🌟 AI-Powered Simulation: Integrating LLMs with Plant Simulation for Next-Gen Models

Presented by Pierpaolo Veltri, PhD Student, Management and Industrial Engineer, University of Calabria, Italy

📅 Event: 2025 Plant Simulation User Conference, Amsterdam, July 2nd 2025

🎤 Track: Plant Simulation AI & Simulation Innovation

🚀 Unlocking New Possibilities in Digital Manufacturing

As digital manufacturing evolves, the need for faster, more intuitive, and accessible simulation tools has never been greater. This year at the 2025 Plant Simulation User Conference in Amsterdam, Pierpaolo Veltri will showcase a groundbreaking approach that blends the analytical power of Siemens Plant Simulation with the intelligence of Large Language Models (LLMs) — ushering in a new era of AI-powered simulation.

Pierpaolo Veltri is an accomplished Industrial and Management Engineer currently completing the final year of his PhD research at the Modeling & Simulation Center – Laboratory of Enterprise Solutions (MSC-LES) at the University of Calabria, with research completion taking place in Beijing, China. Specializing in Adaptive Digital Twin technologies within Siemens Plant Simulation environments, his work focuses on bridging theoretical modeling with practical industrial applications. With a strong academic foundation from his Master’s degree in Management and Industrial Engineering, Pierpaolo has developed advanced simulation-based Digital Twin solutions for major corporations in the energy sector and manufacturing industry, enhancing production scheduling, manufacturing systems design, and product optimization through comprehensive What-If analysis and Industry 5.0 technologies. His doctoral research extends to the integration of Large Language Models (LLMs) for democratizing simulation access via natural-language interfaces. In parallel to his research and industrial collaborations, Pierpaolo actively contributes to the international simulation community as a member of the organizing committees for the prestigious I3M and ISM conferences, both focused on modeling, simulation, and Smart Manufacturing innovation.

