Digital Part Production – additive manufacturing – ep. 4 Podcast

During this Digital Part Production podcast series, we have been discussing how machine builders can leverage digital part production solutions to address machine complexity and increase flexibility by using several differentiated solutions, including highly automated CAM, synchronized part production and additive manufacturing. We have covered some of these topics in our podcast series, including the DPP Overview of the solutions.

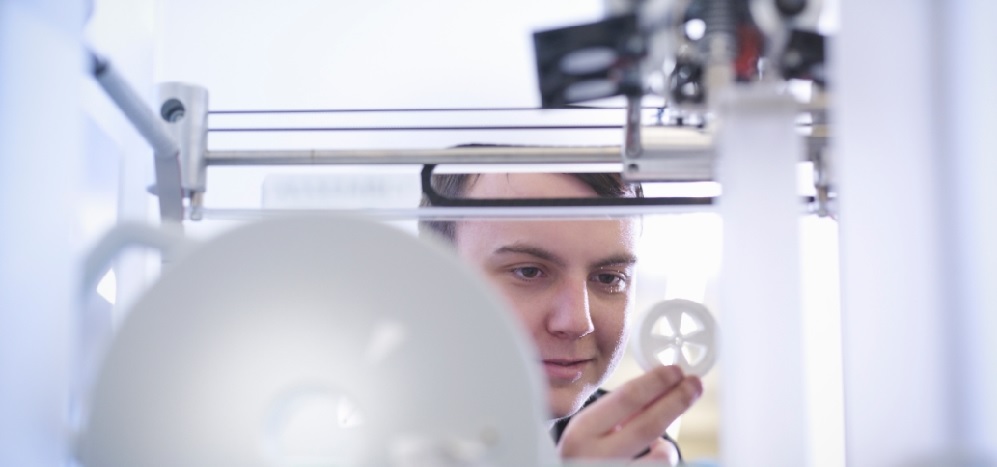

This fourth DPP podcast focuses on the benefits of additive manufacturing. Additive manufacturing helps manufacturers create complex geometries that would be unachievable by using traditional manufacturing methods.

> Listen to the podcast

We are pleased to welcome our engineering experts Rahul Garg, Vice-president of the mid-market program at Siemens Digital Industries Software, and Ashley Eckhoff, Marketing Manager for Siemens Manufacturing Engineering group, concentrating on Additive Manufacturing.

Additive manufacturing, also referred to as 3D printing, is a technology that allows the manufacturing of parts by adding small bits of material at specific points in the 3D space. It is a technology that’s enabling significant improvements to product quality and design. Order equipment manufacturers (OEMs) that adopt this technology early are differentiating themselves from the competition because additive manufacturing helps to create complex geometries and shapes. Subsequently, these geometries are stronger and lighter than traditionally manufactured counterparts.

There is a continual need for customization, seeing smaller lot size requirements for machines that get built. As the number of those built machines reduces, there is a need to get those machines out the door faster, thus taking advantage of additive manufacturing. Additive assists to create parts that are lower in volume and helps to reduce overall weight and improve the strength of those parts. Consequently, this improves the overall performance of the machines, providing higher throughput; and eventually a significant impact on the overall productivity of the machine. Additive plays an essential role in manufacturing as companies look to the next generation of design and machine manufacturing.

There are some challenges with closing the loop on the process and collecting field data, like storing and reusing manufacturing information. This process needs digitalization, because a manual process leads to higher volumes of waste and more mistakes on the shop floor. Whereas, a digital part production process helps manufacturers to fully merge the digital and physical processes to provide continuous communication with feedback loops. In turn, this helps a company to know each challenge during the evolution of a part design, thus impacting the larger manufacturing process: highly automated CAM, integrated CAD/CAM, CNC, additive manufacturing and operations intelligence. All these process steps include information that companies use to fine-tune operations via a closed-loop process that the digital thread enables.

Learn more by listening to DPP podcast04.

Siemens Digital Industries Software drives the transformation to enable a digital enterprise where engineering, manufacturing and electronics design meet tomorrow. Xcelerator, the comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software, helps companies of all sizes create and leverage a comprehensive digital twin that provides organizations with new insights, opportunities and automation levels to drive innovation.

For more information on Siemens Digital Industries Software products and services, visit siemens.com/software or follow us on LinkedIn, Twitter, Facebook and Instagram.

Siemens Digital Industries Software – where today meets tomorrow.

Related links:

Listen to DPP Podcast01 – an introduction to Digital Part Production

Listen to DPP Podcast02 – highly automated CAM

Listen to DPP Podcast03 – synchronized part production

Listen to DPP Podcast04 – benefits of additive manufacturing

About our experts:

Rahul Garg is the Vice President for Industrial Machinery & SMB Program, responsible for defining and delivering key strategic initiatives and solutions and global business development. He and his team are responsible for identifying key initiatives and developing solutions for the industry while working closely with industry leading customers and providing thought leadership on new and emerging issues faced by the machinery industry. Rahul’s experience and insight are derived from 25 year career delivering software-based solutions for product engineering and manufacturing innovation for the global manufacturing industry, spanning a career in R&D to program management, sales and P&L management and having focused exclusively on the industrial machinery and heavy equipment industry since 2007.

Ashley Eckhoff is the Marketing Manager for Siemens Manufacturing Engineering group, concentrating on Additive Manufacturing. He has a background in engineering and has been with Siemens for over 20 years in various capacities. He has spent the past few years deep-diving into additive manufacturing in both product design and marketing roles.