Multi-domain simulation – Unparalleled engineering excellence with Simcenter X Advanced

Capture the real-world complexity with multi-domain simulation using Simcenter X Advanced

Designing complex engineering systems, such as a gas turbine, are often long-time projects where many iterations and extensive collaboration across teams, departments or organizations are needed. The traditional approach is often characterized by siloed domain workflows which additionally cost time and effort. With Simcenter X Advanced, a flexible, Software as a Service (SaaS) multi-domain engineering simulation suite, we provide you with one-license access to a comprehensive and integrated multi-domain simulation solution portfolio to address multidisciplinary complexity in one environment.

Simcenter X Advanced effectively breaks down engineering silos enabling robust, physics-based, AI-augmented decision-making across multiple domains to deliver innovative and dependable engineering solutions faster.

A tribute to gas turbine technology

The really great thing about gas turbines, besides their beauty, is the flexibility of applications the core technology can be applied to. Gas turbines can be found everywhere in our modern daily lives, as heart for sustainable and reliable power generation, as drives in various industrial, chemical or maritime applications or designed as aircraft engines in nearly every commercial or military aircraft. Although the technological idea of a gas turbine is not new and its first applications went back to early 1900, it is still an amazing technology which we can see every day and everywhere and it affects all our lives, even if we don’t know. And today, more than 120 years later, designing a gas turbine has not become a less complex engineering challenge, independently if designed for just a few kilowatts, for hundreds of megawatts as stationery or flying applications.

Designing a gas turbine is an artful interplay of physics and covering multidisciplinary engineering challenges. Since 120 years, gas turbines have marked the spearhead of engineering innovation

Gas turbine development and innovation are driven by ultimate targets to become cleaner, bigger, more silent and flexible. Reducing emissions and enhancing thermal cycle efficiencies have and will remain to be main drivers of new generations of gas turbines. Since decades aero engine and gas turbine manufactures are pushing the Bryton cycle towards higher efficiencies with improvements in materials, coatings, cooling technologies, combustion and more. Faster and closer cross-domain collaboration will be the next crucial factor enabling comprehensive cross-domain and cross-disciplinary design studies to uncover and unleash hidden potential. The only limit? Carnot!

Simcenter X Advanced enables integrated multi-domain simulation engineering to design a micro gas turbine

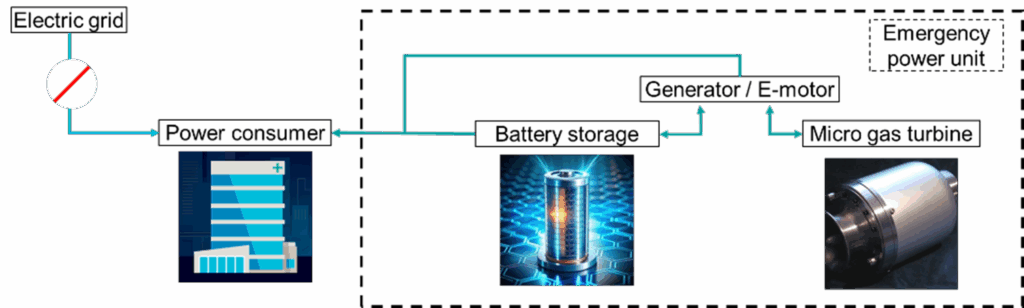

Power outages, while often brief, can severely impact critical infrastructure like hospitals and data centers. To ensure uninterrupted operation, robust emergency power units (EPUs) are essential and can ultimately even decide about life and death. To fulfill their purpose, these systems, often relying on fast-starting gas turbines, need to kick in within seconds. Hybrid EPUs, combining microturbines with battery storage, offers a powerful solution, with batteries bridging the startup time and providing immediate backup.

When an emergency power unit needs to take over, there is usually no acceptance for failure. Imagine, in case of a hospital or intensive care unit power backup, it even becomes live critical. An emergency power unit (EPU) is a complex multidisciplinary engineering system. A system in which various elements need to interact to provide a reliable and functional system which can operate on point, as expected, when expected and in its best-balanced performance.

