What’s new: Simcenter Testlab 2021.2

Simcenter Testlab new release comes with some great features to discover!

As the world evolves, engineers face an increasing number of challenges emerging across all industries. Not only are companies continuously required to cope with growing product complexity, increasing product variants, and customer expectations, but at the same time, they are pressured to bring products to the market faster than ever and with cost savings.

Siemens DISW gathered years of engineering experience, selected the best methods, and carefully designed testing solutions to make physical testing more efficient and sophisticated, allowing test engineers to overcome these challenges.

Our mission, with the 2021.2 release of Simcenter Testlab is to provide engineers with the toolset to innovate and accelerate product development by creating a working environment that merges test and simulation: engineers will be able to take control of the product attributes much earlier in the development cycle.

In this release, you will experience significant advancements in 4 areas:

- System NVH prediction with Virtual Prototype Assembly

- Advanced operational NVH testing

- Simplified and more effective collaboration, comparison and reporting

- Productive testing in harsh and demanding conditions

Watch the video below:

System NVH prediction with Virtual Prototype Assembly

This Simcenter Testlab release allows systems NVH prediction at every stage of the development cycle.

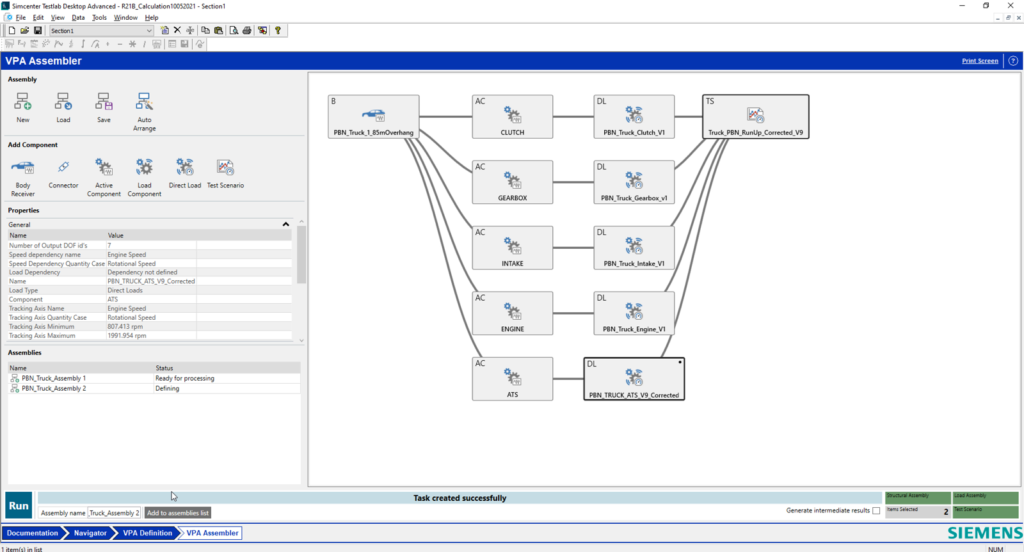

With the new Simcenter Testlab Virtual Prototype Assembly, engineers can create system variants in a virtual environment. Component models coming from test and/or simulation are assembled in a modular way, enabling the NVH performance assessment of the system before having a physical prototype available. In this way, the impact of structural modifications, the difference in performance between several variants and more, can be evaluated as early as possible, reducing troubleshooting time.

The key technology to create accurate components is component-based Transfer Path Analysis (TPA). This allows you to characterize the NVH sources independently from the final receiver.

Test and simulation experts can create each component model and then publish them for analysts for further evaluation. This allows engineers to easily swap in assembly or design alternatives and immediately see the NVH impact before having the system physically available.

Virtual Prototype Assembly creates the perfect marriage between technology and usability, bringing test and simulation models in one working space. It allows manufacturers to deliver excellent NVH performance while keeping development time and cost under control.

Learn more about Virtual Prototype Assembly by reading this blog post: Master the vehicle NVH performance with a virtual prototype.

