Setup an effective and accurate virtual shaker sine base excitation test

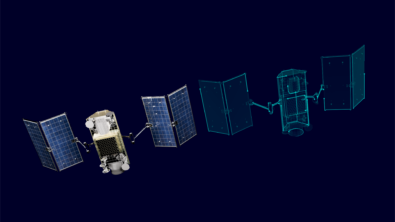

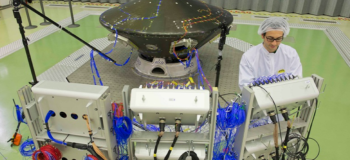

Any space-bound hardware, small or large, needs to complete a thorough dynamic qualification testing process, including for example a sine base excitation test. This should guarantee that the structure can withstand the harsh launch conditions it will be subject to. But putting a multimillion-dollar object on a shaker table is risky business. In space engineering, there is no room for repetitive prototyping. On the contrary, the idea is that the prototype becomes the real structure. So, what if it gets damaged?

To de-risk qualification tests, engineers and analysts prepare them virtually, on a Digital Twin. In this approach, it’s obviously essential that all modeling components are realistic, including the loads.

Simcenter Nastran has a long-standing reputation in various industries for delivering top-notch results effectively by using normal modes in frequency response simulations. But it can require some expert knowledge to define the right setup.

That’s where Simcenter 3D Response Dynamics will be helpful. This software guides analysts and experts in their evaluation of both simple parts and complex assemblies with intuitive events and Nastran modal results. Read below how Simcenter 3D can most effectively and accurately simulate a shaker sine test.

We describe and illustrate this technology in the context of virtual space testing. But the same methods are applicable in, for example, electronics, construction, or any other application where a structure is subject to vibration excitation.

The Simcenter 3D Sine Base Excitation event

The Sine Base Excitation event of Simcenter 3D combines an efficient modal approach with a parallelized solver that leverages advanced analytical expressions. In this way, we achieve the fastest and most accurate simulations with harmonic base excitation. It’s the ideal solution for engineers and analysts to do virtual electrodynamic shaker sine tests.

The most performant solver options

Using a parallelized solver

The solver automatically grabs all available threads to speed up the computation of phase-consistent derived quantities. These include Von Mises stresses, displacement magnitudes and Tsai-Wu failure indices.

Running in batch mode

As the FE model size grows, and as more modes are considered for improved accuracy, a sine base excitation solution can take hours. This obviously shouldn’t lock your desktop. Therefore, you can launch a Sine Base Excitation event solver from the command line on a remote server.

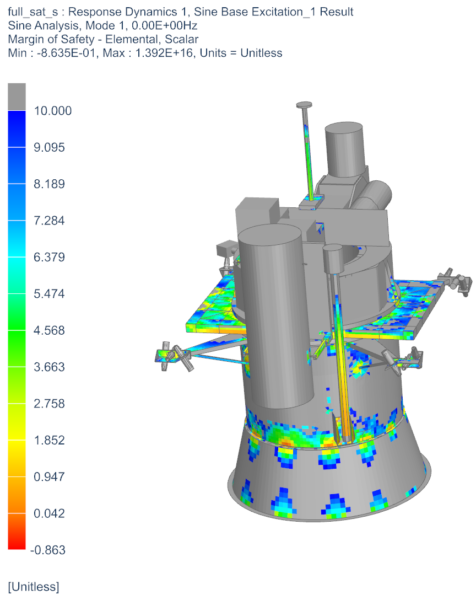

Automatic computation of failure metrics

In most FE projects, calculating the stresses is hardly a goal by itself. Engineers rather validate a design by comparing simulation results to strength or strain limits. The Sine Base Excitation event can extract strengths from Simcenter 3D isotropic and orthotropic materials. Those are stored in the results file of the Nastran normal modes simulation. You can then request failure metrics for homogeneous elements (failure index, margin of safety), as well as laminate failure metrics for composite elements (failure index, strength ratio, margin of safety).

The most accurate virtual shaker sine test

Residual vectors to account for modal truncation

The modal approach of the solver is more efficient than a direct method. But the number of modal vectors you retain will impact accuracy. To compensate for all modes beyond consideration, Simcenter Nastran can compute residual vectors due to inertial loads. The Sine Base Excitation event then accounts for their quasi-static contribution. They are not involved in the dynamic response calculation, so you don’t need to worry about assigning them damping values, or excluding them from the analysis frequency band.

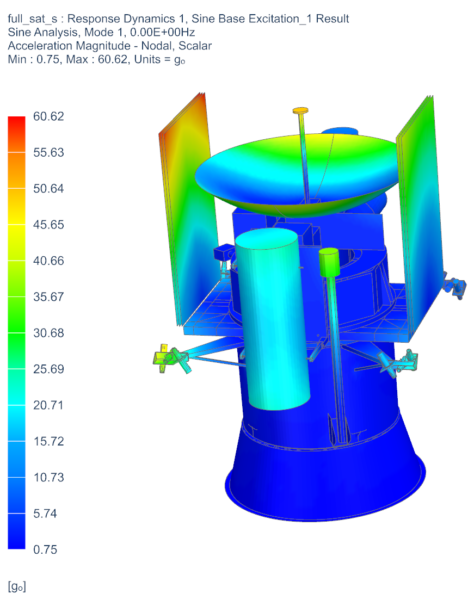

Phase-consistent derived responses

The Sine Base Excitation solver derives responses from various components, which are likely to have different phase angles as they are complex in nature. Therefore, derived responses are reported for the critical phase angle. This is the angle for which the magnitude of the response is maximum. The following derived responses can be computed:

- Nodal translational and rotational magnitudes

- Von Mises, principal and maximum shear stresses and strains

- Laminate failure metrics

Except for principal stresses and strains, which require an additional calculation, the solver uses efficient analytical expressions to determine the maximum phase-consistent derived quantities.

In summary

The Sine Base Excitation event of Simcenter 3D Response Dynamics improves efficiency while increasing results accuracy. It is the perfect solution for frequency response simulation with harmonic base excitation of both simple parts and complex assemblies.

The entire process for virtual shaker sine tests is available in the upcoming Simcenter 3D 2021.2 release.

Related blogs

Do you think this was interesting to read? You might also consider reading the following blogs:

- A shaker table for vibration testing should not play music

- Airbus: priceless payloads ready for space launch

- Shake it and drop it! Testing for laptop reliability

- Vibration control testing for electric cars

Or why note read a white paper on space qualification testing?