Maya HTT: Top Tips on Electronics Cooling Using Simcenter 3D

Top Tips on keeping your electronics cool with Simcenter 3D

Improving products with Electronics Cooling

Boosting performance, improving quality, reducing inefficiencies, driving down costs and helping companies harness the value of their data are all at the heart of Maya HTT’s offerings.

We couldn’t do this without the fantastic Simcenter products for electronics cooling that our engineers use every day.

One particular challenge we’ve worked on is how to meet the increasing demands of electronics cooling.

We’ve all heard the horror stories of mobile phones overheating and catching fire. This might not be a common occurrence, but the simple fact is that electronics generate heat whatever device they are part of. Indeed, whilst fires are a very extreme example of poor thermal management, keeping electronics sufficiently cool is critical to their efficient operation and damage avoidance.

As consumers demand more powerful electronics in smaller devices, these thermal challenges are forever increasing. Therefore, cutting-edge technology is required to design to the highest safety and quality standards whilst keeping development costs under control.

Simcenter 3D is the perfect solution for this. We recently released a three-part series of blogs to demonstrate how we used the features and capabilities to solve many design challenges.

Why Simcenter 3D?

In Part 1, we explain how crucial it is for mechanical and electrical specialists to work together and how Simcenter 3D’s multidisciplinary platform makes this possible.

- Have you struggled to create and maintain your digital twin?

- Finding it hard to pack all the necessary physics into your simulation and reach the optimal design?

Simcenter 3D can help resolve these and many other issues, and the rest of the series will show you exactly why.

See how it’s done

Part 2 digs into the nitty-gritty of how to create and maintain your electronics systems cooling digital twin with a step-by-step guide to working with PCB data in Simcenter 3D.

This guide, complete with instructional videos, shows how to import the PCB data first into Simcenter 3D and then into your electronics package.

We’ll show you how to use Assembly Constraints to provide a reference point so that any changes to the underlying geometry will be accurately reflected throughout the model.

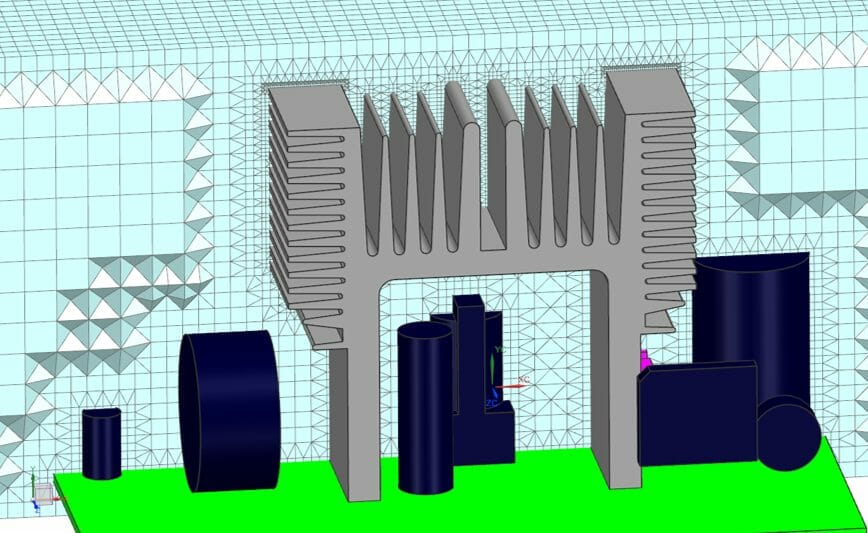

You’ll also learn how we use Immersed Boundary Method (IBM) to perform fluid flow simulation for complex geometries. Its built-in automation gives fast and accurate fluid mesh generation, saving significant time in model preparation.

It wouldn’t be a true digital twin without including the relevant physics for your simulation. The best and quickest way to do this is by using the workflow from PCB Exchange to Simcenter 3D. Our video shows you how to define the correct file paths and point to the component thermal database, then import the simulation objects and solution into the electronics package file.

Then you can use Selection Recipes to define your boundary conditions and create your thermal couplings.

Once this is all configured, Simcenter 3D’s powerful post-processing tools can be used to inspect the thermal response to the imposed loads and boundary conditions. You can view the results in a variety of different ways to give you a true understanding of the thermal behavior of your model.

Keep it optimal

The final part of this series explains how we use Simcenter 3D to set up an optimization study for electronics cooling. We’ve included an example of how we use HEEDS to improve the airflow within a device and reduce the electronic component’s temperature.

We also show how PCB Exchange enables collaboration between ECAD and MCAD specialists by allowing them to easily share the changes made by each team.

It’s not only what you know, it’s the way that you do it

Nothing can replace the expertise and knowledge of our engineers, but software can play a massive part in streamlining our processes and improving collaboration between teams. Simcenter 3D helps us reduce the time spent building, running, and analyzing simulations, allowing engineers to focus on innovation so that they can build the best possible products.

Further Resources on Electronics Cooling

Here are some further articles if you would like more information on this topic:

- What’s New in Simcenter 3D 2021.2?

- Thermal Standards – The Measure of an Industry’s Maturity?

- Further reading on HEEDS

- Effective Blade Cooling and Thermal Assessing of Turbomachines

- Simcenter 3D virtual shaker sine base excitation test Sine base

- Vehicle Electrification Lunch and Simulate Series

- A New Era of Air Mobility: VTOL achieves new heights with a digital twin approach

- Win-win: Model-Based System Testing

- How to Rapidly and Simultaneously Update Multiple Structural Dynamic Models