Break down engineering silos and boost engineering productivity

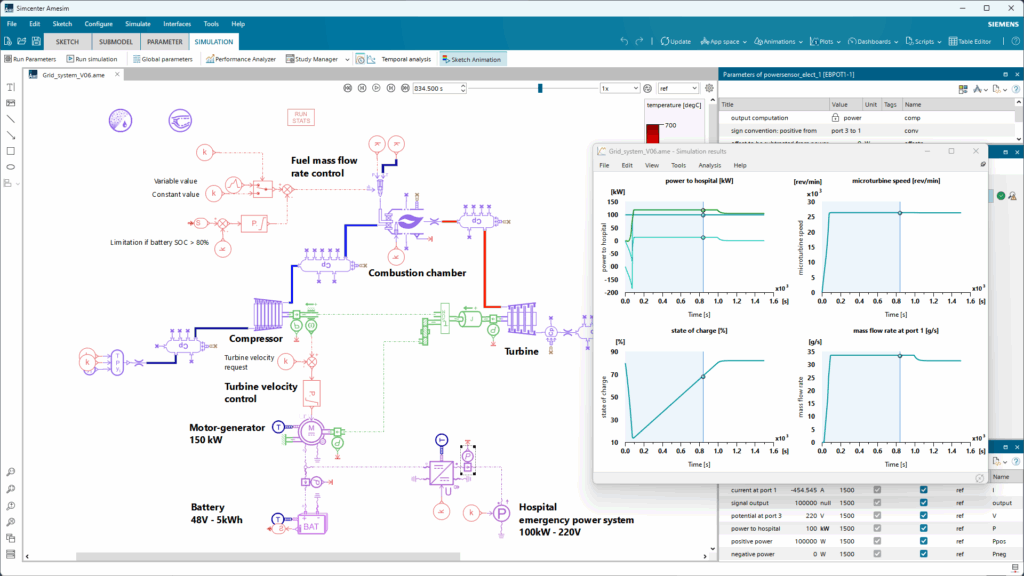

Emergency power units (EPU) have one ultimate goal, they must work reliable and provide power as expected in the case of cases without any option for failure. To design an EPU systems engineering is key to size the entire EPU modules and simulate the case scenarios. System modeling allows tailored engineering towards the application cases and provides the necessary physics-based parameters that are essentially needed for sizing the integrated modules or subsystems such as the gas turbine package.

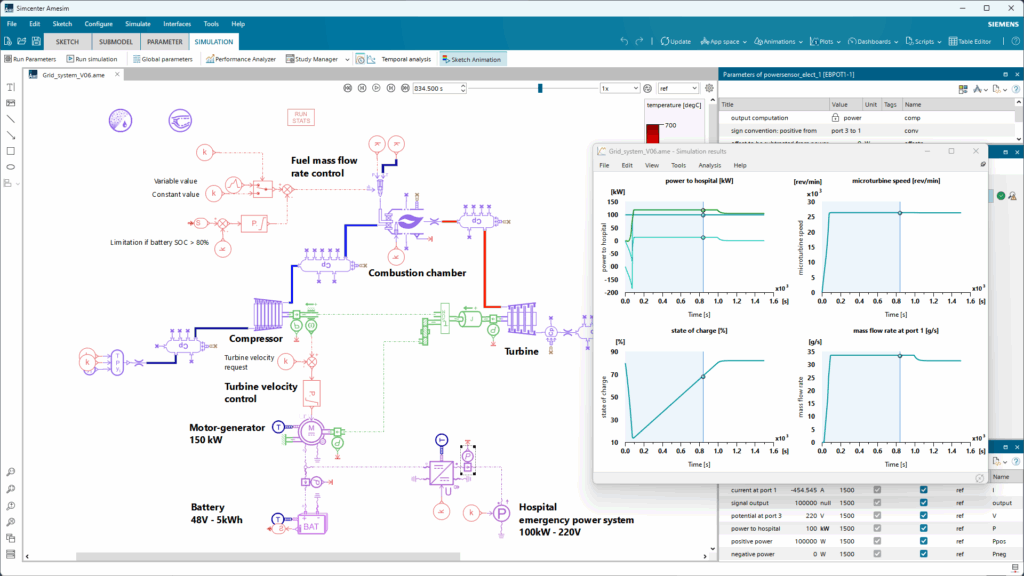

Within Simcenter X Advanced engineers have direct access to powerful Simcenter system solutions such as Simcenter Amesim, which allow a comprehensive system design. In our example, the EPU has an integrated 100kW micro gas turbine. By applying the gas turbine performance application within Simcenter Amesim, engineers can directly specify the architecture of the micro gas turbine and extract relevant pre sizing design parameters for the main gas turbine components.

