5 big reasons Executable Digital Twins will surge in 2026

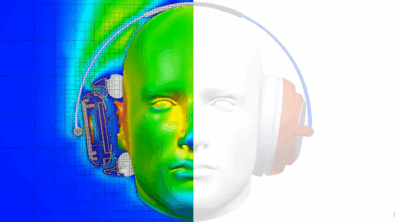

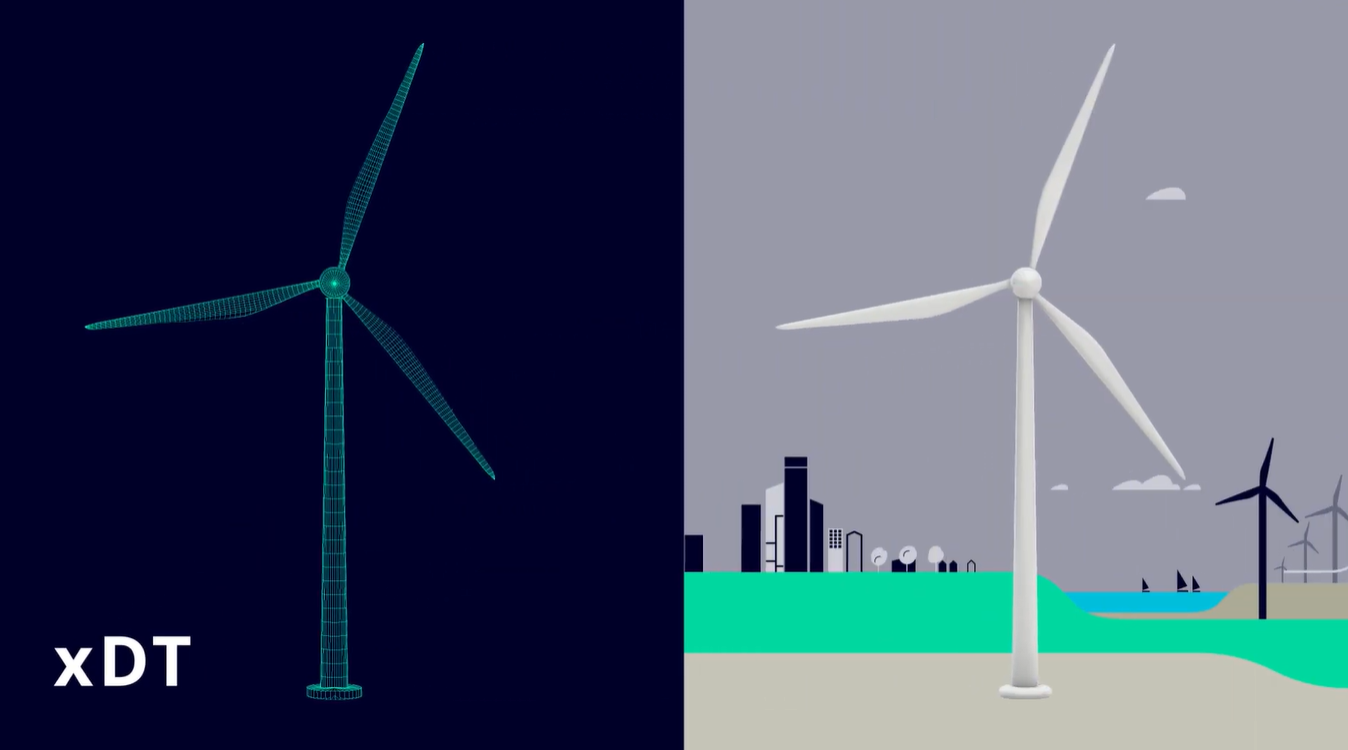

The concept of a digital twin, a virtual model that simulates the behavior of a real-world asset, is nothing new to the engineering community. Executable digital twins (xDTs), on the other hand, may be a new one.

