Electrification in the USA – Will Palo Alto run out of energy this summer?

Electrification of Palo Alto, CA

According to its sustainability and climate action plan, the city of Palo Alto, California, aims to reduce its emissions by 80% from 1990 levels by 2030. It took three decades, from 1990 to 2021, to reduce the emissions by 54%. If they continue at the same pace, they will not hit their target until 2036.

One of the key pillars in this transition is the sustainable electrification of passenger vehicles (EVs) and heat pumps for home heating and cooling. Within 6 years, the city is aiming to make 80% of all vehicles within the city EVs. To meet this target, they require a 6-fold increase in the number of charging ports from the current 4,600 to over 30,000. Consequently, the city government will need to create incentives to drive the adoption of EVs, chargers, energy storage, and heat pumps.

To provide a stable green energy supply, power generation will need to come from a mix of renewable sources and existing conventional sources. Active distributed energy resource management (DERMS) for electric demand and supply, i.e., a smart grid that supports distributed renewables, energy storage, and vehicle-to-grid (V2G) bidirectional energy flow, is inevitable.

Therefore, in 2022 the City of Palo Alto announced that it was investing $150 million – which has now grown to $300 million – to undergo its electrification and modernize its electric grid.

The electric grid is the single point of failure in the electrification transition

EV transition is hard, especially on the grid capacity, reliability and availability. The lack of electric grid investment is often witnessed during extreme weather events. For example, in 2022, California advised limiting EV charging during a heat wave, while in the winter of this year – 2024, EV drivers were stranded in Chicago under extreme cold.

In 2024, Palo Alto is expected to have 7 hot days, with temperatures above 90°F (~32°C), and this will rise to 14 days by 2030. The question for electric utility executives is: On extremely hot or cold days, will my utility give up when it is needed most? The answer is important for critical installations like food warehouses, medical, administrative, financial, data centers, and secure buildings.

The grid of today and tomorrow, i.e., a smart grid, must support bi-directional energy flow and communication and withstand external hacker threats and extreme weather events. Much of the grid is aging and it is being relied upon for an ever-greater number of critical operations, including transportation and heating, as well as its traditional electric requirements. Therefore, the transmission and distribution of the increasing electric load must be done efficiently by the existing grid as it transitions. Therefore, the resilience and stability of a low-emission electric grid are the keys to successfully meeting emission targets and enabling the electrification transition.

“There are places, even today, where we can’t even take one more heat pump without having to rebuild the portion of the system. Or we can’t even have one EV charger go in”

Tomm Marshall, Assistant Director, Palo Alto Utility, as reported in The EV Transition

Electric Power

Electric power is instantaneous electric energy delivered per unit time. It is the product of the voltage (V) and current (I), which are transformed into their direct current (DC) equivalents using the root mean square (rms) for alternating currents (AC). To deliver more power, we often use more phases for AC, with three-phases being the sweet spot for higher power density at a lower cost and transmission losses. The voltage and frequency are fixed for a 50 or 60 Hz grid. For example, 120 V at 60 Hz and 220 V at 50 Hz for residential use in North America and Europe, respectively.

Electric current varies depending on the type of electric device connected to the circuit, i.e., load. It is an indicator of an electric load’s size and the associated joule losses. Joule (I2R) heating losses scale with the square of the current (I) and the resistance (R) of the conductor. They are present in all electric circuits and devices as their conductors (busbars, cables, wires, foils, PCB traces, semiconductor switches, etc) are made from imperfect materials.

Resistance (σL/A) is proportional to the conductivity (σ), the length (L), and inversely proportional to the cross-sectional area (A), of the conductor. At the grid level, joule losses explain the system’s transmission and distribution losses, while resistance explains the use of cheaper, lighter but thicker aluminum power cables. Without going into details, superconductivity mimics perfect conductors (σ≈0), eliminating joule losses, and expelling electromagnetic fields.

In simple electric load analysis, it is important to know when the different loads come online and superimpose their currents for the same voltage rating to size the needed electric equipment and cabling, such as the main breaker, circuit breakers, and cabling. At the grid scale, it explains the logic behind energy efficiency, load shifting, and energy storage to match the demand and supply without heavy investment in generation.

Increasing transformer ratings with the adoption of heat pumps and EV chargers

The Palo Alto electric grid was designed assuming heating (house and water) and cooking to be on natural gas, but this is changing due to increased electrification of appliances. Today, it is possible to find 15 households connected to a single 37.5 kVA distribution transformer, supplying 2 kW of electric power per household. As noted by Tomm Marshall, the Assistant Director for Palo Alto Utility, as of today, in some places, they cannot even add a single heat pump or a charger.

