Modular virtual prototypes are the future of NVH development in the Heavy Equipment industry

Heavy-duty workloads demand heavy machinery that inevitably generate a lot of noise and vibrations. This is not just disturbing for the environment and operator, excessive noise and vibrations can also lead to serious safety and productivity issues. That is why noise, vibration and harshness (NVH) engineers are working hard to make heavy machinery run as quiet as possible in sectors like construction, agriculture, forestry, mining, and more.

NVH development is particularly challenging in the Heavy Equipment industry however. This is due to the immense diversity of workloads, which requires a vast array of specialized machinery with multiple configuration options to fit the requirements and regulations of different markets. The result is that it is simply impossible for NVH engineers to physically test each configuration under development.

Scalable NVH development with Virtual Prototype Assembly

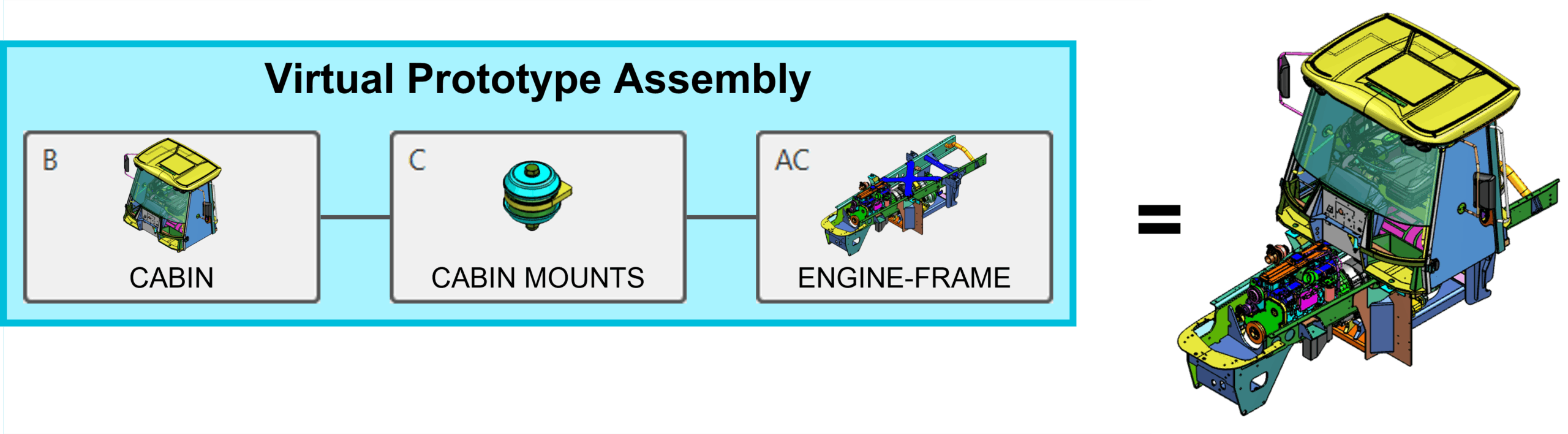

The solution? Adopting an emerging technology called Virtual Prototype Assembly (VPA). This technology uses hybrid component models (obtained using test- or CAE-based methods) to assemble modular virtual prototypes and predict their NVH performance.

VPA allows NVH engineers to analyze and refine the NVH performance of any prototype configuration at any stage of development. The result is a more efficient and scalable NVH development process which identifies NVH problems and their solutions earlier than troubleshooting on physical prototypes.

In this article, I will introduce you to basics of VPA through a step-by-step case study on virtual mount tuning to optimize tractor cabin acoustics.

