What’s new in Simcenter Testlab and Simcenter SCADAS 2506

Empowering test teams with AI-assistance and automation

Product testing teams often struggle with escalating costs, time-consuming processes, and the late discovery of critical issues requiring re-tests. These challenges hinder innovation and delay market entry.

Addressing these pain points, Siemens Digital Industries Software unveils the latest Simcenter Testlab software and Simcenter SCADAS hardware for the 2506 release. This release empowers engineers to test earlier, smarter, and faster. New AI-assisted workflows accelerate modal analysis by up to seven times, significantly reducing personnel needs and enabling faster insights. Automated data capture and processing ensure superior data quality and consistency, fostering smarter decisions. This integrated approach allows for critical validation to occur earlier in the development cycle, streamlining processes and accelerating time-to-market.

“Siemens has clearly stated its commitment to leveraging AI to streamline processes and workflows, minimize manual tasks, and accelerate time to market throughout the engineering lifecycle. The latest enhancements in Simcenter Testlab illustrate our approach to integrating AI in order to transform how teams conduct, manage, and interpret physical testing,” said Jean-Claude Ercolanelli, senior vice president, Simulation and Test Solutions, Siemens Digital Industries Software. “We are leading a significant shift in engineering practices, from design and development through to the essential stages of physical testing.”

Key highlights from the 2506 release focus on these core themes:

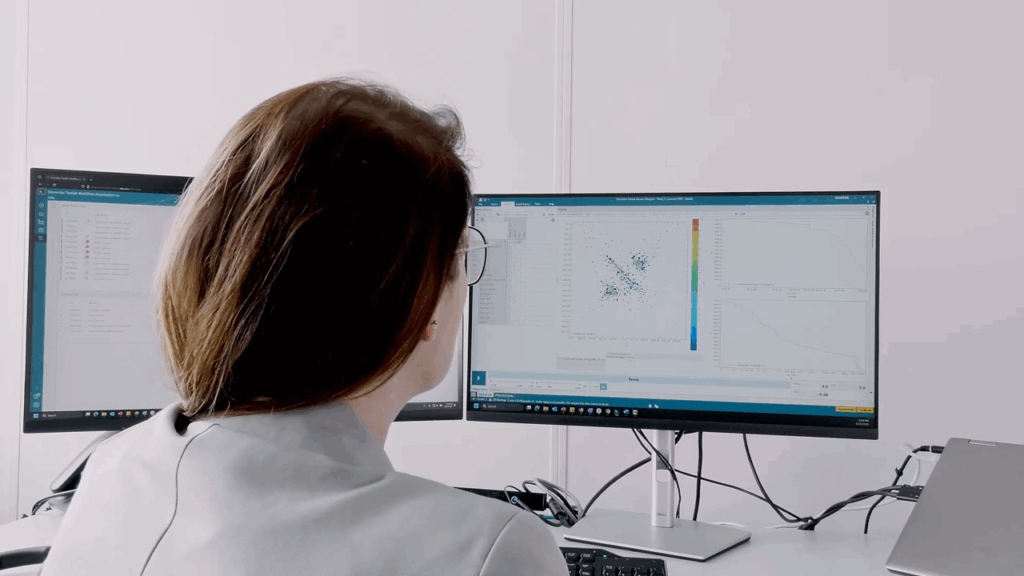

AI-assisted modal analysis

Engineers battle significant hurdles in modal testing, especially with complex structures. Manual processes are slow, resource-intensive, and prone to error. Accurately identifying critical modes remains a painstaking, expert-dependent task. These challenges bottleneck product development, delaying vital dynamic insights and compromising model reliability.

Simcenter Testlab 2506 revolutionizes modal analysis with AI-assisted mode selection and a new dashboard layout, cutting analysis time by up to 7x while ensuring expert-level accuracy. Additionally, it streamlines impact measurements with smart hit selection to automatically identify the best consistent data for analysis. This paradigm shift dramatically reduces manual effort, transforming complex tasks into efficient, reliable operations for faster product validation.