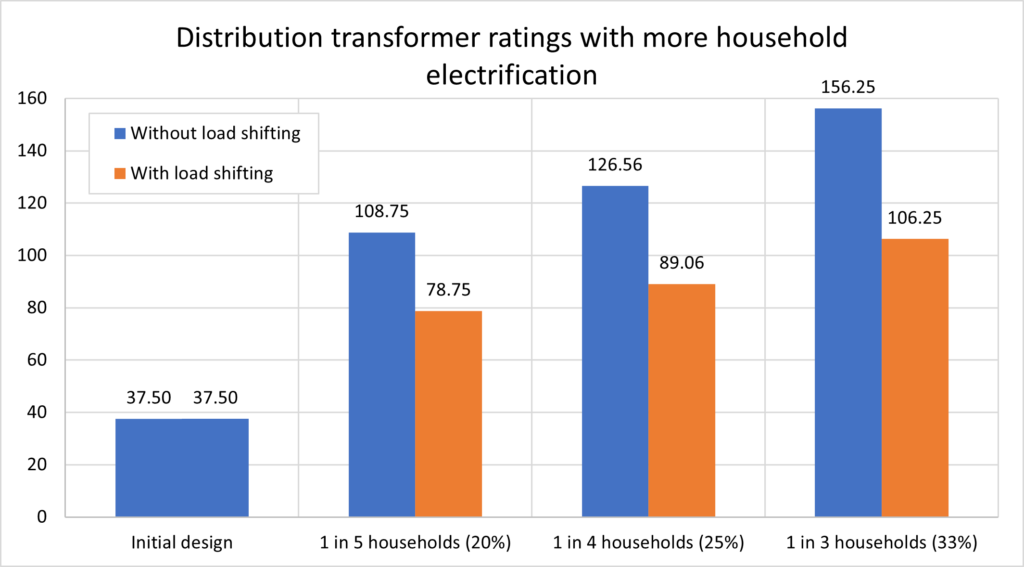

Figure 1 shows that higher transformer ratings are required with more electrification of households. In this example, the initial rating of the distribution transformer is 37.5 kVA. The calculation assumes the adoption of both a heat pump (6 kW) and an L2 charger (13 kW) in a more electrified household. From the figure, it is also evident that load shifting reduces the required transformer size.

Shifting is assumed to be done at the household level, where the heat pump or charger can be availed at any time, but not at the same time. The charger is used for peak load sizing, where the initial 2 kW load is supported as the base load. If possible, centralized DC fast charging would lighten the system upgrades by reducing the peak household load to that of the heat pump.

These higher ratings would mean larger distribution transformers and a costly replacement of their poles. By uprating the system’s voltage, the existing power lines are kept to meet the increasing electric demand, with future expansion capacity. However, the insulation systems, substations, and distribution transformers need an upgrade to support these higher voltages and power ratings. The ace in the hole for utilities is transformers, which are analogous to gear trains. They can step up a system’s voltage like how a gear set transfers speed for torque. This will enable utilities to reuse existing power lines while meeting transmission loss guidelines.

Compact higher rated transformers will address space constraints in urban areas, and the need to replace poles. However, higher ratings require more current, and this produces more heat! In addition, higher system voltage will require an insulation upgrade.

Re-designing transformers for compactness

Our transformer OEM customers are confirming that utilities are asking for higher power ratings for the same overall transformer size.

How do we go about this process?

One starts with a transformer calculator for initial sizing, which is tried and tested for OEMs. While useful, the maintenance of the automation scripts can be time-consuming, especially as they become more complex. The increased expertise tends to result in over-reliance on a small number or even a single engineer, putting the company at a huge risk should that engineer leave or retire.