The difference is that engineers can package xDTs to run as stand-alone software — outside of traditional CAE tools. The digital twins built and used in the early design processes are “app-ified” so others can use them to gain insights (even when the user has no simulation experience). The aim of xDT philosophy is for simulation technology to shift-right into lifecycle stages like operations, maintenance or even retirement.

For a real-world example from BASF, watch the video below:

According to Leoluca Scurria, product manager for Simcenter Executable Digital Twin at Siemens Digital Industries Software (Siemens), 2026 will be the year where xDTs surge in popularity. His reasonings are summarized below.

1. xDT technology has caught up to the hype

The biggest reason xDT will transform from a thought leadership topic into a widely accessible tool is because the technology has caught up to its promises. Digital twins require a lot of data from a lot of sources. For industrial twins, that typically translates into the need for IoT data from brownfield assets.

Since 2020, and partly fueled by the COVID 19 pandemic, companies have invested more into digitalization. Now as all that data comes online, engineers can better train, maintain and utilize xDTs to drive value for organizations beyond the traditional uses of simulation in the product design phase.

“This is specifically true in manufacturing with the convergence of IT and OT,” Scurria explained. “It’s a big topic today: How can IT/OT work together to bring additional value like virtualization in automation? This plays a big role in the xDT space, and it goes hand-in-hand with new ways to use simulation data like AI.”

Siemens has been paying close attention to how companies digitalize their manufacturing data and how it can link to xDT technology. “We are now in a position where we [Siemens] have made significant advancements in the technology,” Scurria said. “We feel that 2026 will be an important year for this to be available on the market at a large scale. We have gained a lot of knowledge about how this tool would be relevant to a lot of industries.”

2. Capturing “real-world” working environments

Engineers design systems to work in particular environments. But once installed the system might experience an environment vastly different to what designers considered earlier in the lifecycle. Scurria notes that xDTs aim to break these kinds of data siloes.

A real-world example from MxD shows how capturing actual working environments with xDTs can save lives. During the COVID-19 pandemic, when ventilators were in short supply and situations were desperate, some healthcare professionals linked two patients onto one ventilator. In response, MxD used xDT technology to explore ways to safely perform this procedure. Watch the video below for more on that project:

Scurria noted another example when it can be difficult to capture real-world working environments. He said, “There is only a number of parameters that can be directly measured in a system. With xDT, we can implement more measurements.” Consider a turbine engine; engineers cannot measure the temperature everywhere as some areas are so hot they would melt the sensor. Instead, a twin can function as a virtual sensor. By measuring data at certain locations, the twin can use that information to estimate measurements throughout.

“In 2026 we have the technology to do this right,” said Scurria. “We’ve been working on reduced order modeling and AI for many years. These technologies are becoming mature enough to work together … it’s about leveraging real-world data to make fast decisions.”

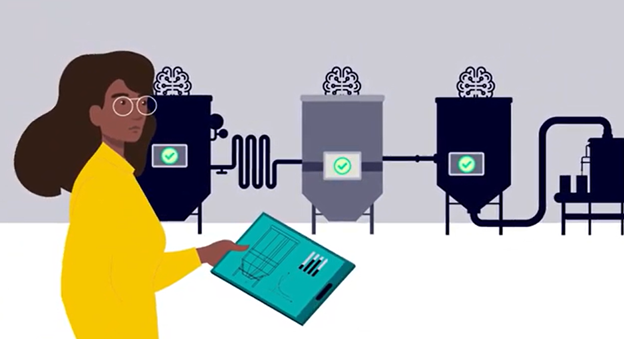

3. xDTs help with system-wide improvements and predictive maintenance

The shift-right philosophy of xDT technology can also help industrial operations by predicting the future. Consider the environmental data of the previous turbine engine example. The twin can use real-time IoT data from real-world assets to predict future behavior — such as an upcoming breakdown. With this information, operators can better plan for downtime, identify bottlenecks and make more informed decisions about maintenance procedures. In the example below, see how RAMPF uses xDT technology to optimize system-wide production, limit material usage and reduce operational costs.

