Farewell physical prototypes? Digitalize your vehicle development process with Simcenter Testlab NVH Simulator

New electric vehicle OEMs in China are taking new vehicle models from concept to production twice as fast as legacy OEMs. That is the shocking conclusion in a recent report by McKinsey & Company on the world’s fastest-growing and most competitive automotive market. As you can imagine, automotive OEMs worldwide are under enormous pressure to streamline their development processes to keep up with these new players.

This begs the question: how do they do it? According to the report, the most impactful way new electric vehicle OEMs differentiate themselves is by leveraging NVH simulators to eliminate time-consuming and expensive physical prototype testing through increased usage of simulation software and virtual prototypes in their testing processes.

China’s automotive OEMs use software simulation and virtual prototypes for 65 percent of their testing, compared with 40 to 50 percent in other regions. (…) We estimate that maximizing this use of virtual testing can cut in half the number of physical prototypes required.

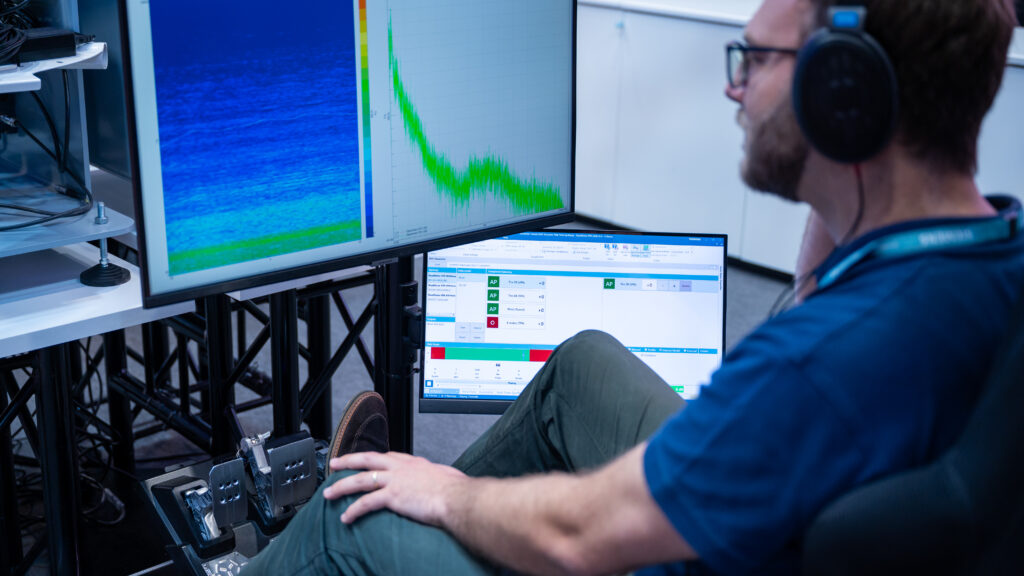

As physical prototypes become increasingly scarce, NVH simulators provide an efficient and scalable solution for NVH engineers to perform vehicle development tasks using a virtual driving experience instead.

Did you know that these virtual driving experiences can now be created in Simcenter Testlab using our new Simcenter Testlab NVH Simulator solution? Even better: the entire end-to-end workflow from NVH model creation to NVH performance synthesis is available via our flexible and cost-effective token-based licensing, so existing users already have access today!

Curious to know more? In this article, I will take you through the NVH Simulator workflow and show you a practical example of how it can digitalize your vehicle development process.

