Boost Vehicle Energy Management (VEM) performance with Simcenter testing and simulation tools: 10 questions answered

Why is Vehicle Energy Management testing so critical?

With the rise of electric and hybrid vehicles, energy efficiency and passenger comfort are now crucial performance benchmarks. Vehicle energy management impacts range, drivability, and component longevity. Accurate testing ensures subsystems perform reliably in real-world conditions. Without precise data, energy strategies can fail or harm performance. Efficient energy use must also balance passenger comfort, which is often the top criterion for electric vehicles after driving range.

What exactly are we testing?

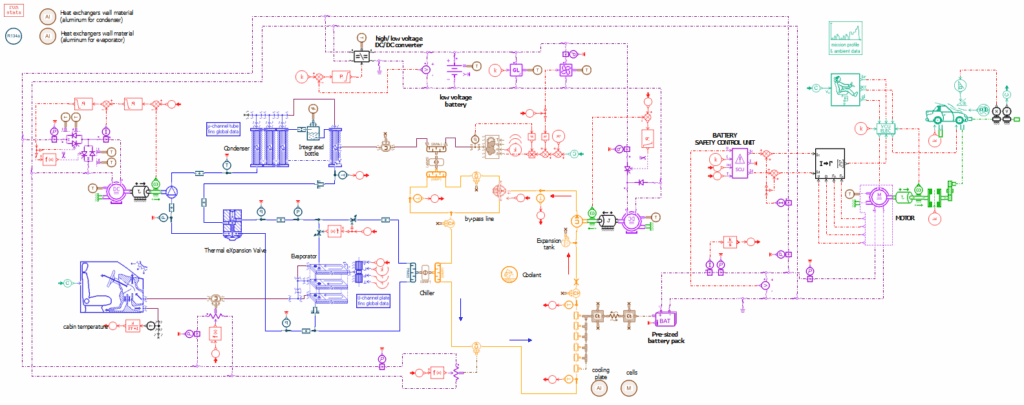

Vehicle energy management extends far beyond the battery, which is simply the new source of ‘fuel’. It involves the entire system: the battery, inverters, power electronics, motors, thermal circuits including heat pumps, and the central energy control unit (ECU). To fully understand system behavior, engineers must measure electrical, mechanical, and thermal domains as well as flow dynamics in a synchronized manner. By capturing these interactions as a whole, they can accurately map energy flows, identify losses, and verify whether control strategies are effective. Full-vehicle data acquisition provides a complete picture of energy distribution across subsystems and of thermal management performance.

Which tests matter most in the test cell?