Step 1: Model the components

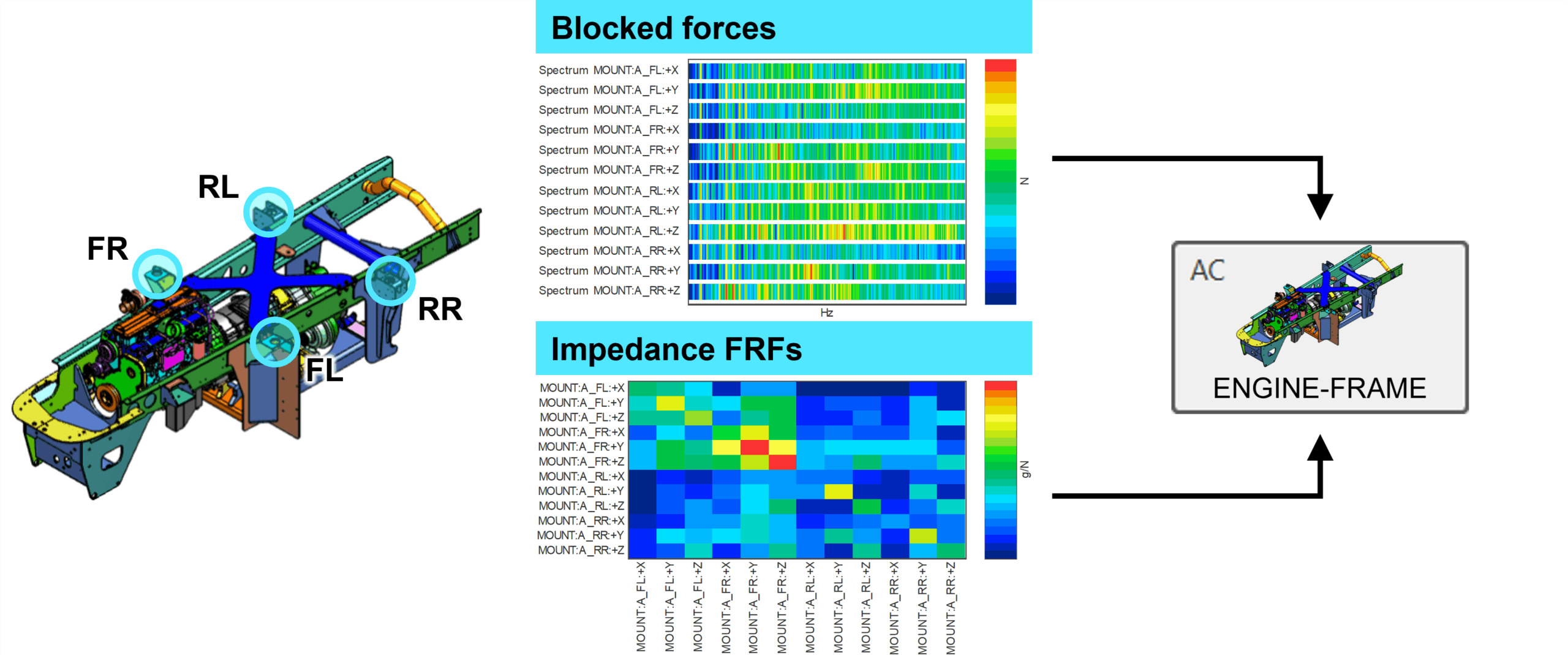

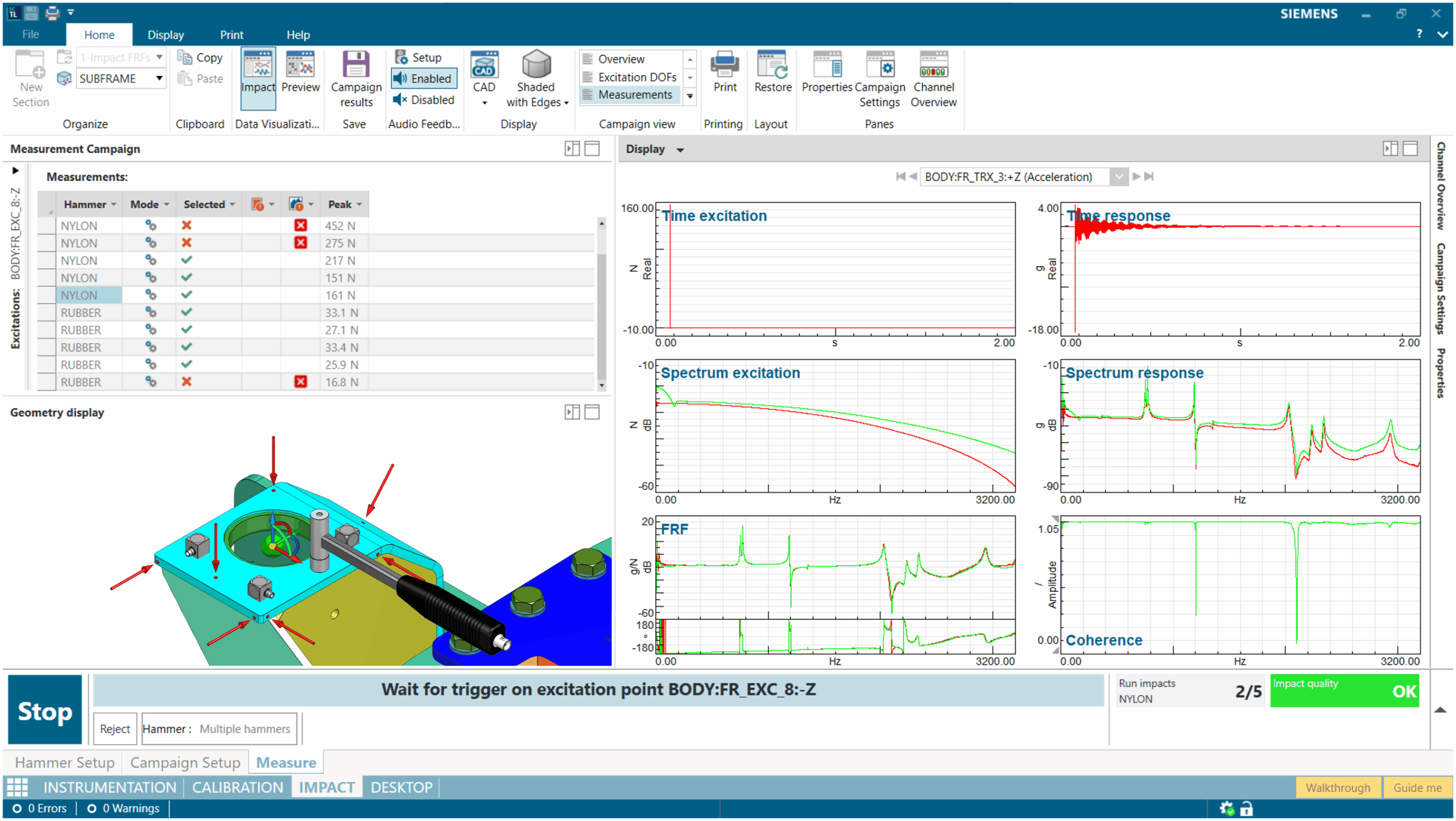

The starting point for VPA is the characterization of all relevant components using Component-based Transfer Path Analysis (C-TPA). The NVH performance of each component can be defined independently from the rest of the assembly using “invariant” component quantities (e.g., “blocked” forces, FRFs, dynamic stiffnesses, …) at its input/output connection interfaces. Crucially, these quantities can be obtained using either test- or CAE-based methods depending on the stage of development.

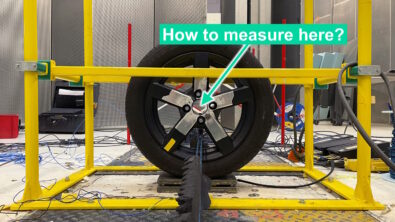

Simcenter Testlab offers a particularly powerful workflow for test-based component characterization by integrating Virtual Point Transformation (VPT) in a streamlined measurement process. This allows NVH engineers to efficiently obtain invariant component data in otherwise unmeasurable conditions (e.g., the center of a mount), improving the compatibility and accuracy of the resulting component models in the virtual prototyping process.

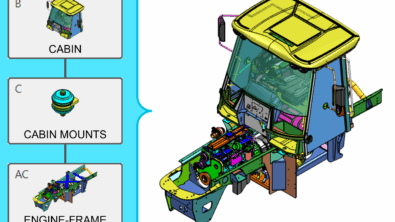

For our tractor cabin case study, we have characterized the following three component models:

- The engine-frame assembly which generates structure-borne excitations, modeled as a source component using test-based blocked forces and impedance FRFs

- The tractor cabin which transfers structure-borne excitations to the operator, modeled as a receiver component using test-based impedance and target FRFs

- The cabin mounts which isolate the engine-frame from the tractor cabin, modeled as a connector component using test-based dynamic stiffness FRFs