🧠 From Natural Language to Automatic Simulation Models Generation

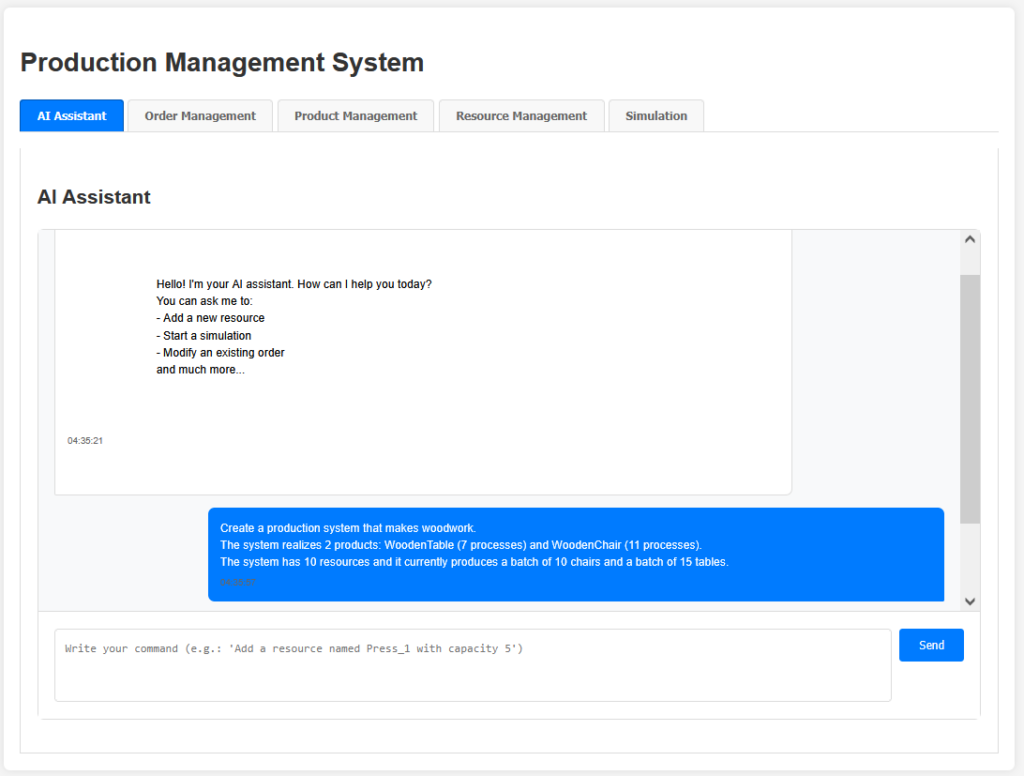

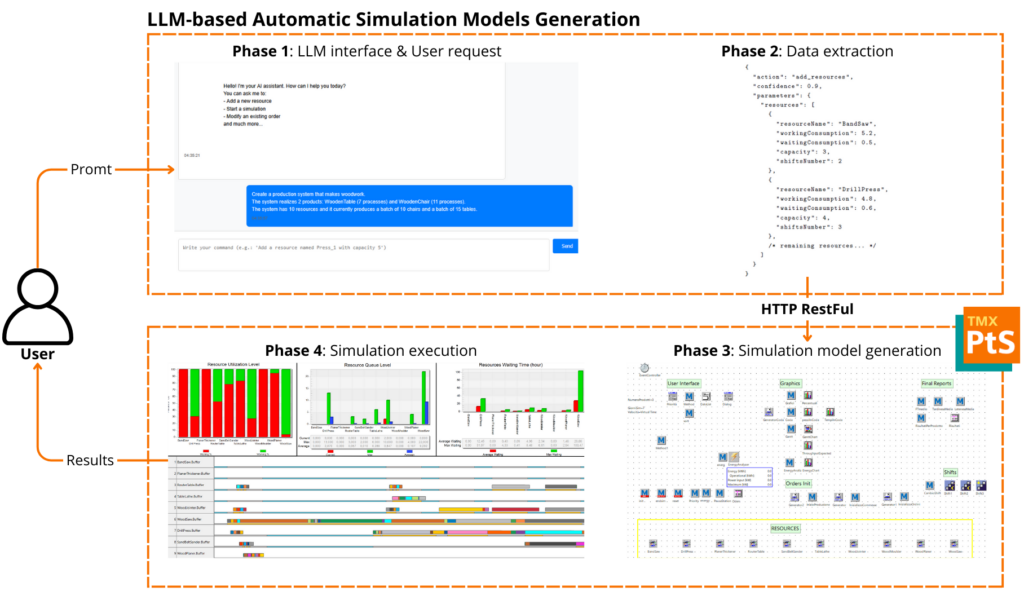

The presentation, titled “AI-Powered Simulation: Integrating LLMs with Plant Simulation for Next-Gen Models,” explores how generative AI technologies can revolutionize the way we interact with complex engineering tools. At the heart of this innovation is the Automatic Simulation Models Generation (ASMG) methodology, which allows users to communicate with simulation environments using natural, spoken language.

No need for extensive modeling knowledge or complex scripting — users simply describe what they need, and the system:

- Extracts key parameters from natural language input

- Generates and configures simulation models automatically using modular libraries

- Executes simulations and delivers results rapidly

This makes manufacturing system modeling and optimization faster, smarter, and accessible to a broader range of users, from experienced engineers to operational staff.

🔍 Why This Matters

Traditionally, simulation model creation has been a time-consuming, specialized task. By integrating LLMs, the process becomes:

- Quicker — reducing model development time dramatically

- More flexible — enabling engineers to test more design alternatives in less time

- Accessible — opening advanced simulation capabilities to non-experts

This fusion of AI and digital manufacturing tools empowers decision-makers with real-time insights, streamlining production planning and enabling agile responses to operational challenges.

💡 What to Expect in the Session

In his session, Pierpaolo Veltri will:

- Demonstrate how natural language control interfaces interact with Plant Simulation

- Share use cases illustrating the benefits of AI-driven What-If analyses

- Dive into technical implementation details of integrating LLMs with simulation environments

- Discuss implications for both academic research and industrial application

Attendees will gain valuable insights into how AI is reshaping manufacturing simulation, along with practical strategies for integrating these technologies into their own workflows.

Transforming Simulation Through AI-Driven Interfaces

At the 2025 Plant Simulation User Conference, Pierpaolo Veltri presents a exploration of how artificial intelligence, particularly Large Language Models (LLMs), is transforming the landscape of industrial simulation. Traditional simulation tools, while powerful, have historically required specialized expertise, often limiting their use to a select group of engineers and analysts. Veltri’s work introduces an intuitive, AI-powered interface that eliminates this barrier by enabling users to interact with Siemens Plant Simulation using natural language. This capability fundamentally redefines how simulation models are conceived, built, and executed. Rather than relying on extensive manual modeling and configuration, users articulate their objectives and system parameters conversationally. The integrated AI then interprets these descriptions, identifies key operational variables, and automatically generates corresponding simulation models. This innovation accelerates model creation, enhances accessibility for non-specialists, and increases the agility of decision-making processes in industrial environments. By embedding AI directly into the simulation workflow, Veltri’s approach represents a critical leap forward for digital manufacturing, offering organizations a tool to swiftly explore operational scenarios and optimize performance without the conventional complexities.