Model the NVH performance

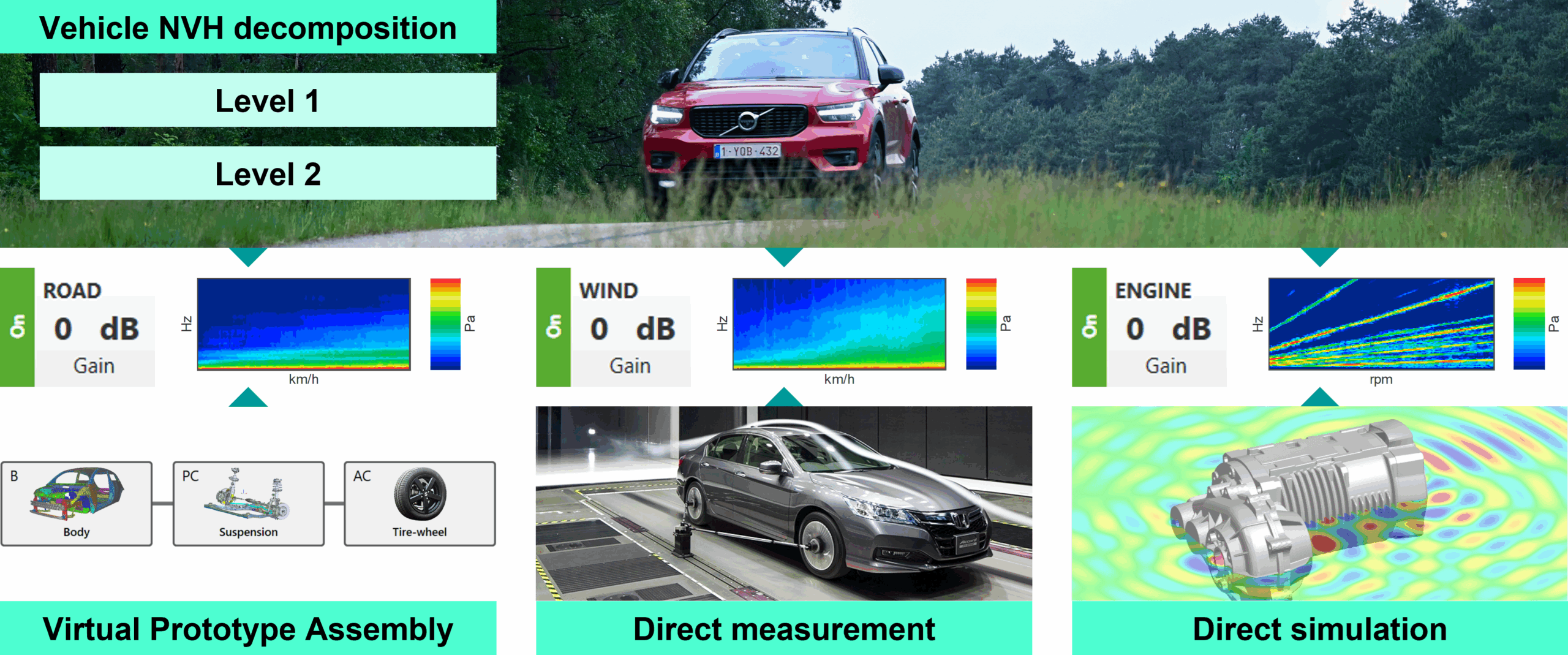

The foundational building blocks of NVH Simulator are the NVH models which contain the component contributions (e.g., road/wind noise) towards the vehicle NVH targets (e.g., driver/passenger ears). Depending on the stage of development, such NVH models can be obtained using either top-down or bottom-up methodologies as detailed below.

Top-down methodology

Top-down NVH models are obtained by decomposing full vehicle NVH performance (measured on a prototype or benchmark vehicle) into component contributions using filtering techniques. The decomposition can be applied at two ‘levels’, depending on the desired granularity of the resulting NVH models.

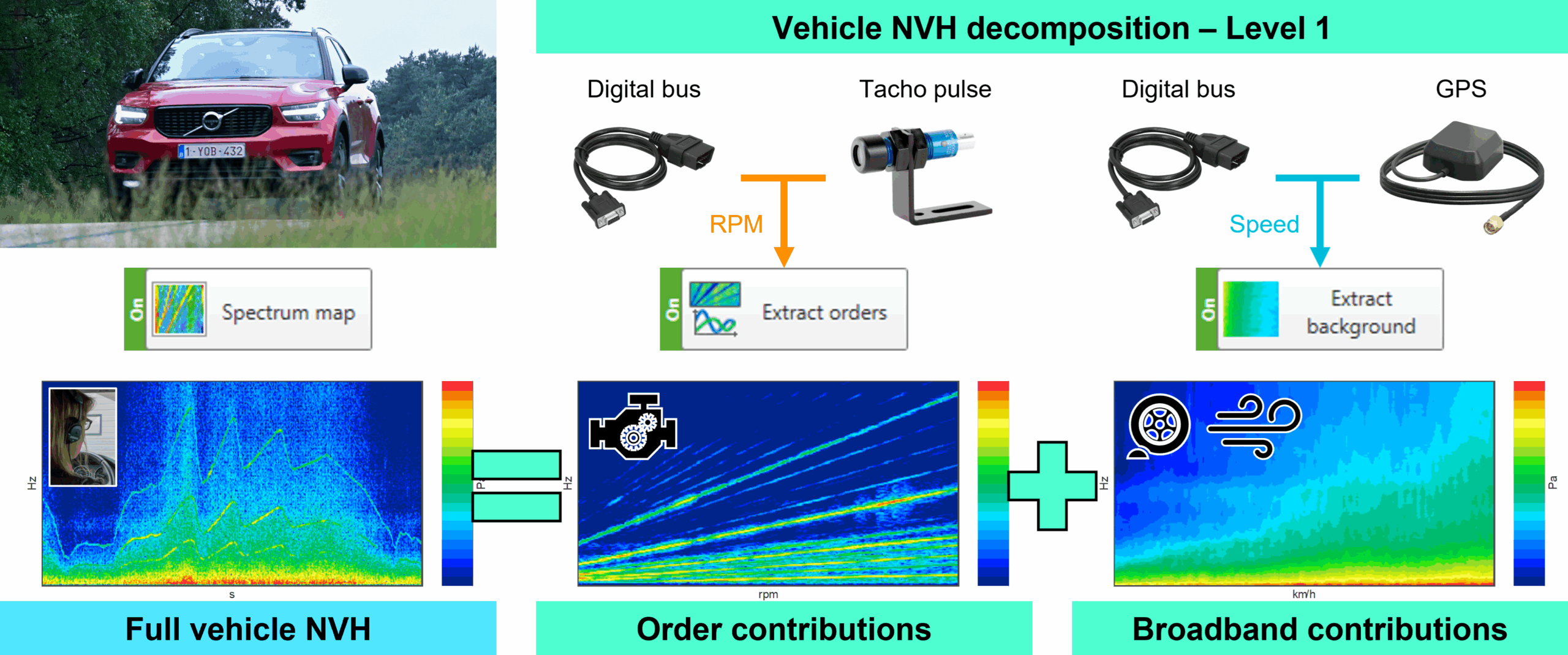

Level 1 decomposition uses operational RPM and vehicle speed signals to separate the full vehicle NVH performance into powertrain orders and broadband background noise. This is a fast approach for obtaining coarse NVH models with limited instrumentation effort.