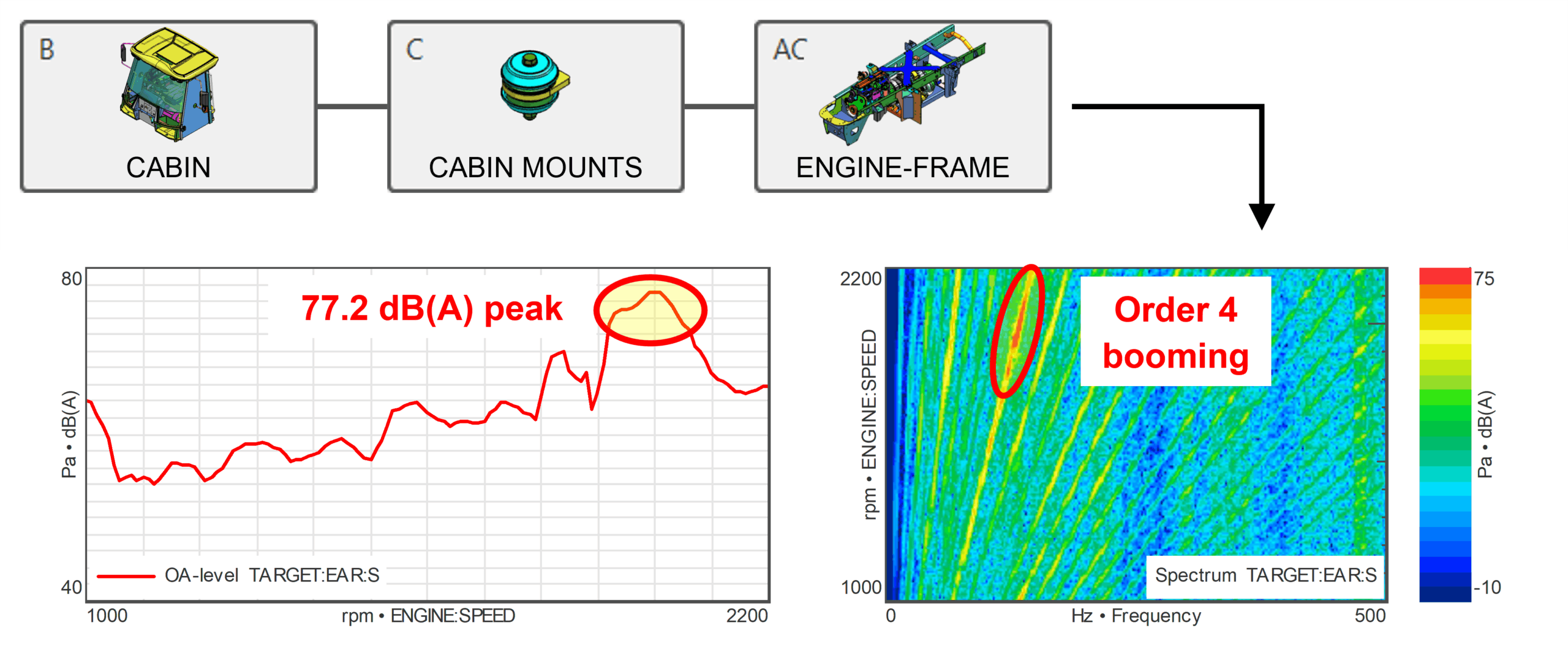

Step 2: Assemble the virtual prototype

The virtual prototype can now be assembled by simply mapping the input/output connection DOFs between the component models. Simcenter Testlab will automatically predict the NVH performance of the assembly using Frequency-based Substructuring (FBS). The calculation results include overall metrics for quick performance assessments, as well as a full contribution analysis for identifying root-cause NVH phenomena.

