Unveiling the future of 3DIC design with Calibre 3DThermal

By Lee Wang

The semiconductor industry is undergoing a transformative shift from traditional 2D integrated circuit (IC) designs to more advanced 2.5D and 3D integrated circuit (3DIC) configurations. This move is driven by the need to achieve greater performance, efficiency, and functionality beyond the limitations of Moore’s Law. However, this advancement also brings new challenges, particularly in the realm of thermal management. Enter Calibre 3DThermal, the cutting-edge solution designed to tackle these challenges head-on and redefine how we approach 3DIC thermal analysis.

The evolution from 2D to 3D integrated circuits

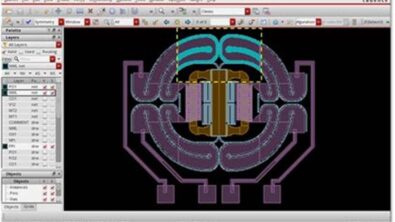

In traditional 2D IC designs, all components are built on a single silicon die, where scaling and performance improvements have largely followed Moore’s Law. However, as we push the boundaries of semiconductor technology, the focus has shifted to 2.5D and 3DIC designs. These advanced configurations involve stacking multiple chiplets or dies in a vertical arrangement, which allows for increased functionality, better performance, and reduced power consumption.

Unlike traditional 2DICs, 2.5D and 3DIC designs offer multiple connection methods such as through-silicon vias (TSVs), bump connections, and direct bonding techniques. This complexity introduces new factors that must be considered, such as thermal effects, stress, and power distribution, which can significantly impact device performance and reliability.

The thermal challenge in 3DIC design

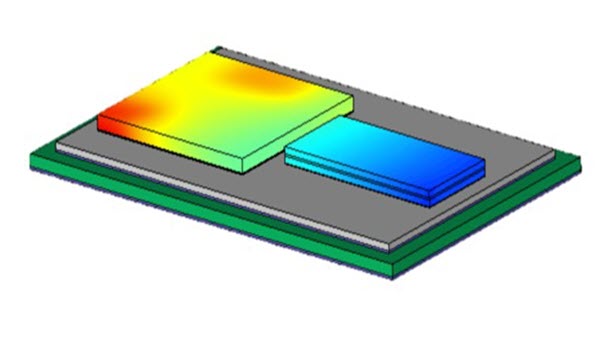

One of the most pressing issues in 3DIC design is thermal management. As semiconductor components become smaller and more densely packed, managing heat becomes increasingly complex. The high power density and stacked nature of 3DICs lead to significant thermal gradients and interactions between dies, which can affect performance and reliability.

Thermal effects in 3DICs are influenced by several factors:

- Power density: High power consumption in advanced IC designs results in increased heat generation.

- Thermal gradients: Stacked dies and complex interconnections create non-uniform heat distribution.

- Heat flow paths: The intricate design of 3DICs requires careful consideration of heat dissipation methods.

These thermal challenges necessitate advanced solutions for accurate thermal analysis and verification.

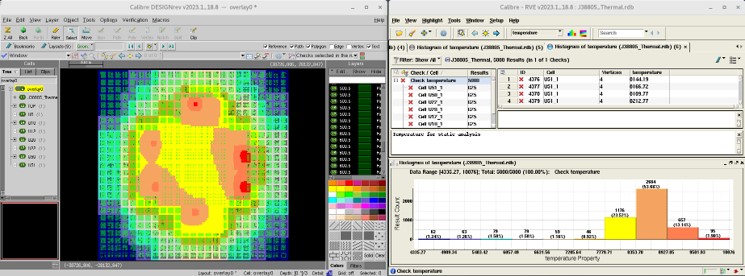

Introducing Calibre 3DThermal: The solution for advanced thermal analysis

Calibre 3DThermal is designed to meet the rigorous demands of 3DIC design by offering a comprehensive suite of features for thermal analysis throughout the entire design flow. Here’s what makes it stand out:

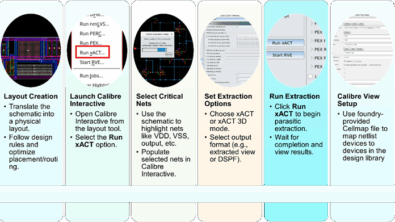

1. Integrated thermal analysis from concept to signoff

Calibre 3DThermal integrates seamlessly into the IC design flow, enabling designers to perform thermal feasibility analysis, debug issues, and verify designs from the initial concept through to final signoff. This end-to-end integration ensures that thermal considerations are an integral part of the design process, rather than an afterthought.

2. High-accuracy thermal simulation

Leveraging an optimized 3D solver from Simcenter Flotherm, Calibre 3DThermal offers highly accurate and efficient thermal simulations down to the nanometer scale. This precision is crucial for identifying and addressing potential thermal issues throughout the design process.

3. Advanced automation and ease of use

Calibre 3DThermal includes advanced automation features that make high-accuracy thermal simulation accessible even to designers who are not thermal experts. Features like automated grid generation, power map compression, and equivalent thermal properties extraction streamline the analysis process and improve usability.

4. Comprehensive design flow integration

With support for both digital and analog mixed-signal ICs, Calibre 3DThermal integrates with all major design environments and supports all standard layout formats. This compatibility ensures that designers can incorporate thermal analysis into their existing workflows without disrupting their design processes.

FAQ: Your top questions about Calibre 3DThermal

Q. What is the primary benefit of using Calibre 3DThermal?

- Calibre 3DThermal offers an easy to use, fast and high-accuracy thermal analysis solution integrated within the IC design flow, allowing designers to identify and address thermal issues throughout the design process. This leads to improved performance, reliability and reduced time to market.

Q. How does Calibre 3DThermal handle complex 3DIC designs?

A. The tool uses advanced algorithms, including an optimized custom solver from industry-leading Simcenter Flotherm, and automation of tasks like generation of time steps in transient analysis and equivalent thermal properties to reduce model complexity.

Q. Can Calibre 3DThermal be used for both digital and analog IC designs?

A. Yes, Calibre 3DThermal supports both digital and analog mixed-signal IC designs, making it a versatile solution for a wide range of semiconductor applications.

Q. How does Calibre 3DThermal integrate with other design tools?

A. Calibre 3DThermal is fully compatible with all standard design formats and integrates with other tools in the IC design ecosystem, including Simcenter Flotherm for extended thermal analysis.

Q. Is Calibre 3DThermal suitable for non-experts in thermal analysis?

A. Yes, the tool’s advanced automation features and user-friendly interface make it accessible to designers who may not have specialized knowledge in thermal analysis.

Conclusion

The move from traditional 2D IC designs to advanced 2.5D and 3DIC configurations represents a significant leap forward in semiconductor technology. However, this advancement also introduces new challenges, particularly in thermal management. Calibre 3DThermal addresses these challenges with a comprehensive, high-accuracy thermal analysis solution that integrates seamlessly into the IC design flow. By enabling designers to tackle thermal issues early and effectively, Calibre 3DThermal paves the way for the successful development of next-generation 3DIC technologies.