Multi-domain engineering solves multidisciplinary challenges best

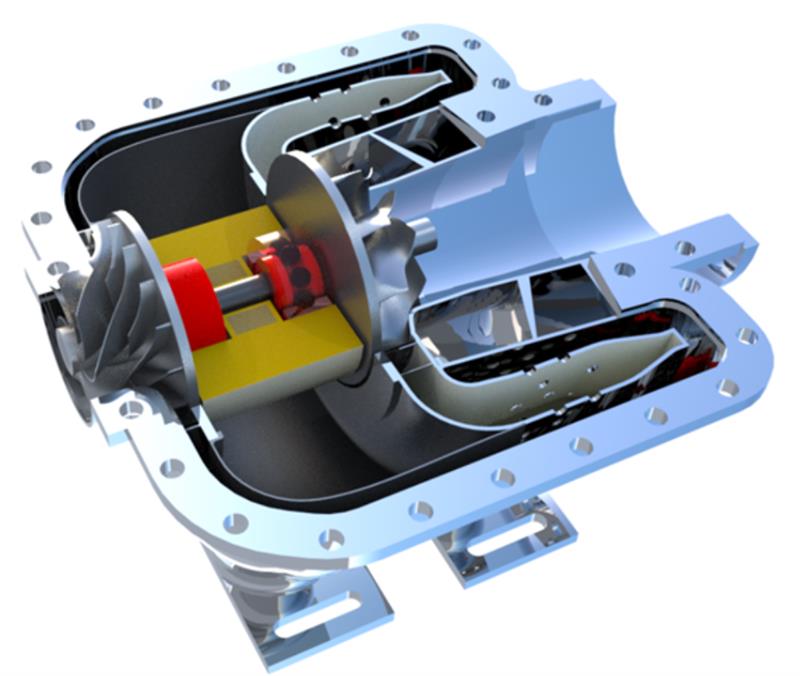

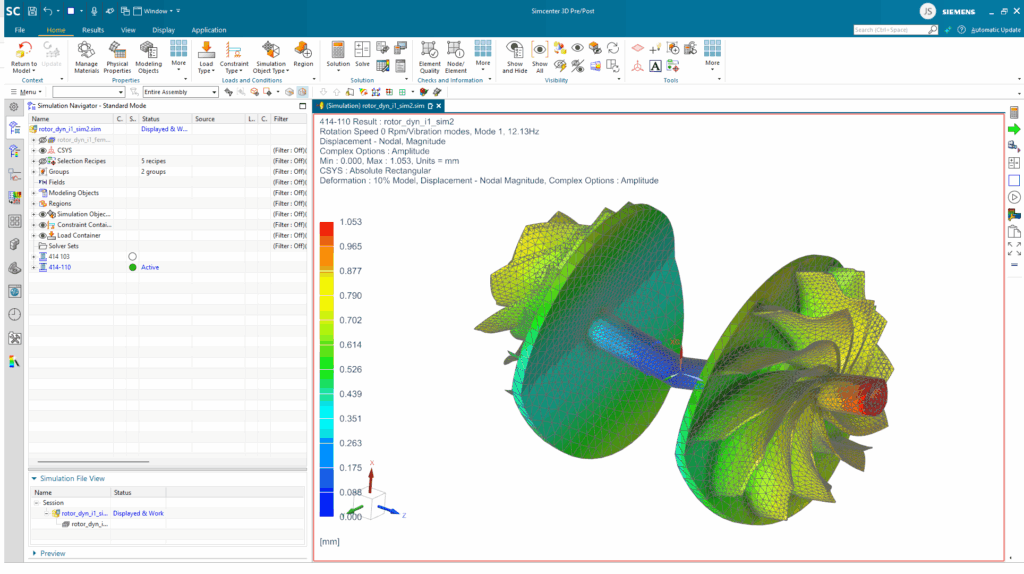

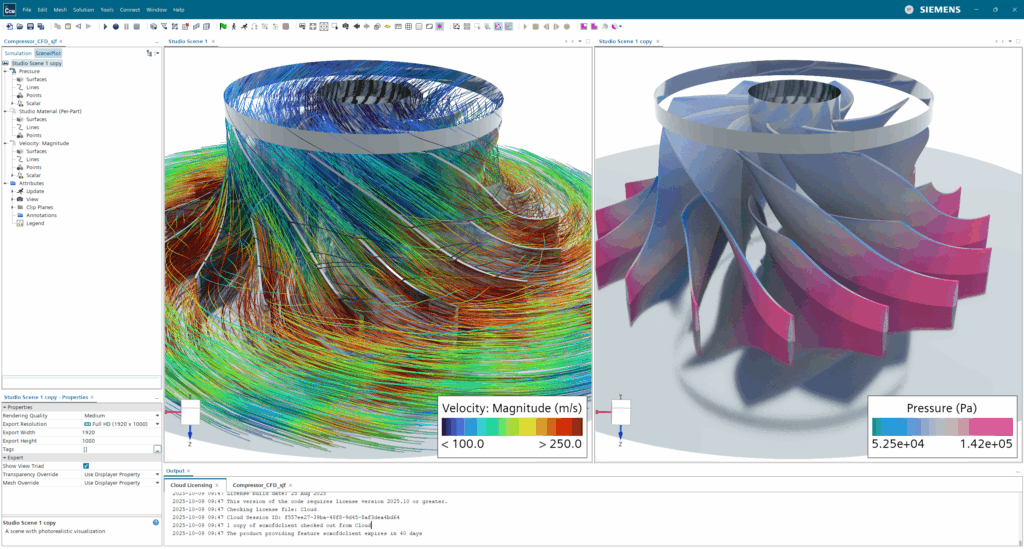

Designing the micro gas turbine requires a comprehensive interplay between different technical disciplines and various multi-domain simulation techniques. As an example, flow path components which have been perfectly designed towards aerodynamic performance need be checked against their to be manufacturability but also need to be checked if they are able to withstand the transient loading during operation. Thus, structural integrity investigation need to go hand in hand with aerodynamic design considerations to be most effective and to avoid unneeded iterations. But even if the single components fulfill all requirements towards aerodynamic and structural performance, the assembly may operate in safety risk condition, e.g. due to rotational resonance.

Simcenter provides a comprehensive multi-domain simulation portfolio that ideally supports turbomachinery engineers to consider all those dependencies and multi domain challenges within one CAE environment.

