Turbine design with a digital test rig: meet your targets faster

We want to work out how it will work in the field, before it is in the field

Rene Braun

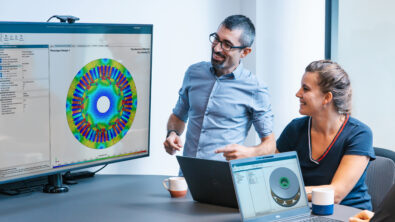

We recently sat down with Rene Braun, technical manager of aerothermal design at B&B-AGEMA, to talk about their digital approach to turbine design, the “design digital rig”. This approach builds up a model of the complete machine in a virtual environment. You can then simulate, analyze and understand performance over all possible operating conditions – before building the machine.

Efficient turbine design

Gas turbines are complex engineering systems. Thousands of parts, rotating at speeds from 3000 to 10,000 rpm or more. Temperatures ranging from ambient to over 1000 Celcius. Combustion, with mixing gases, complex flames and emissions. All operating inside a sealed system making monitoring almost impossible. Customers expect their machines to operate reliably, with minimal downtime, over lifetimes of years. At the same time, only the most efficient turbines will be adopted by the market.

Building and testing a physical prototype is expensive and time-consuming, but suppliers must test every aspect of turbine performance during the design phase. Digital design is key to ensuring reliable and efficient turbines, while reducing design times.

Exploring the possibilities with a digital test rig

“We want to figure out how it will work in the field, before it is in the field” says Rene. And Simcenter tools are enabling B&B-AGEMA to do just that: building geometry, analyzing airflow, heat transfer and combustion and rapidly exploring alternative designs. “We can achieve a high quality turbine in a very short time” states Rene.

Watch the video to find out more about B&B-AGEMA’s use of Simcenter:

Learn more

B&B-AGEMA use a complete, automated design approach, with NX for model design, Simcenter STAR-CCM+ for 3D CFD and HEEDS for design exploration and optimization. Read more about their design process for hydrogen-fueled turbines. And find out more about Simcenter’s use for turbine design in these blogs:

Comments

Comments are closed.