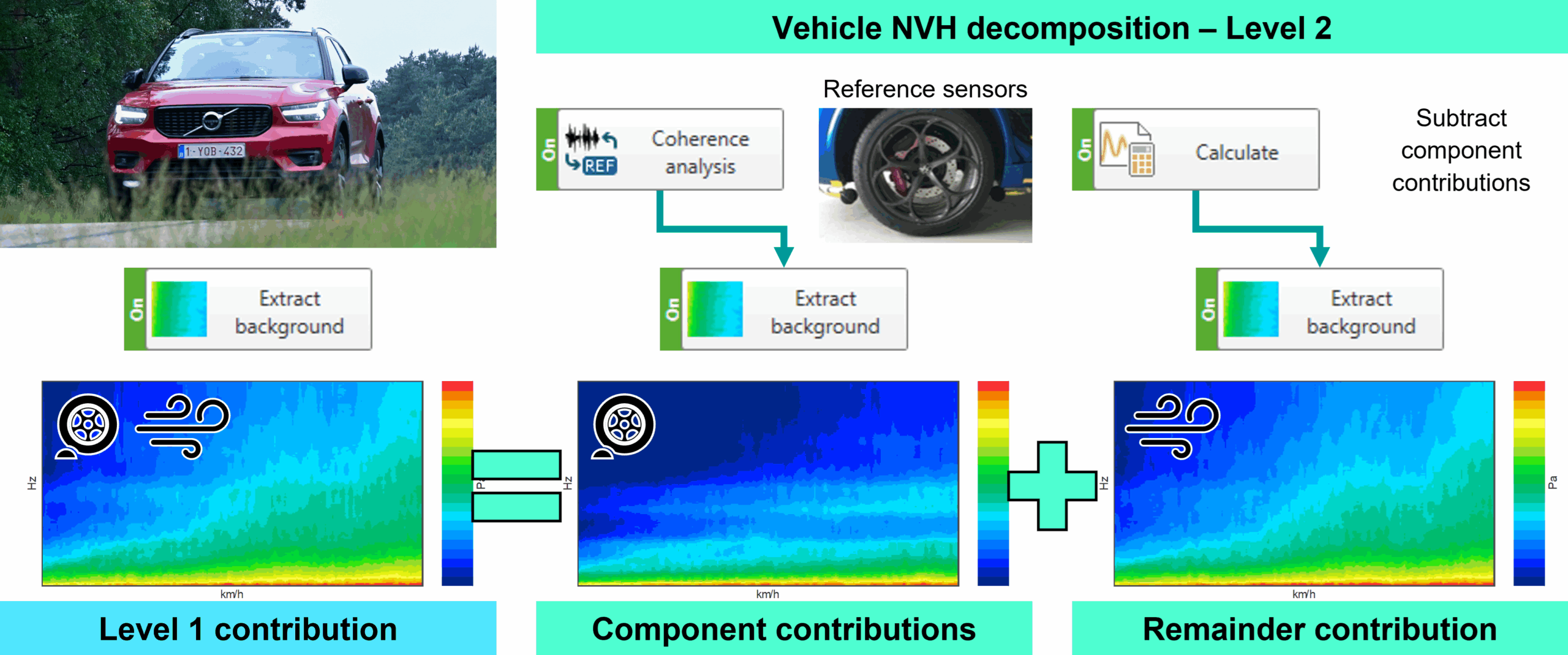

Level 2 decomposition uses operational reference sensor signals to separate the full vehicle NVH performance into component contributions via correlation filtering. This is an in-depth approach for obtaining granular NVH models in return for a higher instrumentation effort.