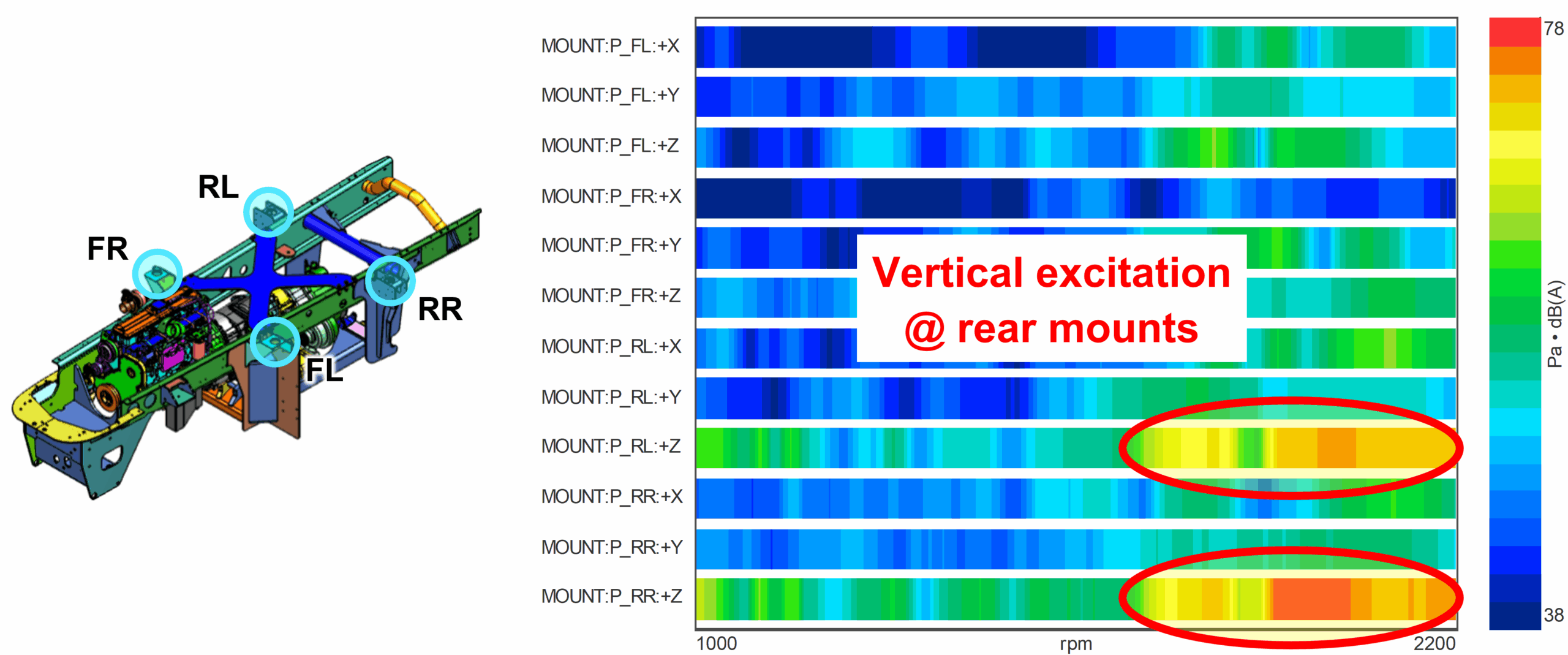

Let’s start by looking at the expected cabin noise during a simple engine run-up. The overall cabin noise peaks at 77.2 dB(A) around 2000 RPM. From the spectrum map, we can see that this is due to a booming of order 4 in this particular RPM range.

By further decomposing this result into path contributions, we can see that the booming noise is mainly generated by vertical excitations at the two rear cabin mounts. This insight is incredibly valuable for identifying effective redesign strategies.

Step 3: Optimize the design

One of the major advantages of VPA is that the component models are invariant. This means that any given component can be replaced by an alternative design without affecting the rest of the assembly. This makes VPA an incredibly powerful tool for performing sensitivity studies and optimizing design parameters.

