Optimize data center cooling with innovative computational fluid dynamics simulation (CFD)

AI’s power surge

Artificial intelligence (AI) has significantly increased the power consumption of data centers. Ten years ago, a 30-megawatt (MW) center was considered large, but today, a 200-MW facility is normal. This increase is driven by the computing power required for AI workloads, which in turn bumps up energy consumption.

According to Goldman Sachs Research1, the overall increase in data center power consumption from AI is estimated to be on the order of 200 terawatt-hours per year between 2023 and 2030. By 2028, AI is expected to represent about 19% of data center power demand.

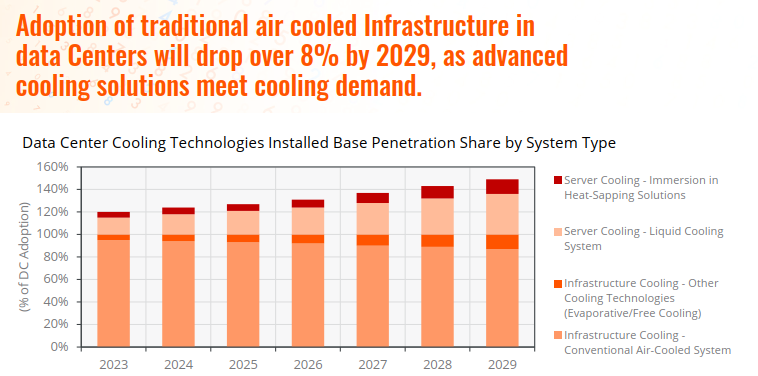

With the rise of AI, traditional air-cooling methods to prevent equipment malfunction, long the de-facto industry standard, are becoming increasingly inefficient and unsustainable to manage the enormous amounts of heat generated by servers. This challenge has led to the rise of immersion cooling as a superior alternative.

The problem with air cooling

Conventional air cooling relies on large fans and air conditioning systems to manage server heat. This approach is not only energy-intensive but also environmentally detrimental due to its reliance on refrigerants with high global warming potential. As server densities continue to increase, air cooling struggles to keep up, prompting a shift toward liquid cooling methods.

Source: ABI Research

The rise of liquid cooling

Liquid cooling offers a more efficient and sustainable alternative. Unlike air, liquid can carry much more heat, allowing for smaller volume flows and less energy consumption. Liquid cooling systems also provide more stable temperatures, which is beneficial for equipment reliability. Moreover, the heat absorbed by the liquid can potentially be reused for other purposes, such as local heating.

Immersion cooling: a game-changer for data centers

One of the most favorable forms of liquid cooling is immersion cooling. Data center equipment is submerged in a dielectric fluid – a liquid that does not conduct electricity. This fluid absorbs the heat generated by the equipment and is then pumped out, cooled, and recirculated. Immersion cooling can be either single-phase, where the liquid remains in a liquid state, or two-phase, where the liquid boils and then condenses. While two-phase cooling can offer higher heat transfer efficiency, single-phase cooling provides a more reliable, cost-effective, and easier-to-implement solution for many data center applications.

There are three main types of dielectric fluids for single-phase immersion cooling: fluorocarbons, hydrocarbons, and plant-based oils, each with its own set of advantages and disadvantages.

Fluorocarbons have a high global warming potential and are not biodegradable, raising environmental concerns. Hydrocarbons, made from fossil oil or natural gas, offer higher thermal conductivity and are biodegradable, but are more viscous. Plant-based oils, the most environmentally friendly option, have zero global warming potential, are made from renewable materials, and are non-toxic and biodegradable, making them ideal for sustainable data centers.

“Deploying immersion cooling technology is the best and fastest way for data centres to increase capacity, use less power and water, and reduce costs. The process involves cooling IT equipment (up to entire servers) in thermally conductive and dielectric liquid. It’s a cut above other liquid cooling solutions like direct-to-chip because it captures all heat across all components (including increasingly hot DIMMs and GPUs). Plus, it’s easier to then reuse the captured heat. And it’s more environmentally friendly and cost-effective than throwing millions of gallons of water at the problem..”

Source: Submer.com

Optimizing data center cooling with Simcenter

Immersion cooling presents a promising future but selecting the right dielectric fluid and optimizing system design are critical challenges—challenges best addressed through advanced computational fluid dynamics (CFD) simulation. CFD enables engineers to optimize cooling strategies, assess fluid dynamics behavior, improve overall performance, and ensure long-term reliability in data centers.

Simcenter Flotherm is a cutting-edge powerful CFD simulation tool for electronics cooling applications that enables data centers to achieve optimal cooling performance. This simulation software allows for detailed 3D thermal analysis of servers and components. Engineers can simulate different cooling configurations, analyze component temperatures, and optimize heat dissipation strategies.

Leveraging these advanced simulation tools can not only reduce operational costs but also help to stay ahead of regulatory and environmental challenges.

As data centers continue to expand, immersion cooling—enhanced by CFD simulation—will play a crucial role in ensuring higher efficiency, reliability, and sustainability for years to come.

Want to know more?

Watch this webinar if you would like to understand how CFD simulation helps optimize data center cooling strategies by modeling coolant pressure, flow, and heat distribution, allowing for precise design adjustments that improve overall performance and reduce energy consumption. You’ll understand how oils, and especially plant-based oils, as opposed to fluorocarbon-type dielectric liquids, are emerging as a viable alternative for data center immersion cooling.

(1) https://www.goldmansachs.com/insights/articles/AI-poised-to-drive-160-increase-in-power-demand