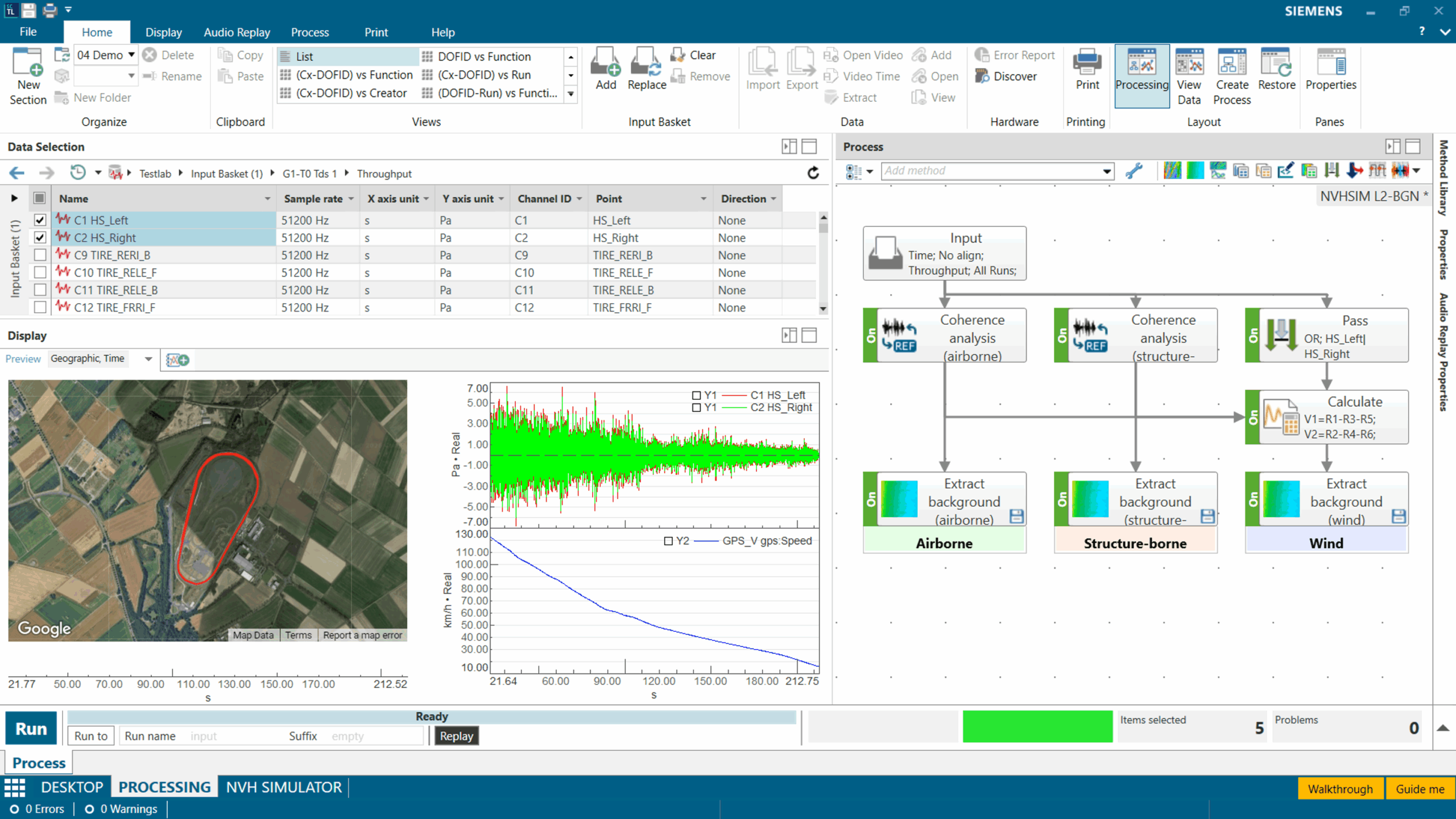

Both level 1 and level 2 decompositions can be easily performed in Simcenter Testlab Process Designer. The graphical programming interface allows you to build customized processing flows and automate repetitive tasks such as data validation and selection, enabling rapid batch processing across multiple operating conditions.

Bottom-up methodology

Bottom-up NVH models are obtained by directly measuring or simulating the component contributions. Direct measurements are typically performed on specialized test benches, such as measuring a vehicle’s wind noise performance in a wind tunnel.