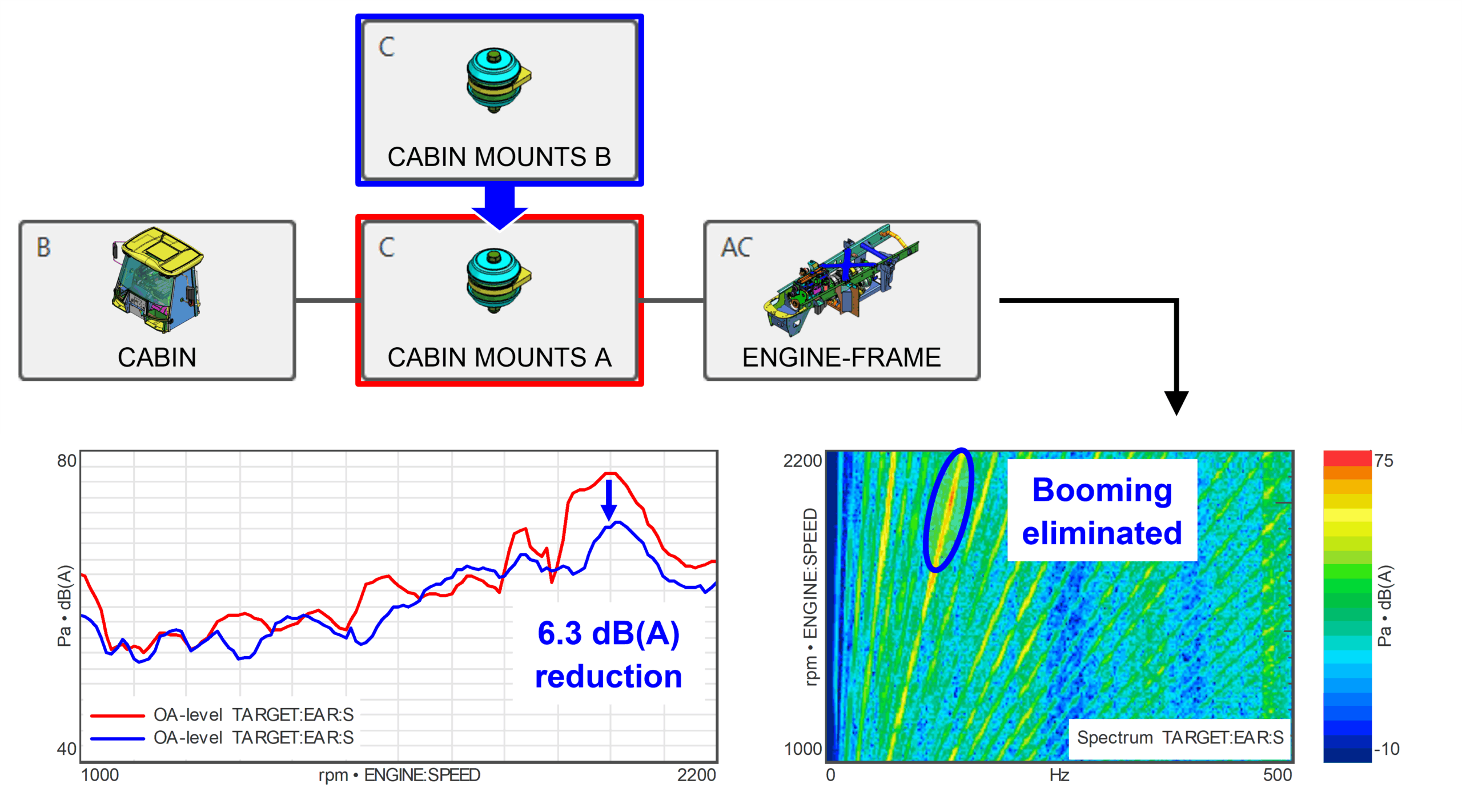

In our case study, we will use this approach to optimize the selection of the cabin mounts. We have access to an updated cabin mount design which is slightly softer in the frequency range where the booming noise is dominant (0-200 Hz). The effectiveness of this updated design can be validated by simply replacing the connector component model and comparing the predicted NVH performance.

A visual inspection confirms that the updated cabin mount design has indeed significantly improved the booming noise. However, Simcenter Testlab is also capable of synthesizing the predicted NVH performance for a subjective assessment using audio replay with interactive filtering. Grab a pair of headphones (the booming noise issue is quite low frequent) and listen for yourself!

Conclusion

Using VPA, we were able to identify and solve a critical NVH performance issue before entering the physical prototyping stage. This approach allows NVH engineers to focus more physical prototype testing time on product validation rather than troubleshooting. Additionally, it can easily be scaled to any number of prototype configurations, making it a perfect match for the immense diversity of products typically seen in the heavy equipment industry.

Has this article left you curious about the technology and process behind predicting NVH performance using virtual prototypes? Watch our free on-demand webinars on Component-based Transfer Path Analysis (C-TPA) and Virtual Prototype Assembly (VPA) to learn more.

If you are looking for a hands-on learning experience, consider registering for our upcoming masterclass on Component-based Transfer Path Analysis and Virtual Prototyping. This event will be hosted at our Simulation & Testing Solutions headquarters in Leuven, Belgium from 18-20 November 2025.