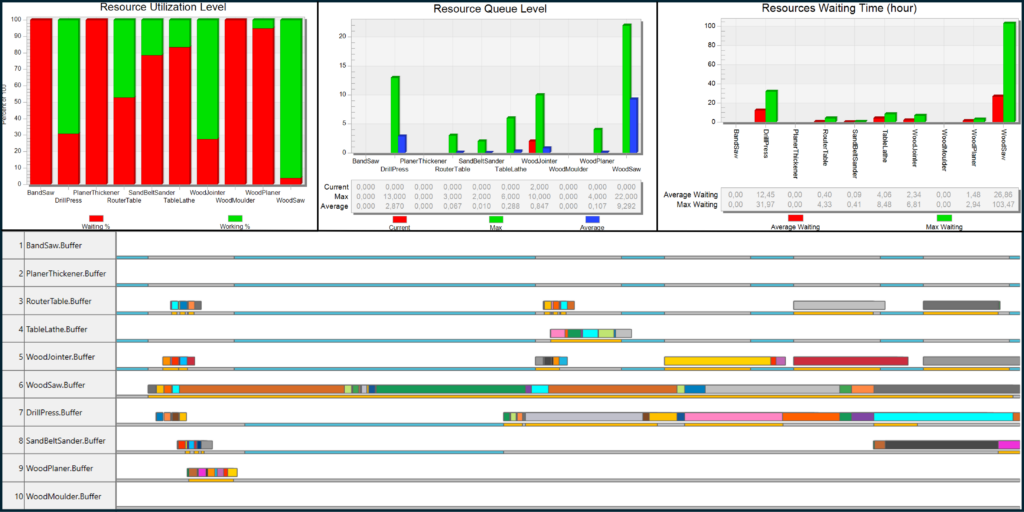

The Automatic Simulation Models Generation (ASMG) Methodology

Central to Veltri’s research is the development of the Automatic Simulation Models Generation (ASMG) methodology, a sophisticated framework designed to support the translation of user requests into functional simulation environments. This process leverages specialized modular libraries within Siemens Plant Simulation, replicating manufacturing resources, production lines, and logistics systems with precision. Once a user submits a natural-language request—for example, to adjust throughput rates, modify workstation capacities, or perform a What-If analysis—the integrated AI interprets the request, selects the appropriate simulation modules, and configures them accordingly. The system then initiates the simulation run, collecting and presenting results through user-friendly dashboards and data visualizations. This architecture significantly shortens the traditionally labor-intensive modeling cycle, promoting faster iterations and broader experimentation. Furthermore, ASMG enhances the flexibility of manufacturing system design, allowing stakeholders to dynamically test new configurations, resource allocations, and production strategies in a virtual environment before implementing them physically. The methodology’s modularity ensures scalability, making it suitable for both small-scale facilities and complex, multi-plant manufacturing ecosystems. Veltri’s lecture details the technical structure of ASMG and its potential to redefine simulation modeling within Industry 5.0 environments.

Bridging Research and Industry with Practical Impact

Veltri’s presentation also emphasizes the importance of closing the gap between theoretical research and operational industry challenges. While digital twins and advanced simulation models have become central to modern manufacturing strategies, their practical adoption is often hindered by technical barriers and resource constraints. By integrating AI-powered natural-language processing into simulation workflows, Veltri offers a pragmatic solution that democratizes access to advanced modeling tools. His work not only reduces the need for specialized knowledge but also empowers decision-makers to directly engage with simulation technology, fostering a more inclusive and responsive operational culture. The session highlights real-world applications of this AI-driven simulation system, including collaborations with energy sector leaders and manufacturing firms seeking to enhance production planning and supply chain agility. Through these case studies, Veltri demonstrates how the adoption of AI-enhanced simulation models can deliver measurable improvements in operational efficiency, risk mitigation, and strategic planning. He concludes by inviting the audience to consider how AI-integrated simulation tools will shape the future of digital manufacturing, urging both researchers and practitioners to embrace these transformative technologies and redefine how industrial systems are designed, analyzed, and optimized.

📣 Join the Conversation

If you’re passionate about the future of AI in manufacturing and curious to see how generative AI can simplify and accelerate simulation processes, don’t miss this session at the 2025 Plant Simulation User Conference in Amsterdam.

Discover how AI-powered simulation is not just a concept for the future — it’s happening now.