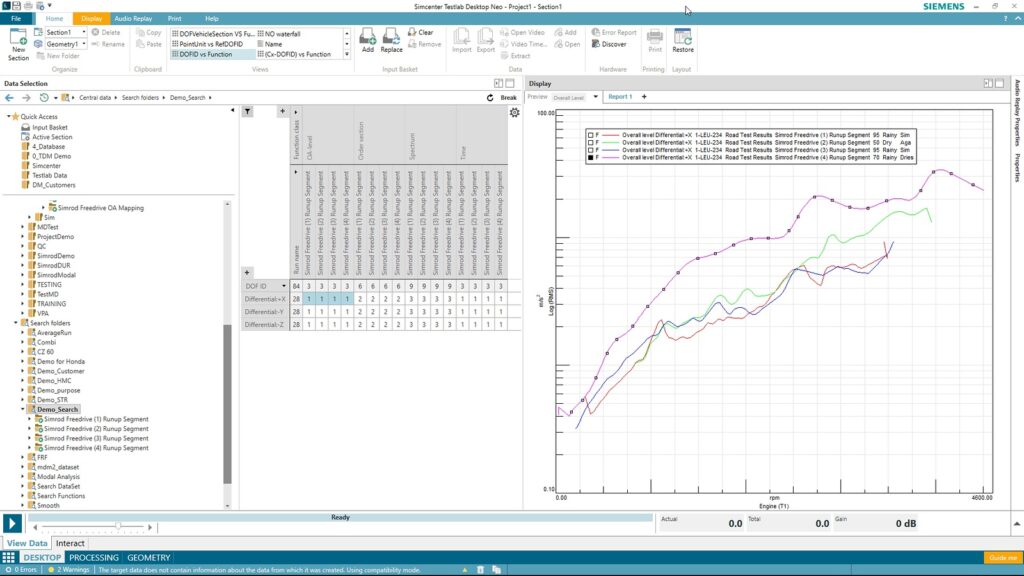

Advanced operational NVH testing with Simcenter Testlab Neo

Simcenter Testlab Neo comes with new enhancements for increased efficiency when evaluating NVH performance. As a Simcenter Testlab Neo 2021.2 Process Designer user, you can now filter and select only the data or segments recorded under specific operating conditions. And that’s not all! With Simcenter Testlab Neo 2021.2 Process Designer, you can even set up selection automation based on the defined operating conditions. And as the next step, you can use it in procession sequence Simcenter Testlab Process Designer.

Next to this, Simcenter Testlab 2021.2 comes with new enhancements for advanced audio reproduction and sound quality analysis.

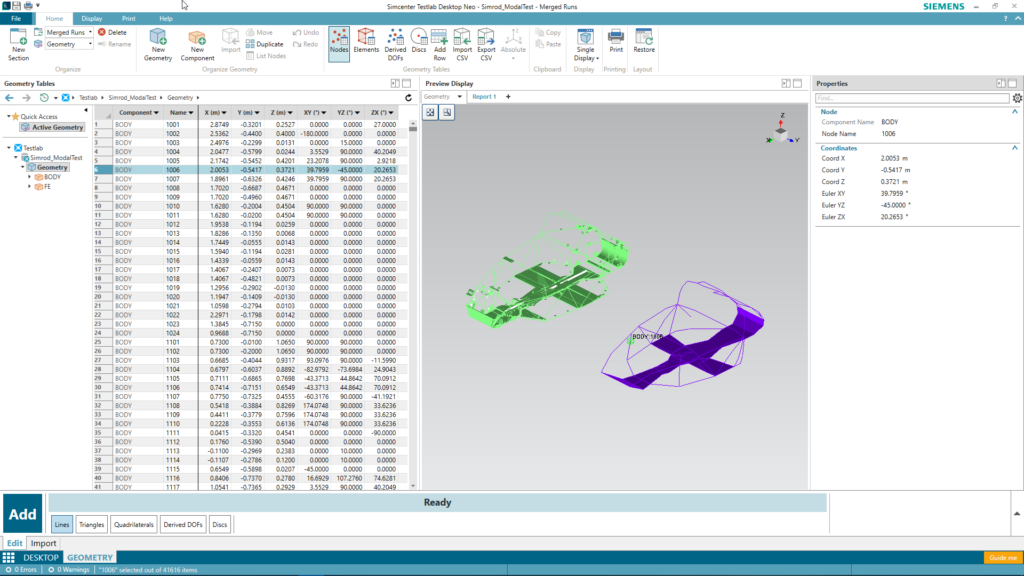

Simcenter Testlab Neo additionally offers new features for managing multiple geometries in one project. Now you can import Finite Element or STL files, merge them with existing geometries and digitally create a 3D representation of a tested system.