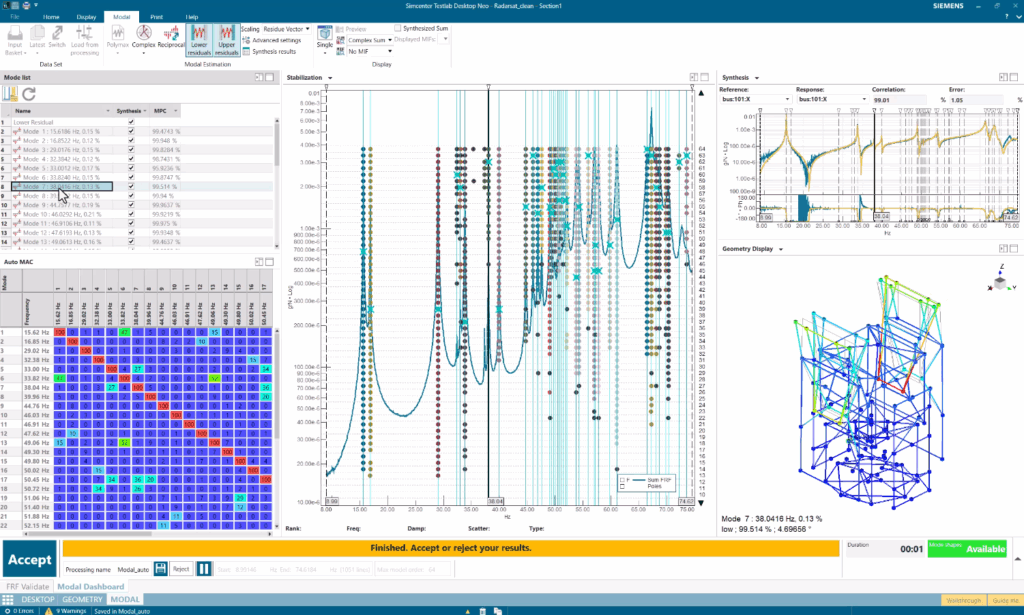

Redesigned, AI-assisted modal analysis for 7X faster process

New AI-assisted modal analysis automates complex mode selection and validation, drastically reducing manual effort and operator dependency. Coupled with a redesigned modal dashboard, this innovation streamlines workflows, cutting analysis time by up to seven times—transforming an hour-and-half process into just 15 minutes. Crucially, AI-assisted results consistently match expert accuracy, even in complex scenarios. This release enables faster, more reliable, and resource-efficient product validation.

