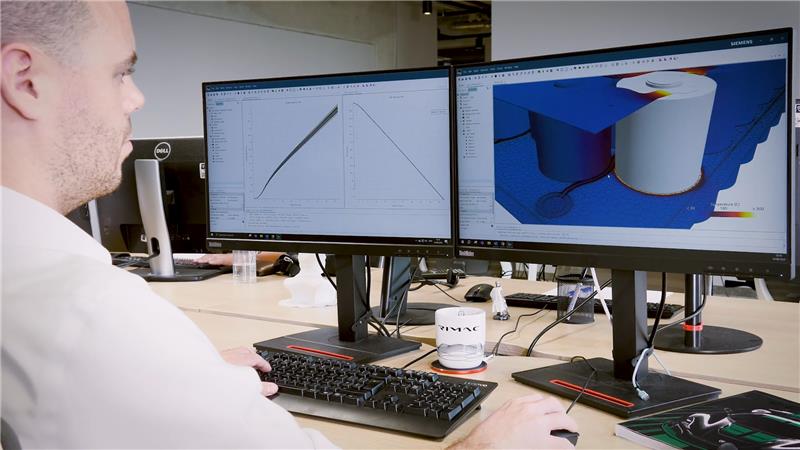

To see just how far the industry has come in advanced battery simulation, we headed down to Zagreb and were lucky enough to catch George Oates, a true expert in battery systems.

“We are constantly trying to improve battery thermal management. We need to design a thermal management system for the battery pack that doesn’t take up too much space, doesn’t cost too much and is relatively easy to manufacture. These are all really big requirements for us, and we need to make sure we’ve optimized for those three and safety, of course,” says George Oates, Lead Thermal Engineer at Rimac Technology.

