Auto IC Market: Revving Up Product Line Means Revving Up Reliability

By Matthew Hogan, Mentor Graphics

Designing electronics for automotive use means meeting stringent safety and reliability standards.

Many of the challenges faced by new entrants in the automotive IC market are attributed to the industry’s safety and reliability standards.

The adoption of electronics in the automotive market seems to be on the upswing.

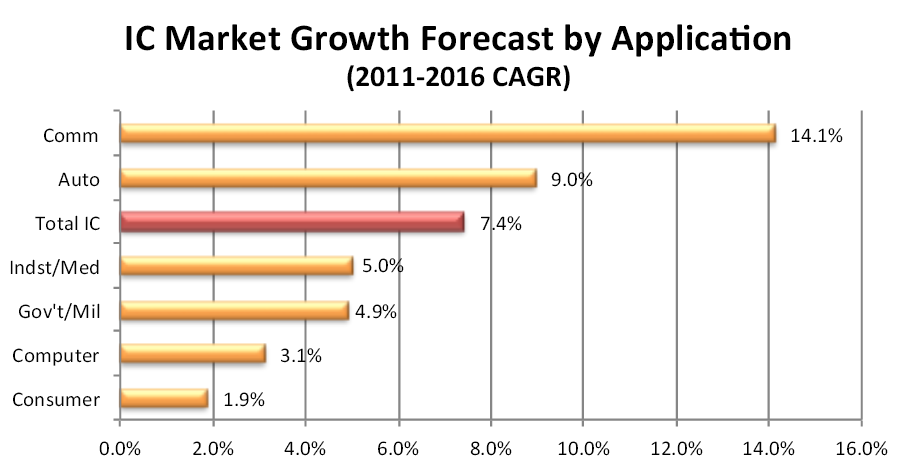

Many industry reports and forecasts on integrated circuit (IC) growth point squarely at the automotive market to outpace growth in other IC related areas. IC Insights published a report showing communications and automotive to be the two strongest growth segments for 2011-2016, with the automotive market forecast to reach $28 billion in 2016, or 53% growth from its 2011 size. (See Figure 1.) In 2012, Europe was the largest regional market for automotive ICs, accounting for 37% of the market. By 2016, the Asia-Pacific market is expected to be approximately the same size as Europe.

Figure 1

Figure 1

The automotive IC market shows strong potential growth.

(Image: IC Insights)

These forecasts seem to be resonating well with recent financial disclosures by those focused on the automotive industry. For example, Freescale disclosed in July that 45% of its revenue today is “automotive-related.”

Also interesting is the acknowledgement that incumbents in this market have longstanding relationships that allow them to capitalize on this growth.

Many of the challenges faced by new entrants are attributed to the industry’s safety and reliability standards.

The automotive industry has developed an adaptation of the International Electrotechnical Commission’s Functional Safety standard, IEC 61508 for Electric/Electronic Systems, to create its International Organization for Standardization (ISO) 26262. This standard for functional safety features forms an integral part of each automotive product development phase, from the initial specifications to design, implementation, integration, verification, validation, and production release.

There are many opportunities on the safety side, particularly with recent US Department of Transportation mandates for vehicle-to-vehicle communications. (See Figure 2.) However, organizations that are already plugged into the safety automotive supply chain have a head start.

Figure 2

Vehicle-to-vehicle communication.

(Source: US DOT)

IC growth in automotive is not solely limited to safety applications. In-vehicle infotainment systems and “connected” cars are satisfying market needs for greater automotive integration with consumers’ digital lives. Though not safety systems (and not subject to the rigors of ISO 26262), these systems find themselves facing standards compliance that can be much more stringent than the standards normally encountered in the consumer market. One example of such standards is provided by the Automotive Electronics Council (AEC).

If you’ve been designing your IP for less rigorous environments or uses, the question becomes how to leverage current IP into these high-reliability environments for your next system-on-chip design? For many, the question comes down to rigorous design and verification of their IC designs. What tools are you using to validate your designs? What measures are you taking to assure compliance?

The AEC electrical component qualification requirements identify wearout reliability tests, which specify the testing of several failure mechanisms.

- Electromigration

- Time-dependent dielectric breakdown (or gate oxide integrity test) — for all MOS technologies

- Hot carrier injection — for all MOS technologies below 1 micron

- Negative bias temperature instability

- Stress migration

Verification against these failure modes during the design process provides assurance that the actual device performance will meet reliability expectations.

In many traditional IC verification flows leveraging design rule checking, layout vs. schematic, and electrical rule checking techniques, validation of these rules may be problematic, because these tools each focus on one specific aspect of design verification. What is needed is access to a reliability verification platform capable of helping designers understand weaknesses in their designs from a holistic approach. A new breed of EDA tools can help in what would otherwise be a daunting task with traditional IC verification tools.

One such tool is Calibre® PERC™, a reliability verification platform well suited to these types of verification issues. With the ability to consider not only the devices in your design, but also the context in which they are used, as well as their physical implementation, Calibre PERC’s “whole problem” view of a design provides visibility to interoperability issues of IP used in the design.

When looking to adapt your technology to new markets, particularly the automotive one, re-using your IP is both desirable and possible, but only with a clear and well-developed understanding of your IC’s reliability thresholds.

What are the most troubling reliability challenges you face? How do you solve them? Embracing new verification technologies is critical to understanding and correcting the reliability issues in your designs, which is essential to achieving success in the rapidly growing market of automotive electronics.

Author

Matthew Hogan is a product marketing manager for Calibre Design Solutions at Mentor Graphics with more than 15 years of design and field experience.

This article was originally published on www.eetimes.com