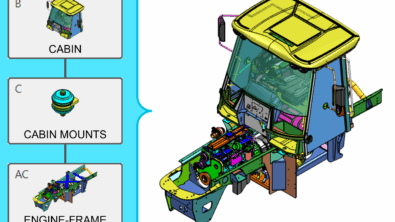

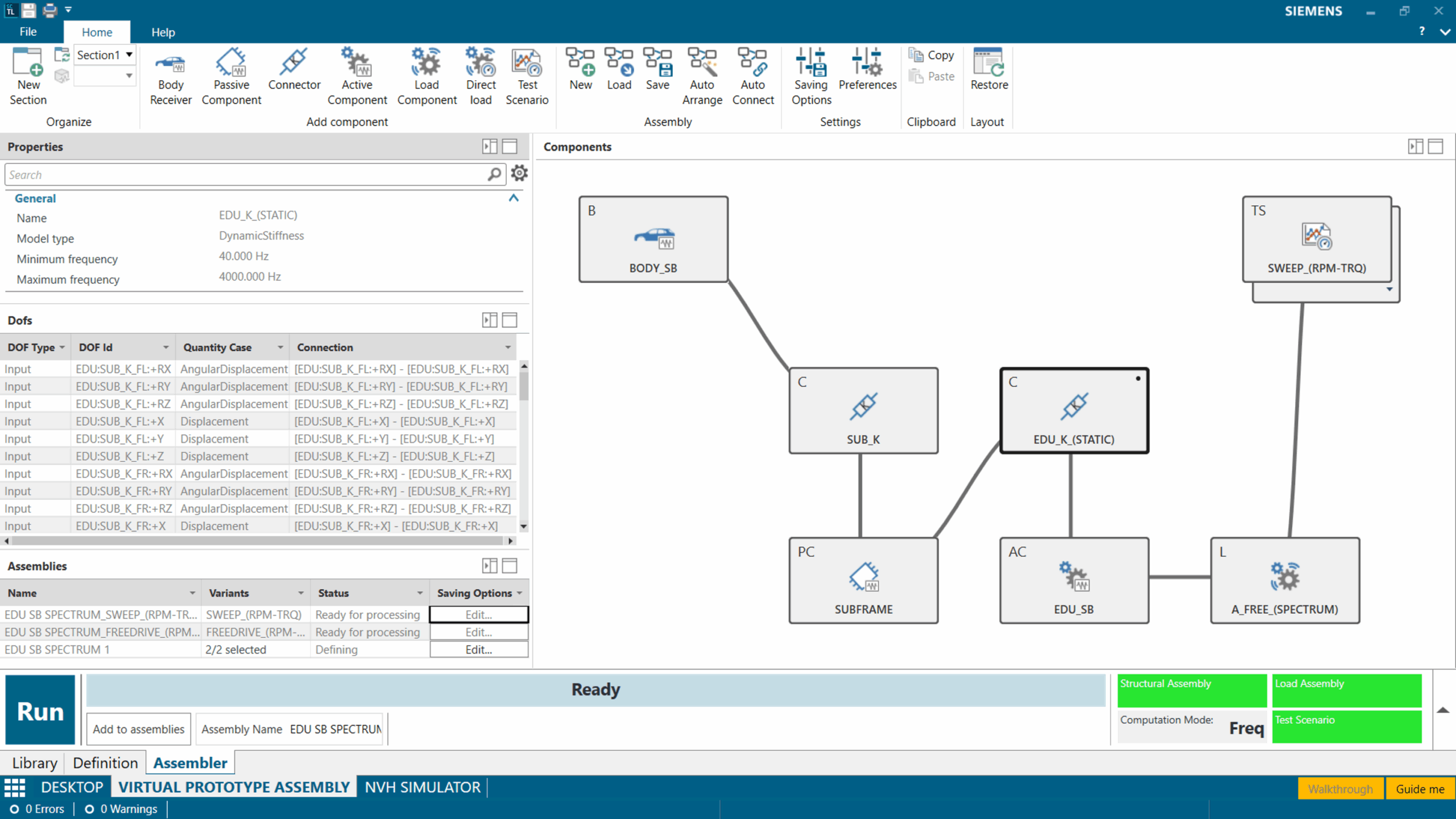

A unique feature of NVH Simulator is its integration with Simcenter Testlab Virtual Prototype Assembly to predict bottom-up NVH models using hybrid virtual prototypes. This powerful synergy allows NVH test and CAE engineers to rapidly explore component designs and validate their impact on the vehicle using a virtual driving experience.