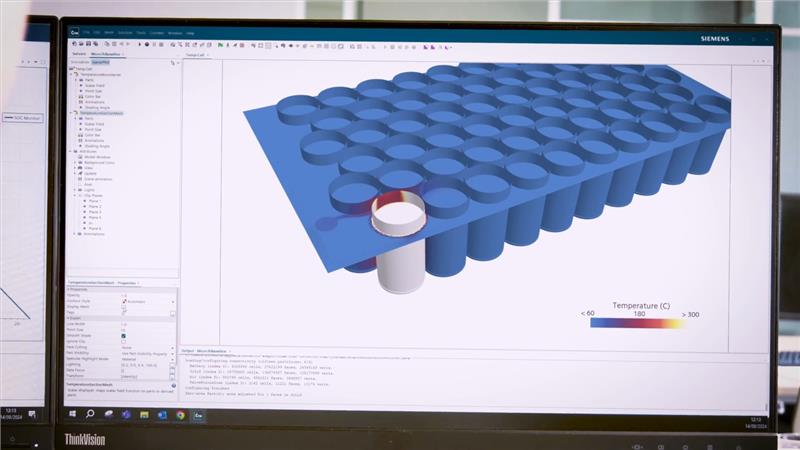

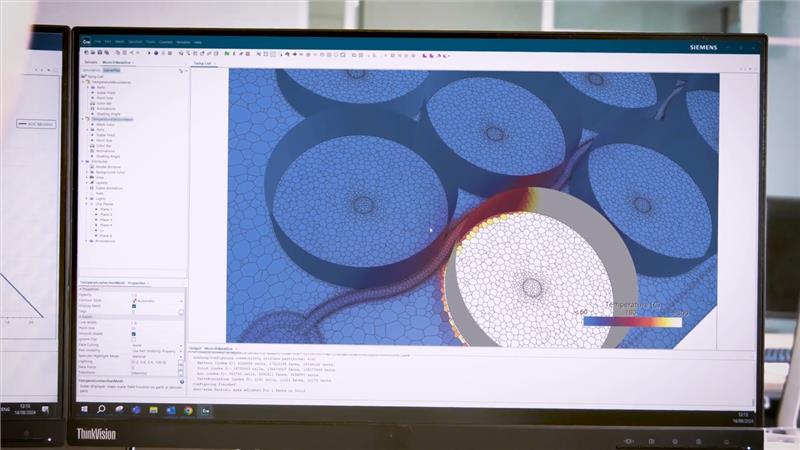

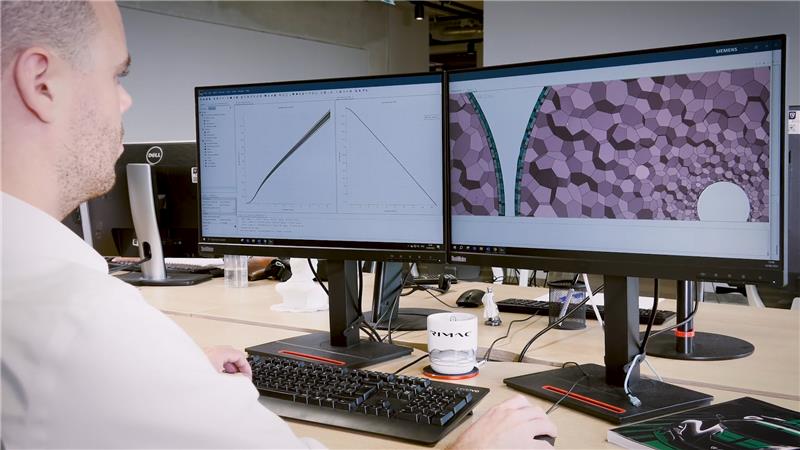

“Simulation and CFD are really key to this engineering process. The manufacturing of physical prototypes is really expensive and time-consuming. When that’s compounded with the expensive and dangerous nature of testing some of these requirements, such as thermal runaway and short circuits, Simcenter STAR-CCM+ is a really valuable tool for us. It allows us to quickly iterate designs and test them against those difficult and dangerous requirements in a very efficient and cost-effective manner,” he adds.

The benefits are clear. The team can design car battery packs according to customer specs quicker and more accurately while minimizing costly prototyping and — when it comes to testing — quite a lot of the dangerous and expensive steps can be completed virtually using the Simcenter digital twin.

“To correctly predict the outcomes of these events, we need to model the entire battery pack. The most time-consuming part of the whole simulation workflow is geometry preparation and meshing. The mesher inside Simcenter is really robust. We’re able to mesh everything non-conformal and using tools such as the thin mesher enables us to really quickly get our geometries from CAD into CFD, and then we can actually start solving the physics.”

“We need less testing, less prototypes because we’re failing less tests. We’re able to deliver prototypes to the customer with much higher maturity,” adds George Oates. “The Simcenter CFD simulation process has allowed us to generate designs with much higher maturity, much faster, so we’re able to pass our requirements first time, most of the time.”

For Rimac Technology this is all good news. It allows the company to accept much tighter deadlines from the customer as well as cutting design and development costs. Which, by the way, leaves a lot more time for those serious engineers to do some wickedly serious engineering…. for example, the technical masterpiece that is the advanced electric powertrain on the Bugatti Tourbillon.