“When you understand the bottlenecks,” said Scurria, “you can improve them and drive improvements and understand if a system is working at its optimal point, or make adjustments to get the system to operate there.”

Scurria added that xDT can do more than “optimize how the system is operating. [It] also has the ability to inject uncertainty into the models to not only model behavior ‘as designed’ but also to cover unexpected edge cases.”

In short, by fully understanding the asset and its environment, xDTs help organizations truly optimize systems so they can reduce energy consumption, downtime and waste while optimizing throughput.

“Every year there is a push to have more efficiency and sustainability,” said Scurria. In 2026, “we’ve reached a point where we can really improve these areas by combining the virtual world with the real world and use xDT in that context.”

4. Making assets evergreen and as-a-service models

Once engineers realize they can use xDTs to optimize existing assets the natural progression is to ensure said equipment is evergreen. Consider a chemical plant , it could last 40 years with minimal hardware updates. But every so often the creators of the plant’s equipment will improve their products, designs and software. Thanks to the brownfield compatibility of xDT technology, many of those improvements can be available to customers using older equipment.

“It’s about using existing hardware and sensors while putting an xDT on top of it to improve how it’s operating,” clarified Scurria. “There are technologies to run these models thanks to the additions of edge computers. So, machines now have computing power and data connection to a central data lake to execute digital twins.”

Taking this evergreen product advantage to the extreme, there has been a trend of outlets offering industrial equipment on an “as-a-service” basis. This trend is expected to grow in 2026. To explain equipment-as-a-service, consider a company selling a mixer to a chemical plant. They could charge for each replacement part or software upgrade, or the supplier could charge a premium for advanced monitoring services that ensure high asset availability. The benefit here is that suppliers of industrial equipment can smooth cash flow from their customers. Meanwhile, with the help of predictive xDT, the suppliers give their customers everything they need to run the equipment including regular maintenance, part replacements, software upgrades and more. This lightens the customer’s operational costs.

As for ‘what will be the big as-a-service boom for 2026,’ Scurria has an inkling. “The main trend we expect in 2026 is digital-twin-as-a-service,” he half-joked. “There is a lot of value to capture out there, and a lot of companies don’t have the knowledge to integrate digital twins. So, third party companies are helping the end customer develop and deploy xDT … we at Siemens have the technology, and with our Simcenter Engineering Services, we have a wealth of expertise in supporting, guiding and training customers to help them leverage our technologies.”

5. What-if scenarios, emergency training and informing future assets

The ability of xDT to inform the future can help many people from a company’s various departments. For instance, by using the technology a workforce can train on equipment without ever setting foot on the shop floor. This digital training has become more realistic thanks to the virtual reality (VR) and haptic feedback controllers that have been made available in 2026 and beyond. Organizations can use computers, VR headsets and even haptic VR gloves to train their workforce to be up to date on all procedures.

But training does not have to be limited to the day-to-day routine, in fact, it should not be. Instead, organizations should use xDT to prime its workforce for what-if scenarios, emergency situations, disasters and more. Optimizing a workforce is “not based on experience anymore,” said Scurria. “It’s based on data.”

Bringing the concept of xDT full circle, the data it collects on the shop floor can also be of benefit to design teams. Consider the earlier example of a product’s real-world environment differing from its intended environment. By capturing data on what the equipment will really experience in the field, design engineers can better optimize the next release to the needs of their customers. Though this workflow was bleeding edge just a few years ago, in 2026 it has become a norm.

“There is the ability to have much more information on the current product which can influence future ones,” explained Scurria. “This can be used to have a better understanding of the limitations of the current product. This can [then] be fed back to the design team to make new, better versions.”

In 2026 and beyond, the benefits of xDT will expand as knowledge of the tool grows. From optimizing production to hardware-in-the-loop testing, this technology brings the benefits of simulation to lifecycle stages outside product development. In fact, they are tools for success for every stage of a lifecycle from development, testing, prototyping, manufacturing, operations and much more.

To learn more about xDT access this infographic or read this blog series: