Simcenter STAR-CCM+ 2302 Released! What’s new?

Model the complexity of battery thermal runaway with ease. Run more cost- and energy-efficient CFD simulations thanks to ARM64 CPU support and further GPU-enabled acceleration. Speed up your CFD simulations by more than 30% with the SIMPLEC scheme. Document, share, and review detailed model information within the CFD software.

Simcenter STAR-CCM+ 2302 comes with numerous new capabilities that let you go faster while modeling the complexity.

Learn how to use Support Center

New enhancements in Simcenter STAR-CCM+ are aimed at helping you:

Model the complexity

Battery thermal runaway setup in minutes

With the rapid growth of electric vehicles circulating on the roads, new safety rules have been put in place at the country level but also internationally with new UN safety rules regarding the use of Li-ion batteries.

Such legislation forces major players making and using batteries to conduct numerous costly and lengthy tests to obtain certifications. This leads to an increasing demand for simulation to reduce the cost of testing and make safety design economically efficient.

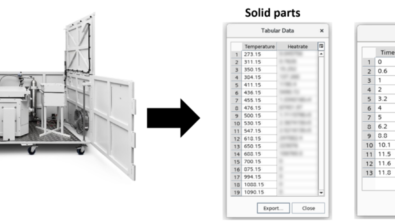

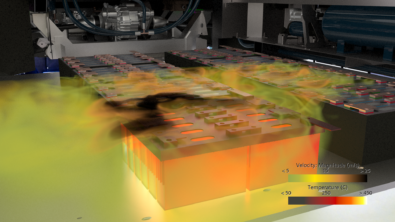

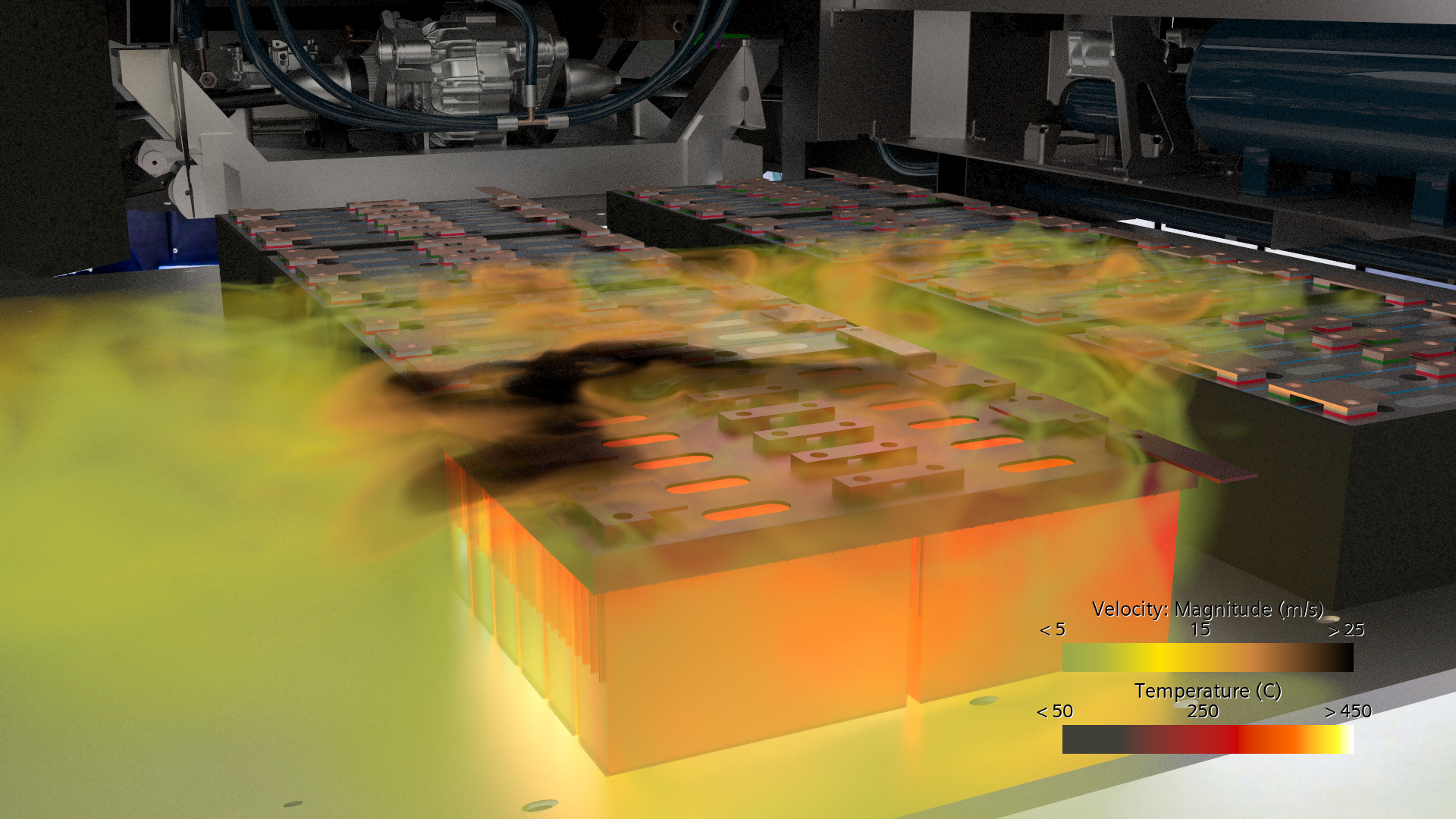

In Simcenter STAR-CCM+ 2302 we release a dedicated workflow to accelerate the setup time of thermal runaway propagation simulations for batteries from hours down to minutes. Thanks to a focused workflow you can now handle large packs of hundreds or thousands of cells with ease yet retaining high modeling fidelity. The workflow supports the straightforward simulation of a “failed” cells’ exothermal heat release with an empirical model and can be accessed as part of the Simcenter STAR-CCM+ Batteries add-on.

Thanks to its powerful multiphysics capabilities and the all-new dedicated workflow, Simcenter STAR-CCM+ is perfectly suited to study the propagation of thermal runaway events on a complex pack geometry. Simcenter STAR-CCM+ offers a comprehensive solution to better understand this hazardous safety event and helps design pack and mitigation measures, thereby reducing the needs for costly tests.

Easy and accurate modeling of motion with overset meshes

Store separation, valves, dip coating and many other applications involve moving bodies, with small gaps together with complex fluid dynamics. To simulate such complex applications with CFD, overset meshing technology together with Adaptive Mesh Refinement (AMR) has become a key technology.

With Simcenter STAR-CCM+ 2302 we make it easier to run such cases through an automatic refinement of the overset region to match the refinement level of the background region. Small gap scenarios will immediately benefit from the new capability by guaranteeing valid meshes and ensured convergence without any additional user effort.

Model new applications involving drying of wet solid materials

Many applications in the chemical processing, mining, steel, food and battery manufacturing industry involve drying of wet solids. The CFD simulation of such systems requires both a precise prediction of particle motion and respective phase-change phenomena.

In Simcenter STAR-CCM+ 2022.1, we therefore introduced the Liquid-Solid-Gas material for Lagrangian non-DEM particles allowing to apply evaporation modeling for droplets containing solid materials. This functionality is for example successfully used to simulate milk droplets in spray drying.

With Simcenter STAR-CCM+ 2302 we extend the capability to Discrete Element Method (DEM) particles allowing to apply evaporation models to DEM phases. This enables you to model new applications involving drying solid materials where DEM is the particle-dynamics method of choice by enabling evaporation of liquid components in DEM particles.

Thanks to the new feature you can accurately simulate drying processes in direct, convection-based dryers like drum dryers, spray dryers, fluidized bed dryers or indirect conduction-based dryers using the Discrete Element Method for the wet solid phase.

Go faster

Better performance per price with ARM support

Simulation has become a critical factor in time and resource-efficient product development. And while CFD simulation is significantly less resource-intense than corresponding physical testing, to stay competitive, companies must take it a step further. With ever increasing volume of simulation-driven product design, to have a competitive edge, you must optimize energy consumption and cost associated with those high-fidelity simulations. Ultimately, a sustainable, cost- and energy-efficient digital twin is a distinguishing factor and competitive advantage in virtual product development.

With Simcenter STAR-CCM+ 2302 we allow you to run larger, faster CFD simulations for less cost and energy using Advanced Reduced Instruction Set Computer Machines (ARM) CPU technology.

Currently, the technology is supported on Linux and available through different cloud vendors like AWS EC2 instances or the Fugaku super-computer provided by Fujitsu in Japan.

With ARM support we add another option to running your CFD simulation in an increasingly heterogeneous hardware architecture landscape. Whether it’s GPU or CPU, on-premises or cloud, ARM or conventional CPUs, Simcenter STAR-CCM+ offers a variety of options to maximize your throughput.

Larger and faster simulations on GPUs

Typically, the size of simulation that can be run on GPUs is limited by the available memory (RAM) of a GPU card. Therefore, by reducing memory consumption of a given simulation you can fit larger meshes onto a single GPU. This is particularly useful as the most efficient GPU performance is seen when the cards are “maxed out” meaning fitting as many cells as possible on a single card.

To maximize the benefits, Simcenter STAR-CCM+ 2302 comes with a reduced memory overhead and improved performance through more efficient use of AmgX as well as upgrades to CUDA, the NVIDIA API. On top of the already existing performance benefits of GPUs from previous releases these enhancements result in a memory reduction of up to 40 % as well as runtime performance improvements of up to 10%. As an example a single NVIDIA A100 with 80GB of memory can now fit around 60 million trimmed cells in mixed precision.

With these enhancements we continue our strategy to support fast and efficient CFD simulation on GPUs while maintaining consistency with CPU based results.

Up to 40% faster simulations at no cost

Adding to the benefits of new hardware and massive scalability for high-performance computing, speeding up your CFD simulation through more efficient solver techniques remains the most cost-efficient way to go faster.

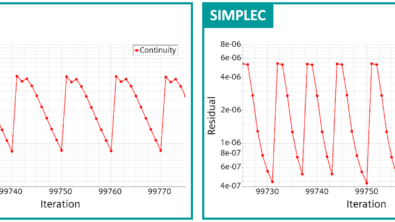

In Simcenter STAR-CCM+ 2302, we introduce a new unsteady implicit scheme for the Segregated Flow Solver: the SIMPLE-Consistent, so-called SIMPLEC.

SIMPLEC enables significant acceleration for simulation of transient flows due to a deeper convergence of the solution within the time step. Thanks to SIMPLEC you can obtain the same accuracy as SIMPLE with a reduced number of inner iterations per time step. By using convergence-based stopping criteria for inner iterations there is no need for tuning when applying the new SIMPLEC scheme.

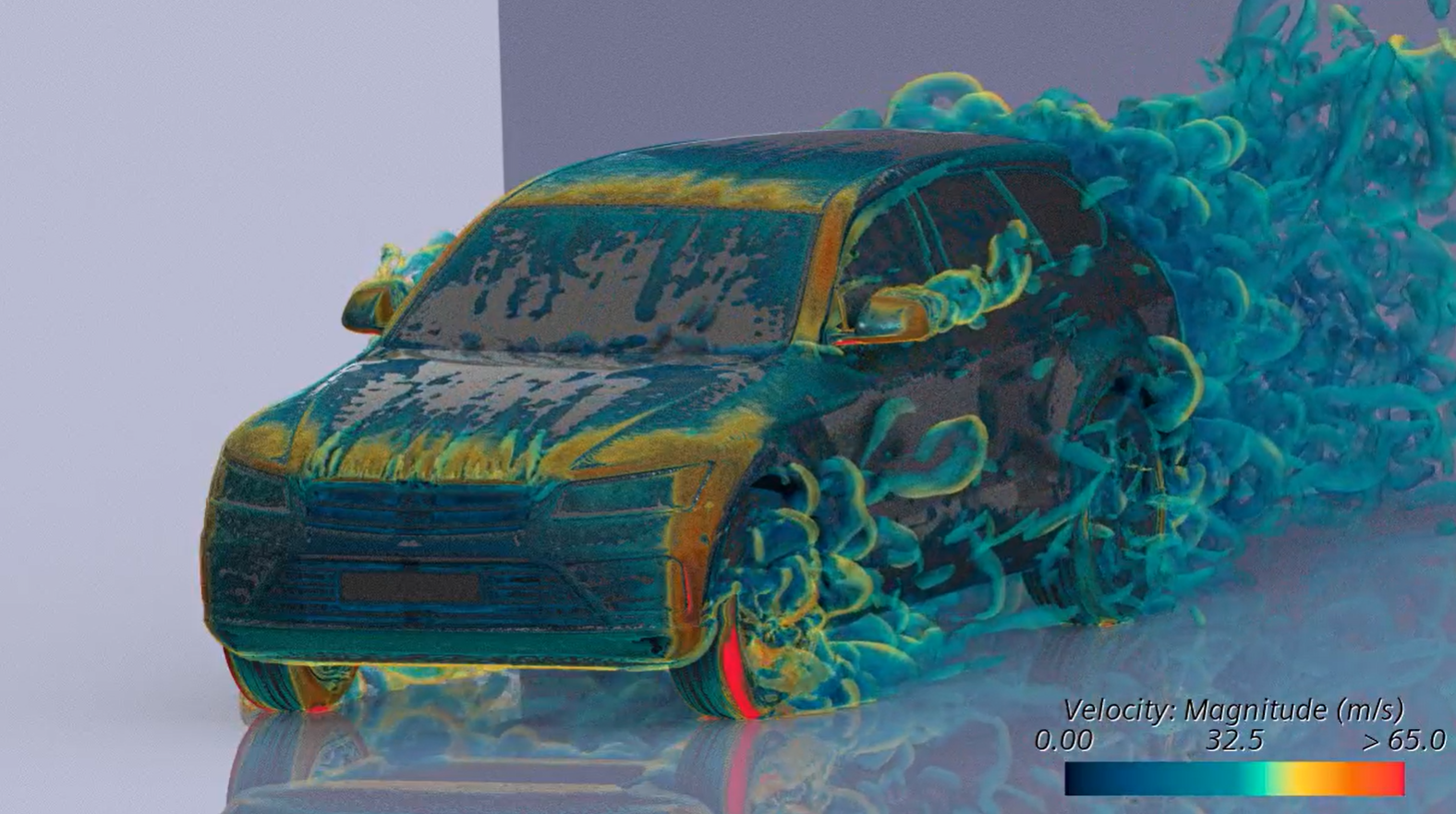

For applications ranging from vehicle external aerodynamics through side-mirror and HVAC aeroacoustics to airplane wing icing, leveraging SIMPLEC results in a reduction of up to almost 30% of the total turnaround time. All this while ensuring consistency of results between SIMPLE and SIMPLEC approaches. And at no additional cost.

Accelerate multiphase simulations without losing fidelity

In applications like gear box splashing droplets may break-up in smaller and smaller size until you can no longer model the very small droplets as Lagrangian particles. At the same time you still need to model the free surface of the bulk liquid. For such applications Mixture Multiphase with Large Scale Interface modelling (MMP-LSI) has become the method of choice. In general, MMP-LSI is relevant anywhere you have Volum Of Fluid (VOF) but that would be too expensive, and a mixture is present.

But just like VOF, MMP-LSI comes at a comparably high cost if you can’t decouple the choice of flow timestep from that needed to fulfill the small timestep required for the volume fraction due to Courant (CFL) number constraints. To overcome this challenge we previously rolled out Implicit Multi-Step for VOF where simulations were typically sped up by 3-4x and in some cases by up to an order of magnitude.

In Simcenter STAR-CCM+ 2302 we are adding the same capability for MMP-LSI. Implicit Multi-Step allows a larger timestep to be used for the flow (excluding volume fraction) by sub-stepping for the volume fraction multiple times withing the flow timestep. This decouples the choice of flow timestep from that required for the volume fraction due to CFL constraints.