Learn more about NVH Testlab Neo Process Designer by reading this blog post: NVH Processing in Simcenter Testlab Neo Process Designer.

Simplified and more effective collaboration, comparison and reporting

Simcenter Testlab Data Management allows quick and easy comparison of measurement, analysis and simulation results of multiple test items across different test sites. It is a truly powerful tool for making the most of the data organization, visualization and reporting capabilities of Simcenter Testlab.

For publishing and searching data, Simcenter Testlab Data Management interacts with Peak’s ODS server software, which supports the latest ASAM standards and databases.

The great enhancement of this release is also that the new Simcenter Testlab Data Management solution for standardized central data management allows teams from different departments to publish consistent datasets, search for contextual information, and reuse the data for further analysis and reporting. Consequently, your colleagues can now access your data in a more structured way.

Learn more about Simcenter Testlab Data Management by reading this blog post: Why test data management is essential for team collaboration.

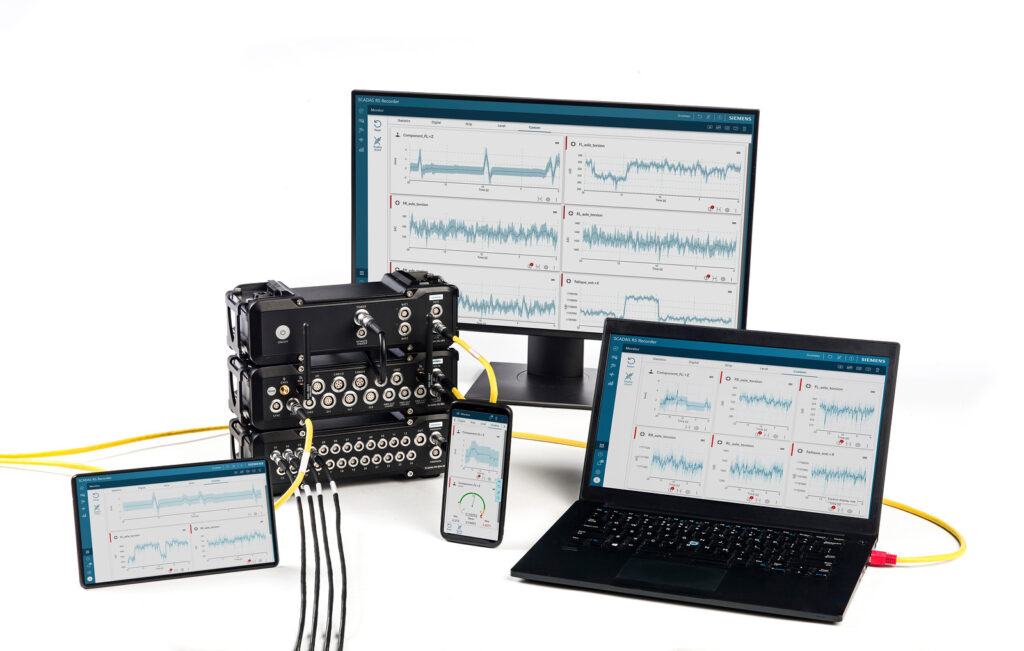

Productive testing in harsh and demanding conditions

Simcenter SCADAS RS is the latest member of our Simcenter SCADAS data acquisition hardware, introduced this year. Test engineers are challenged by testing reliably under demanding conditions. Off-highway vehicle development often involves testing under extreme temperatures, humidity, mud, dust and vibration. This is where the new version of Simcenter Testlab 2021.2 comes into play. The brand new Simcenter SCADAS RS rugged data acquisition system is designed for fast and cost-effective data acquisition in harsh environments on agricultural, construction and mining equipment. To get the most out of Simcenter SCADAS RS, Simcenter Testlab 2021.2 enables test preparation, test setup definition, data acquisition and validation.

Learn more about Simcenter SCADAS RX by reading our blog post: [What’s New] Simcenter SCADAS RS for rugged data acquisition.

More information about the Simcenter Testlab release

All in all, this new release is the result of a team of hard working, talented engineers and developers located in multiple countries, with the final mission of empowering you to be successful in your testing projects and to effectively overcome many of the present-day challenges.

Learn more about Simcenter Testlab 2021.2 by joining us for our YouTube Premiere on September 16th, 2021!

Read more about Simcenter Testlab 2021.1 in this fact sheet.

Visit the website for more information about Simcenter Testlab.