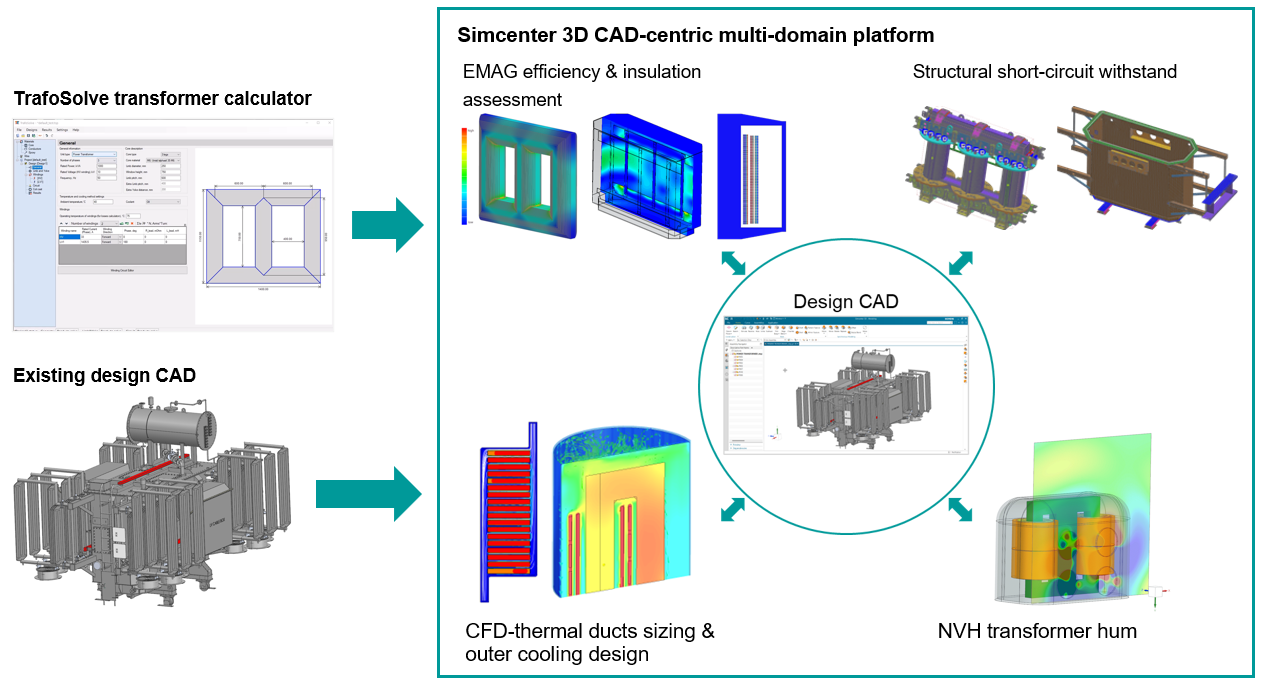

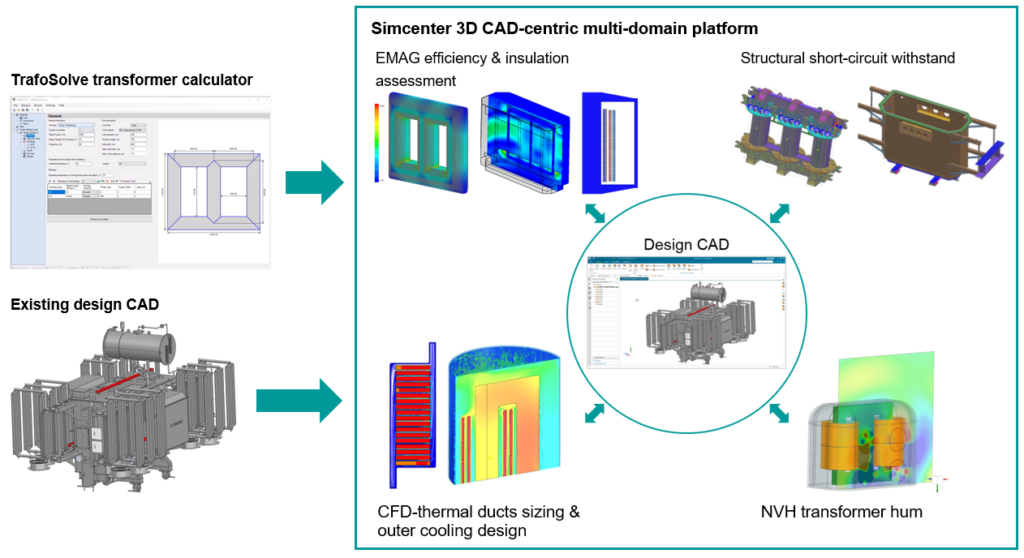

TrafoSolve, by our partner Infologic Design, is an FEA-based (MAGNET solver) transformer calculator for fast initial electrical design for efficiency, insulation strength, and thermal analysis. After settling on a design, TrafoSolve can export a 3D geometry of the active parts, which are assembled in Simcenter 3D with the structural parts to create the transformer design CAD. Simcenter 3D is a CAD-centric and multi-domain platform with flexible licensing. Alternatively, the analysis can start from an existing transformer design.

Further detailed mechanical analysis in terms of thermal (ducts sizing, and radiators/coolers), structural short-circuit withstand, and hum (noise), is done in Simcenter 3D. This is further enabled by the new release of Simcenter 3D 2406, which now supports multi-variable parameterization in addition to CAD associativity. Therefore, multiple geometric and material configurations are evaluated on how they meet both electrical and mechanical targets.

This Simcenter transformer simulation workflow, from Siemens Digital Industries Software (a separate legal entity from Siemens-Energy, a transformer OEM) is illustrated in Figure 2, and summarized as follows:

- TrafoSolve transformer for the initial electrical design transformer calculations.

- Extracting a transformer geometry from a design CAD assembly.

- Detailed electrical design (electromagnetic and solid insulation).

- Internal transformer thermal design (low-voltage, high-voltage, and core thermal ducts).

- External transformer thermal design (natural, forced, fins, radiators/coolers).

- Structural analysis to confirm the design can withstand a short-circuit.

- Transformer noise/hum analysis.

Summary – the electrification of a city

Electric grid capacity demand is rising due to the increased electrification of our cities, such as the addition of heat pumps and EV chargers to the initial household loads.

Utility companies can manage the cost of upgrades by uprating the system’s voltage and continuing the use of existing powerlines at acceptable system losses. However, this still requires the upgrade of the insulation systems, substations, and distribution transformers. Transformers are the possible weak link during this upgrade process, because they need to be redesigned for the higher voltage and power ratings, with future reserve capacity. Simcenter transformer simulation solution is helping transformer OEMs design next-gen grid transformers. It covers initial sizing for efficiency, solid-insulation assessment, thermal performance, and detailed electrical and mechanical design, balancing multi-attribute performance in terms of efficiency, thermal, structural integrity, and noise.