Experience the virtual prototype

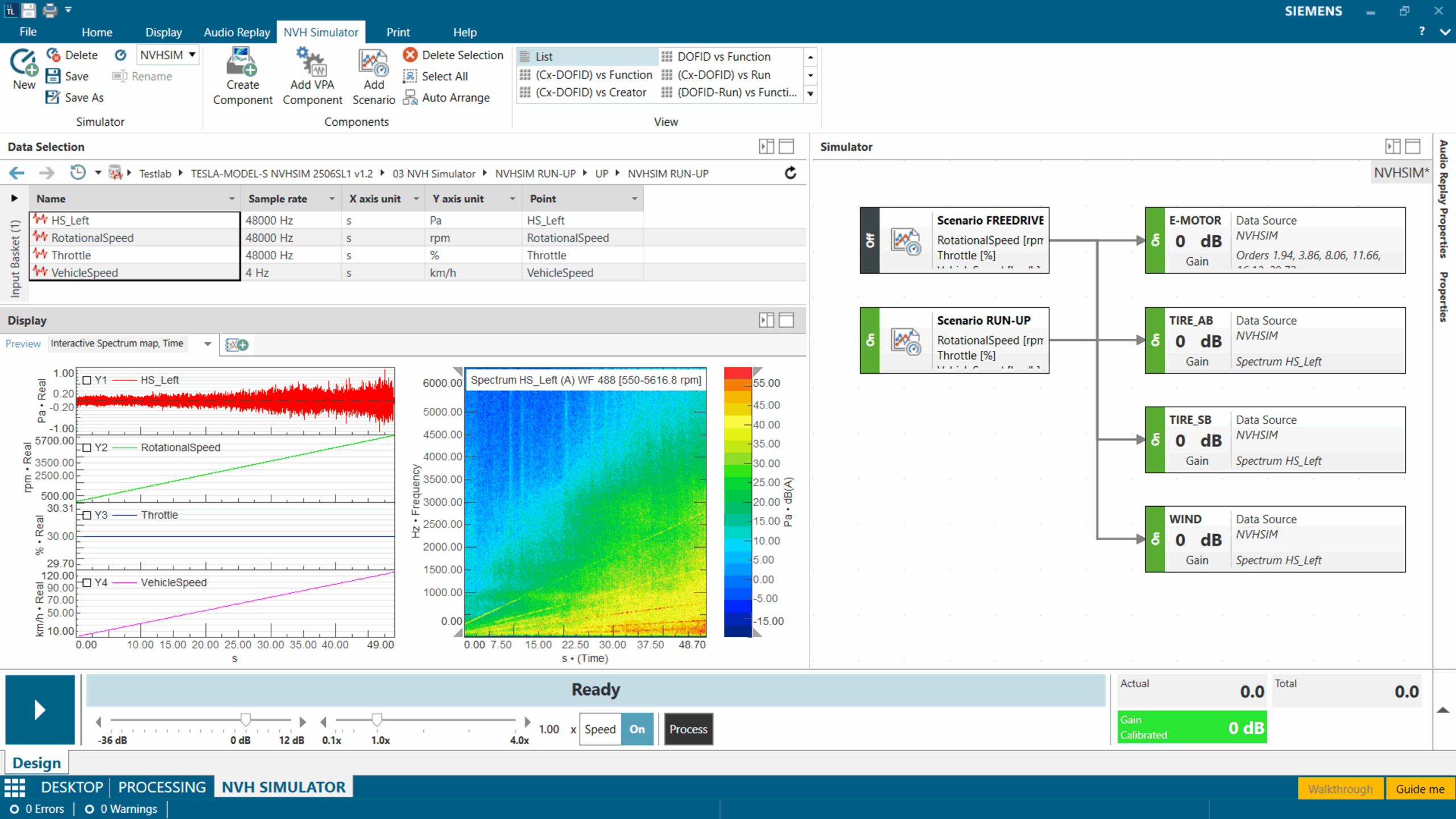

Creating virtual driving experiences in NVH Simulator starts with assembling virtual vehicle topologies using the previously obtained NVH models. The NVH performance of the virtual vehicle topologies is then synthesized by applying relevant operating conditions to each NVH model in either an offline or online mode.

In offline mode, the NVH performance synthesis is based on fixed drive profiles, such as the operational RPM and vehicle speed measured on a digital bus during a test track maneuver. This mode is useful for repeatable A-B comparisons between topologies using subjective replay and objective KPI metrics.

In online mode, the NVH performance synthesis is based on real-time operating conditions, such as a vehicle performance model being fed with the throttle position and gear selection inputs from the driver. This mode is useful for interactively experiencing topologies and modifying NVH model contributions.

Case study: firewall trim optimization

How does all of this come together to digitalize the vehicle NVH development process? Let me show you a case study on optimizing firewall trim thickness using NVH Simulator.