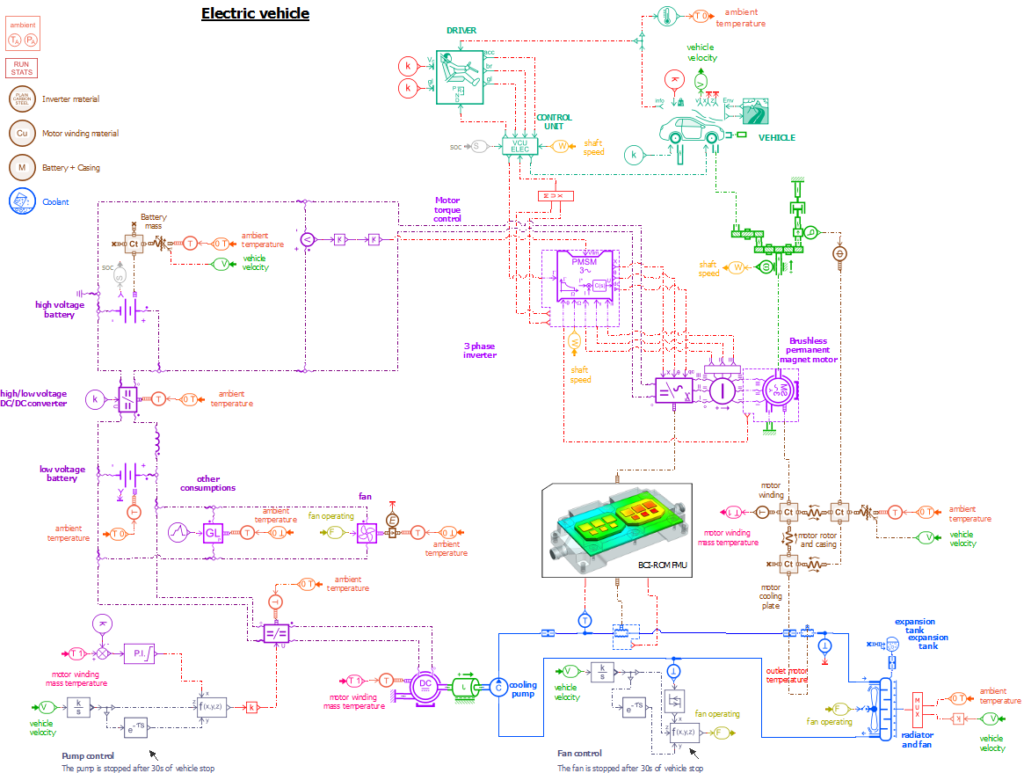

A well-rounded testing program typically combines several types of tests. Steady-state tests are performed to map efficiency and losses at constant operating points. Dynamic driving cycle tests challenge the vehicle with accelerations, decelerations, and load variations to capture realistic performance and provide high-quality operational data for calibrating digital twin models in Simcenter Amesim. Thermal tests are conducted to understand how cooling and heating systems affect energy efficiency. Finally, engineers evaluate control strategies to verify how the ECU distributes energy across subsystems in real time. Each of these steps follows the Simcenter Physical Testing standards, ensuring that test results remain repeatable, consistent, and directly compatible with simulation workflows.

What makes measuring vehicle energy flows so challenging?

The challenge lies in the complexity of the systems involved. Energy must be measured across many subsystems at once, resulting in very high channel counts. Synchronization between electrical, mechanical, and thermal measurements is critical, since even minor timing mismatches can distort results. In addition, engineers must capture fast electrical transients as well as low-noise thermal signals, which traditional systems often struggle to handle. Missing or inaccurate data can easily lead to incorrect efficiency calculations, making early design decisions riskier and more expensive.

Why choose Simcenter SCADAS RS?

Simcenter SCADAS RS delivers high-precision, reliable measurements of analog and digital sensor data, even under demanding test conditions. Its flexible, distributable and scalable architecture allows engineers to monitor multiple sensors simultaneously, handling complex, high-channel-count systems. Real-time data acquisition ensures fast transients are captured accurately, while seamless integration with Simcenter software enables efficient data transfer from the test cell to simulation environments, streamlining workflows and reducing the risk of errors.

Simcenter SCADAS RS plays a vital role in vehicle energy management by providing a comprehensive platform for accurate data acquisition and system optimization. It captures electrical, mechanical, and thermal power flows, allowing engineers to precisely calibrate and fine-tune batteries, motors, inverters, and thermal systems.

The system enables in-depth evaluation of battery and motor performance, including charge and discharge cycles, and demanding driving conditions such as towing or steep slopes. It demonstrates vehicle capabilities and motor efficiency under various thermal loads. The platform also opens possibilities for advanced testing, such as analyzing how regenerative braking recovers energy depending on the battery’s state of charge, or how the battery is derated under extreme temperatures during strenuous driving. Additionally, it supports testing of cold-start strategies to warm the battery and helps engineers determine the optimal approaches to minimize energy loss and extend battery life while maximizing energy recovery during braking.