Design and validation of gas turbines, from early system level via component to entire whole engine modeling. With Simcenter X Advanced, engineers get now ultimate access to a comprehensive multiphysics CAE platform via one license. With integrated PLM connectivity and data management the digital thread is not a vision anymore, with Simcenter X Advanced it becomes real.

When failure is not an option: Multi-disciplinary engineering excellence with Simcenter X Advanced

In our demonstrator study “When failure is not an option: Designing a micro gas turbine in context of emergency power generation” we put Simcenter X Advanced for multi-domain simulation to the test. The result: A real world engineering example of an end-to-end design workflow established with Simcenter X Advanced.

- system and architecture design of EPU and gas turbine sub model

- aerodynamic design and validation of compressor and turbine

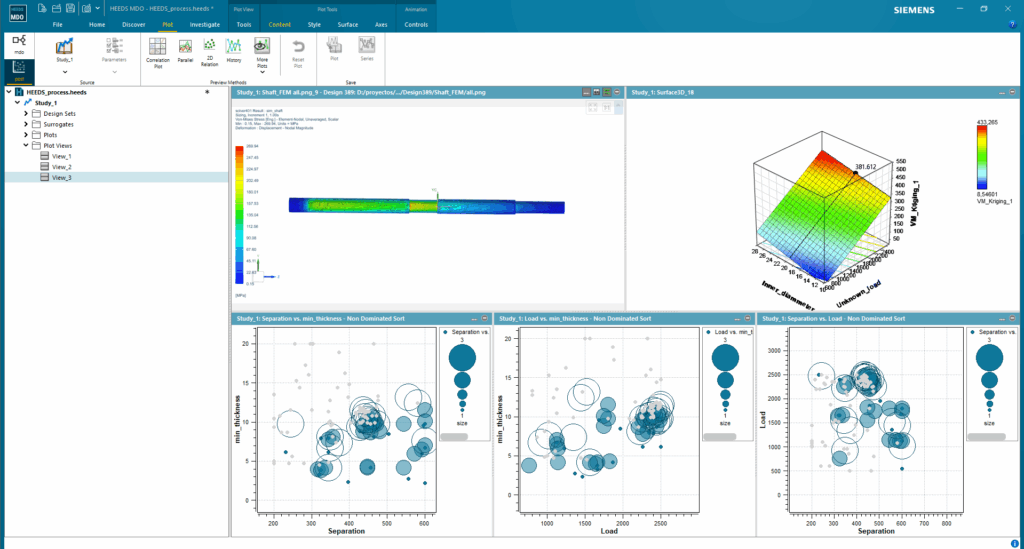

- AI accelerated optimization of rotor shaft design

- structural design and validation of compressor, turbine and rotor

- rotor dynamic and self-excitation investigation, automatic creation of Campbell diagram

- fluid-structure co-simulation for automated cold-to-hot transformation and operational gap clearance investigation