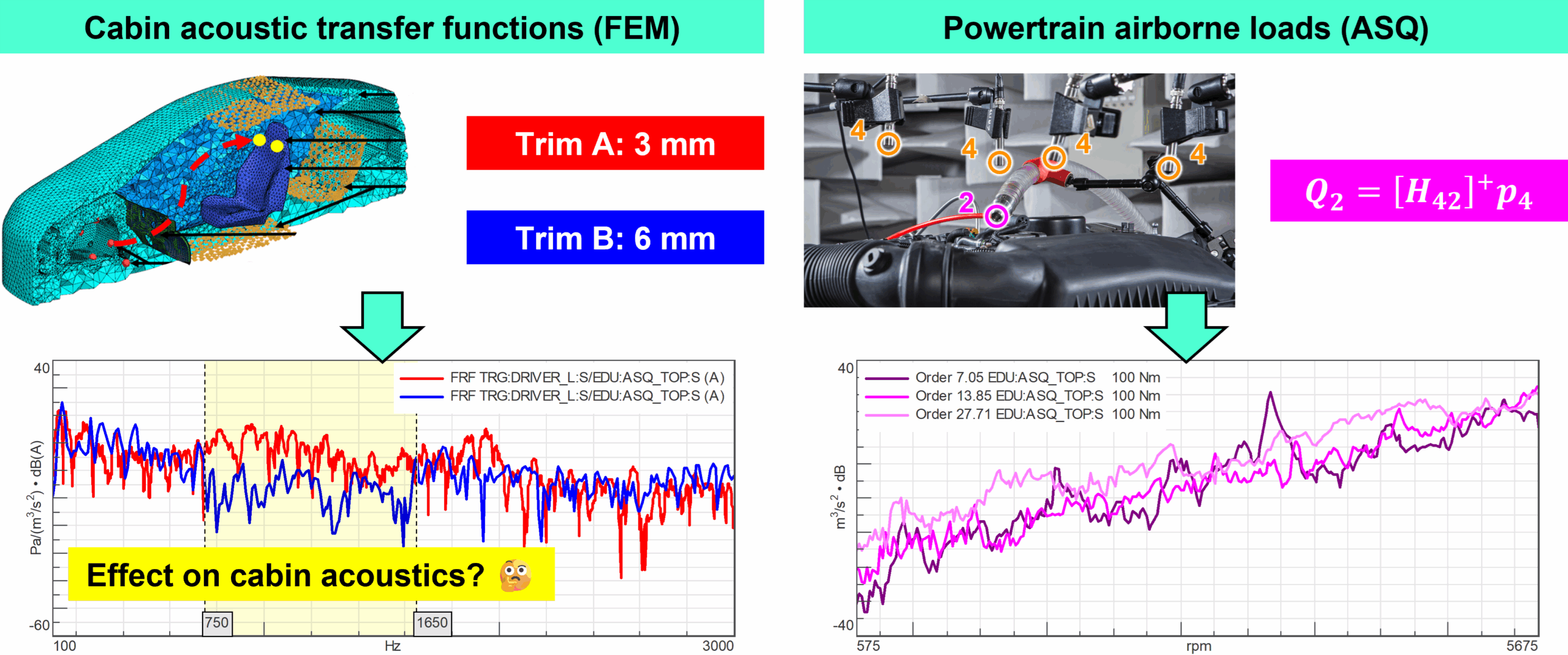

To quickly explore firewall trim thickness options, a body-cavity Finite Element model was used to simulate the cabin’s acoustic sensitivity to airborne powertrain loads for each thickness value. The real airborne powertrain loads were estimated on a test bench using Airborne Source Quantification (ASQ) for all relevant operating conditions.

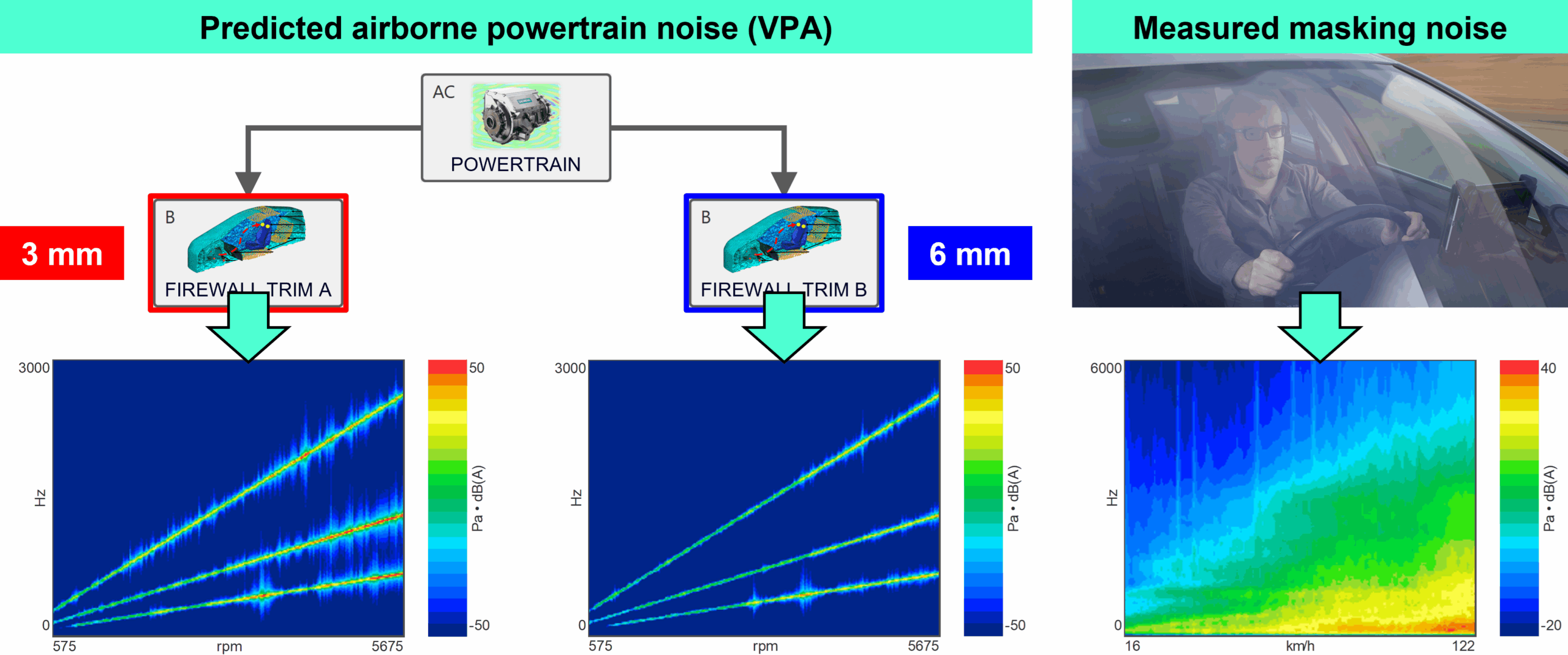

The simulated cabin sensitivities and measured airborne powertrain loads were combined in a hybrid virtual prototype to predict bottom-up powertrain noise NVH models for each firewall variant in Virtual Prototype Assembly.

However, powertrain noise does not exist in a vacuum. A level 1 decomposition was therefore also applied on a benchmark vehicle to obtain a top-down background noise NVH model for studying the masking effect of road and wind noise contributions.

Virtual vehicle topologies were then assembled in NVH Simulator for each firewall variant. The NVH performance of each topology was synthesized in offline mode using realistic operating conditions measured on the benchmark vehicle during a test track maneuver.

