If your products are smart, why isn’t your manufacturing?

If your electronics business isn’t growing, it’s dying!

Because of such a low barrier of entry to the industry, new competition is constantly springing up. Even though many of these new companies provide substitutes for well-known high-tech devices, this competition fuels a market for cheaper alternatives that provide many of the same advanced features.

A quick online shopping site search for wireless headphones, for example, will yield 20 pages of results composed mainly of brands that have no name recognition. Many of these “manufacturers” didn’t exist a decade ago. I use the term “manufacturer” loosely because it appears so many of the results are identical versions of each other, with just slightly different brand messaging.

This example is not a commentary on these companies’ manufacturing, quality, or marketing practices. It, instead, simply exposes a small portion of the challenges industry leaders – those pioneering new ground in electronics – are facing. In order to achieve the unchanged business goals of reducing costs and getting to market faster than the competition the answer is to be more innovative, and a great place to start is with manufacturing processes.

Product and market complexity is the real challenge

Today’s electronics are the most complex they’ve ever been, and that complexity swells further when working within a global supply chain. That level of intricacy introduces myriad other problems. Lack of skilled technicians to keep up with rapid changes is one of the biggest for companies slow to adapt to the digital transformation.

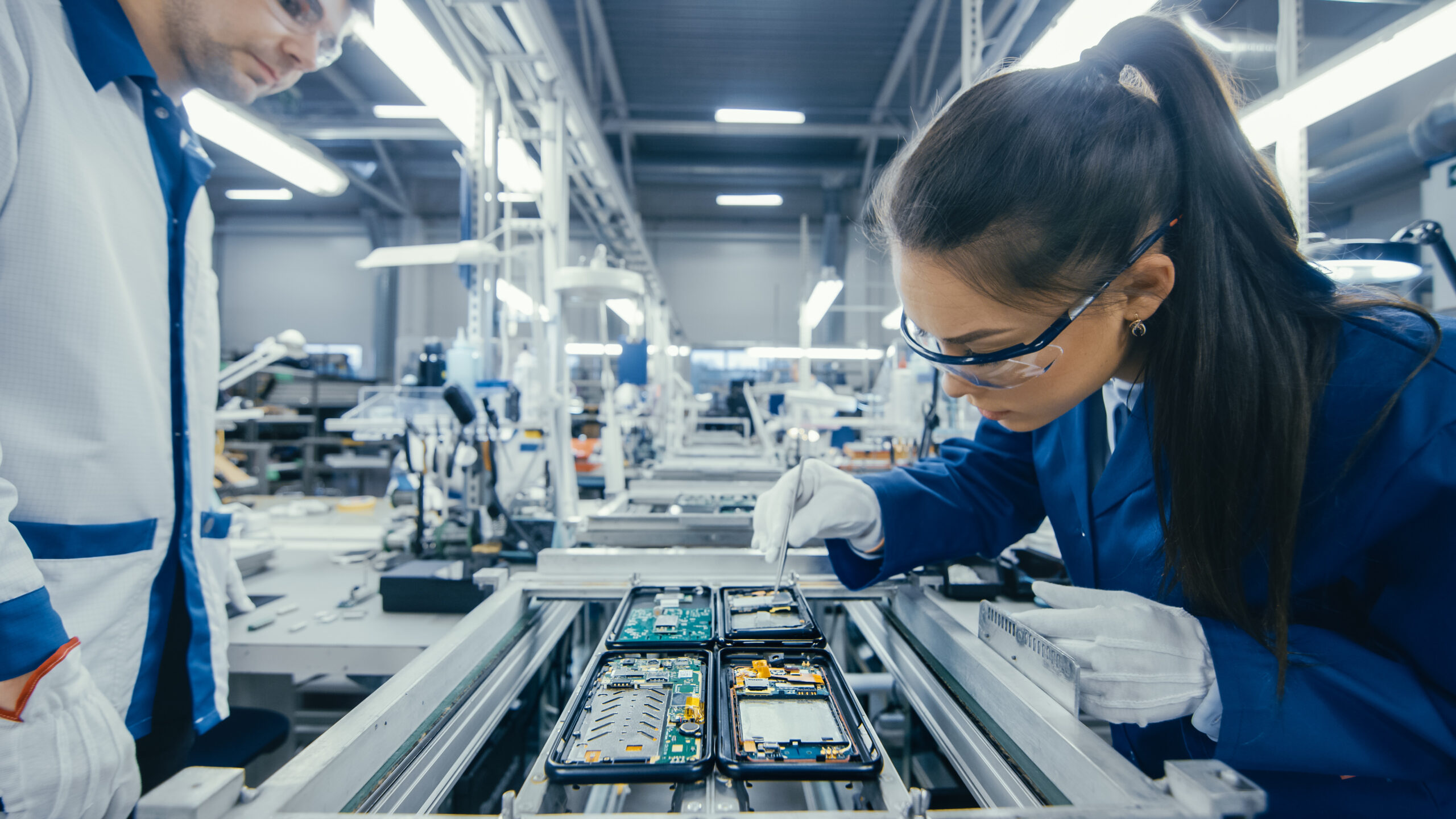

But with the right tools and mentality, a smart manufacturing program for electronics changes the way products are realized. Breakthroughs such as additive manufacturing, machine learning, augmented and virtual reality, and automation is swiftly becoming relied upon on shop floors worldwide. Entire plants and processes can be fully simulated before the first machines are in place. This cuts production ramp-up time significantly. Other time-consuming activities like working from paper instructions and creating physical prototypes can be all but eliminated.

The definition of Industry 4.0 is somewhat fluid

At a minimum, it demands processes be intelligent, aware, connected, and responsive. To get there, data must be driven by a single source of truth.

Never has so much data been available to manufacturers, especially with the evolution of the Internet of Things (IoT). For a company to successfully exploit this information, it takes a holistic approach to adopt new methods and software systems. However, this doesn’t require discarding your ERP and various software pieces that have required large amounts of money, training, and effort to customize. It does mean bringing all those disparate systems together with PLM tools to create a “central nervous system” that allows for open integration of data sources from various vendors.

Making sense of all the data to make better descisions

Harnessing all the information through the advanced analytics offered within a fully integrated software ecosystem puts business leaders in a position to make better decisions. With flexibility, managers can react to changes in materials and customizations on the fly. Using apps that present stakeholders with only the information most relevant to them, decision-makers can break down mass amounts of data into actionable chunks.

The factory of the future is here today!

The factory of the future is available today, at least for electronics companies looking to thrive in a crowded marketplace. Download this new eBook to learn more about the key components of a smart manufacturing strategy for electronics companies and how its implementation can lay the groundwork for years of successful programs.

Blog co-written with Robert Lyons, Sr. Writer for Siemens Digital Industries Software.