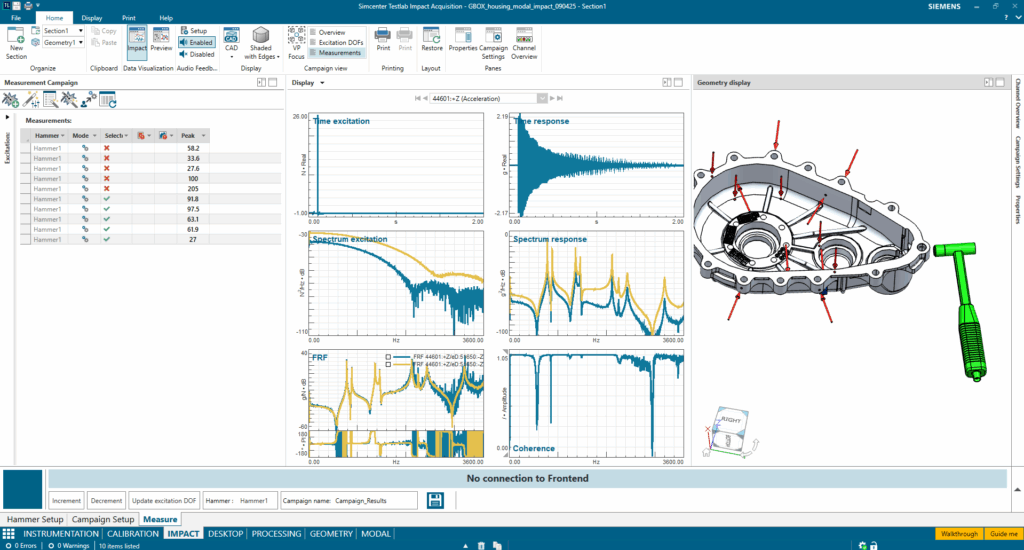

One-person operation during impact testing

Simcenter Testlab 2506 dramatically simplifies impact measurements with a new intelligent smart hit selection mechanism. This innovative feature automatically monitors and assesses hit quality, eliminating the tedious and error-prone need for manual, one-by-one verification. The system proactively tracks all impacts, intelligently identifying and selecting only the highest-quality data for analysis. This not only liberates valuable engineering resources from constant supervision but also guarantees unparalleled data consistency and reliability. Coupled with intuitive CAD-based instrumentation, Simcenter Testlab 2506 ensures that engineers effortlessly acquire superior quality FRF datasets, accelerating the entire testing process and boosting confidence in their results.

Streamlined system NVH prediction

NVH engineers pursuing zero prototypes struggle to validate virtual models with minimal physical tests. Transfer Path Analysis (TPA) is a key challenge: accurately decoupling complex noise/vibration sources from their paths and validating intricate models under realistic conditions. This often leads to prolonged, costly testing and development delays, hindering the journey to fewer physical prototypes.

Simcenter Testlab 2506 accelerates NVH component characterization by up to 40%. Automated data preparation and redesigned transfer path analysis streamline workflows. The patented Simcenter Testlab Automated Component Model Extraction offers one-click, repeatable blocked force measurements. Achieve faster, simpler, robust NVH characterization, accelerating your journey towards zero prototypes.

Redesigned transfer path analysis for 40% time reduction

Simcenter Testlab 2506 completely transforms the transfer path analysis process. It starts with Process Designer, which automates everything from raw measurements to principal component calculations. This intuitive, robust workflow slashes data preparation time by up to 40%. Furthermore, the redesigned TPA in Simcenter Testlab Neo simplifies visualization and interpretation, empowering even less experienced users. The ability to run multiple analyses in parallel further accelerates comparisons by up to 30%. The result is a significantly faster, simpler, and more robust characterization of NVH sources at the component level, streamlining product development.