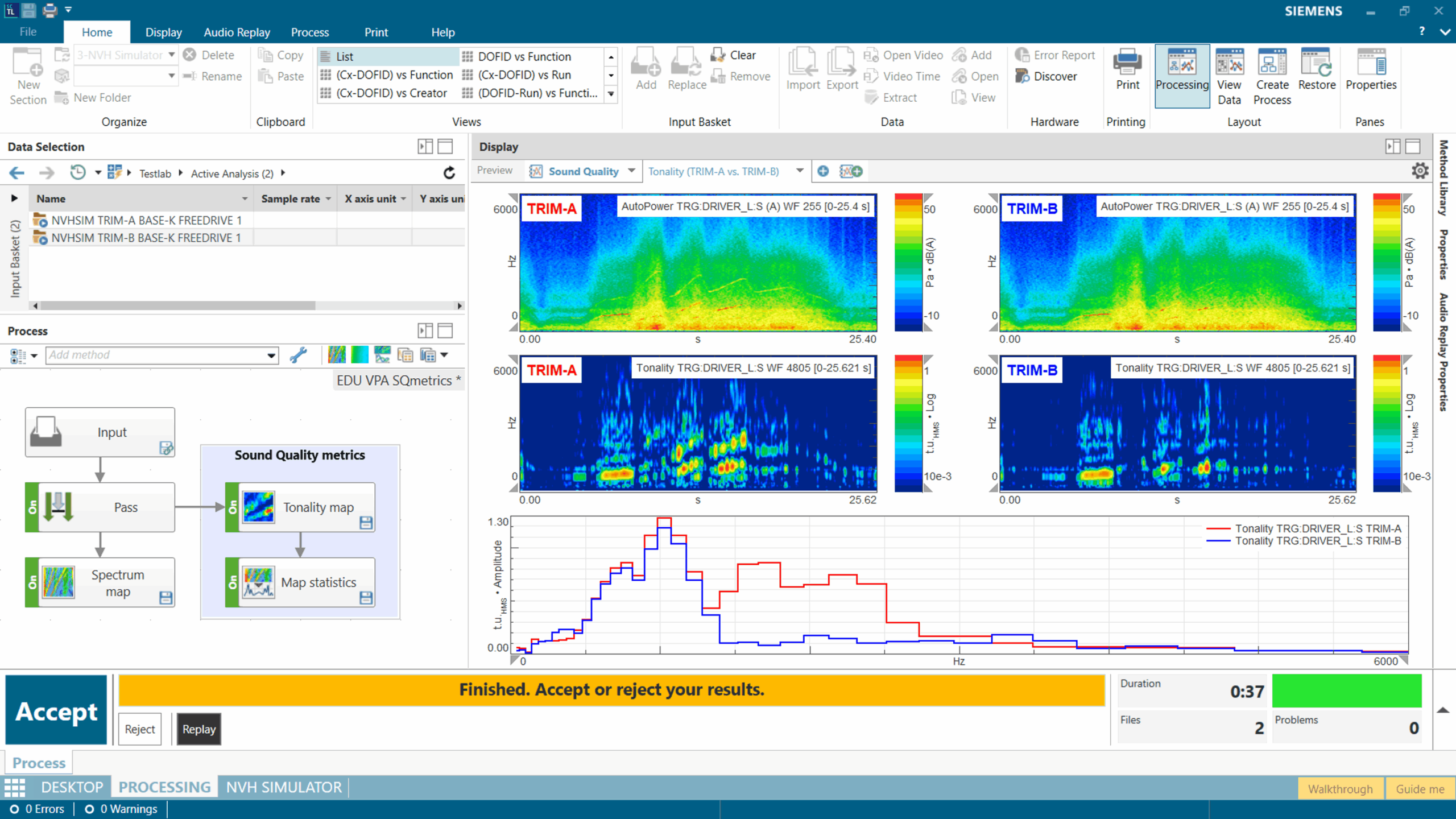

The firewall variants were first subjectively compared by replaying the synthesis results. A noticeable improvement of the powertrain tonality can be observed when increasing the firewall thickness.

Finally, the firewall variants were objectively compared by calculating sound quality metrics in Process Designer. This revealed that increasing the firewall thickness mainly improves tonality in the frequency range of the highest powertrain orders, while the lowest powertrain orders remain unaffected.

These results can be easily scaled up to any number of firewall variants to find the optimal trim thickness value that perfectly balances powertrain tonality with manufacturing cost and vehicle weight.

Conclusion

Physical prototypes are becoming increasingly scarce in today’s NVH engineering landscape. Simcenter Testlab NVH Simulator provides a powerful and cost-effective solution to replace physical prototypes with virtual driving experiences. The unique synergy between NVH Simulator and Simcenter Testlab Virtual Prototype Assembly is the key to implementing a more efficient and scalable digitalized NVH development process.

Has this article left you curious to learn more about hybrid virtual prototyping? Watch our free on-demand webinars on Component-based Transfer Path Analysis (C-TPA) and Virtual Prototype Assembly (VPA) to learn more.