Cutting-edge car battery and e-powertrain tech

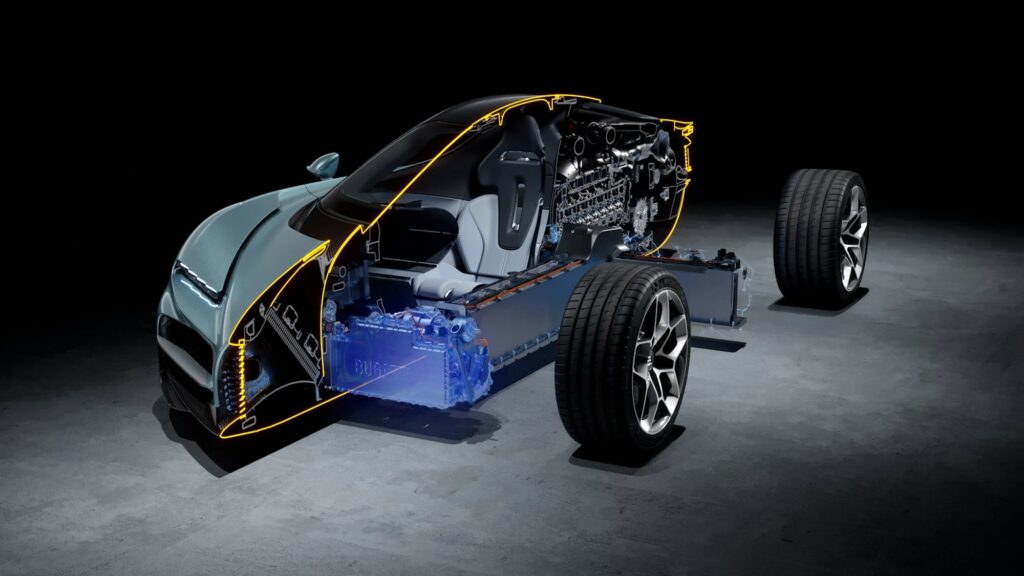

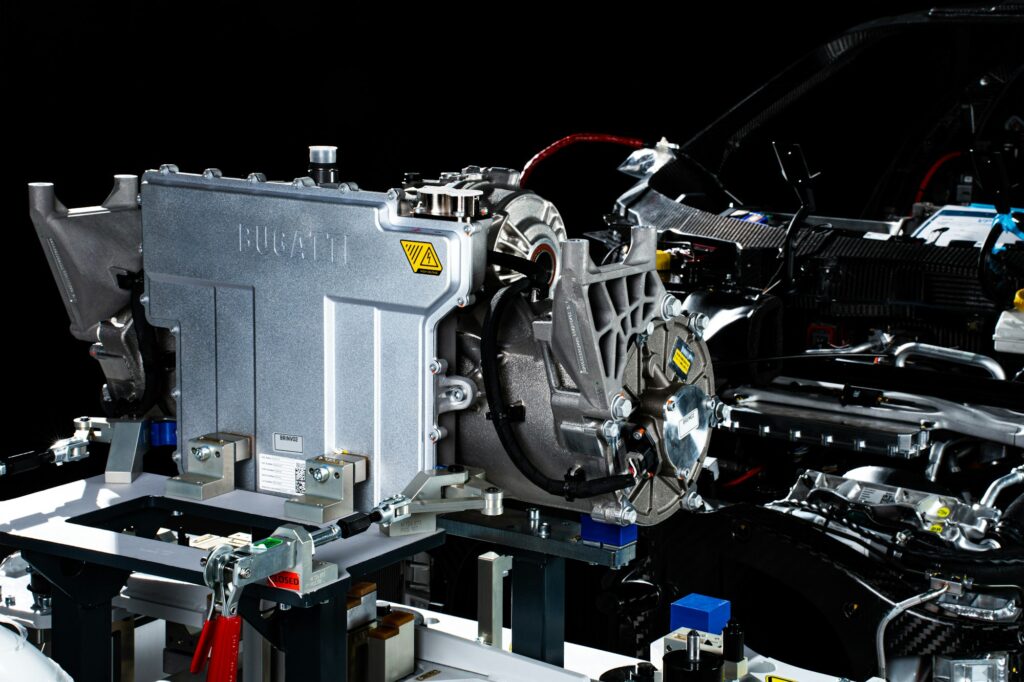

In close collaboration with Bugatti Rimac’s engineering teams, Rimac Technology designed a sophisticated 800V hybrid system that seamlessly integrated with the Tourbillon’s 8.3-liter V16 engine.

The Rimac Technology electric powertrain features three high-performance electric motors – two mounted at the front axle and one at the rear. These motors collectively produce 800 horsepower and can hit a massive 24,000 rpm, powering an e-axle with one of the highest power densities in the industry.

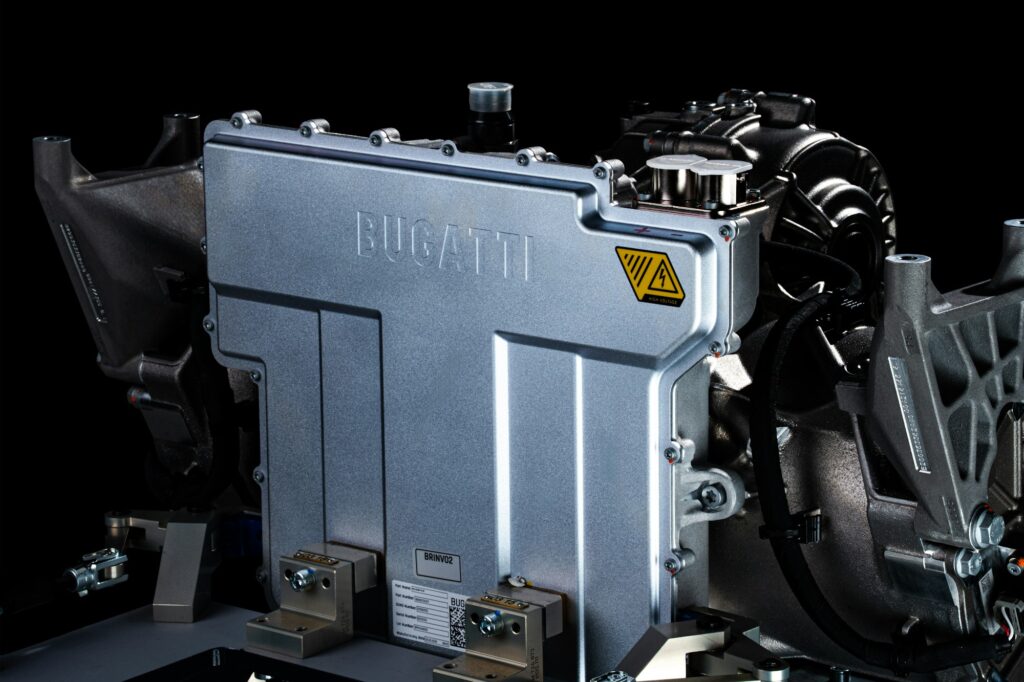

The electric powertrain features the Rimac Silicon Carbide inverter technology and proprietary software for high performance, exceptional efficiency and operational safety. Even with all this powertrain tech (three motors, the battery pack, the software and the V16 engine itself), the new Tourbillon is both shorter and lighter than its predecessor, which was solely powered by the legendary quad-turbo W16 engine.