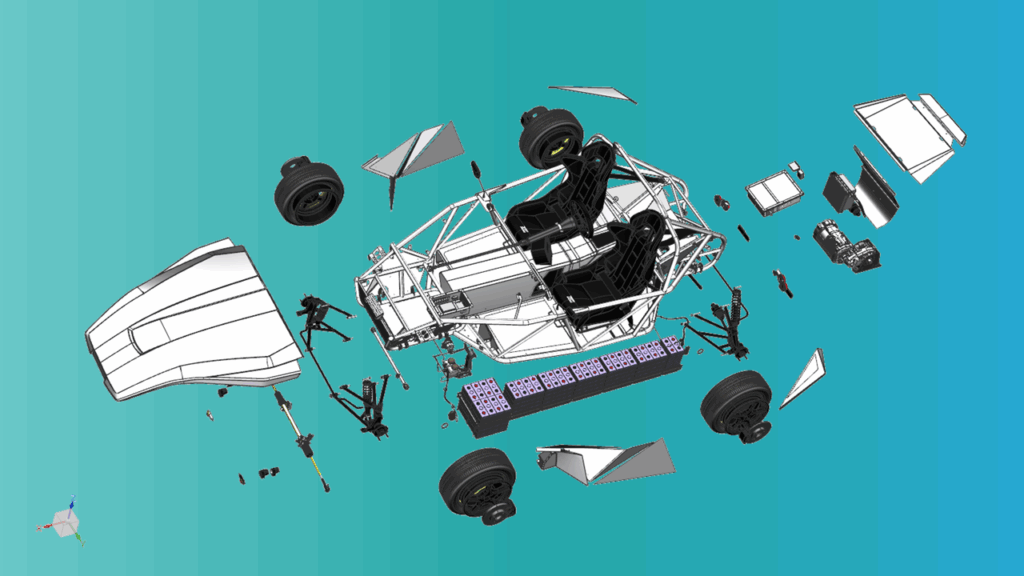

Automated component model extraction

Simcenter Testlab 2506 introduces the groundbreaking, patented Simcenter Testlab Automated Component Model Extraction, a market-first solution to accelerate component characterization and reduce physical prototypes. This new solution combining Simcenter hardware and software fully automates blocked force measurements and calculations, enabling precise component model integration into virtual assemblies for early NVH assessment. This system eliminates uncertainties from limited repeatability, operator dependency, and reliance on highly skilled personnel. With minimal user interaction and fixed instrumentation, it ensures absolute consistency and ISO 20270 compliant precision. Simcenter Testlab Automated Component Model Extraction transforms weeks of manual effort into hours, bridging the gap between simulation and physical testing and delivering trusted, repeatable results to accelerate your virtual prototyping journey.

Automation of more testing processes

Operational testing engineers face immense pressure from growing complexity and demands for faster, annotated results. A critical challenge is the late discovery of measurement repeats, leading to costly delays and rework. This hinders efficiency and complicates the delivery of comparable, high-quality test outcomes, making it difficult to meet tight deadlines and stringent requirements.

Simcenter Testlab 2506 can help you drastically improve operational testing. It proactively addresses complexity by streamlining test preparation, automating data processing, and ensuring full traceability. This integrated approach eliminates costly measurement repeats and guarantees consistent, high-quality results. Seamlessly integrating with data management, it empowers engineers to achieve faster, more reliable outcomes, meeting stringent demands with confidence.