Explore the Possibilities

Easily understand a design space using contour plots

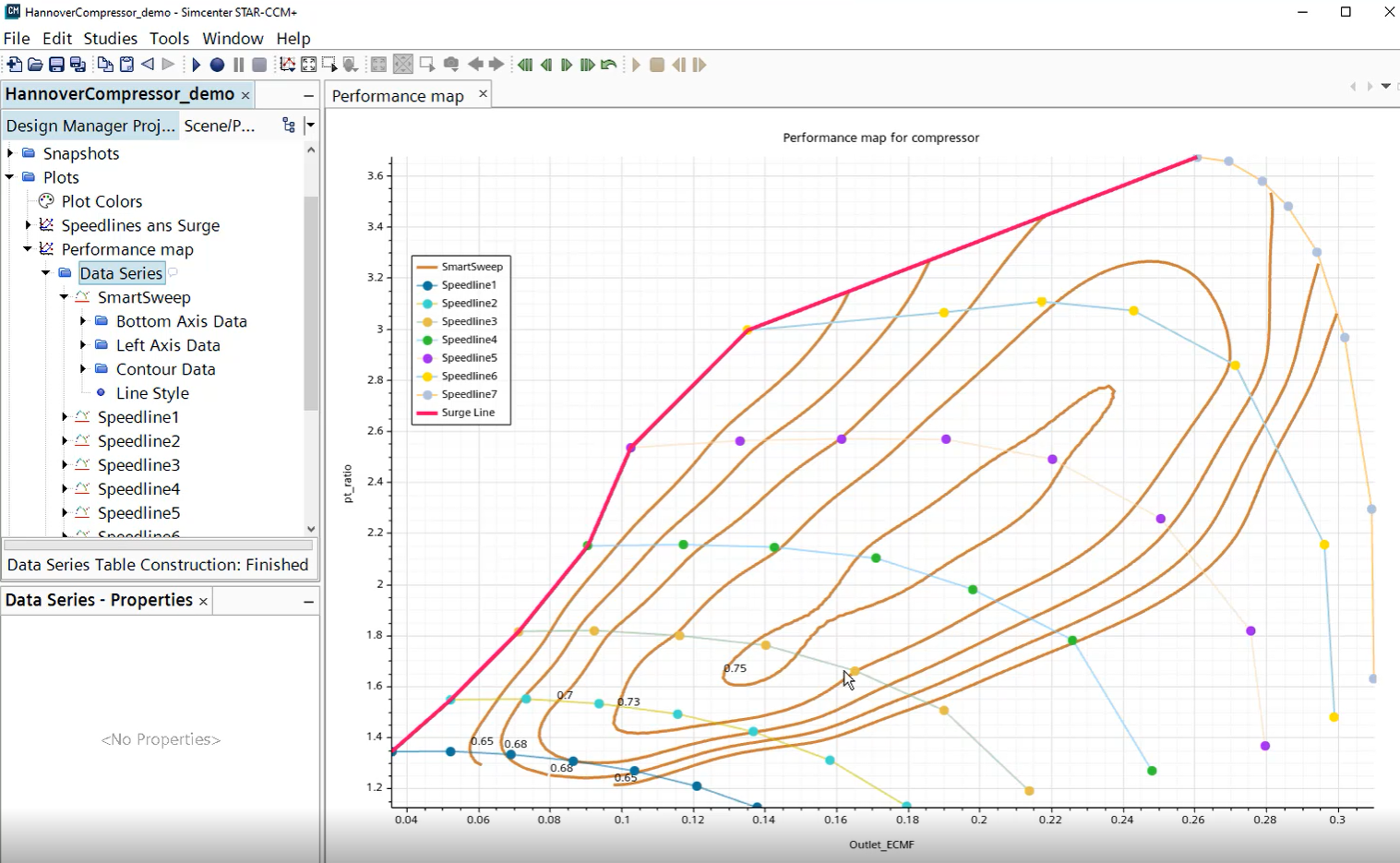

For many applications, like e.g. turbomachines, CFD is a very powerful and cost-effective tool to generate performance maps through automated sweeps. Such maps will give immediate insights into the performance in from as a dependent variable as a function of multiple independent variables.

With Simcenter STAR-CCM+ 2302 you can now quickly and easily generate performance maps with two independent and one dependent variable. This will allow you to add a layer of information to the standard XY plot through contour plots. Interpolation is used to draw the contour lines and the display of external data, say from experiments, is supported through tables.

Thanks to the new capability you will gain insights into a complete performance map with isolines in a few clicks.

Stay integrated

Integrated access to simulation information

In today’s complex engineering world efficient collaboration and sharing relevant information between engineers is more important than ever. For simulation engineers wasting your time searching external disconnected resources for the latest simulation setup documentation or usage instructions for templated simulations is a massive productivity burden. For CFD simulations this implies traceable data and workflow management and the ability to work in an integrated environment allowing you to access all relevant simulation information quickly and directly.