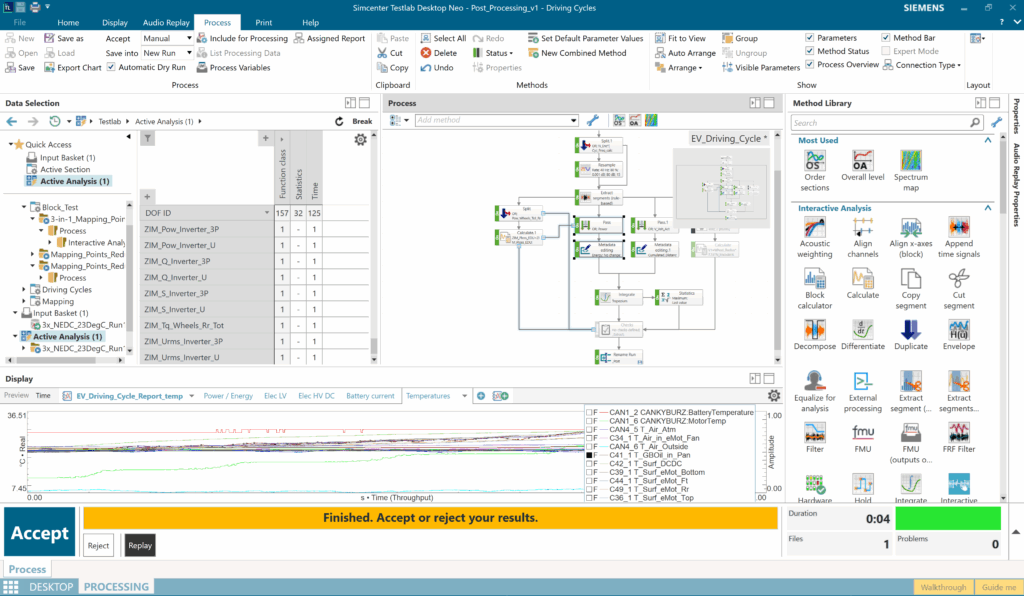

With advanced signal processing in Simcenter Testlab Neo, post-processing can begin immediately after test execution, minimizing delays and inconsistencies. Embedded Simcenter Amesim models within the Testlab Neo Process Designer further bridge the gap between test and simulation, enabling engineers to verify data quality through built-in checks and accelerate prototype validation.

Thermal management review ensures batteries and motors operate within safe, efficient temperature ranges—improving performance and extending system lifetime. In addition, third-party devices can connect seamlessly via digital bus protocols such as XCP or CAN, enhancing flexibility in test setups.

Ultimately, Simcenter SCADAS RS enables a tight integration of physical testing with simulation, giving engineers the ability to correlate real-world measurements with virtual predictions. This empowers them to develop and optimize energy management strategies tailored to diverse driving conditions.

How does it integrate with Simcenter Amesim?

A key advantage of Simcenter SCADAS RS, and the Simcenter SCADAS portfolio as a whole, is its seamless integration with Simcenter Amesim. Test cell data flows directly into simulation models, giving engineers the ability to calibrate models, fine-tune control algorithms, and perform predictive testing for scenarios that haven’t yet been physically validated. By bridging the physical and virtual worlds, this connection shortens costly iteration cycles, speeds up validation, and empowers teams to refine energy management strategies with greater accuracy and confidence.

How do I know lab results reflect the real world?

Test-cell data is precise and repeatable, but it must reflect real-world driving. With Simcenter SCADAS RS, engineers use the same system in the lab and on the road, directly correlating test-cell and on-road performance—critical for modern energy-efficient vehicles. For BEVs and PHEVs, driving range is a key factor for users, yet real-world range often falls short of official specs due to variables like road quality and slopes. Using Simcenter SCADAS RS ensures lab efficiency maps match on-road performance and reveals hidden losses, allowing engineers to address them early.

What benefits will I see?

The use of Simcenter SCADAS RS in vehicle energy management testing context delivers tangible benefits at both technical and business levels. Engineers gain accurate, high-fidelity data they can rely on, which accelerates the development of optimized energy strategies. At the same time, companies can shorten development cycles, reduce over-engineering, and improve vehicle efficiency and durability. The result is a smoother path to market, lower risks, and vehicles that perform better against customer expectations and regulatory demands.

Is Simcenter SCADAS RS future-proof?

Yes. The system has been designed to evolve alongside the rapid development of next-generation vehicles. Its modular architecture makes it easy to expand capacity, integrate new sensors, and support emerging standards. Whether a team is working on today’s EV architectures or preparing for future systems with multiple batteries and more advanced power electronics, Simcenter SCADAS RS provides a platform that can grow with their needs rather than becoming obsolete.

How can Simcenter SCADAS RS help me optimize energy management?

By bridging the gap between lab and road testing, Simcenter SCADAS RS provides a comprehensive and accurate view of energy flows. It enables faster, more reliable development of energy strategies, ensures simulation models reflect real-world behavior, and helps create vehicles that are efficient, offer top-level thermal comfort, and deliver reliable, high performance. With Simcenter SCADAS RS, vehicle energy management becomes a data-driven, validated process that accelerates development and maximizes overall performance.

Contact us

Interested in learning more or have questions? Our industry experts are here to help you navigate your Simcenter Physical Testing needs. We look forward to assisting you and providing guidance tailored to your testing requirements.

Safak Has — LinkedIn Profile

Mathieu Sarrazin — LinkedIn Profile

Siemens also offers expert Simcenter engineering services that deliver precise, reliable measurements, in-depth sensor deployment and analysis, digital twin model creation and calibration and much more. If you want to reduce risks and accelerate your development process, partner with us to test and simulate faster, smarter, and safer.

Nicolas Sabatier — LinkedIn Profile

Related resources

Check out the following links for more information:

Stand-alone data acquisition system

Switching Frequencies and Pulse Width Modulation (PWM) Signals