Automate more measurement tasks

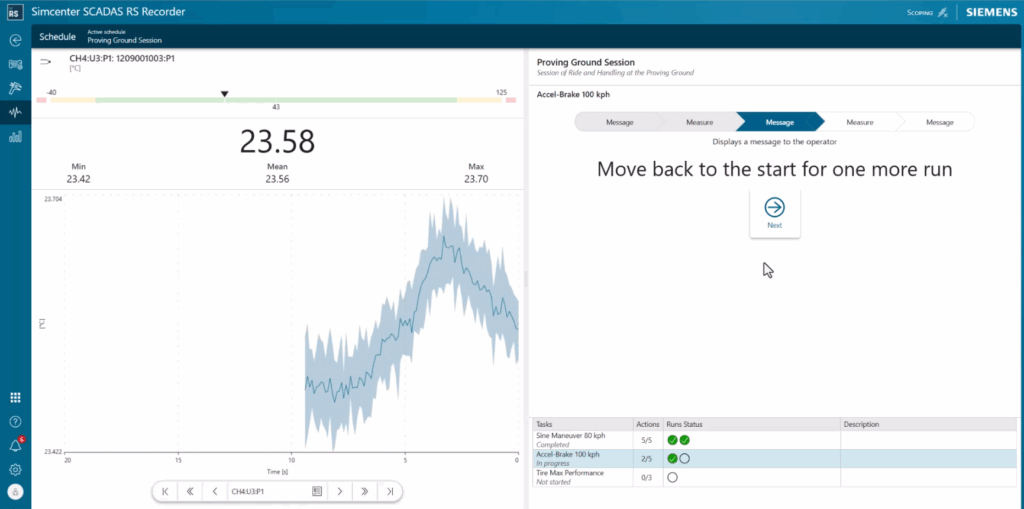

Comprehensive automation across acquisition, processing, and reporting can help you revolutionize your testing processes. The new Simcenter Testlab Schedule Designer streamlines test preparation, defining instrumentation, measurement settings, and operator tasks, ensuring full data traceability. This allows technicians to focus solely on measurement, guided by clear instructions displayed on devices connected to Simcenter SCADAS RS hardware. Post-acquisition, Simcenter Testlab Workflow Automation processes data automatically, guaranteeing consistent results and eliminating manual effort. Finally, processed data is seamlessly published to centralized data management systems, either on-premises or in the cloud. This integrated approach delivers unparalleled efficiency, accuracy, and reliability throughout the entire test campaign.

Automate more processing tasks

Simcenter Testlab 2506 significantly enhances automation within the Process Designer, empowering engineers with unprecedented efficiency and reliability. New extensions allow processing variables to directly read values from Microsoft Office, ideal for applications like mission synthesis and life damage calculations. Crucially, descriptive annotations captured during acquisition now intelligently guide data processing, enabling conditional workflows based on factors like component type or test conditions. Furthermore, the system introduces automatic validation of processed data, allowing comparisons against target curves or rejection of measurements outside defined limits. This comprehensive automation across instrumentation, acquisition, processing, and publishing streamlines the entire workflow, making engineers dramatically more efficient and ensuring consistent, high-quality results.

Efficient, versatile and open data acquisition

Data acquisition presents significant challenges for test engineers. Integrating diverse sources, including high-voltage EV, often demands costly, separate hardware. Poor planning causes errors and re-runs. Managing disparate third-party analysis tools complicates workflows, increasing investment and hindering efficiency.

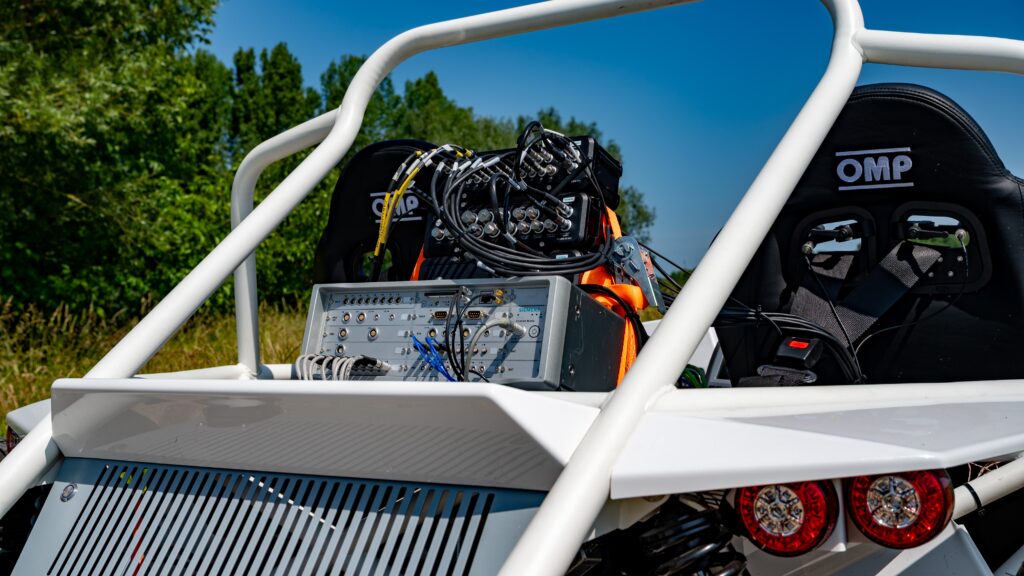

The latest Simcenter SCADAS RS hardware simplifies data acquisition. It integrates diverse sources (high-voltage EV, XCP/PTP). Modular design expands capabilities, integrating with other existing Simcenter SCADAS units. Schedule Designer guides operators for precise, consistent data. Universal data export ensures hardware openness, safeguarding investments.