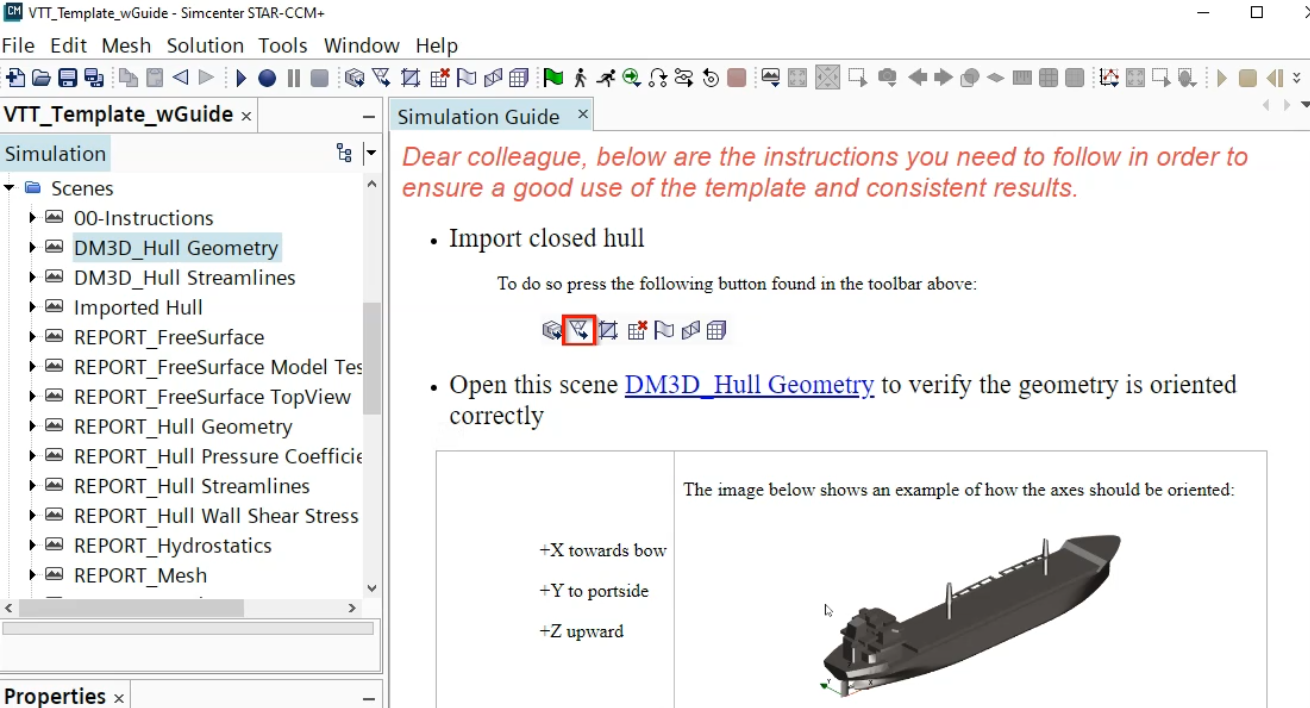

In Simcenter STAR-CCM+ 2302 we are introducing the Simulation guide. The Simulation guide allows you to store all relevant information inside the simulation file. Having notes or instructions directly in the simulation file increases your productivity as you spend less time looking for information. With an embedded editor, you can add all relevant meta information exactly where it’s needed: within the simulation file. The editor allows you to write text, format it, add images, create tables. As a consequence, the simulation guide enables you to seamlessly share, update and review information relevant to the simulation. It helps your team collaborate and build collective knowledge.

Together with the template simulation file introduced in Simcenter STAR-CCM+ 2022.1 the simulation guide will lift your productivity to new heights: Simulation template authors can leave detailed instruction just where needed while template users can now quickly understand setup steps by leveraging streamlined workflow instructions while staying inside the CFD environment.

These are just a few highlights in Simcenter STAR-CCM+ 2302. Those features will enable you to design better products faster than ever, turning today’s engineering complexity into a competitive advantage.

To learn more, join Rodolfo Piccioli, Principal Engineer, and Stamatina Petropoulou, Product Manager Physics, as they walk you through these and more exciting new capabilities, 40 minutes packed with detailed insights, from engineer to engineer:

We value authentic feedback on our products and services from our customers, we would like to invite you to share your experience with Simcenter STAR-CCM+