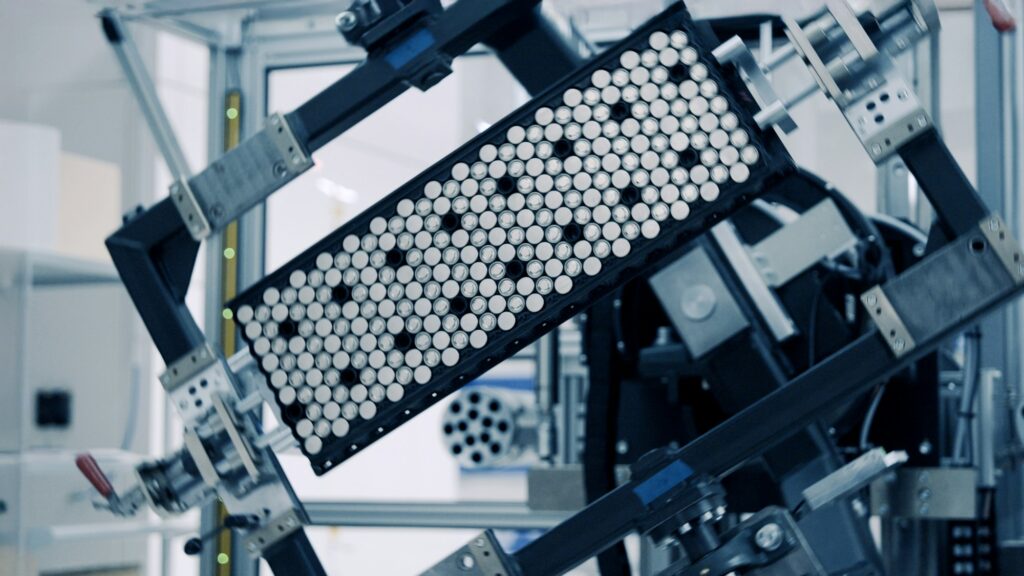

The car battery pack itself features an innovative T-shaped design that neatly serves as an energy storage system and a structural vehicle component. This 800V battery system incorporates Rimac’s advanced oil-cooling technology and over 1,500 individual cells immersed in oil, managed by the company’s fifth-generation Battery Management System (BMS). The BMS, developed in accordance with ASPICE Level 2 standards and supporting the highest automotive safety standard (ASIL D), ensures optimal performance, longevity, and safety throughout the battery’s lifecycle.

“The Bugatti Tourbillon project represents a perfect showcase of Rimac Technology’s capabilities as a full-system integrator and technology provider. We’ve leveraged our decade of experience in developing high-performance electric powertrains to create a hybrid system that not only delivers extraordinary performance but also demonstrates remarkable efficiency and packaging innovation,” explains Mate Rimac, Founder and President of the Rimac Group, CEO Bugatti Rimac and Rimac Technology.

The complete rear powertrain assembly – including the V16 engine, eight-speed dual-clutch transmission, torque-vectoring differential, and the 250-kilowatt rear electric motor – weighs just 430 kilograms, matching the weight of the Bugatti Chiron’s engine alone.

Rimac Technology’s expertise extends beyond the core powertrain components. The backbone of Tourbillon’s electrical architecture consists of three powerful domain electronic control units, with both hardware and software fully designed, developed and produced by Rimac Technology, following the highest quality and functional safety standards.

Similarly, Rimac Technology’s expertise in thermal management has been crucial in developing the sophisticated cooling systems required to maintain optimal performance across all operating conditions. The integrated approach to thermal management ensures that both the battery pack and electric motors maintain peak efficiency, even under the extreme performance demands of a 445 km/h hyper-car.

“This is exactly what we’ve always been exceptional at, extremely bespoke, high-performance, low-volume applications that are engineered without compromise. Projects like this will always serve as a showcase of our ultimate capabilities and what’s possible when there are no constraints. But as well as these showcase projects, we also produce hundreds of thousands of battery and powertrain units annually, working with the likes of Porsche, BMW, CEER Motors and many others. It’s our aim to provide the same engineering excellence and innovation we bring to projects like the Tourbillon to hundreds of thousands of other vehicles each year, helping established OEMs to bridge the gap to electrified vehicles,” adds Mate Rimac.

Only 250 Bugatti Tourbillons will be hand-crafted and assembled in the Bugatti atelier in Molsheim, France. With an estimated price tag hovering around 5 million USD, this stellar vehicle features Rimac Technology’s hybrid powertrain – developed with the help of Siemens Simcenter software. Unfortunately for those of you who put one on your wish list, these stellar cars are sold out.