Enhanced XCP over Ethernet with Precision Time Protocol

Simcenter SCADAS RS now dramatically enhances data acquisition capabilities with significantly improved XCP over Ethernet support, integrating Precision Time Protocol (PTP) synchronization for unparalleled precision. This advancement enables seamless connection of third-party conditioning units, ensuring high-bandwidth data transfer with precise time synchronization. Whether conducting critical measurements in challenging high-voltage zones or extracting vital data from diverse digital networks and buses, Simcenter SCADAS RS can now be powerfully augmented. This expansion profoundly broadens its applicability, empowering engineers to tackle a wider array of complex testing scenarios and unlock new levels of efficiency and data integrity across various industrial applications.

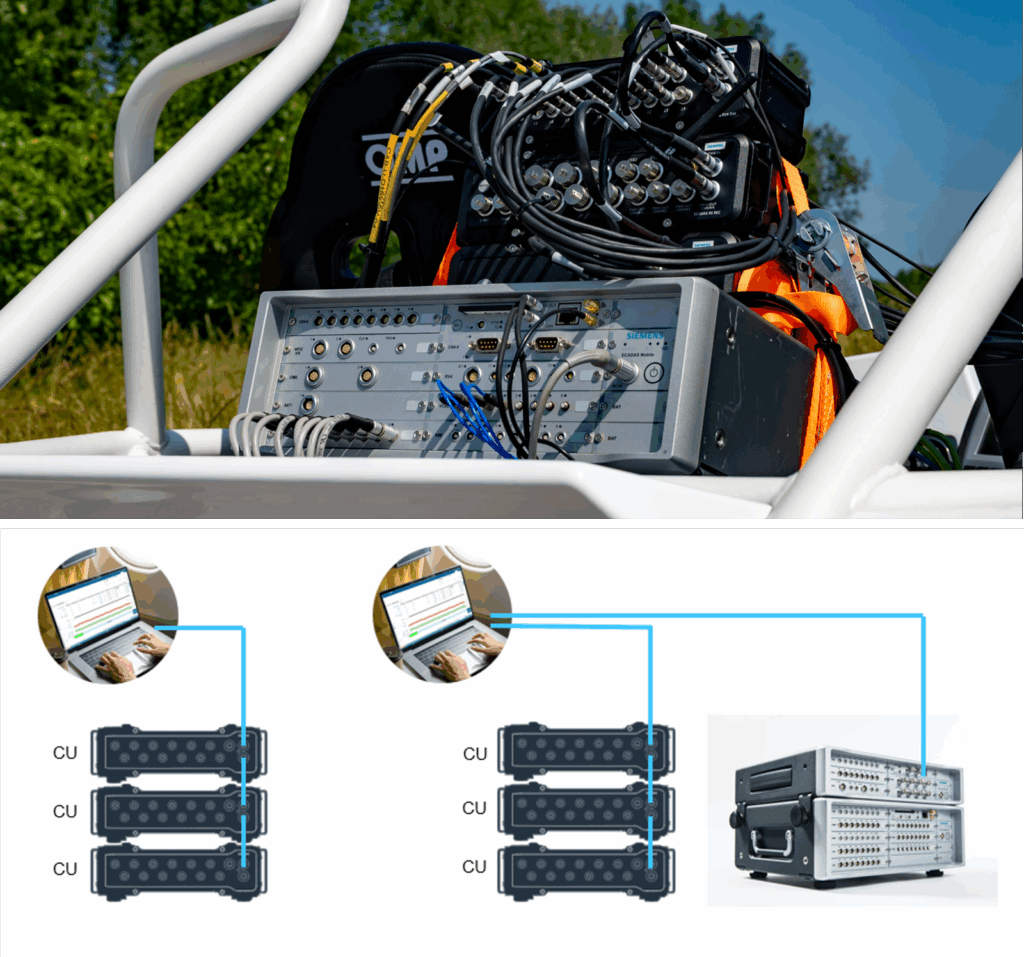

Combine Simcenter SCADAS RS with Simcenter SCADAS Mobile, Recorder or Lab

Simcenter SCADAS RS is a flexible and modular system that supports extended configurations. Rugged, PC-free standalone acquisition is possible, powered by the intuitive Recorder App, and you also benefit from rich connectivity with Wi-Fi and 5G. The good news is that you can now enjoy all the benefits of Simcenter SCADAS RS conditioning units (CUs) even when combining it with Simcenter SCADAS Recorder, Mobile, and Lab systems. Notably, for this combination to happen, you can proceed without a Simcenter SCADAS RS Recorder (REC) unit, unless you require standalone acquisition, onboard data storage, or expanded connectivity. This way, you not only expand your channel counts but also upgrade capabilities, ensuring your investment moves in the right direction.

Directly provide scheduled instructions and streamline data validation

Simcenter SCADAS RS supports the new Simcenter Testlab Schedule Designer, which was introduced above. The test schedule and instructions defined in the Schedule Designer seamlessly pass into the Simcenter SCADAS RS Recorder App to provide clear, simple instructions directly to the operator via a tablet during testing. This provides clear guidance to the operator on what to do next and eliminates miscommunication and testing inconsistencies.

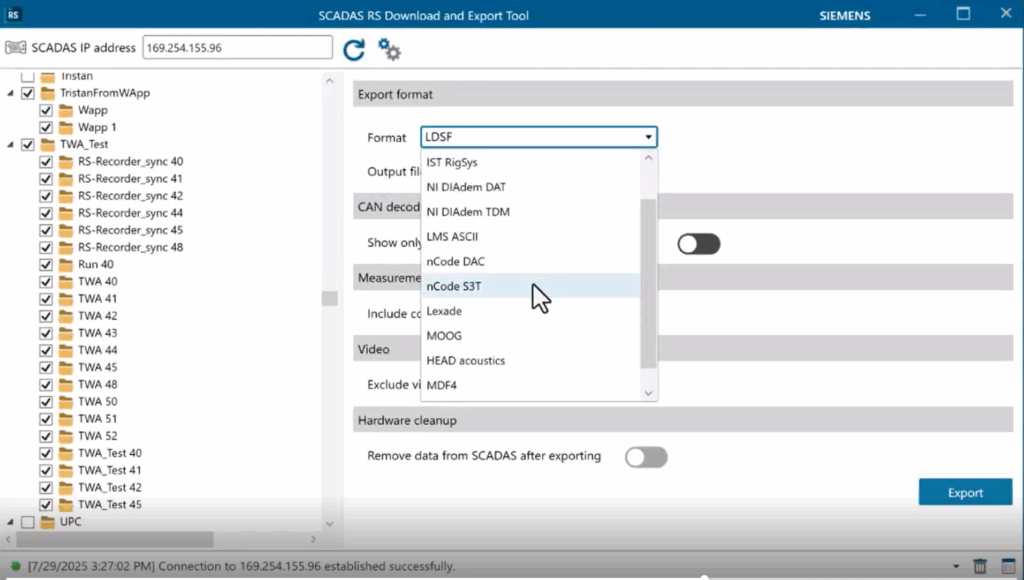

Export to universal 3rd-party formats

In keeping with Siemens’ philosophy of openness, you can now export data in universal or third-party formats from Simcenter SCADAS RS, allowing you to seamlessly continue using your preferred software platform for data processing and analysis. This hardware openness provides you with flexibility and safeguards your existing investments.

Keep up to date

Be sure you have all the latest news by following ‘The latest news from Simcenter Physical Testing’, our monthly blog with all the content on Simcenter Testlab, Simcenter SCADAS, Simcenter Micred and Simcenter Anovis.